Thingiverse

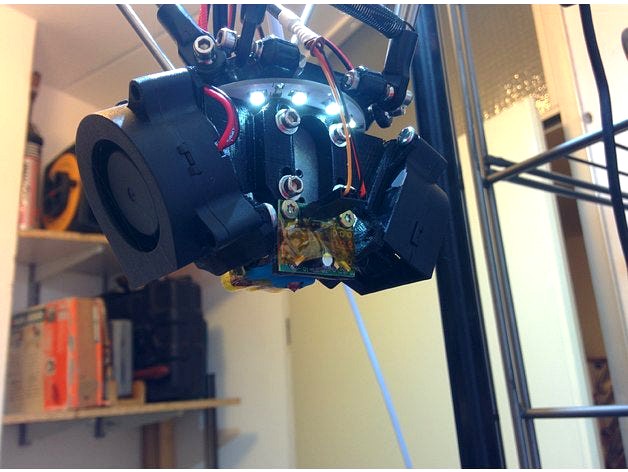

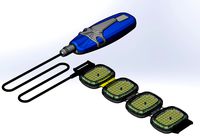

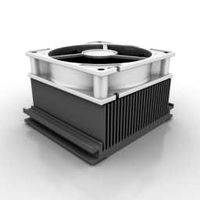

E3D clone DC42 IR sensor and 40mm radial part cooler adapter by Nanocube

by Thingiverse

Last crawled date: 3 years, 1 month ago

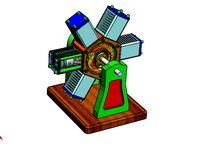

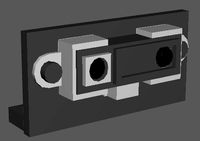

Designed for a HE3D K280 delta printer; would doubtless work on K200 and many other Chinese deltas that use a E3D clone hotend having a square cold-sink block with 4x unused mounting holes on the reverse side to the fan (17mm apart). It leaves the grub-screws securing the heatbreak accessible.

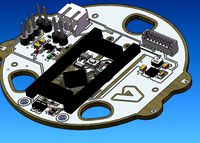

A version without the fans is provided as a DC42 IR mount if you already have part cooling.. And a version without the IR42 mount to complete the set..

The DC42 IR board is protected from the heatblock by a backing plate, with allowance for the through-plated pins of the connector and capacitor. Some vertical adjustment is allowed for on the main mounting bracket so it can be lowered when using volcano hotends etc. On my rig I have the assembly pushed up as far as it goes, which clamps the LED light ring in place, and leaves the IR level offset at approx 1mm.

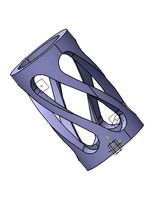

Fan version uses 40mm radial fans, NOT the 50mm ones that came with the K280!

Be Warned! it makes your effector wider than normal, make sure you still have clearance to belts and towers on your maximum travel (it is tight on my K280, but nothing touches)

40mm blowers are quiet and small enough to fit under the effector carriage configured for a 'big mouth' effect, blowing down on the whole print, but angled in on the nozzle.

I may return to this and separate the fan mounts into something that prints separately, and flat, which would allow me to add some simple ducting to make the air go more towards the nozzle for PLA work. Maybe even make a 50mm fan version.

Use a silicone sock on the hotend to ensure it does not get cooled too much by the fans as they come on, and to protect the IR probe.

Not the prettiest thing once printed due to small size and some nasty overhanging angles; even printing slow and small-layered it needed a bit of cleaning up (craft knife.. take care) and the fan holes reaming out.

SCAD file included; dont laugh.. it's ugly. My first attempt OK!

A version without the fans is provided as a DC42 IR mount if you already have part cooling.. And a version without the IR42 mount to complete the set..

The DC42 IR board is protected from the heatblock by a backing plate, with allowance for the through-plated pins of the connector and capacitor. Some vertical adjustment is allowed for on the main mounting bracket so it can be lowered when using volcano hotends etc. On my rig I have the assembly pushed up as far as it goes, which clamps the LED light ring in place, and leaves the IR level offset at approx 1mm.

Fan version uses 40mm radial fans, NOT the 50mm ones that came with the K280!

Be Warned! it makes your effector wider than normal, make sure you still have clearance to belts and towers on your maximum travel (it is tight on my K280, but nothing touches)

40mm blowers are quiet and small enough to fit under the effector carriage configured for a 'big mouth' effect, blowing down on the whole print, but angled in on the nozzle.

I may return to this and separate the fan mounts into something that prints separately, and flat, which would allow me to add some simple ducting to make the air go more towards the nozzle for PLA work. Maybe even make a 50mm fan version.

Use a silicone sock on the hotend to ensure it does not get cooled too much by the fans as they come on, and to protect the IR probe.

Not the prettiest thing once printed due to small size and some nasty overhanging angles; even printing slow and small-layered it needed a bit of cleaning up (craft knife.. take care) and the fan holes reaming out.

SCAD file included; dont laugh.. it's ugly. My first attempt OK!

Similar models

thingiverse

free

1730 Hotend mount for RobotDigg effector by tomasf

...ing a 1730 hotend (plus a dc42 ir sensor) to a robotdigg delta effector. it's meant to be used together with my nimble mount.

thingiverse

free

40mm Axial to 50mm radial fan adapter by Flare_Ryder

...apter by flare_ryder

thingiverse

adapter plate for the v6 hotend mount to replace 40mm axial fan on hotend to a 50mm radial fan.

thingiverse

free

Differential IR sensor mounts for AnyCubic Delta printers by siddharta

... for a larger probe area diameter and (possibly) more accurate calibration.

thanks to dc42 for designing this really nice sensor.

thingiverse

free

Delta Effector for E3D V6 by Osechi

...effector offset : 25mm

i use the following parts,

・lj12a3-4-z-bx

・e3d v6 hotend

・3010 fans

・3010 blower fan

・m3 screws & nuts

thingiverse

free

Fan holder and sample cooling for E3D v6, Robotdigg effektor, Kossel by Teilchen

...: after excessive testing i have noticed that ir sensor holder isn't stiff enough for my liking... so i made it a bit thicker

thingiverse

free

E3D V5-V6 Delta Rostock by pindemand

...the effector and the mount (1mm)

the fan is from :https://www.caseking.de/en/noiseblocker-blacksilent-fan-xm-2-40mm-luno-019.html

thingiverse

free

E3D v6 Hotend mount for Overlord 3D by Wwuully

...e3d v6 hotend mount for overlord 3d by wwuully

thingiverse

this 60mm effector uses the e3dv6 hotend and 2 40mm fans.

thingiverse

free

K8200 E3D V5 Mount and nozzle fan by abrooksdavis

...v5 mount allowing for a hotend fan duct.

this uses the original 30mm fan from the e3d extruder and a 40mm fan for the fan duct.

thingiverse

free

Magnetic Effector & Carriage & Double 50mm radial Filament Cooler for Delta Printer (E3D V6 mount) by hoaze

...

added the slider v5 using a nose on the upper side for optical endstop and n52 type neodymium magnets 14mm diameter x 3mm hight.

thingiverse

free

Delta Effector by Typpa

...ffector by typpa

thingiverse

delta effector with ir dc42 and e3dv6

good prints at all ... be happy

https://youtu.be/8mxrmostkxw

Nanocube

thingiverse

free

nanocube rgb hood by ejpsx

...nanocube rgb hood by ejpsx

thingiverse

nanocube rgb ledhood

thingiverse

free

Nanocube light hood by ejpsx

...nanocube light hood by ejpsx

thingiverse

nanocube led light hood

thingiverse

free

NanoCube 6 Aquarium Overflow by jdebriyn

...nanocube 6 aquarium overflow by jdebriyn

thingiverse

simply overflow for small nanocube 6 gal aquarium

thingiverse

free

nanoCUBE by varykap

...tar.

dimensiones 280x280x280

volumen 130x140x140

estructura openbeam

https://www.peakapic.com/

http://varykap.blogspot.com.es/

thingiverse

free

Aquarium Edge Cover (Dennerle Nanocube)

...rle nanocube 60l but should also fit on the other models of dennerle.

also suitable as bear seat :-d

freecad files are included.

thingiverse

free

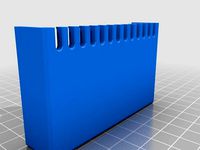

Simple Key Rack by Nanocube

...imple key rack by nanocube

thingiverse

a simple key rack with 3d lettering.

prints easily with 10% infill and no support needed.

thingiverse

free

NanoCube Flow Diverter by CopabX

...s made for a filter head of .78" diameter and is made at .8" to compensate for the small amount of error during prints.

thingiverse

free

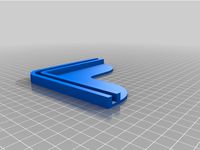

eenvoudig sleutelrek by Nanocube

...telrek

afdrukken met 10% vulling, geen ondersteuning.

de 'dikke' versie was een mk1, ik geef de voorkeur aan de slankere.

thingiverse

free

DC05-nFurminator by Nanocube

...very crudely) replaced the connector with a simple cylinder and tapered cone sized for the nozzle adapter on my dc05. works well.

thingiverse

free

Low Poly Sphere by Nanocube

...aximum rule).

might need a big brim and/or a raft if your bed level or adhesion is poor.

update: improved version with scad file!

Dc42

thingiverse

free

DC42 Precision Kossel printed parts by dc42

...hingiverse

printed parts for precision kossel printer described at https://miscsolutions.wordpress.com/dc42s-large-kossel-build/

thingiverse

free

DC42 IR support for mosquito hotend

...nd

thingiverse

dc42 ir's support for mosquito hotend

source files in this project :https://www.thingiverse.com/thing:4220454

thingiverse

free

X carriagbe Mosquito Dualblower for DC42

...x carriagbe mosquito dualblower for dc42

thingiverse

0.2

90% petg

no support

thingiverse

free

Duet Ethernet enclosure by dc42

...

this is an enclosure to fit duet ethernet electronics on a robotdigg scara arm 3d printer in place of the original electronics.

thingiverse

free

DC42 IR Sensor mount to 40mm fan by firebug24k

...s infrared bed height sensor (https://miscsolutions.wordpress.com/mini-height-sensor-board/) to a standard 40mm fan. adjustable.

thingiverse

free

HyperCube Chimera/Cyclops Hotend with DC42 IR probe mount by ThePhilStrongProject

...42 ir probe mount by thephilstrongproject

thingiverse

remix of boweeble's hotend mount to add support for the dc42 ir probe.

thingiverse

free

Ormerod dc42 Z-Probe cover by fotomas

...nd one for the dual nozzle board.

more info about the probe here: https://miscsolutions.wordpress.com/ormerod-hot-end-board-v2/

thingiverse

free

DC42-IRProbe-Mount by Guyaros

...rs), and instaed of the nozzele, i inseted the probe mount.

but, i believe this design can be usefull for other printers as well.

thingiverse

free

DC42 IR Probe Mount for BI V2.5 by slepp

...industries v2.5. it replaces the stock z probe sensor and allows for simple adjustment up and down for the ir probe in its place.

thingiverse

free

Duet 2 Maestro enclosure by dc42

...ngiverse

this is a variation on a previous duet enclosure (see https://www.thingiverse.com/thing:2490655) for the duet 2 maestro

Ir

turbosquid

$65

FLIR Vue Pro IR Camera

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Subwoofer F&D IHOO 5.1 IR

...oofer f&d ihoo 5.1 ir for download as sldpr, max, and ige on turbosquid: 3d models for games, architecture, videos. (1523229)

3ddd

$1

Grohe Eurosmart CE IR electronic

...t ce ir electronic

3ddd

grohe , смеситель

смеситель для раковины с инфракрасным сенсором

turbosquid

$40

AK 47 Dual Laser Sight with IR Illuminator

...k 47 dual laser sight with ir illuminator for download as obj on turbosquid: 3d models for games, architecture, videos. (1586129)

turbosquid

$30

IR Bracelet Light Therapy Pain Recovery System

...acelet light therapy pain recovery system for download as ige on turbosquid: 3d models for games, architecture, videos. (1493109)

3ddd

$1

GRAMERCY HOME - Bastian Chandelier CH058-5-IR

...5-ir

3ddd

gramercy home

gramercy home

bastian chandelier

ch058-5-ir

ширина 47 см

глубина 47 см

высота 25 см

www.gramercy-home.ru

turbosquid

$20

IR-RF PLC USB TRANSMITTER 2014 RAW

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Speakers Centr F-D - Sven IHOO 5-1 IR

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Speakers Front F-D F and D - Sven IHOO 5-1 IR

...) - sven ihoo 5-1 ir for download as max, ige, stl, and sldpr on turbosquid: 3d models for games, architecture, videos. (1144599)

3d_export

$15

be meyers mawl-c1 ir-laser

...station for more<br>tri count: 8,335 vertex count: 4,405 texture: pbr-4k<br>https://www.artstation.com/artwork/yaed4v

Radial

3d_ocean

$5

Radial engine

...dial engine

3docean

engine radial

this is a radial engine used by the old airplanes. it is made in autodesk inventor and autocad.

3d_export

$5

radial engine

...ne , clearly shows how a radial engine works and all the parts present in it for a student or an engineer to have a glans on it .

3d_export

$5

shaft radial bearing

...shaft radial bearing

3dexport

shaft radial bearing

turbosquid

$7

Radial engine

...bosquid

royalty free 3d model radial engine for download as on turbosquid: 3d models for games, architecture, videos. (1672376)

turbosquid

$7

Radial Tyre

...osquid

royalty free 3d model radial tyre for download as max on turbosquid: 3d models for games, architecture, videos. (1433150)

turbosquid

$60

Radial engine

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$35

VOITH RADIAL PROPELLER

...alty free 3d model voith radial propeller for download as max on turbosquid: 3d models for games, architecture, videos. (1338129)

3d_export

$20

radial engine assembly

...radial engine assembly

3dexport

turbosquid

$4

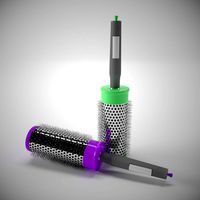

Radial Hair Brush

... 3d model radial hair brush for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1183870)

turbosquid

$39

Wheel ATS Radial

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Cooler

archibase_planet

free

Cooler

...hibase planet

wine-cooler wine cooler kitchen equipment

rk wine cooler uc - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Cooler

...cooler

archibase planet

cooler

cooler seyedmms n271212 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Cooler

...cooler

archibase planet

refrigerator cooler kitchen's technics

cooler - 3d model for interior 3d visualization.

archibase_planet

free

Cooler

...er

archibase planet

pc equipment cooler computer equipment

cooler n040908 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Cooler

...cooler

archibase planet

cooler cpu fan pc equipment

cooler asus n080211 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

Cooler

...cooler

3dexport

water cooler. program maya 2018. materials v-ray 3.6.

3d_export

$5

Juice cooler

...juice cooler

3dexport

juice cooler

turbosquid

$10

Cooler

...uid

royalty free 3d model cooler for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1478561)

turbosquid

$20

cooler

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

cooler

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

E3D

turbosquid

$23

E3D - Google Home

... 3d model e3d - google home for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1192509)

cg_studio

free

e3d model

...e3d model

cgstudio

- e 3d model, royalty free license available, instant download after purchase.

turbosquid

$2

Syringe C4D (E3D Ready)

...lty free 3d model syringe c4d (e3d ready) for download as c4d on turbosquid: 3d models for games, architecture, videos. (1336720)

turbosquid

$12

Microphone USB E3D and C4D

...ree 3d model microphone usb e3d & c4d for download as c4d on turbosquid: 3d models for games, architecture, videos. (1568216)

turbosquid

$29

E3D - OnePlus 6 Black

...model e3d - oneplus 6 black for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1358534)

turbosquid

$29

E3D - Motorola One 2018

...del e3d - motorola one 2018 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1358533)

turbosquid

$29

E3D - Disney MagicBands 2

...l e3d - disney magicbands 2 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1355515)

turbosquid

$29

E3D - Samsung Z4 Smartphone

...e3d - samsung z4 smartphone for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1182179)

turbosquid

$23

E3D - Razer Phone model

...del e3d - razer phone model for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1231207)

turbosquid

$23

E3D - Alcatel Idol 5

... model e3d - alcatel idol 5 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1212799)

40Mm

turbosquid

$10

40MM Bullet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$49

40mm Vickers-Terni

... free 3d model 40mm vickers-terni for download as lwo and obj on turbosquid: 3d models for games, architecture, videos. (1260063)

turbosquid

$3

40mm grenade M9XX

...y free 3d model 40mm grenade m9xx for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1408150)

turbosquid

$3

40mm grenade M3XX

...y free 3d model 40mm grenade m3xx for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1408145)

turbosquid

$3

40mm grenade M1XX

...y free 3d model 40mm grenade m1xx for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1408144)

turbosquid

$8

40mm Smith & Wesson

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Free 40mm grenade M433

...e 3d model free 40mm grenade m433 for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1404768)

turbosquid

$98

40mm 6G30 grenade launcher

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Famas G2 M203 40mm.

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

40mm Bofors TNT-11606

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Clone

3d_export

$5

Clones great republic

...clones great republic

3dexport

clones great republic.those same clones from the star wars movie universe.4 clones available.

3d_export

$10

Clone 3D Model

...clone 3d model

3dexport

clone woman girl female lady chamber sci fi

clone 3d model calcm1 51695 3dexport

turbosquid

$5

Clone machine

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

archive3d

free

Clone trooper 3D Model

...nd army soldier trooper

clone trooper 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

free

Lego Clone Walker

...ree 3d model lego sw clone walker for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1292252)

turbosquid

$15

Clone trooper helmet

...d model clone trooper helmet for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1199355)

archive3d

free

Clone trooper 3D Model

...and army soldier trooper

clonetrooper 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archive3d

free

Clone trooper 3D Model

...and army soldier trooper

clonetrooper 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_ocean

$35

Surface Clone C4D materials

...+ of the most well made materials for maxon’s cinema 4d; on the internet today. each material is crafted with a specific purpo...

turbosquid

$3

Sci-fi cloning vats

...cloning vats for download as 3ds, obj, wrl, x, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1290168)

Sensor

3d_export

free

parking sensor

...parking sensor

3dexport

car parking sensor

turbosquid

$1

Sensor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Smoke sensor

...port

smoke sensor, can be an impressive element for your projects. easy to use, realistic image, low polygon, quality materials.

3d_export

$5

Air Quality Sensor v1

...air quality sensor v1

3dexport

air quality sensor v1

3d_export

$15

float sensor

...e up render. - all parts and materials are logically named. other formats ================= - collada (.dae) - autodesk fbx - obj

turbosquid

$26

Wind sensor C

...free 3d model wind sensor c for download as 3ds, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1328943)

turbosquid

$26

Wind sensor B

...free 3d model wind sensor b for download as 3ds, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1328168)

3d_export

$5

ultrasound sensor

...ivers convert ultrasound into electrical signals, and transceivers can both transmit and receive ultrasound. export in: -obj -fbx

3ddd

free

Вытяжка Shindo pallada sensor

... вытяжка

вытяжка shindo pallada sensor. в двух размерах - 600 и 900. текстуры в комплекте.

turbosquid

$52

Wind sensor A B C

...

royalty free 3d model wind sensor a b c for download as fbx on turbosquid: 3d models for games, architecture, videos. (1408406)

Adapter

3d_export

$10

Adapter 3D Model

...adapter 3d model

3dexport

adapter

adapter 3d model mur 20260 3dexport

archive3d

free

Adapter socket 3D Model

...dapter socket adapter

adapter socket n090211 - 3d model (*.3ds) for interior 3d visualization.

turbosquid

$400

cell adaptation

...

royalty free 3d model cell adaptation for download as blend on turbosquid: 3d models for games, architecture, videos. (1701655)

archive3d

free

Adapter 3D Model

...ups pc equipment

adapter extron n180813 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$5

usb adapter

...royalty free 3d model usb adapter for download as ige and stl on turbosquid: 3d models for games, architecture, videos. (1582234)

turbosquid

$15

Power adapter

...free 3d model power adapter for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1510024)

turbosquid

$8

USB adapter

...e 3d model usb adapter for download as max, fbx, obj, and dwg on turbosquid: 3d models for games, architecture, videos. (1713542)

turbosquid

$30

adapter.3ds

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Nokia Adapter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Universal adapter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Part

3d_export

$5

Parts

...parts

3dexport

parts

3d_export

$5

Part

...part

3dexport

part

3d_export

$5

Part

...part

3dexport

machine part

3d_export

$65

Part

...part

3dexport

simple rendering of the scene file

3d_export

$65

Part

...part

3dexport

simple rendering of the scene file

3d_export

$30

fan part

...fan part

3dexport

this is a part of fan of pedastal

3d_export

$10

machine parts

...machine parts

3dexport

3d part modeling work ,contact for 3d work

turbosquid

$59

Mechanical Part

...id

royalty free 3d model mechanical part for download as c4d on turbosquid: 3d models for games, architecture, videos. (1410833)

turbosquid

$17

Road parts

...bosquid

royalty free 3d model road parts for download as 3ds on turbosquid: 3d models for games, architecture, videos. (1192967)

turbosquid

$9

Cutter Parts

...squid

royalty free 3d model cutter parts for download as stl on turbosquid: 3d models for games, architecture, videos. (1220010)