Thingiverse

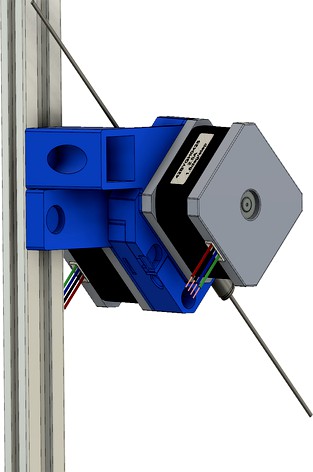

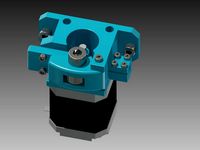

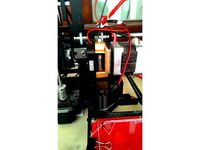

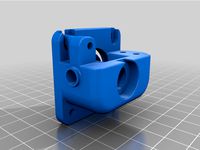

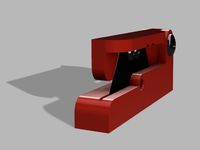

Dual stepper MK8 gear direct drive bowden extruder

by Thingiverse

Last crawled date: 4 years, 2 months ago

Having dual steppers driving an extruder allows to use 0.9 deg/step motors for more accuracy or 1.8 deg/step steppers for increased torque. Largest benefit is gained if used with a dedicated stepper driver instead of connecting the steppers in series or parallel to one stepper driver.

Additional parts needed:

2x MK8 drive gears

2x 625 sized bearings for filament guiding

8x M3x12 DIN 912 screws for mounting to stepper motors

4x M3 nuts

2x M3x16 DIN 912 screws for fixing the extruder halves together

2x M3x10 DIN 912 screws for adjusting drive gear pressure against the filament

2x M3x12 DIN 912 screws for holding the bearings in place

2x M3 washer for holding the bearings in place

2x pneumatic push-in fittings with M5 threads for the bowden tube diameter in use

Additional parts needed:

2x MK8 drive gears

2x 625 sized bearings for filament guiding

8x M3x12 DIN 912 screws for mounting to stepper motors

4x M3 nuts

2x M3x16 DIN 912 screws for fixing the extruder halves together

2x M3x10 DIN 912 screws for adjusting drive gear pressure against the filament

2x M3x12 DIN 912 screws for holding the bearings in place

2x M3 washer for holding the bearings in place

2x pneumatic push-in fittings with M5 threads for the bowden tube diameter in use

Similar models

thingiverse

free

Rackprint Bowden Extruder by Alex_RP

...x m3 screw ~20mm and nuts

2x m3 screw 15mm

bearing 608zz

mk8 drive gear

2x spring ~20mm with ~3mm inner diameter

thingiverse

free

Super Simple Bowden Extruder V2 by _AlexY

...aring

nema 17 stepper

4x m3x8mm screws

m3x30mm screw

extruder spring

m3 locknut

2x m5x8mm screws + 2x t-nuts for mounting to 2020

thingiverse

free

Extruder / Bowden - 3mm filament by dinizhobby

...zhobby

thingiverse

extruder for bowden filament 3mm

you need mk8 driver gear and one bearing 6x13x5 and shaft 6mm with screw m4

thingiverse

free

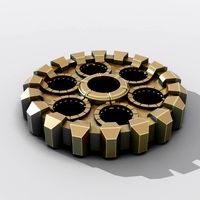

Gearstruder J4 - Dual Drive Extruder by walter

...t.

there is also a nema17 version and info about several other dual drive bowden extruders i've just uploaded on thrinter.com

thingiverse

free

MK8 Bowden Extruder 1,75mm for 2020 Extrusion with Filament Sensor by laubed

...m4x20 ant over to the m4x10

attach the microswitch to the extruder3/extruder2 assembly for filament detection with 2 m2x10 screws

grabcad

free

autorobotics FLE-X-trude

... 5x13x4, mk8 filament screw, screws (m3 (2x))+ springs, m3 screw nuts (2x)

for wade: no fixing plate, but carriage + screws, ...

thingiverse

free

Compact Bowden MK8 Remix by loco

...mm)

(4x) m3x8mm

(1x) m3x16mm

(2x) m4x8mm

(1x) m4x16mm

(2x) m3x30mm or longer, depending on your springs

(2x) m3 nut

(2x) m4 t-nut

thingiverse

free

Makerbot MK8 1.75mm Filament all-Metal Bowden Extruder Wire feeder Ultimate Upgrade by Vanadusan

...ations search on www.instructables.com for: mk8 metal bowden extruder wire feeder ultimate upgrade)

i am sorry for my english ;)

thingiverse

free

Fostruder H4 - Dual Drive Extruder by walter

...ther dual drive bowden extruders i've just uploaded on thrinter.com

printed in atomic filament ruby red petg*

*affiliate link

thingiverse

free

Gearstruder J7 - Dual Drive Extruder by walter

...t.

there is also a nema14 version and info about several other dual drive bowden extruders i've just uploaded on thrinter.com

Mk8

3d_export

$99

Mitsubishi Lancer Ralliart sedan 2004 3D Model

...lancer ralliart sedan 2004 3d model 3dexport mitsubishi ralliart mk8 2004 2005 4-door sedan saloon japan japanese eighth generation...

3d_ocean

$89

Mitsubishi Lancer Ralliart sedan 2004

...2004-2005 4-door eighth generation japan japanese mitsubishi mitsubishi ralliart mk8 ralliart saloon sedan the 3d model was created on...

thingiverse

free

MK8 by IsaiRochaSegura

...chasegura

thingiverse

in this thing i share a replace bar for mk8 extruder. i include the solidworks files for any modification.

thingiverse

free

MK8 Duct by ombranova

...mk8 duct by ombranova

thingiverse

duct for extruder mount mk8 on prusa i3

thingiverse

free

MK8 Flex Guide by loganjkd

...mk8 flex guide by loganjkd

thingiverse

just an inset for the mk8

thingiverse

free

MK7 / MK8 Mold by JMDesigns

...mk7 / mk8 mold by jmdesigns

thingiverse

mk7 / mk8 mold

thingiverse

free

Support extruder MK8 by rickshaolin

...support extruder mk8 by rickshaolin

thingiverse

support extruder mk8

thingiverse

free

MK8 Fan bracket by rocktang2003

...mk8 fan bracket by rocktang2003

thingiverse

mk8 fan bracket

thingiverse

free

HyperCube Mk8 mount by machala737

...hypercube mk8 mount by machala737

thingiverse

remix hypercube mk8 mount

thingiverse

free

mk8 fan holder by everythingother

...mk8 fan holder by everythingother

thingiverse

this is mk8 amazing fan holder

Bowden

turbosquid

$199

Vintage Ben Bowden Spacelander bike

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Manooi Artica

...and pendants in various sizes and forms. suspension: galvanized bowden - dia. 1,5 mm. bulb: max 60 w -...

thingiverse

free

Remix Compact Bowden extruder - m6 bowden couplers and bowden tube pass-through

...ouplers and bowden tube pass-through

thingiverse

remix compact bowden extruder - m6 bowden couplers and bowden tube pass-through

thingiverse

free

Bowden Extruder

...bowden extruder

thingiverse

i have created bowden extruder for flsun delta 3d printer.

thingiverse

free

bowden 3mm by spee_D

...bowden 3mm by spee_d

thingiverse

for bowden 3mm

thingiverse

free

Bowden Tube Cutter

...bowden tube cutter

thingiverse

bowden tube cutter

thingiverse

free

Customizable Bowden Clip

...customizable bowden clip

thingiverse

customizable bowden clip

thingiverse

free

Bowden Oiler by fcheshire

...bowden oiler by fcheshire

thingiverse

inline bowden oiler

thingiverse

free

Bowden adapter by helkaroui

...bowden adapter by helkaroui

thingiverse

this is a fixed bowden adapter

thingiverse

free

Adventure3 Bowden Clip

...adventure3 bowden clip

thingiverse

adventure3 bowden clip

Stepper

turbosquid

$85

Stepper

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$22

Mini Stepper

...gymnastic indoor legs machine mini silver sport stepper trainer workout

3d model of silver and black mini stepper with a counter.

turbosquid

$3

stepper deluxe

...osquid

royalty free 3d model stepper deluxe for download as on turbosquid: 3d models for games, architecture, videos. (1284335)

turbosquid

$49

Stepper Motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Fitness Stepper

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

stepper motor driver

...stepper motor driver for download as , fbx, dae, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1688860)

turbosquid

$1

Stepper motor driver

... model stepper motor driver for download as obj, stl, and ige on turbosquid: 3d models for games, architecture, videos. (1577811)

3d_export

$5

Stepper motor Nema17 17HS4401

...stepper motor nema17 17hs4401

3dexport

turbosquid

$1

Nema 17 Stepper motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Nema 17 Stepper Motor 59Nm

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Dual

turbosquid

free

Dual Pistols

...ls

turbosquid

free 3d model dual pistols for download as fbx on turbosquid: 3d models for games, architecture, videos. (1320360)

turbosquid

$2

Dual Axe

...urbosquid

royalty free 3d model dual axe for download as fbx on turbosquid: 3d models for games, architecture, videos. (1332372)

turbosquid

$10

Dual Lesaths

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

плитка Dual Bianco (Испания)

...й плитки venis dual (испания). технические качества: устойчивость к стирания, отличная геометрия, отсутствие проблем при укладке.

turbosquid

$35

Dual Mesh Fonts

...ree 3d model dual mesh fonts for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1352989)

turbosquid

$29

Dual Flask with Bungs

...del dual flask with bungs for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1210512)

turbosquid

$19

Dual Socket Plug

...3d model dual socket plug for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1303912)

turbosquid

$13

Dual Adjustable Pulley

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Amoi N809 Dual

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Dual Turret Tank

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Direct

design_connected

free

Compas Direction

...compas direction

designconnected

free 3d model of compas direction by vitra designed by prouvé, jean.

design_connected

$18

Direction Pivotant

...direction pivotant

designconnected

vitra direction pivotant computer generated 3d model. designed by prouvé, jean.

turbosquid

$6

not direct the front

...oyalty free 3d model not direct the front for download as max on turbosquid: 3d models for games, architecture, videos. (1213034)

turbosquid

$10

Rails Direct

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Picto toilet directions

...lude 3d files next to rhino6: x3dv, step, igus, obj and stl. double-sided, flipping changes the gender directions to the toilets.

3ddd

$1

fauteuli direction

...d

chair , vitra , fauteuli

fauteuli vitra chair

design_connected

$18

Fauteuil Direction, 1951

...fauteuil direction, 1951

designconnected

vitra fauteuil direction, 1951 computer generated 3d model. designed by prouvé, jean.

3d_export

$5

Directional tactile 3D Model

...tactile 3d model

3dexport

directional tactile braille tile flooring interior

directional tactile 3d model renob000 71068 3dexport

turbosquid

$26

Radio direction finder A

...ty free 3d model radio direction finder a for download as fbx on turbosquid: 3d models for games, architecture, videos. (1212490)

turbosquid

$7

Wooden direction signage

...ty free 3d model wooden direction signage for download as max on turbosquid: 3d models for games, architecture, videos. (1453747)

Drive

turbosquid

$90

Drive

...turbosquid

royalty free 3d model drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1654393)

3d_export

$10

cycloidal drive

...cycloidal drive

3dexport

cycloidal drive

3d_ocean

$5

Flash Drive

...h drive included : – materials – scene ( lighs / room ) – .c4d + .obj for any questions please feel free to contact me thank you.

3d_ocean

$5

Usb drive

...s shaders and a lighting setup. it also has a small animation of it going in and out. i saved it out as both a .blend file and...

3d_ocean

$5

Pen Drive

...est computer drive game model good low poly new pen pen drive textured unwrapped uv very low poly

a very beautiful low poly model

3d_ocean

$10

External hard drive

... is a detailed model of a trekstor external hard drive. you can easily modify the label on the top. simply edit the text objects.

turbosquid

$60

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1254314)

turbosquid

$50

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1263524)

turbosquid

$45

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1287060)

turbosquid

$40

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1261902)

Extruder

3ddd

$1

Extruded Chair

...extruded chair

3ddd

extruded , tom dixon

inspired by tom dixon extruded chair

turbosquid

$15

Extruded Table

... extruded table for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1634137)

turbosquid

$2

3D Printer Extruder

...d

royalty free 3d model 3d printer extruder for download as on turbosquid: 3d models for games, architecture, videos. (1537359)

turbosquid

$1

Zombie extruded text

...oyalty free 3d model zombie extruded text for download as obj on turbosquid: 3d models for games, architecture, videos. (1322198)

turbosquid

$4

Extruder conical screw

...el extruder conical screw for download as sldpr, ige, and stl on turbosquid: 3d models for games, architecture, videos. (1524433)

turbosquid

$50

3d PRINTER - Extruder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Extruded Table 2

...xtruded table 2 for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1621846)

turbosquid

$10

Maya Extrude Tool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

world earth extrude map

...world earth extrude map

3dexport

3ddd

$1

Simply Elegant Extruded Tree Coffee Table Design

...ble by link studios. the silhouette of a tree is visible at one angle, extruded from the surface to create the support structure.

Gear

3d_ocean

$4

Gears

...gears

3docean

gear gears iron

4 different size of gears

3d_export

$5

gear

...gear

3dexport

gear

3d_export

free

Gears

...gears

3dexport

gears

3d_export

$5

gear

...gear

3dexport

a simple model of gear

3d_export

$5

gear

...gear

3dexport

gear for transmission , case machine

3d_ocean

$3

Gears

...nical parts process steampunk vehicle wheel work

10 different gear models volume 01-10 files: .3ds .c4d .obj note: you need vray

3d_ocean

$1

Spur Gear

...spur gear

3docean

decoration gear

a typical spur gear

3d_ocean

$4

Gear wheels

...gear wheels

3docean

engine engineering gear gears industry machinery mechanical toothwheel wheel

pair of gear wheels : animated.

turbosquid

$9

Gear

...gear

turbosquid

royalty free 3d model gear for download as on turbosquid: 3d models for games, architecture, videos. (1712328)

turbosquid

$2

Gears

...rs

turbosquid

royalty free 3d model gears for download as ma on turbosquid: 3d models for games, architecture, videos. (1166710)