Thingiverse

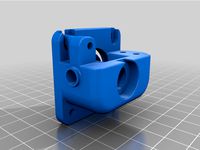

E3D V6 Volcano + Blower + Proximity Sensor Bowden Mount by WayneWeng

by Thingiverse

Last crawled date: 2 years, 12 months ago

Hot end mount on x-carrier like Prusa i3 or similar stuff.

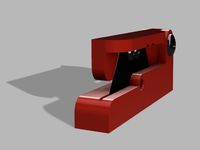

SpecificationMounting Hole: M3 bolts, 25mm or 30mm center to center distance.Hot End: E3D V6 Volcano or standard heat block.Heat Sink Cooling: 40mm Axial Fan with this Fan Duct or 30mm Axial Fan with standard E3D Fan DuctFilament Cooling: 5015 Blower like THIS with the designed blower duct.Auto Bed Leveling Probe: 12mm diameter Inductive Proximity Sensor.

NOTES

I wish to design this mount for both E3D V6 Volcano and Standard heat block. And the only thing to do is just to change different blower duct. It only matters of height in order to make the air blown to beneath the nozzle. But currently only blower duct for volcano was designed (I use volcano.) For standard heat block, blower duct will be added soon!

For heat sink cooling, I've tried 30mm axial fan and It's not making good thermal condition. Simply because it does not supply enough air pressure to push air through heat sink.

Therefore, I stick with 40mm fan just like for my V5. Now I'm using 4028 axial fan like FFB0412UHN-SP4Z

and it has better performance, not letting the hot end to warm up on the top of heat sink. But it's quite noisy though.

For filament cooling, I use BFB0512HH-F00. Larger air flow than other brand 5015 fan.

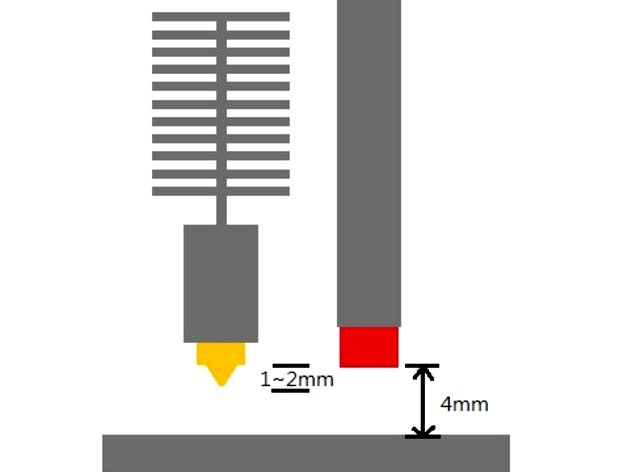

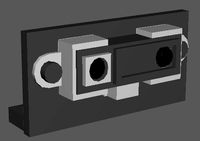

For auto bed leveling, I use FOTEK PM12-04N Inductive Proximity Sensor. With 4mm metal trigger distance. Other brands may work as well. It can't be used on a glass surface. Print bed must be metal. Aluminium works but with trigger distance shorter. But it still provides enough distance margin for probing and prevent the probe from hitting things while printing. You need to adjust it carefully before it goes on probing. The nozzle must sit somewhere between probe and bed surface. Make sure:

When z height drops to the point where the probe triggers, that nozzle doesn't touch the bed surface.

When printing starts, nozzle goes down close to the bed surface. You don't want the probe to touch the bed and it should be higher than the nozzle.

The probe might have LED indicators. Otherwise, use G code M119 to check probe status.

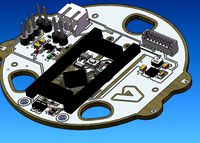

For the wiring, because mostly these sensors are powered from above 10VDC. We need to make sure output doesn't go above 5V(for arduino). Though the probe is NPN Normal Open Output type, it still may have internal pull-up resistors with a large value. Therefore, we should limit the output voltage with something like diode 1n4148 or so. I use the wiring from the picture. I didn't place a external diode. Instead, I rely on the internal IO pin protection diode in most digital IOs. It should limit the voltage quite safely. Thus, I don't need any external components from this setup. You could still leave the external diode there for more safety, it's fine. And for those powering with 24VDC, I presume it will still be OK(Quite a small current flow through the large internal pull-up resistor), but let's not make conclusions yet.(If you have experimented to prove OK, I'll be glad for you!)

Video:FAN DEMOProbing and Printing

SpecificationMounting Hole: M3 bolts, 25mm or 30mm center to center distance.Hot End: E3D V6 Volcano or standard heat block.Heat Sink Cooling: 40mm Axial Fan with this Fan Duct or 30mm Axial Fan with standard E3D Fan DuctFilament Cooling: 5015 Blower like THIS with the designed blower duct.Auto Bed Leveling Probe: 12mm diameter Inductive Proximity Sensor.

NOTES

I wish to design this mount for both E3D V6 Volcano and Standard heat block. And the only thing to do is just to change different blower duct. It only matters of height in order to make the air blown to beneath the nozzle. But currently only blower duct for volcano was designed (I use volcano.) For standard heat block, blower duct will be added soon!

For heat sink cooling, I've tried 30mm axial fan and It's not making good thermal condition. Simply because it does not supply enough air pressure to push air through heat sink.

Therefore, I stick with 40mm fan just like for my V5. Now I'm using 4028 axial fan like FFB0412UHN-SP4Z

and it has better performance, not letting the hot end to warm up on the top of heat sink. But it's quite noisy though.

For filament cooling, I use BFB0512HH-F00. Larger air flow than other brand 5015 fan.

For auto bed leveling, I use FOTEK PM12-04N Inductive Proximity Sensor. With 4mm metal trigger distance. Other brands may work as well. It can't be used on a glass surface. Print bed must be metal. Aluminium works but with trigger distance shorter. But it still provides enough distance margin for probing and prevent the probe from hitting things while printing. You need to adjust it carefully before it goes on probing. The nozzle must sit somewhere between probe and bed surface. Make sure:

When z height drops to the point where the probe triggers, that nozzle doesn't touch the bed surface.

When printing starts, nozzle goes down close to the bed surface. You don't want the probe to touch the bed and it should be higher than the nozzle.

The probe might have LED indicators. Otherwise, use G code M119 to check probe status.

For the wiring, because mostly these sensors are powered from above 10VDC. We need to make sure output doesn't go above 5V(for arduino). Though the probe is NPN Normal Open Output type, it still may have internal pull-up resistors with a large value. Therefore, we should limit the output voltage with something like diode 1n4148 or so. I use the wiring from the picture. I didn't place a external diode. Instead, I rely on the internal IO pin protection diode in most digital IOs. It should limit the voltage quite safely. Thus, I don't need any external components from this setup. You could still leave the external diode there for more safety, it's fine. And for those powering with 24VDC, I presume it will still be OK(Quite a small current flow through the large internal pull-up resistor), but let's not make conclusions yet.(If you have experimented to prove OK, I'll be glad for you!)

Video:FAN DEMOProbing and Printing

Similar models

thingiverse

free

E3D V6 30mm heatsink fan 30mm volcano Fan Ducts by zerosl

...s by zerosl

thingiverse

i designed a 30mm fan duct for my volcano nozzle. it attaches to the existing v6 heatsink fan

print with

thingiverse

free

SK-Go invisible hotend cooling duct e3d v6 (note: Precision Piezo users only) by superhans

...onto the heat sink and heater block.

the matching part cooling fan duct from the photo: https://www.thingiverse.com/thing:4700411

thingiverse

free

E3D V6 40mm Triple Fan Blower Duct by wooddragon48

...mm long m3 screw, nut and washers for extra clamping. the center fan can be either 10mm or 20mm thick if extra cooling is needed.

thingiverse

free

Anet A6 Fan Duct and Proximity Sensor Holder for E3D v6 by chekcian

...d e3d v6 heatsink. works flawlessly with e3d v6 clone all metal hotend without jam when used with pla. also tested on abs

enjoy

thingiverse

free

E3D V6 Cooling Fan Duct for 30mm fan by RaymondHOPK

...n duct for 30mm fan by raymondhopk

thingiverse

e3d v6 cooling fan duct for 30mm fan

update: ver3 only use 2 screws to install.

grabcad

free

Voron Afterburner V6 Volcano

...;t included the rest of the parts as they can be found on the voron github here: https://github.com/vorondesign/voron-afterburner

thingiverse

free

Delta Smart Effector dual 40mm blower cooling system by 3dprintbase

...i can't test even if make for the volcano. i'm sharing fusion 360 and other files, someone with the volcano can remix it.

thingiverse

free

Minimalist E3D 40mm Part cooling duct by DEJello

...rse

i remixed the blower fan cooling duct from media man's minimalist e3d v6 mount to accept a 40mm silent fan. works great.

thingiverse

free

E3D V6 Fan Duct 30mm 40mm fans by thaug29

...e3d v6 fan duct 30mm 40mm fans by thaug29

thingiverse

fan duct for e3d v6. uses 30mm fan and 40mm fan.

thingiverse

free

E3D V6 cooler fan and blower duct by joy1

...w on pla.

to use this system, make sure fan are installed right way. hot-end fan has to blow and blower fan have to suck the air.

Wayneweng

thingiverse

free

QCopterNano Motor Holder by WayneWeng

...qcopternano motor holder by wayneweng

thingiverse

7mm motor holder for qcopternano.

githubhackpad

thingiverse

free

3cm fan cover by WayneWeng

...3cm fan cover by wayneweng

thingiverse

protection cover for generic 3cm fan.

thingiverse

free

LED Light mount angle roatary. by WayneWeng

...led light mount angle roatary. by wayneweng

thingiverse

led light mount angle roatary.

thingiverse

free

Speaker vibration damp by WayneWeng

...3 of this and place underneath your speaker cabinet with a sheet of soft rubber will dampen out vibrations on your shelves/desks.

thingiverse

free

Push Button Switch by WayneWeng

...tton switch by wayneweng

thingiverse

couldn't find a nice model of this.

so i created one.

2.5mm pin pitch. 6mm row distance

thingiverse

free

Sidney Big 3DP parts by WayneWeng

...parts by wayneweng

thingiverse

including some useful endstop switch mount for 4040 aluminium extrusions.

z max end stop mount.

thingiverse

free

Songle Relay SPDT MODEL by WayneWeng

...odel by wayneweng

thingiverse

a relay 3d model of songle 5 pin srd-05vdc-sl-c.

songle relay spdt model.

step file available.

thingiverse

free

Wade's extruder idler with tube fitting by WayneWeng

...ube fitting by wayneweng

thingiverse

wade's extruder idler with tube fitting,

for those who had their filament fed remotely.

thingiverse

free

Servo Z probe arm customizable by WayneWeng

...

servo z probe arm customizable

based on sg90s or mg90

updated:

v1.1 : shaft geometry defined, printed and tested.

length 6 cm.

thingiverse

free

Magnetic Honeycomb Hex Bit Box 6.35mm by WayneWeng

...ayneweng

thingiverse

a simple box for hex screw bit storage, in a honeycomb style.

magnetic attachment to metal.

magnet: 10x2 mm

Proximity

3d_export

$5

side table proximity

...side table proximity

3dexport

64 x 64 x h. 37,5 cm https://www.eichholtz.com/ru/side-table-proximity-114398.html

turbosquid

$5

Proximity Land Mine

...d model proximity land mine for download as png, tga, and obj on turbosquid: 3d models for games, architecture, videos. (1265367)

3d_export

$14

proximity nesting tables

...mall:<br>width: 36,83 cm<br>depth: 36,83 cm<br>height: 55,88 cm<br>scene objects are organized by groups.

3d_ocean

$12

Alrisha Pendant Lamp

...of aluminum twisted ribbons held in place in close proximity to the...

3d_export

$7

Tibial Intramedullary Nail

...e. solidworks 2017 modeled and 3d studio max 2018 version attached too. rendered with keyshot 7. many file formats are available.

3d_export

$5

6 conifer topiary trees

...ats<br>3ds max - vray / corona<br>cinema 4d - vray / standard<br>blender<br>obj<br>fbx<br>stl

3d_export

$5

Cocos Palm Trees

...ats<br>3ds max - vray / corona<br>cinema 4d - vray / standard<br>blender<br>obj<br>fbx<br>stl

3d_export

$5

Winter paper birch tree forest

...ats<br>3ds max - vray / corona<br>cinema 4d - vray / standard<br>blender<br>obj<br>fbx<br>stl

3d_export

$5

Winter Juniperus virginiana with snow

...ats<br>3ds max - vray / corona<br>cinema 4d - vray / standard<br>blender<br>obj<br>fbx<br>stl

3d_export

$5

Winter and Summer Pinus Pinea Trees

...ats<br>3ds max - vray / corona<br>cinema 4d - vray / standard<br>blender<br>obj<br>fbx<br>stl

Volcano

3d_export

$10

volcano

...volcano

3dexport

erupting volcano for 3d printing

3d_export

$5

volcano

...volcano

3dexport

an erupting volcano with lava flows

design_connected

$11

Volcano

...volcano

designconnected

chista volcano computer generated 3d model.

3d_export

free

volcano

...volcano

3dexport

a volcano surrounded by stones<br>perfect for simple, unre demanding games

3d_export

$10

temple in volcano

...temple in volcano

3dexport

temple in volcano for 3d printing

turbosquid

$8

Volcano

... free 3d model volcano for download as fbx, stl, obj, and dae on turbosquid: 3d models for games, architecture, videos. (1664127)

turbosquid

$40

volcano

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Volcano

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Volcano

...e 3d model volcano for download as ma, max, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1567779)

3d_export

free

volcano

...volcano

3dexport

low poly volcano<br>.blend<br>.obj<br>if you feel any problem, please message.

Blower

3d_export

$5

ball blower

...ball blower

3dexport

ball blower

3d_export

$10

engine blower assambly

...engine blower assambly

3dexport

engine blower assambly

3d_export

$5

air pipe blower

...air pipe blower

3dexport

air pipe blower

3d_export

$5

air hand blower

...air hand blower

3dexport

air hand blower

3d_export

$5

Blower Boom 3D Model

...blower boom 3d model

3dexport

boom blower

blower boom 3d model bkl1989 63079 3dexport

turbosquid

$44

blower-dxf

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$39

Old Blower

...l old blower for download as ma, max, gltf, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1638848)

3d_export

$7

zy series centrifugal blower

...zy series centrifugal blower

3dexport

zy series centrifugal blower

3d_export

$5

root blower compressor

...oot blower compressor

3dexport

you will get both .stl and .sldprt format of root blower compressor from here at very cheap rate.

turbosquid

$5

V8 engine with blower

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Bowden

turbosquid

$199

Vintage Ben Bowden Spacelander bike

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Manooi Artica

...and pendants in various sizes and forms. suspension: galvanized bowden - dia. 1,5 mm. bulb: max 60 w -...

thingiverse

free

Remix Compact Bowden extruder - m6 bowden couplers and bowden tube pass-through

...ouplers and bowden tube pass-through

thingiverse

remix compact bowden extruder - m6 bowden couplers and bowden tube pass-through

thingiverse

free

Bowden Extruder

...bowden extruder

thingiverse

i have created bowden extruder for flsun delta 3d printer.

thingiverse

free

bowden 3mm by spee_D

...bowden 3mm by spee_d

thingiverse

for bowden 3mm

thingiverse

free

Bowden Tube Cutter

...bowden tube cutter

thingiverse

bowden tube cutter

thingiverse

free

Customizable Bowden Clip

...customizable bowden clip

thingiverse

customizable bowden clip

thingiverse

free

Bowden Oiler by fcheshire

...bowden oiler by fcheshire

thingiverse

inline bowden oiler

thingiverse

free

Bowden adapter by helkaroui

...bowden adapter by helkaroui

thingiverse

this is a fixed bowden adapter

thingiverse

free

Adventure3 Bowden Clip

...adventure3 bowden clip

thingiverse

adventure3 bowden clip

E3D

cg_studio

free

e3d model

...e3d model

cgstudio

- e 3d model, royalty free license available, instant download after purchase.

turbosquid

$2

Syringe C4D (E3D Ready)

...lty free 3d model syringe c4d (e3d ready) for download as c4d on turbosquid: 3d models for games, architecture, videos. (1336720)

turbosquid

$12

Microphone USB E3D and C4D

...ree 3d model microphone usb e3d & c4d for download as c4d on turbosquid: 3d models for games, architecture, videos. (1568216)

cg_studio

$35

Picture Frame Style E3d model

...

cgstudio

.3ds .max .obj .wrl - picture frame style e 3d model, royalty free license available, instant download after purchase.

cg_studio

$10

EVE from cartoon WALL-E3d model

...3d model

cgstudio

.3ds .max - eve from cartoon wall-e 3d model, royalty free license available, instant download after purchase.

cg_studio

$45

WW2 Pz VI Tiger SdKfz 181 Ausf. E3d model

....lwo .ma .max .obj - ww2 pz vi tiger sdkfz 181 ausf. e 3d model, royalty free license available, instant download after purchase.

3d_ocean

$6

Love Heart Element 3D & Cinema4D

...red heart romance valentines simple project simple heart models e3d files, cinema 4d files & obj files step 1...

3d_export

$14

Xiaomi mi band 6

...360. materials for rendering are configured in keyshot, v-ray, e3d blender. the keyshot has 6 strap colors configured. there...

3d_export

$20

apple airpods 3

...max vray, keyshot, e3d. - formats: 3dm, aep, bip, e3d f3d, iges, ksp, max 2013, max 2016, obj, fbx,...

3d_export

$20

Samsung galaxy tab s8 ultra

...blue, beige, white, black, graphite. - in blender and e3d one color of the model is configured, graphite. -...

V6

3d_export

$100

v6 engine

...engine

3dexport

complete v6 engine modeled on solidworks 2017 along with .stl, .sldprt and .sldasm of all th parts and assembly.

3d_export

$10

V6 engine

... the first v6 engines were designed and produced independently by marmon motor car company, deutz gasmotoren fabrik and delahaye.

3d_export

$35

v6 engine

...s a complete model of a v6 engine containing over 400 components. you can contact me for a video of all the components assembling

3d_export

$10

v6 engine

...v6 engine

3dexport

turbosquid

$25

Bed1001-v6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$22

Chair2-v6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

V6.mb

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$20

V6 engine

...rovided in this package is all the parts in sldprt format and assembly in sldasm format. i can also convert the format on demand.

3ddd

$1

Стол V6

...6" в стиле дизельпанк изготовлен из блока двигателя, 4х поршней и 4х шатунов.

столешница изготовлена из стекла толщиной 8мм.

cg_studio

$199

V6 VVTi3d model

...v6 vvti3d model

cgstudio

.3ds - v6 vvti 3d model, royalty free license available, instant download after purchase.

Sensor

3d_export

free

parking sensor

...parking sensor

3dexport

car parking sensor

turbosquid

$1

Sensor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Smoke sensor

...port

smoke sensor, can be an impressive element for your projects. easy to use, realistic image, low polygon, quality materials.

3d_export

$5

Air Quality Sensor v1

...air quality sensor v1

3dexport

air quality sensor v1

3d_export

$15

float sensor

...e up render. - all parts and materials are logically named. other formats ================= - collada (.dae) - autodesk fbx - obj

turbosquid

$26

Wind sensor C

...free 3d model wind sensor c for download as 3ds, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1328943)

turbosquid

$26

Wind sensor B

...free 3d model wind sensor b for download as 3ds, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1328168)

3d_export

$5

ultrasound sensor

...ivers convert ultrasound into electrical signals, and transceivers can both transmit and receive ultrasound. export in: -obj -fbx

3ddd

free

Вытяжка Shindo pallada sensor

... вытяжка

вытяжка shindo pallada sensor. в двух размерах - 600 и 900. текстуры в комплекте.

turbosquid

$52

Wind sensor A B C

...

royalty free 3d model wind sensor a b c for download as fbx on turbosquid: 3d models for games, architecture, videos. (1408406)

Mount

3d_export

free

mounting bracket

...mounting plate is the portion of a hinge that attaches to the wood. mounting plates can be used indoors, cabinetry and furniture.

turbosquid

$2

MOUNTING

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mounts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mount Fuji

...fuji

turbosquid

free 3d model mount fuji for download as obj on turbosquid: 3d models for games, architecture, videos. (1579977)

3d_export

$5

Headphone mount LR

...headphone mount lr

3dexport

headphone mount l+r

turbosquid

$39

Mount rainier

...quid

royalty free 3d model mount rainier for download as fbx on turbosquid: 3d models for games, architecture, videos. (1492586)

turbosquid

$5

pipe mounting

...quid

royalty free 3d model pipe mounting for download as obj on turbosquid: 3d models for games, architecture, videos. (1293744)

turbosquid

$3

Mounting Tires

...uid

royalty free 3d model mounting tires for download as fbx on turbosquid: 3d models for games, architecture, videos. (1708511)

3d_export

$5

Magnetic GoPro Mount

...pro mount

3dexport

cool magnetic mount for gopro. allows you to mount the camera on flat metal surfaces and get exclusive shots.

turbosquid

$5

Stone Mount

...ty free 3d model stone mount for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1370306)