GrabCAD

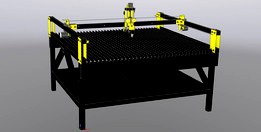

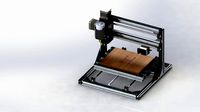

Economy CNC Plasma Table

by GrabCAD

Last crawled date: 1 year, 11 months ago

WIP (casual build during design) - Simple table that someone else is constructing from their/my parts on hand, our junk boxes, and common fasteners. Final work dimensions have not yet been determined (will probably be 50x50 in.).

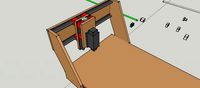

Hacks: Single start 0.5 in. ACME bored to accept pressed in 5mm NEMA 17 shaft that was TIG welded in place for a cheap/permanent captive lead. Two smooth shaft collars were turned so that each has face that does not contact outer race of an adjacent R8 bearing. 16mm 01 tool steel rails were flame hardened and annealed (probably not necessary) and could be replaced with Asian hardened linear rails.

Hacks (cont.): The junk SCS16UU inserts were replaced with quality Igus DryLin RJ4JP-01-16 linear bearings. The two Z rod support brackets were 3D printed from ABS by the builder. The $2 Asian inductive sensors are not very accurate, but individually produce repeatable results (all I've used or tested) with 24+ volt supply, and don't false trigger (with minimal hardware or software debounce) in a noisy plasma environment.

RM2-2RS v-wheels on phenolic resin rails - which is best/cheapest linear motion scheme I've found for a filthy plasma environment. Plasma cut steel parts (0.075 in.) were designed for easy 90 deg. bends in a manual press or finger brake. NEMA 23, Gates XL belts, SDP timing pulleys, and Openbuilds style Delrin smooth idlers for X and Y.

Inductive sensors home each axis and monitor Z switch (backup for Ohmic sensing). Overly long Z switch travel allows convenient access to plasma consumables while paused and without repositioning Z axis. IMService (eBay/web) Delrin anti-backlash nut (DumpsterCNC copy) for Z.

The steel V wheels a cause shiny glaze to appear on contact surfaces in the phenolic resin V grooves. 2000 build, now with 2 years of near-daily use, hasn't required bearing adjustments and no wear can be felt in the V grooves. New RM2-2RS bearings should be disassembled (remove rubber seals), cleaned, and greased before any use.

Don't buy cheap/no-name XL belting or cheap plastic/Nylon timing pulleys. Larger pulleys provide faster acceleration and keep motor RPM down in the torque bands.

Pros: Cheap. Fast. Accurate. Low maintenance. "Press-Play" operation (LinuxCNC/PlasmaC).

Cons: Asian parts. Upper rail grooves must be kept clear of obstructions (dried bird droppings can cause missed steps).

Photos will be added when I receive them.

SC 029

Hacks: Single start 0.5 in. ACME bored to accept pressed in 5mm NEMA 17 shaft that was TIG welded in place for a cheap/permanent captive lead. Two smooth shaft collars were turned so that each has face that does not contact outer race of an adjacent R8 bearing. 16mm 01 tool steel rails were flame hardened and annealed (probably not necessary) and could be replaced with Asian hardened linear rails.

Hacks (cont.): The junk SCS16UU inserts were replaced with quality Igus DryLin RJ4JP-01-16 linear bearings. The two Z rod support brackets were 3D printed from ABS by the builder. The $2 Asian inductive sensors are not very accurate, but individually produce repeatable results (all I've used or tested) with 24+ volt supply, and don't false trigger (with minimal hardware or software debounce) in a noisy plasma environment.

RM2-2RS v-wheels on phenolic resin rails - which is best/cheapest linear motion scheme I've found for a filthy plasma environment. Plasma cut steel parts (0.075 in.) were designed for easy 90 deg. bends in a manual press or finger brake. NEMA 23, Gates XL belts, SDP timing pulleys, and Openbuilds style Delrin smooth idlers for X and Y.

Inductive sensors home each axis and monitor Z switch (backup for Ohmic sensing). Overly long Z switch travel allows convenient access to plasma consumables while paused and without repositioning Z axis. IMService (eBay/web) Delrin anti-backlash nut (DumpsterCNC copy) for Z.

The steel V wheels a cause shiny glaze to appear on contact surfaces in the phenolic resin V grooves. 2000 build, now with 2 years of near-daily use, hasn't required bearing adjustments and no wear can be felt in the V grooves. New RM2-2RS bearings should be disassembled (remove rubber seals), cleaned, and greased before any use.

Don't buy cheap/no-name XL belting or cheap plastic/Nylon timing pulleys. Larger pulleys provide faster acceleration and keep motor RPM down in the torque bands.

Pros: Cheap. Fast. Accurate. Low maintenance. "Press-Play" operation (LinuxCNC/PlasmaC).

Cons: Asian parts. Upper rail grooves must be kept clear of obstructions (dried bird droppings can cause missed steps).

Photos will be added when I receive them.

SC 029

Similar models

grabcad

free

CNC Router - RM2 Bearings in "C" Rails - HGR15R/HGH15CA Z - NEMA 23

...for cnc router with rm2 bearings in "c" rails (similar to an openbuilds extrusion but more rigid), hgr15r/hgh15ca linear...

grabcad

free

V groove W2 RM2 2RS Bearing

...v groove w2 rm2 2rs bearing

grabcad

v groove bearing / v wheel for linear guide in cnc machines

3dwarehouse

free

Inexpensive CNC Plasma Table

...adcad link below. exported from cad, but modification of su file to fix orientation results in a huge skp file (at least for me).

grabcad

free

RM2-2RS V-Groove 3/8" Ball Bearing

...rm2-2rs v-groove 3/8" ball bearing

grabcad

rm2-2rs v-groove 3/8" ball bearing

3dwarehouse

free

RM2-2RS 3/8' V Groove Guide Bearing

...rm2-2rs 3/8' v groove guide bearing

3dwarehouse

grabcad

free

3D Printer 051

...cad components. stray holes in x rail allowed bolting dissimilar x and y rails together (see photos) to route...

grabcad

free

Another Inexpensive/Budget CNC Plasma Table

.... idler pulleys are openbuilds smooth idler style with 688 bearings and shim. nylock nuts will be used everywhere.

sc plasma 023

thingiverse

free

Eccentric Spacer by cterraza

...eccentric spacer by cterraza

thingiverse

eccentric spacer for rm2-2rs 3/8" v-groove guide bearing

units are in mm

thingiverse

free

sliding, for rectangular sections by GMFerrari

...;rm2-2rs 3/8'' 9.525 30.73 11.1mm v groove sealed ball bearing v groove"http://www.youtube.com/watch?v=dkwfpbn4z_s

grabcad

free

ZCarriageAssambly

...45

2 linear rails ø8x400

1 nema 17 motor support(50mm)

1 nema 17 motor

1 belt drive(gt2)

1 belt pulley(gt2)

1 belt pulley support

Economy

turbosquid

$29

Economy Hotel

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$9

economy lamp

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$40

premium economy class seat

...e 3d model the premium economy class seat for download as max on turbosquid: 3d models for games, architecture, videos. (1396558)

turbosquid

$10

Economy Class Train Wagon

...y free 3d model economy class train wagon for download as max on turbosquid: 3d models for games, architecture, videos. (1463622)

3d_export

$230

Detailed PASSENGER ECONOMY CLASS SEATING

...detailed passenger economy class seating

3dexport

3d_export

$230

Detailed PASSENGER ECONOMY CLASS SEATING

...detailed passenger economy class seating

3dexport

turbosquid

$45

12 Set Of Economy Clas Seats

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$50

5 LowPoly Economy Cars 3D Model

...ota iq opel agila chevrolet aveo european car american low poly japan urban

5 lowpoly economy cars 3d model be_fast 8875 3dexport

3d_export

$99

Fiat Palio Fire Economy 2012 3D Model

... 2011 2012 2013 2014 5-door hatchback compact italy italian brazil

fiat palio fire economy 2012 3d model humster3d 70859 3dexport

turbosquid

$50

Airplane Economy Seat - Animated C4D xpresso

...plane economy seat - animated c4d xpresso for download as c4d on turbosquid: 3d models for games, architecture, videos. (1286841)

Plasma

3d_ocean

$25

Plasma Cannon, Plasma Turret

...ily be used in any sf type of game, especially in tower defense games. - plasma cannon: 4462 polygons - textures: 6000...

3d_ocean

$19

Plasma Turret

... be used in any sf type of game, especially in tower defense games. - plasma turret: 6239 polygons - props: 522 polygons - tex...

turbosquid

$10

Plasma

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

plasma lamp

...plasma lamp

3dexport

detailed normal scale plasma lamp used indoors as a decorative object

turbosquid

$3

Plasma drone

...rbosquid

royalty free 3d model plasma drone for download as on turbosquid: 3d models for games, architecture, videos. (1337186)

turbosquid

$15

plasma gun

...bosquid

royalty free 3d model plasma gun for download as fbx on turbosquid: 3d models for games, architecture, videos. (1324248)

turbosquid

$12

Plasma Corvette

...id

royalty free 3d model plasma corvette for download as obj on turbosquid: 3d models for games, architecture, videos. (1442325)

turbosquid

$1

Plasma Rifle

...squid

royalty free 3d model plasma rifle for download as obj on turbosquid: 3d models for games, architecture, videos. (1485980)

turbosquid

$25

Plasma Pistol

...free 3d model plasma pistol for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1559545)

turbosquid

$10

Plasma Grenade

...d model plasma grenade for download as max, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1280730)

Cnc

3d_export

$35

Cnc

...cnc

3dexport

the cnc machine is unfinished

3d_export

$10

cnc router

...cnc router

3dexport

prototipe cnc router

3d_export

$10

cnc machine

...cnc machine

3dexport

cnc machine model with individual model files with assembly

3d_export

$5

Cnc 3D Model

...cnc 3d model

3dexport

cnc

cnc 3d model csiszar 61289 3dexport

turbosquid

$10

cnc bedroom

...osquid

royalty free 3d model cnc bedroom for download as max on turbosquid: 3d models for games, architecture, videos. (1494981)

turbosquid

$9

cnc(wood)

...rbosquid

royalty free 3d model cnc(wood) for download as max on turbosquid: 3d models for games, architecture, videos. (1189189)

turbosquid

$1

CNC Frame

...rbosquid

royalty free 3d model cnc frame for download as stl on turbosquid: 3d models for games, architecture, videos. (1371706)

turbosquid

free

cnc table

...rbosquid

royalty free 3d model cnc table for download as max on turbosquid: 3d models for games, architecture, videos. (1500926)

turbosquid

$30

CNC Lathe

...

royalty free 3d model cnc lathe for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1284634)

turbosquid

$25

CNC Machine

...

royalty free 3d model cnc machine for download as ma and fbx on turbosquid: 3d models for games, architecture, videos. (1307199)

Table

3ddd

free

Table

...table

3ddd

table

table

archibase_planet

free

Table

...table

archibase planet

table glass-table round table glass table

table n240311 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Table

...e

archibase planet

table dining-room table dinner table round table

table - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

table

...table

3dexport

table classic-table

archibase_planet

free

Table

...se planet

table glass table round table glass-table

table tonin habitat n280111 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Table

...table

archibase planet

table dining-room table dinner table

table - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Table

...table

archibase planet

table coffee table glass table

table - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Table

...table

archibase planet

table glass-table coffee table

table - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Table

...table

archibase planet

table writing table office table

table - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_ocean

$5

Table

...table

3docean

dining table furniture home kitchen table

simple wooden table.