Thingiverse

Dual Z Mount for Anycubic Mega Zero by 1CM69

by Thingiverse

Last crawled date: 3 years, 1 month ago

I got inspiration from: https://www.thingiverse.com/thing:3796938

and thought that this was a extremely clean and simple answer to adding a second Z stepper & leadscrew to my Anycubic Mega Zero 2.

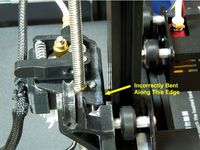

Having tried many other designs to attempt this upgrade/mod, each failing for some reason, this too did not work out for me.

I know, it's specifically for the Ender 3 & I am using a Mega Zero, so no surprise that it does not work but I have no idea why before now I didn't see the problem when using these Ender 3 designed mounts with my Mega Zero, even if I'd mirrored the model in CURA (as the Mega Zero's X gantry is opposite to the Ender's).

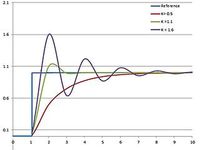

Most of these type of printer all look the same or very similar and I took that for granted, fool me, however it turns out that the hole centres between the top & bottom wheels running on the Z axis of the Ender is 72mm, on the Mega Zero this is 70mm.

Obvious to me now that this is why all the previous Ender 3 mounts caused a certain amount of binding when attempting to implement the dual z axis mod on my Mega Zero.

With all that said I decided that I needed to design a mount to properly mod my Mega Zero for a dual Z axis setup.

My design contains a number of parts:

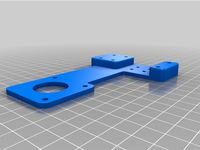

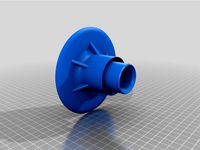

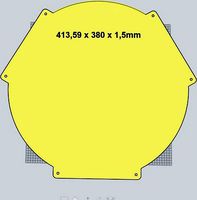

Leadscrew_Mount_[PART-A] - this is the main carrier and is attached to the front side of the left hand X gantry carriage via the wheel screws.

This means that it is not necessary to move the PSU from it's OE fixings on the Mega Zero 2.

Leadscrew_Mount_[PART-B][16mm] & Leadscrew_Mount_[PART-B][18mm] - basically the same part but while designing this I found that there are a couple of different rectangular leadscrew nuts, either 16mm or 18mm centres between the fixing screw holes.

Print whichever one suits the leadscrew nut you have.

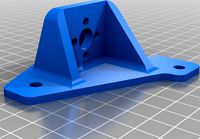

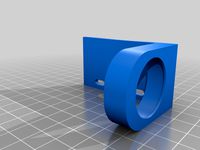

Stepper_Mount - this is the mount that attaches the second Z stepper to the outside of the printers frame.

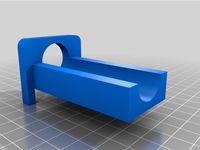

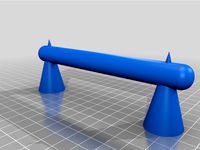

Z_Align_Block - these are optional but do aid with alignment (sync) of the Z axis, you'll need to print 2 of these.

My print settings are as follows:

All parts except the Z Align Blocks - LH 0.12mm 100% Infill in PETG

Z Align Blocks - LH 0.2mm 100% Infill in PLA

NO Supports required.

I chose to use 100% infill for added strength & 0.12mm LH for the majority of the parts for fit & finish.

Hardware used as follows:

PART-A to X carriage - 2x M5x35mm machine screws hex button head + thin washers & use existing M5 nyloc nuts.

PART-B to PART-A - 2x M3x20mm machine screws hex button head & 2x M3 nuts. Plus optional solvent to weld parts together.

Leadscrew nut to PART-B - 2 x M3x15mm machine screws hex button head & 2x M3 nuts if required (some leadscrew nuts are threaded).

Stepper Mount to frame - 2x M5x16mm machine screw hex button head & 2x M5 T-Nuts.

Stepper Motor to Stepper Mount - 4x M3x8mm machine screws & thin washers.

Z Align Blocks to frame - 2x M3x20mm machine screws & thin washers & 2x M3 T-Nuts each.

The Stepper Mount allows for some alignment to get the leadscrew running as true as possible.

I decided against using or designing leadscrew stabilizers as there is talk that the ends of the leadscrews need to be free & not transfer any wobble to the printers frame.

For Z axis sync with a dual axis setup I followed this YouTube video:

https://youtu.be/U_RiwMSG9rE

but I used fixed blocks (Z Align Blocks) on the inside of the Z axis frame on my printer & placed a starting GCODE in CURA as well as adding a Custom Menu option in Marlin.

In CURA:

; ALIGN DUAL Z

M117 Homing Z ...

G1 Z0 ;move Z to min endstops

M117 Homing X/Y ...

G28 X0 Y0 ;move X/Y to min endstops

G28 Z0

G1 Z200 ;MAX HEIGHT

G28 Z0 ;move Z to min endstops

M117 Z Axis Synced

; END OF ALIGN DUAL Z

In Marlin - Configuration_adv.h:

'#define CUSTOM_USER_MENUS'

'#define USER_DESC_1 "Align Z Axis"'

'#define USER_GCODE_1 "G1 Z0\nG28\nG1 Z200\nG28 Z0\nM117 Z Axis Synced"'

'CHANGE Z200 TO YOUR OWN REQUIREMENTS AFTER FOLLOWING VIDEO ABOVE'

Hopefully this all makes sense & I have included everything required.

Thanks for looking.

p.s. wise to perform a new bed level after fitting this mod & running the 'Align Z Axis' option.

and thought that this was a extremely clean and simple answer to adding a second Z stepper & leadscrew to my Anycubic Mega Zero 2.

Having tried many other designs to attempt this upgrade/mod, each failing for some reason, this too did not work out for me.

I know, it's specifically for the Ender 3 & I am using a Mega Zero, so no surprise that it does not work but I have no idea why before now I didn't see the problem when using these Ender 3 designed mounts with my Mega Zero, even if I'd mirrored the model in CURA (as the Mega Zero's X gantry is opposite to the Ender's).

Most of these type of printer all look the same or very similar and I took that for granted, fool me, however it turns out that the hole centres between the top & bottom wheels running on the Z axis of the Ender is 72mm, on the Mega Zero this is 70mm.

Obvious to me now that this is why all the previous Ender 3 mounts caused a certain amount of binding when attempting to implement the dual z axis mod on my Mega Zero.

With all that said I decided that I needed to design a mount to properly mod my Mega Zero for a dual Z axis setup.

My design contains a number of parts:

Leadscrew_Mount_[PART-A] - this is the main carrier and is attached to the front side of the left hand X gantry carriage via the wheel screws.

This means that it is not necessary to move the PSU from it's OE fixings on the Mega Zero 2.

Leadscrew_Mount_[PART-B][16mm] & Leadscrew_Mount_[PART-B][18mm] - basically the same part but while designing this I found that there are a couple of different rectangular leadscrew nuts, either 16mm or 18mm centres between the fixing screw holes.

Print whichever one suits the leadscrew nut you have.

Stepper_Mount - this is the mount that attaches the second Z stepper to the outside of the printers frame.

Z_Align_Block - these are optional but do aid with alignment (sync) of the Z axis, you'll need to print 2 of these.

My print settings are as follows:

All parts except the Z Align Blocks - LH 0.12mm 100% Infill in PETG

Z Align Blocks - LH 0.2mm 100% Infill in PLA

NO Supports required.

I chose to use 100% infill for added strength & 0.12mm LH for the majority of the parts for fit & finish.

Hardware used as follows:

PART-A to X carriage - 2x M5x35mm machine screws hex button head + thin washers & use existing M5 nyloc nuts.

PART-B to PART-A - 2x M3x20mm machine screws hex button head & 2x M3 nuts. Plus optional solvent to weld parts together.

Leadscrew nut to PART-B - 2 x M3x15mm machine screws hex button head & 2x M3 nuts if required (some leadscrew nuts are threaded).

Stepper Mount to frame - 2x M5x16mm machine screw hex button head & 2x M5 T-Nuts.

Stepper Motor to Stepper Mount - 4x M3x8mm machine screws & thin washers.

Z Align Blocks to frame - 2x M3x20mm machine screws & thin washers & 2x M3 T-Nuts each.

The Stepper Mount allows for some alignment to get the leadscrew running as true as possible.

I decided against using or designing leadscrew stabilizers as there is talk that the ends of the leadscrews need to be free & not transfer any wobble to the printers frame.

For Z axis sync with a dual axis setup I followed this YouTube video:

https://youtu.be/U_RiwMSG9rE

but I used fixed blocks (Z Align Blocks) on the inside of the Z axis frame on my printer & placed a starting GCODE in CURA as well as adding a Custom Menu option in Marlin.

In CURA:

; ALIGN DUAL Z

M117 Homing Z ...

G1 Z0 ;move Z to min endstops

M117 Homing X/Y ...

G28 X0 Y0 ;move X/Y to min endstops

G28 Z0

G1 Z200 ;MAX HEIGHT

G28 Z0 ;move Z to min endstops

M117 Z Axis Synced

; END OF ALIGN DUAL Z

In Marlin - Configuration_adv.h:

'#define CUSTOM_USER_MENUS'

'#define USER_DESC_1 "Align Z Axis"'

'#define USER_GCODE_1 "G1 Z0\nG28\nG1 Z200\nG28 Z0\nM117 Z Axis Synced"'

'CHANGE Z200 TO YOUR OWN REQUIREMENTS AFTER FOLLOWING VIDEO ABOVE'

Hopefully this all makes sense & I have included everything required.

Thanks for looking.

p.s. wise to perform a new bed level after fitting this mod & running the 'Align Z Axis' option.

Similar models

thingiverse

free

Z axis Adjustment blocks by Honkytime

...

thingiverse

made for the ender 3

110mm tall adjustment blocks for setting z axis height on dual stepper motor z axis leadscrews

thingiverse

free

Ender 3 / Dual Z Drive / Collision Alignment by BIueberry

...berry

thingiverse

z spacer for dual collision of the inner rollers for aligning and syncing dual stepper motors of the ender 3.

thingiverse

free

Ender3 ACME Anti-Backlash Nut Block Mount by approx_eng

...acme anti-backlash nut blocks on the ender 3 or similar instead of the more normal brass nuts. with the...

thingiverse

free

Ender 3 Adjustable Z Stepper Mount up to 48mm steppers by Its_3d_Willy

...0mm/60 tooth pulleys, any size will work

1x timing belt (from 696mm to ~800mm, i use 752mm)

m3 mounting hardware and t slot nuts.

thingiverse

free

Anycubic Mega Zero Stepper Motor Mount for Flexible Z Couplers by djos_1475

...crews:

1st stepper motor:

2x 20mm m4 screws

2x 16mm m3 screws

2nd stepper motor:

2x 12mm m4 screws

2x m4 t-nuts

2x 16mm m3 screws

thingiverse

free

Ender 3 / Pro / V2 Dual Z axis motor mount with T-nut by Flapstaart

...mount

2x m3x8 for stepper motor at the far end of the mount

printed using 0.2mm layer height and a 0.6mm nozzle without supports.

thingiverse

free

Ender 3 Pro Z Stepper Bracket by KyleRL

...end drilling and tapping the frame for the best connection. sans that, use t nuts and rest the stepper motor on the bottom frame.

thingiverse

free

Creality Ender-3 Z-Axis Alignment Correction by RonaldWalters

...iage bracket corrects the problem.

the stl file is for a 0.3mm thick paper shim as shown being used.

https://youtu.be/xnznd_fimky

thingiverse

free

Z axis Leadscrew to leadscrew coupler (8mm to 5mm) with 0.14mm clearence

...adscrew to leadscrew coupler (8mm to 5mm) with 0.14mm clearence

thingiverse

extra parts required:

2x m3 nuts

2x m3 screws (8mm+)

thingiverse

free

Ender 3 Dual Z axis - No Z loss, stock mounting hardware, anti backlash nut compatible by Its_3d_Willy

...0mm/60 tooth pulleys, any size will work

1x timing belt (from 696mm to ~800mm, i use 752mm)

m3 mounting hardware and t slot nuts.

1Cm69

thingiverse

free

LDR Sensor Enclosure by 1CM69

...lu pla from aliexpress.

the dropdown box does not have my exact printer but it is:

anycubic mega zero 2

hotend @ 190°c

bed @ 60°c

thingiverse

free

AnyCubic Mega Zero 2 Y Carriage Cover by 1CM69

...omplements these v slot covers: http://www.thingiverse.com/thing:3396601

cover @ 0.2mm lh

badge @ 0.12mm lh

no supports req'd

thingiverse

free

Right Hand Slimcase Extrusion Standoff - Xtra Fixings by 1CM69

...nt.

0.2mm lh.

have included the freecad file, (excuse the mess, i am no professional), incase anyone wishes to alter this model.

thingiverse

free

BTT UPS 24V V1.0 Case by 1CM69

...d to have the cables entering from the front of your printer, mine exit at the back and i have my enclosure mounted under my bed.

thingiverse

free

608-2RSH Bearing Fitment Test by 1CM69

...m id

middle: 22.25mm od & 8.25mm id

right: 22.5mm od & 8.5mm id

i printed at 0.2mm layer height with 10% infill using pla

thingiverse

free

Anycubic Mega Zero 2nd Z Leadscrew Mount by 1CM69

...& will cause binding, i know, i've been there done that.

designed for 0.2mm lh

i use 100% fill for strength & use pla

thingiverse

free

Raspberry Pi Zero W Enclosure c/w Logo by 1CM69

...one but i print on a glass plate with a few coats of pva brushed on & dried with a hairdryer for adhesion.

hotend is at 190°c

thingiverse

free

BTT Smart Filament Detection Module Mount by 1CM69

... necessary to move the stepper pinion ever so slightly further up the shaft too, this is easily done by loosening the grub screw.

thingiverse

free

DJI Mini 2 & Mavic Air 2/2s RC iPhone Holder by 1CM69

...d files in case anyone wants to edit their own version.

print models in the orientation of these files, no supports are required.

Anycubic

thingiverse

free

anycubic filament holder

...anycubic filament holder

thingiverse

anycubic filament holder

thingiverse

free

Cableholder Anycubic Mega

...cableholder anycubic mega

thingiverse

cableholder anycubic mega

thingiverse

free

AnyCubic Toolholder by WildManPrinting

...anycubic toolholder by wildmanprinting

thingiverse

anycubic i3 mega toolholder that clips on the side of the spool a-frame.

thingiverse

free

AnyCubic Funnel by phana007

...anycubic funnel by phana007

thingiverse

funnel for anycubic resin and also a reducer for a normal soda bottle.

thingiverse

free

Anycubic Kossel PID calibration

...ir mount:

kossel raspberry camera ir mount

extruder pid calibration.

simple extruder temperature calibration of your 3d printer.

thingiverse

free

anycubic mega i3

...anycubic mega i3

thingiverse

anycubic i3 mega/mega s led 30mm 10-14v 6500k

thingiverse

free

Handle for anycubic by cruiser7

...handle for anycubic by cruiser7

thingiverse

its easier to handle the cover of the anycubic mono x and wash&care

thingiverse

free

anycubic predator Printbed by Lihyon

...anycubic predator printbed by lihyon

thingiverse

anycubic predator printbed

thingiverse

free

Anycubic Predator Triggers by marcelcountry

...anycubic predator triggers by marcelcountry

thingiverse

anycubic predator triggers

thingiverse

free

support anycubic cable by sarpdental

...support anycubic cable by sarpdental

thingiverse

support anycubic cable

Mega

3ddd

$1

BoConcept / Mega

...boconcept / mega

3ddd

boconcept

boconcept mega

3ddd

free

Angelo - Mega shoin

... mega shoin , shoin

angelo - mega shoin - 3dmax 2008

3ddd

$1

Комод MEGA

...вана по фото с учетом реальных размеров.

стек не сколапсен, есть возможность регулировки уровня сглаживания.

текстуры в архиве.

3ddd

$1

Hulsta / Mega-design

...hulsta / mega-design

3ddd

hulsta

hulsta mega-design

design_connected

$18

Tolomeo Mega

...

photo-realistic 3d models of the tolomeo mega floor lamps from artemide for 3d architectural and interior design presentations.

turbosquid

$119

Mega Soldier

... free 3d model mega soldier for download as obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1148568)

turbosquid

$100

Mega Yacht

... free 3d model mega yacht for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1368903)

3ddd

$1

Massproductions Mega

... massproductions , mega

ширина: 180 см

глубина: 90 см

высота: 79 см

3d_export

$4

mega metro station

...mega metro station

3dexport

mega metro station. ready to game. thanks all downloaders!!

3ddd

$1

BAS Mega

...bas mega

3ddd

bas , ванна

ванна

Zero

3ddd

$1

ZERO, BEAM

...zero, beam

3ddd

zero

поворотная люстра zero , beam

design_connected

$9

Zero-in

...zero-in

designconnected

established & sons zero-in tables computer generated 3d model. designed by jay osgerby .

3ddd

free

Sub-Zero

...sub-zero

3ddd

sub-zero , голова

sub-zero corona render!

3ddd

$1

Metalspot / Zero

...metalspot / zero

3ddd

metalspot

metalspot zero

3ddd

$1

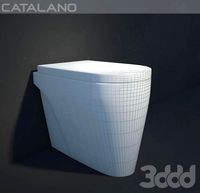

Catalano Zero

...catalano zero

3ddd

catalano , унитаз

catalano zero

3ddd

$1

SUB ZERO

... sub zero

the first and only 3d model of sub zero refrigerator.

the model is very accurate.

turbosquid

free

Zero

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Zero

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Zero

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

ZERO / Hide

...zero / hide

3ddd

zero

polys: 25486

wire-spline

Dual

turbosquid

free

Dual Pistols

...ls

turbosquid

free 3d model dual pistols for download as fbx on turbosquid: 3d models for games, architecture, videos. (1320360)

turbosquid

$2

Dual Axe

...urbosquid

royalty free 3d model dual axe for download as fbx on turbosquid: 3d models for games, architecture, videos. (1332372)

turbosquid

$10

Dual Lesaths

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

плитка Dual Bianco (Испания)

...й плитки venis dual (испания). технические качества: устойчивость к стирания, отличная геометрия, отсутствие проблем при укладке.

turbosquid

$35

Dual Mesh Fonts

...ree 3d model dual mesh fonts for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1352989)

turbosquid

$29

Dual Flask with Bungs

...del dual flask with bungs for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1210512)

turbosquid

$19

Dual Socket Plug

...3d model dual socket plug for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1303912)

turbosquid

$13

Dual Adjustable Pulley

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Amoi N809 Dual

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Dual Turret Tank

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Z

3d_export

$5

nissan z

...nissan z

3dexport

nissan z

3ddd

$1

Vase Z

...vase z

3ddd

vase z

3ddd

$1

полотенцесушить Z

...полотенцесушить z

3ddd

полотенцесушитель

полотенцесушить z

design_connected

free

Z-Chair

...z-chair

designconnected

free 3d model of z-chair designed by karman, aleksei.

design_connected

$11

Z Lamp

...z lamp

designconnected

phillips z lamp computer generated 3d model. designed by kalff, louis.

3d_export

$5

Dragon balls z

...dragon balls z

3dexport

dragon ball z

turbosquid

$20

Fighter Z

...

turbosquid

royalty free 3d model fighter z for download as on turbosquid: 3d models for games, architecture, videos. (1292563)

turbosquid

$9

Pen Z

...pen z

turbosquid

free 3d model pen z for download as obj on turbosquid: 3d models for games, architecture, videos. (1686775)

turbosquid

free

z chair

...z chair

turbosquid

free 3d model z chair for download as max on turbosquid: 3d models for games, architecture, videos. (1410230)

turbosquid

$5

Letter Z

...urbosquid

royalty free 3d model letter z for download as max on turbosquid: 3d models for games, architecture, videos. (1408540)

Mount

3d_export

free

mounting bracket

...mounting plate is the portion of a hinge that attaches to the wood. mounting plates can be used indoors, cabinetry and furniture.

turbosquid

$2

MOUNTING

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mounts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mount Fuji

...fuji

turbosquid

free 3d model mount fuji for download as obj on turbosquid: 3d models for games, architecture, videos. (1579977)

3d_export

$5

Headphone mount LR

...headphone mount lr

3dexport

headphone mount l+r

turbosquid

$39

Mount rainier

...quid

royalty free 3d model mount rainier for download as fbx on turbosquid: 3d models for games, architecture, videos. (1492586)

turbosquid

$5

pipe mounting

...quid

royalty free 3d model pipe mounting for download as obj on turbosquid: 3d models for games, architecture, videos. (1293744)

turbosquid

$3

Mounting Tires

...uid

royalty free 3d model mounting tires for download as fbx on turbosquid: 3d models for games, architecture, videos. (1708511)

3d_export

$5

Magnetic GoPro Mount

...pro mount

3dexport

cool magnetic mount for gopro. allows you to mount the camera on flat metal surfaces and get exclusive shots.

turbosquid

$5

Stone Mount

...ty free 3d model stone mount for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1370306)