Thingiverse

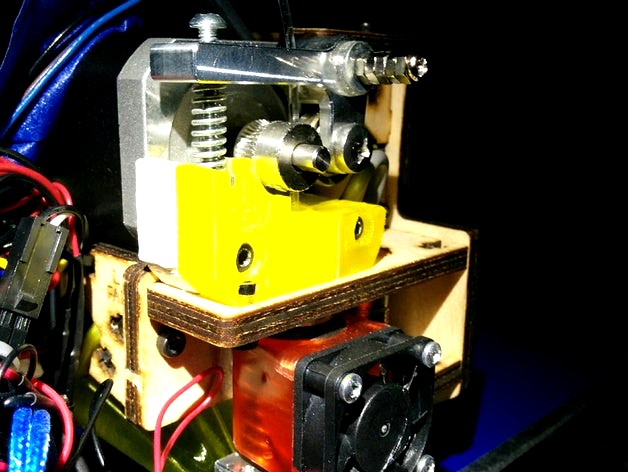

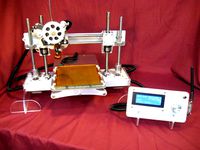

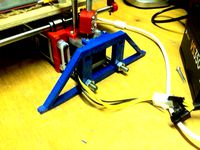

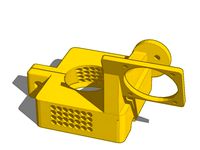

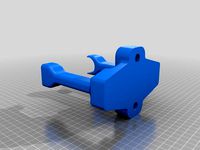

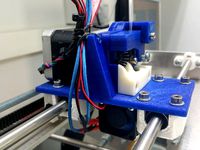

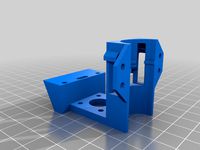

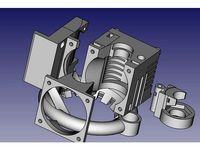

E3D V6 and V6 LITE adapter for Printrbot Simple 1405 by mrAkuaku

by Thingiverse

Last crawled date: 3 years ago

This is an adapter for the E3D V6 and V6LITE for the Printrbot Simple 1405 Makers kit. It was modified from and requires a few more parts than this http://www.thingiverse.com/thing:559657, but you don't have to glue anything to you hotend, allowing for easier PTFE adjustments.

Additional required parts for mod

Printrbot simple

E3D V6 or V6LITE

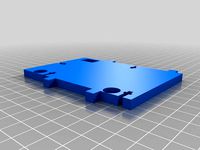

top piece and hardware of Printrbot Alu Extruder (If you don't have the top piece of the exturder, a STL for one can be downloaded here: https://www.youmagine.com/designs/printrbot-alu-extruder#information).

Instructions:

Print out all pieces with your current hotend (or have them printed for you). *Fan needed to be rotated on its Y axis by 245 degrees.

Cut away walls that are 0.4mm thick that were included as support material.

Use some needle nose pliers, angle cutters and/or forceps in difficult to reach areas.

Swap old cooling fan out for new one

Place 3 3M nuts in exturder along bottom of it

Use 3M bolt to secure front left and back piece of extruder to E stepper motor.

Pop in assembled E3D hotend (the overhang of the back piece of the extruder should help hold it in place for now.

Slide in front right piece of extruder to front left piece, then secure to E stepper motor.

Adjust Auto-level probe (http://printrbot.com/project/simple-metal/)

Flash Your Printrbot with Marlin firmware with a version that uses the type of thermistor E3D uses.

If your frame starts driving itself into the print bed (the frame hit one of the M3 screws on the last probing point), adjust your printer max X position, or probing points.

Wiring notes:

I still wanted to be able to swap my current hotend, but I didn't have the required connectors to do so. So what I did was use male (or female where needed) 22awg (maybe that's a bit thin for the hotend) "premium breadboard connectors" and cut them close to the connector, then soldered them to the hotend wires. These could then be fitted to the molex connectors (some needed one corner to be cut in order to fit.. I did this with a utility knife).

Additional required parts for mod

Printrbot simple

E3D V6 or V6LITE

top piece and hardware of Printrbot Alu Extruder (If you don't have the top piece of the exturder, a STL for one can be downloaded here: https://www.youmagine.com/designs/printrbot-alu-extruder#information).

Instructions:

Print out all pieces with your current hotend (or have them printed for you). *Fan needed to be rotated on its Y axis by 245 degrees.

Cut away walls that are 0.4mm thick that were included as support material.

Use some needle nose pliers, angle cutters and/or forceps in difficult to reach areas.

Swap old cooling fan out for new one

Place 3 3M nuts in exturder along bottom of it

Use 3M bolt to secure front left and back piece of extruder to E stepper motor.

Pop in assembled E3D hotend (the overhang of the back piece of the extruder should help hold it in place for now.

Slide in front right piece of extruder to front left piece, then secure to E stepper motor.

Adjust Auto-level probe (http://printrbot.com/project/simple-metal/)

Flash Your Printrbot with Marlin firmware with a version that uses the type of thermistor E3D uses.

If your frame starts driving itself into the print bed (the frame hit one of the M3 screws on the last probing point), adjust your printer max X position, or probing points.

Wiring notes:

I still wanted to be able to swap my current hotend, but I didn't have the required connectors to do so. So what I did was use male (or female where needed) 22awg (maybe that's a bit thin for the hotend) "premium breadboard connectors" and cut them close to the connector, then soldered them to the hotend wires. These could then be fitted to the molex connectors (some needed one corner to be cut in order to fit.. I did this with a utility knife).

Similar models

thingiverse

free

printrbot simple 1405 E3d lite6 mount by zackMcMurrin

... also added the custom mount i use for mounting the e3d lite hotend, it could be improved upon.

update: added thicker fan shroud.

thingiverse

free

Printrbot Simple Alu Fitting for 10mm Bowden screwin coupler by klop2031

...use the screwin coupler with the alu extruder that comes with the e3d v6.

settings i used:

print at 0.2mm layer height

30% infill

thingiverse

free

Printrbot 1405 Tri Rod Mod Short (For hotends like the e3d v6) by Foolish_Dave

...nation of jonlawrence's short extruder mount for the no sag mod with threefer's tri rod mod. should work with the e3d v6.

thingiverse

free

Precision Piezo and E3D V6, holder for E3D V6 and one touch connector by YMita

...touch connector which holds teflon tube.

i use precision piezo - piezo20 hotend z probe https://www.thingiverse.com/thing:2319993

thingiverse

free

AIO volcano e3d v6 pop off with probe

... with left side 40mm to 30 mm front fan to 18mm right side probe cut wire clip and just pull off hotend. made it for ease of use.

thingiverse

free

Printrbot 1405 E3D v6 Bowden Mount by Raptorfx

...ons on the main part and added the missing hole for the bed-leveling probe.

update 18.10.2014

final changes, fits perfectly now

thingiverse

free

Printrbot simple E3D by Jfv

...#39;t any need to modify the old printrbot fan that you use to cool down the pla.

update - now you can add auto-leveling probe

thingiverse

free

Direct Drive Holder for E3D Hotend & Exturder by CarolHaz391

...carolhaz391

thingiverse

this is my version of a direct drive set up for an e3d v6 hotend. it is very simple and easy to install.

thingiverse

free

Printrbot Simple 1405 E3D v6 Fan Shroud Mk. VII by ItsJustMidnight

...ds to be rotated sideways, with the heater cartridge between the nozzle and the leveling probe.

let me know about your results.

thingiverse

free

Solidoodle Bowden Extruder Mount for e3d v6 with servo probe by airfield20

... sanded (i got away with rubbing them together really fast) and hot glued on. as will the servo. i use this setup as of 12/13/16.

Mrakuaku

thingiverse

free

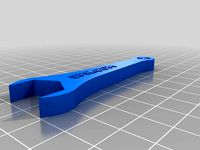

Printrbot_leveling_screw_remix by mrAkuaku

...he heads of my m3 bolts. i just trimmed a bit off the top and bottom to make it easier to tighten them with an adjustable wrench.

thingiverse

free

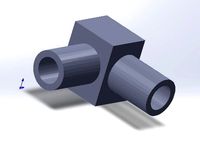

Coupler 5mm to 5mm for Stepper motor by mrAkuaku

... to 5mm for stepper motor by mrakuaku

thingiverse

this is a small coupler i made. it uses 3m nuts and bolts and fits 5mm to 5mm.

thingiverse

free

Snip cover by mrAkuaku

... made this cap and clip. you only need one of them to hold your snips closed, the cap is more durable, but takes longer to print.

thingiverse

free

Double Shepherd's whistle by mrAkuaku

...hingiverse.com/thing:360499

this one plays a deeper and louder bass sound, but can't hit the same high notes as the original.

thingiverse

free

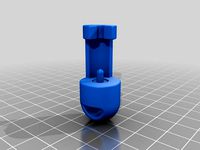

Coupler 5mm to 8mm for stepper motor by mrAkuaku

...

thingiverse

this is a small coupler i made. it uses 3m nuts and bolts and fits 5mm to 8mm.

print 100% infill

layer height 0.3

thingiverse

free

Night-light Tap-light by mrAkuaku

...p-light night-light/mood-light

here's a link to that project.http://www.instructables.com/id/beautiful-tap-light-night-light/

thingiverse

free

2 Piece coupler 8mm to 5mm by mrAkuaku

...this coupler is held together with 4 m3 screws and 4 m3 nuts.

... haven't tried printing it out yet, but it should work fine.

thingiverse

free

Needle nose pliers cap by mrAkuaku

...'s a cap for some small needle nose pliers. i didn't like how they always stayed open a bit when i wasn't using them.

thingiverse

free

Luer lock by mrAkuaku

... outside ring needs to be scaled up.

it would probably be good to print with a higher resolution printer, like an sla one though.

thingiverse

free

Shepherd's whistle by mrAkuaku

...er 18, 2014: uploaded gcode of improved whistle because current version of repetier and slic3r aren't working as well for it.

1405

thingiverse

free

Printrbot 1405 Filament Guide by Meek66e

...printrbot 1405 filament guide by meek66e

thingiverse

a simple filament guide for the printrbot simple 1405.

thingiverse

free

Holder for Printrbot 1405 by AlexKhil85

...holder for printrbot 1405 by alexkhil85

thingiverse

keep one of them (wires with spiral tube)

thingiverse

free

Printrbot Simple 1405 Fan Shroud by beyersito

... beyersito

thingiverse

work in progress of fan shroud for the old simple 1405, have to print it and test fit, but it should work

thingiverse

free

1405 Feet by brentevjen

...e underneath if you need to! you'll need 4 for an entire set.

made with tinkercad.

(my first upload to thingiverse yay!)

thingiverse

free

Printrbot Simple 1405 Adjustable YZ Plate by iamjonlawrence

...e yz plate by iamjonlawrence

thingiverse

this is for the 1405 version of the printrbot simple. please see source for more info.

thingiverse

free

Printrbot Simple Maker 1405 Extruder Handle by 3Dlirious

...andle by 3dlirious

thingiverse

this is a simple remix of http://www.thingiverse.com/thing:507944/ to fit the wooden simple 1405.

thingiverse

free

Printrbot 1405 Handle by bread_bird

...the z-axis.

please note that i cannot be responsible for any damage to the printer that results from the use of this accessory.

thingiverse

free

1405 Simple X Ends by iamjonlawrence

... "rodendclamp1405-oriented.stl" which will fit on a 100mmx100mm build plate. you will need to turn off brim and skirt.

thingiverse

free

Printrbot Simple 1405 upgrade to 10mm Z by lukewin8

... z by lukewin8

thingiverse

work in progress

upgrade your printrbot simple 1405 with this 10mm z upgrade.

standard 3d parts used

thingiverse

free

Rear leg Printrbot 1405 by mikei

...rights for the width of the printrbot. the original and the front legs can be found here:http://www.thingiverse.com/thing:350256

Lite

thingiverse

free

DS Lite Stylus

...ds lite stylus

thingiverse

ds lite stylus.

thingiverse

free

Huawei p20 Lite

...huawei p20 lite

thingiverse

great docking station for huawei p20 lite.

thingiverse

free

Lite Kroozer by Tsubureru

...lite kroozer by tsubureru

thingiverse

lite kroozer suitable for battlefleet gothic or similar space games.

thingiverse

free

Hornet XTpro Lite by Lynxtouchl5210

...hornet xtpro lite by lynxtouchl5210

thingiverse

a slinghsot that is lite :)

thingiverse

free

GoPro Lite Mount by DonMigel

...gopro lite mount by donmigel

thingiverse

gopro lite mount

thingiverse

free

MAG-LITE HOLDER by Sautech

...mag-lite holder by sautech

thingiverse

mag-lite holder

thingiverse

free

DS Lite Volume Slider

...ds lite volume slider

thingiverse

ds lite volume slider.

thingiverse

free

Taranis x9 Lite things

...taranis x9 lite things

thingiverse

somethings to taranis x9 lite

thingiverse

free

wind5 Lite by NoxesOne

...wind5 lite by noxesone

thingiverse

.

thingiverse

free

Huawei P30 Lite Case

...huawei p30 lite case

thingiverse

this is the case for cell phone huawei p30 lite.

Printrbot

thingiverse

free

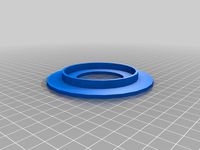

printrbot gasket by Usernameunavailible

...printrbot gasket by usernameunavailible

thingiverse

a part for printrbots

thingiverse

free

Printrbot Aluminum by Chris_the_Carpenter

...printrbot aluminum by chris_the_carpenter

thingiverse

a redesign of the awesome printrbot, in aluminum.

thingiverse

free

PrintrBot keychain by SuperMaku

...printrbot keychain by supermaku

thingiverse

printrbot keychain. may need to be scaled up.

thingiverse

free

Printrbot foot by aliekens

...printrbot foot by aliekens

thingiverse

add wider feet to a printrbot for improved stability.

thingiverse

free

Printrbot to CNC by mmrrsiam

...printrbot to cnc by mmrrsiam

thingiverse

make your printrbot also a small cnc machine....

thingiverse

free

Printrbot Keychain by jackbivona

...printrbot keychain by jackbivona

thingiverse

printrbot keychain for all you pb customers out there

thingiverse

free

Printrbot+ Nutkeepr by DonaldJ

...printrbot+ nutkeepr by donaldj

thingiverse

clip to retain nut on z-axis threaded rod of printrbot+

thingiverse

free

PrintrBot Tool Caddy by spr_consulting

...printrbot tool caddy by spr_consulting

thingiverse

printrbot tool caddy.

thingiverse

free

Printrbot Sensor Wrench by spr_consulting

...printrbot sensor wrench by spr_consulting

thingiverse

curvaceous printrbot sensor wrench.

thingiverse

free

Spool Holder for Printrbot by doubleAdoubleU

...spool holder for printrbot by doubleadoubleu

thingiverse

spool holder for a printrbot simple metal

V6

thingiverse

free

clip intercomunicador v6 // intercom clip v6 by javitoraz

...v6 by javitoraz

thingiverse

clip para soporte de intercomunicador v6 casco moto //clip for intercom support v6 motorcycle helmet

thingiverse

free

E3D V6

...e3d v6

thingiverse

just another remix with the belt mounting points raised 5mm. not tested yet as i still do not have a v6.

thingiverse

free

3D model E3D V6 extruder

...3d model e3d v6 extruder.

e3d v6 radiator

e3d v6 volcano nozzle

e3d v6 heat break

e3d v6 heater block

e3d v6 volcano heater block

thingiverse

free

ROBOT V6 SANTINO by chirimbolo

...robot v6 santino by chirimbolo

thingiverse

robot v6

thingiverse

free

Nut V6

...ogeqn5jnbdayqq

motherboard capacitors 1000uf 16v low esrhttps://www.ebay.com.au/itm/173841745704

donatehttp://paypal.me/rixtronix

thingiverse

free

Based_vase_hex-tapped v6 by 728design

...based_vase_hex-tapped v6 by 728design

thingiverse

based_vase_hex-tapped v6

thingiverse

free

DStike v6 oled by h4x0r1

...dstike v6 oled by h4x0r1

thingiverse

for dstike v6 oled

thingiverse

free

Flower Pot V6 by 3DPino

...flower pot v6 by 3dpino

thingiverse

flower pot v6

thingiverse

free

E3D-V6 FAN by qqbbpp1234

...e3d-v6 fan by qqbbpp1234

thingiverse

e3d v6 fan

thingiverse

free

E3D-V6 Back Support

...e3d-v6 back support

thingiverse

e3d-v6 back support

E3D

thingiverse

free

E3D fan Duck adapted for e3D mount by tambu22

...e3d fan duck adapted for e3d mount by tambu22

thingiverse

just try to adapt it to e3d mount

thingiverse

free

Extruder for E3D by xtopolx

...extruder for e3d by xtopolx

thingiverse

extruder for e3d

thingiverse

free

E3D mount by crota

...e3d mount by crota

thingiverse

e3d mount

thingiverse

free

UNI 3D E3D

...uni 3d e3d

thingiverse

e3d for uni 3d

thingiverse

free

Nozzle Holder E3D 8x / Düsenhalter E3D 8x by Walkabout77

...nozzle holder e3d 8x / düsenhalter e3d 8x by walkabout77

thingiverse

nozzle holder e3d 8x

thingiverse

free

E3D Support by Mamath

...e3d support by mamath

thingiverse

integrate e3d heat, for 40mm fan

thingiverse

free

E3d Cyclop and E3d Chimera by TanManGuy

... modeled up the cyclop and chimera

if looking for a fan shroud for it

(check this out- http://www.thingiverse.com/thing:614803)

thingiverse

free

E3D by alex16

...e3d by alex16

thingiverse

enclosure cooling e2d

thingiverse

free

3D model E3D V6 extruder

...3d model e3d v6 extruder.

e3d v6 radiator

e3d v6 volcano nozzle

e3d v6 heat break

e3d v6 heater block

e3d v6 volcano heater block

thingiverse

free

E3D Hemera Model

...e3d hemera model

thingiverse

official mounting cad for designing your own custom mounts for the e3d hemera.

Adapter

thingiverse

free

Adapter

...adapter

thingiverse

adapter to use filament rolls with 72mm inside diameter

thingiverse

free

adapter by Ladehoff

...adapter by ladehoff

thingiverse

adapter

thingiverse

free

adapter by eslyuta

...adapter by eslyuta

thingiverse

adapter

thingiverse

free

Clean 45RPM adapter, single adapter

...clean 45rpm adapter, single adapter

thingiverse

clean, basic 45rpm adapter. fits most turntables.

thingiverse

free

Fan Adapter

...fan adapter

thingiverse

fan adapter

thingiverse

free

Lens adapter

...lens adapter

thingiverse

lens adapter

thingiverse

free

Fahrradventiel Adapter

...fahrradventiel adapter

thingiverse

fahrradventiel adapter

thingiverse

free

adapter with by dougthegr8

...adapter with by dougthegr8

thingiverse

adapter holder

thingiverse

free

gopro adapter

...gopro adapter

thingiverse

angal adapter for gopro

thingiverse

free

Socket Adapter

...socket adapter

thingiverse

hand twist socket adapter

Simple

thingiverse

free

Simple Box / Boîte simple by Falkos

...simple box / boîte simple by falkos

thingiverse

simple box

thingiverse

free

Simple Diamond

...simple diamond

thingiverse

simple diamond.

thingiverse

free

Simple Bookend

...simple bookend

thingiverse

a simple bookend

thingiverse

free

Simple Cross

...simple cross

thingiverse

simple cross

thingiverse

free

Vase simple

...vase simple

thingiverse

vase simple

thingiverse

free

Simple Lance

...simple lance

thingiverse

simple lance

thingiverse

free

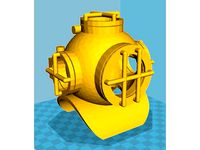

Escafandra simple. Simple scuba. by Unseulmot

...ot

thingiverse

modelo simple de una escafandra para imprimir de una pieza.

simple model of a diving suit for one-piece printing.

thingiverse

free

Simple Balisong

...simple balisong

thingiverse

simple design of a balisong.

thingiverse

free

Simple Bowl

...simple bowl

thingiverse

just a simple bowl

thingiverse

free

Simple Keychains

...simple keychains

thingiverse

simple keychain design