Thingiverse

Elastomer by Zeeflyboy

by Thingiverse

Last crawled date: 4 years, 3 months ago

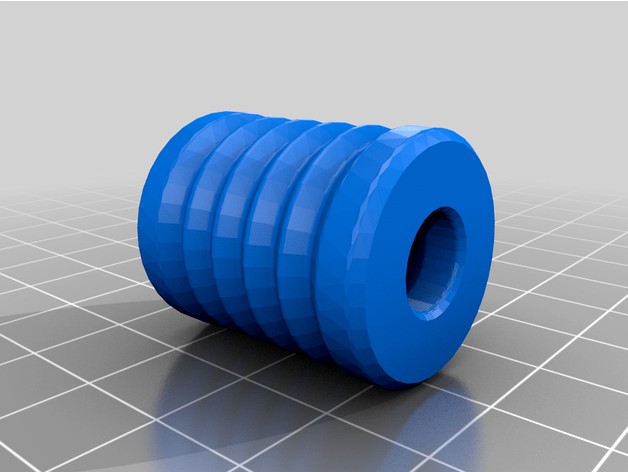

Decided to attempt my own elastomers for a DIY loadcell brake project, this was end result of multiple tests

Print using TPU, I personally used 85A ninjaflex and I wouldn't recommend going harder unless you want it to be really stiff.

Vary wall perimeters and infill to achieve different stiffness 2-3 works well. Highly recommend gyroid infill as in my tests it allows compression much better than others and aim for 15-30% as a start point but feel free to experiment!

Make sure your TPU is dry and adjust for thermal expansion/contraction if dimensions are critical - eg increase scale X/Y by 1% (101) for ninjaflex.

Damper measures 28mm tall, 23mm diameter and through hole is 8.8mm (designed to freely slide on 8mm shaft without grabbing during compression).

Print using TPU, I personally used 85A ninjaflex and I wouldn't recommend going harder unless you want it to be really stiff.

Vary wall perimeters and infill to achieve different stiffness 2-3 works well. Highly recommend gyroid infill as in my tests it allows compression much better than others and aim for 15-30% as a start point but feel free to experiment!

Make sure your TPU is dry and adjust for thermal expansion/contraction if dimensions are critical - eg increase scale X/Y by 1% (101) for ninjaflex.

Damper measures 28mm tall, 23mm diameter and through hole is 8.8mm (designed to freely slide on 8mm shaft without grabbing during compression).