Thingiverse

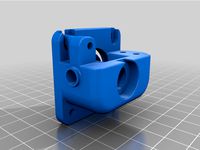

E3D v6 Bowden extruder for Wanhao Duplicator i3 by JonBAL

by Thingiverse

Last crawled date: 3 years, 1 month ago

E3D v6 Bowden extruder for Wanhao i3

This include holders of step motor to top frame, x-carrage block for E3D and more.

Need to buy

E3D v6 (j-head) hotend for 1.75mm (include cooling fan, hotend fitting)

PTFE tube for 1.75mm (1 meter) with cold end fitting (I use 0.5m only)

Kit of nozzle for E3D v6 (line is very wide, from 0.2 to 1.0mm)

Fasteners (M3 and M4 nuts, screws of different lengths)

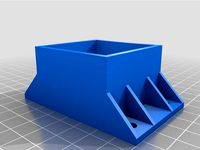

Mounting of the stepper motor

It is possible to mount of stepper motor on the top of printer's frame only. May be I design a mount for another places.

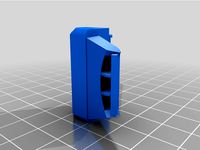

Holder v1.0 include

Step_motor_holder_frame_v.1.0_nut.stl - 2pcs

Step_motor_holder_frame_v.1.0_rest.stl - 1pcs

Step_motor_clamp_v1.0.stl - 1pcs

M4 nuts - 2pcs

Short M4 screws (9-10mm) - 2pcs

Holder v1.1 include (more difficult to print than v.1.0)

Step_motor_holder_frame_v.1.1.stl -1pcs

M4 nuts - 2pcs

Short M4 screws (9-10mm) - 2pcs

Cold end

I use:

Stock parts of MK10

kharar's MK9 bowden extruder - MK9_bowden.stl

M3 screws 20mm - 2pcs

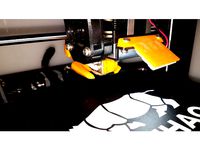

Extruder E3D v6 mount

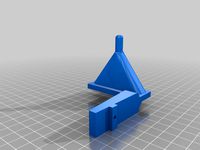

X-axis belt holder is mount on bearing block:

E3D_hotend_base_v1.0.stl (need add support in nut's holes) or E3D_hotend_base_v1.0_wSupp.stl - 1pcs (infill 50-60%)

E3D_hotend_clamp_v1.0.stl - 1pcs (infill 50-60%)

X-axis_endstop_holder.stl - 1pcs

M4 nuts - 2pcs

M4 screws (40mm or more) - 2pcs

M3 screws (7-8mm) for x-endstop holder - 2pcs

Stock M3 screws for mount cable chain - 2pcs

Stock M2 screws for mount x-endstop - 2pcs

X-axis belt holder is mount on screws in back side:

E3D_hotend_base_v1.0.stl (need add support in nut's holes) or E3D_hotend_base_v1.0_wSupp.stl - 1pcs (infill 50-60%)

E3D_hotend_clamp_v1.0.stl - 1pcs (infill 50-60%)

X-axis_endstop_holder.stl - 1pcs

M4 nuts - 4pcs

M4 screws (40mm, not more) - 2pcs

M4 screws (20-25mm) for back side - 2pcs

M3 screws (7-8mm) for x-endstop holder - 2pcs

Stock M3 screws for mount cable chain - 2pcs

Stock M2 screws for mount x-endstop - 2pcs

What else need to start?

You need desicion few questions:

If you install this extruder, than change height of nozzle. It will be higher than stock extruder. You need move the Z-axis endstop below. Not more Z-axis adapter can move down. I desing this simple adapter, you can use it. Print this before installing extruder!

It is not critical. In this extruder nozzle misses on the bed. You can make Y-axis endstop adapter and fix it.

Modifications

You may have noticed a lot of holes in mount extruder. This is done for easy mount additions and need M3 screws (7-10mm).

You can make Wire_clamp.stl for fixing wires.

Cooling

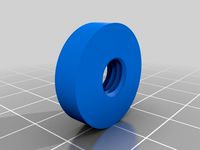

I make the adapter (Fan_holder_for_saldots_design_v1.0.stl) for saldot's desing fan holder. One adapter include:

Fan_holder_for_saldots_design_v1.0.stl - 1pcs

M3 nut - 1pcs

M3 screw (20mm) - 1pcs

M3 screws (7-10mm) - 2pcs

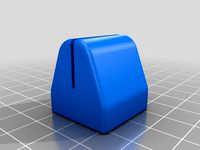

And I design mount for radial fan 50mm, it is very efficient. But printing is not simple: you should be able to make bridges.

Radial_fan_50mm_mount_v1.0.stl - 1pcs

M3 nut - 1pcs

M3 screws (20mm) - 2pcs

M3 screws (7-10mm) - 2pcs

Radial fan 5015 (size 50x50x15mm) - 1pcs

Problems

Maximum printing height is main problem in this realise. Height 160mm is limit for non-problem printing. If extruder lifted higher than 160mm, then PTFE tube rubbing the stepper motor.

In the feature I desing new mount for stepper motor. This will increase the height of the print.

Give back "I Made One", please. This is pleasant for designers))

This include holders of step motor to top frame, x-carrage block for E3D and more.

Need to buy

E3D v6 (j-head) hotend for 1.75mm (include cooling fan, hotend fitting)

PTFE tube for 1.75mm (1 meter) with cold end fitting (I use 0.5m only)

Kit of nozzle for E3D v6 (line is very wide, from 0.2 to 1.0mm)

Fasteners (M3 and M4 nuts, screws of different lengths)

Mounting of the stepper motor

It is possible to mount of stepper motor on the top of printer's frame only. May be I design a mount for another places.

Holder v1.0 include

Step_motor_holder_frame_v.1.0_nut.stl - 2pcs

Step_motor_holder_frame_v.1.0_rest.stl - 1pcs

Step_motor_clamp_v1.0.stl - 1pcs

M4 nuts - 2pcs

Short M4 screws (9-10mm) - 2pcs

Holder v1.1 include (more difficult to print than v.1.0)

Step_motor_holder_frame_v.1.1.stl -1pcs

M4 nuts - 2pcs

Short M4 screws (9-10mm) - 2pcs

Cold end

I use:

Stock parts of MK10

kharar's MK9 bowden extruder - MK9_bowden.stl

M3 screws 20mm - 2pcs

Extruder E3D v6 mount

X-axis belt holder is mount on bearing block:

E3D_hotend_base_v1.0.stl (need add support in nut's holes) or E3D_hotend_base_v1.0_wSupp.stl - 1pcs (infill 50-60%)

E3D_hotend_clamp_v1.0.stl - 1pcs (infill 50-60%)

X-axis_endstop_holder.stl - 1pcs

M4 nuts - 2pcs

M4 screws (40mm or more) - 2pcs

M3 screws (7-8mm) for x-endstop holder - 2pcs

Stock M3 screws for mount cable chain - 2pcs

Stock M2 screws for mount x-endstop - 2pcs

X-axis belt holder is mount on screws in back side:

E3D_hotend_base_v1.0.stl (need add support in nut's holes) or E3D_hotend_base_v1.0_wSupp.stl - 1pcs (infill 50-60%)

E3D_hotend_clamp_v1.0.stl - 1pcs (infill 50-60%)

X-axis_endstop_holder.stl - 1pcs

M4 nuts - 4pcs

M4 screws (40mm, not more) - 2pcs

M4 screws (20-25mm) for back side - 2pcs

M3 screws (7-8mm) for x-endstop holder - 2pcs

Stock M3 screws for mount cable chain - 2pcs

Stock M2 screws for mount x-endstop - 2pcs

What else need to start?

You need desicion few questions:

If you install this extruder, than change height of nozzle. It will be higher than stock extruder. You need move the Z-axis endstop below. Not more Z-axis adapter can move down. I desing this simple adapter, you can use it. Print this before installing extruder!

It is not critical. In this extruder nozzle misses on the bed. You can make Y-axis endstop adapter and fix it.

Modifications

You may have noticed a lot of holes in mount extruder. This is done for easy mount additions and need M3 screws (7-10mm).

You can make Wire_clamp.stl for fixing wires.

Cooling

I make the adapter (Fan_holder_for_saldots_design_v1.0.stl) for saldot's desing fan holder. One adapter include:

Fan_holder_for_saldots_design_v1.0.stl - 1pcs

M3 nut - 1pcs

M3 screw (20mm) - 1pcs

M3 screws (7-10mm) - 2pcs

And I design mount for radial fan 50mm, it is very efficient. But printing is not simple: you should be able to make bridges.

Radial_fan_50mm_mount_v1.0.stl - 1pcs

M3 nut - 1pcs

M3 screws (20mm) - 2pcs

M3 screws (7-10mm) - 2pcs

Radial fan 5015 (size 50x50x15mm) - 1pcs

Problems

Maximum printing height is main problem in this realise. Height 160mm is limit for non-problem printing. If extruder lifted higher than 160mm, then PTFE tube rubbing the stepper motor.

In the feature I desing new mount for stepper motor. This will increase the height of the print.

Give back "I Made One", please. This is pleasant for designers))

Similar models

thingiverse

free

Adapter with rotation for Mantis Gripper to EEZYbotARM MK2

..._mount_b

1pcs martins_gripper_claw_3_r

1pcs martins_gripper_claw_3_l

1pcs martins_gripper_gear

2pcs martins_gripper_bearingfix_2x

thingiverse

free

E3D V6 HOLDER/AMOUNT by dillonning

... 4pcs

m330 2pcs

m325 2pcs

m310 1pcs

thingiverse

free

Smartrap E3D v6 hotend with proximity sensor by Ideas3D

...3d

thingiverse

e3d v6 adapter for smartrap.

you will need 3 screws m3 10mm and 1 hex nut bolt, 2 screws m4 50mm and 2 hex bolts.

thingiverse

free

y endstop holder by AndyKl

...y endstop holder by andykl

thingiverse

smal y-endstop holder for prusa i3

you need only:

screw m4 - 1pcs

m4 nut - 1pcs

thingiverse

free

Anycubic i3 Mega X axis 10x15 dragchain holder by mokush

... upper linear bushing

extruder motor side:

-2pcs m3x8 screws

-2pcs m3 nuts

to attach the dragchain to the holder

-2 long zip ties

thingiverse

free

Flying Extruder 2 by kfceric

...x8 extrude gear x 1pcs

e3d v6 fasten connector ( need heating to fitting )

3x6mm rubber ban.

tpfe tube

nema 17 35mm stepper motor

thingiverse

free

X cable chain adapter for E3D V6 direct mount by Lunatic3bl4

...e first two links near the x stepper so that it can bend upwards, otherwise the extruder stepper will hit the chain while homing.

thingiverse

free

E3D V6 Extruder Dual Mount by 3D_Newbie

...rinter with common x-axis sled.

for mounting use m3 screws to install on x-axis, and m5 screws and nuts for clamping the hotends.

thingiverse

free

Z adjustable sainsmart endstop holder for Prusa i3 by hackermagnet

...the endstop holder

1 m4x30 or longer screw, 1x m4 nut and a spring. also wou will need two longer screws for the x stepper motor.

thingiverse

free

V-slot fan holder (60,80mm) by CaptainDz

... secret screw - 2pc.

m4 nut - 3pc.

for 60mm fan need's:

30mm m4 secret screw - 1pc.

20mm m4 secret screw - 2pc.

m4 nut - 3pc.

Jonbal

thingiverse

free

nema17 mount by JonBAL

...nema17 mount by jonbal

thingiverse

nema17 mount

thingiverse

free

Wanhao i3 adjustable Y endstop by JonBAL

...wanhao i3 adjustable y endstop by jonbal

thingiverse

this need for use non-stock extrider only.

don't need extra screws.

thingiverse

free

Holder back light for 31.6mm seat post bicycle bike by JonBAL

...holder back light for 31.6mm seat post bicycle bike by jonbal

thingiverse

it need couple of nuts and screws m3.

thingiverse

free

Ciclop 3D scanner - disc/platform/bed in 3 parts by JonBAL

...lop 3d scanner - disc/platform/bed in 3 parts by jonbal

thingiverse

this is for ciclop 3d scanner - disc/platform/bed in 3 parts

thingiverse

free

Hanger for calendar, photo or document by JonBAL

... sheets.

print hanger, make holes using the eyelet punch, and enjoy

also, you can conveniently hang the documents punched pocket.

thingiverse

free

Locker for Wanhao I3 Filament Guide for Top Spool Holder by JonBAL

... for top spool holder by jonbal

thingiverse

this is locker for wanhao i3 filament guide https://www.thingiverse.com/thing:979847

thingiverse

free

ION Air Pro camlock action extreme camera lock by JonBAL

...action extreme camera lock by jonbal

thingiverse

ion air pro camlock action extreme camera. lock, mount, repair, part, cam lock.

thingiverse

free

Cap cover tube thread BSP 1/4 and BSP 3/8 by JonBAL

...cap cover tube thread bsp 1/4 and bsp 3/8 by jonbal

thingiverse

cap cover tube thread bsp 1/4 and bsp 3/8

thingiverse

free

Knife Handle - from scan image by JonBAL

...xtrude

add fillet

add holes

make mirror

add to one side holes for screw head

add to other side hex-shape holes for nuts

print it!

thingiverse

free

Wanhao i3 Z-endstop large range of change by JonBAL

...uired.

you can change the height on both sides. upwards such as glass on the bed. or down, if you are using a different extruder.

Wanhao

thingiverse

free

Wanhao Logo Plate / Wanhao Logo Schild by JMDesigns

...wanhao logo plate / wanhao logo schild by jmdesigns

thingiverse

wanhao logo plate / wanhao logo schild

thingiverse

free

Wanhao logo by nebtio

...wanhao logo by nebtio

thingiverse

wanhao logo

thingiverse

free

Wanhao keychain by Rein3003

...wanhao keychain by rein3003

thingiverse

a keychain with the logo of wanhao

thingiverse

free

Wanhao Di3 v2 Light / Wanhao Di3 v2 Beleuchtung by JMDesigns

...wanhao di3 v2 light / wanhao di3 v2 beleuchtung by jmdesigns

thingiverse

wanhao di3 v2 light / wanhao di3 v2 beleuchtung

thingiverse

free

TUSH For Wanhao by wtmi1992

...tush for wanhao by wtmi1992

thingiverse

the ultimate spool holder, modified for the top of the wanhao control box. fits snug.

thingiverse

free

fanduct wanhao d12 by theopoilmek

...fanduct wanhao d12 by theopoilmek

thingiverse

fanduct pour wanhao d12

thingiverse

free

Wanhao i3 Marlin by johan21

...wanhao i3 marlin by johan21

thingiverse

marlin for wanhao i3 rampsboard 1.4.

thingiverse

free

Wanhao Duplicator i3 by imagineering4

...wanhao duplicator i3 by imagineering4

thingiverse

these are the stl files for the improvements to the wanhao duplicator i3, v2

thingiverse

free

Wanhao D6 filament guard

...wanhao d6 filament guard

thingiverse

this is a filament guard for wanhao d6 machine to avoid the filament unrolling

thingiverse

free

Wanhao Duplicator i3 Model by Hilde3D

...wanhao duplicator i3 model by hilde3d

thingiverse

wanhao duplicator i3 model

Duplicator

turbosquid

$10

duplicate

...

turbosquid

royalty free 3d model duplicate for download as on turbosquid: 3d models for games, architecture, videos. (1566034)

turbosquid

$20

Wonderful duplicate kids room

...ul duplicate kids room for download as skp, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1609462)

archive3d

free

Copier 3D Model

...hine duplicating machine

copier n160808 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$30

connect four set

...ate objects that can be disassembled. includes one red and one black checker which can be duplicated to the standard 42 checkers.

3ddd

$1

Черепица

...del

- put it in your scene and duplicate

- level of detail can be edited

- open with 3ds max 2010-2013 or import in your program.

3d_export

$27

Dividing Cell / Ovule 3D Model

...al microbe blob ovum fiction science ovule duplication divide dividing

dividing cell / ovule 3d model duchampmodels 9691 3dexport

3d_ocean

$16

Folding Chair

...tubing. designed to be good low poly at a distance and mesh smooth pretty well and light weight for duplicating a lot. package...

3d_export

$8

wooden fence

... one post separate so the fence can be duplicated and extended. created in blender 3.0 file format fbx with texture painted maps.

3d_export

$8

wooden fence

... one post separate so the fence can be duplicated and extended. created in blender 3.0 file format fbx with texture painted maps.

3d_ocean

$2

DNA Strands Of 5 Types

... strands that can be multiplied and can be made long chains by duplicating them and can be easily applied materials and textures.

Bowden

turbosquid

$199

Vintage Ben Bowden Spacelander bike

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Manooi Artica

...and pendants in various sizes and forms. suspension: galvanized bowden - dia. 1,5 mm. bulb: max 60 w -...

thingiverse

free

Remix Compact Bowden extruder - m6 bowden couplers and bowden tube pass-through

...ouplers and bowden tube pass-through

thingiverse

remix compact bowden extruder - m6 bowden couplers and bowden tube pass-through

thingiverse

free

Bowden Extruder

...bowden extruder

thingiverse

i have created bowden extruder for flsun delta 3d printer.

thingiverse

free

bowden 3mm by spee_D

...bowden 3mm by spee_d

thingiverse

for bowden 3mm

thingiverse

free

Bowden Tube Cutter

...bowden tube cutter

thingiverse

bowden tube cutter

thingiverse

free

Customizable Bowden Clip

...customizable bowden clip

thingiverse

customizable bowden clip

thingiverse

free

Bowden Oiler by fcheshire

...bowden oiler by fcheshire

thingiverse

inline bowden oiler

thingiverse

free

Bowden adapter by helkaroui

...bowden adapter by helkaroui

thingiverse

this is a fixed bowden adapter

thingiverse

free

Adventure3 Bowden Clip

...adventure3 bowden clip

thingiverse

adventure3 bowden clip

E3D

turbosquid

$23

E3D - Google Home

... 3d model e3d - google home for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1192509)

cg_studio

free

e3d model

...e3d model

cgstudio

- e 3d model, royalty free license available, instant download after purchase.

turbosquid

$2

Syringe C4D (E3D Ready)

...lty free 3d model syringe c4d (e3d ready) for download as c4d on turbosquid: 3d models for games, architecture, videos. (1336720)

turbosquid

$12

Microphone USB E3D and C4D

...ree 3d model microphone usb e3d & c4d for download as c4d on turbosquid: 3d models for games, architecture, videos. (1568216)

turbosquid

$29

E3D - OnePlus 6 Black

...model e3d - oneplus 6 black for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1358534)

turbosquid

$29

E3D - Motorola One 2018

...del e3d - motorola one 2018 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1358533)

turbosquid

$29

E3D - Disney MagicBands 2

...l e3d - disney magicbands 2 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1355515)

turbosquid

$29

E3D - Samsung Z4 Smartphone

...e3d - samsung z4 smartphone for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1182179)

turbosquid

$23

E3D - Razer Phone model

...del e3d - razer phone model for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1231207)

turbosquid

$23

E3D - Alcatel Idol 5

... model e3d - alcatel idol 5 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1212799)

V6

3d_export

$100

v6 engine

...engine

3dexport

complete v6 engine modeled on solidworks 2017 along with .stl, .sldprt and .sldasm of all th parts and assembly.

3d_export

$10

V6 engine

... the first v6 engines were designed and produced independently by marmon motor car company, deutz gasmotoren fabrik and delahaye.

3d_export

$35

v6 engine

...s a complete model of a v6 engine containing over 400 components. you can contact me for a video of all the components assembling

3d_export

$10

v6 engine

...v6 engine

3dexport

turbosquid

$25

Bed1001-v6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$22

Chair2-v6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

V6.mb

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$20

V6 engine

...rovided in this package is all the parts in sldprt format and assembly in sldasm format. i can also convert the format on demand.

3ddd

$1

Стол V6

...6" в стиле дизельпанк изготовлен из блока двигателя, 4х поршней и 4х шатунов.

столешница изготовлена из стекла толщиной 8мм.

cg_studio

$199

V6 VVTi3d model

...v6 vvti3d model

cgstudio

.3ds - v6 vvti 3d model, royalty free license available, instant download after purchase.

I3

3d_export

$10

suv i3

...suv i3

3dexport

suv i3 2013 series

3d_ocean

$89

BMW i3 2012

...y, in real units of measurement, qualitatively and maximally close to the original. model formats: - *.max (3ds max 2008 scanl...

cg_studio

$99

BMW i3 20143d model

...

cgstudio

.3ds .c4d .fbx .lwo .max .obj - bmw i3 2014 3d model, royalty free license available, instant download after purchase.

cg_studio

$99

BMW i3 20123d model

...tudio

.3ds .c4d .fbx .lwo .max .mb .obj - bmw i3 2012 3d model, royalty free license available, instant download after purchase.

cg_studio

$99

BMW i3 20143d model

...tudio

.3ds .c4d .fbx .lwo .max .mb .obj - bmw i3 2014 3d model, royalty free license available, instant download after purchase.

humster3d

$75

3D model of BMW i3 2014

...

buy a detailed 3d model of bmw i3 2014 in various file formats. all our 3d models were created maximally close to the original.

humster3d

$40

3D model of Kitchen Set I3

...uy a detailed 3d model of kitchen set i3 in various file formats. all our 3d models were created maximally close to the original.

3d_ocean

$30

Kitchen set i3

...ensils oven plates shelves sink table ware

kitchen set i3 include 3d models: cooker, oven, sink, cupboards, table, chair, plates.

3d_ocean

$89

BMW i3 2014

...y, in real units of measurement, qualitatively and maximally close to the original. model formats: - *.max (3ds max 2008 scanl...

cg_studio

$99

BMW i3 Concept 20113d model

...i3

.3ds .c4d .fbx .lwo .max .obj - bmw i3 concept 2011 3d model, royalty free license available, instant download after purchase.

Extruder

3ddd

$1

Extruded Chair

...extruded chair

3ddd

extruded , tom dixon

inspired by tom dixon extruded chair

turbosquid

$15

Extruded Table

... extruded table for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1634137)

turbosquid

$2

3D Printer Extruder

...d

royalty free 3d model 3d printer extruder for download as on turbosquid: 3d models for games, architecture, videos. (1537359)

turbosquid

$1

Zombie extruded text

...oyalty free 3d model zombie extruded text for download as obj on turbosquid: 3d models for games, architecture, videos. (1322198)

turbosquid

$4

Extruder conical screw

...el extruder conical screw for download as sldpr, ige, and stl on turbosquid: 3d models for games, architecture, videos. (1524433)

turbosquid

$50

3d PRINTER - Extruder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Extruded Table 2

...xtruded table 2 for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1621846)

turbosquid

$10

Maya Extrude Tool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

world earth extrude map

...world earth extrude map

3dexport

3ddd

$1

Simply Elegant Extruded Tree Coffee Table Design

...ble by link studios. the silhouette of a tree is visible at one angle, extruded from the surface to create the support structure.