Thingiverse

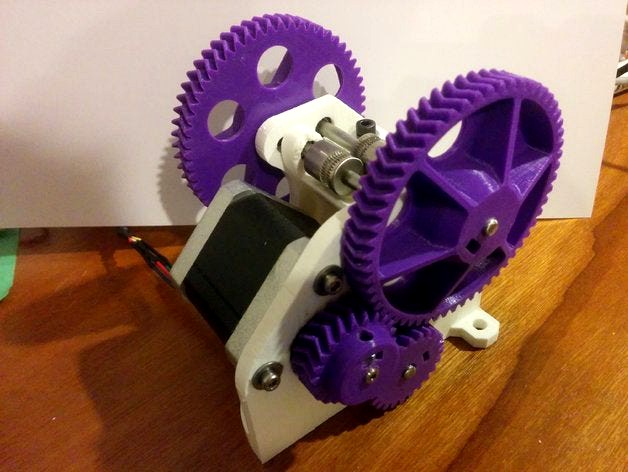

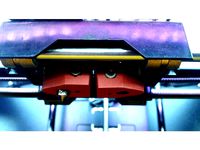

Dual Drive Bowden Extruder by invent3d

by Thingiverse

Last crawled date: 3 years ago

UPDATE 14-01-16:

New files added for use with MK8 drive gears. Unfortunately I would have had to compromise the design too much to make a version which can do both MK7 and MK8 gears, so theres two slightly different parts with slight changes to the geometry. The smaller diameter MK8 drive gears will give a slightly higher gear ratio, so more force on the filament, however they will also have slightly less grip as there will be less teeth in contact.

UPDATE 06-01-16:

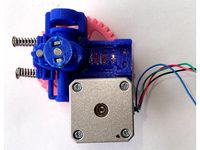

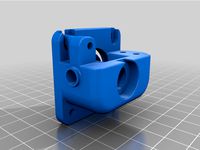

Some updates to the V2 extruder frame and pivot arm. All the geometry is the same but there are now better mounting holes, a filament guide above the drive gears, some levers to grab to make it easier to change filament!

UPDATE 13-10-15:

I have left the MK1 files there in case anyone wants to remix or modify them, but MK2 is superior in many ways so if your building one for the first time, MK2 should be the one to build.

Lots of updates, now using off the shelf MK7 drive gears so you don't need to hob anything (unless you want to), its easier to print, there are bearings on the pivot arm, and the drive gears are now located in between the shaft bearings so you can apply much more clamping force without the arm or frame twisting!

There are many extruder designs out there already, why do we need another one?

Well, you might not. If you are running a small printer, with a direct extruder, then this is not for you. If you are running a small printer with a direct drive bowden extruder, then its still probably not for you. This is aimed at BIG printers, with the aim of going FAST.

I run a relatively large delta printer, not the largest out there by any means, but large enough to get some pretty large volume prints on the plate. And the problem you soon discover with large prints is that they take AAAGGGEEESSS. My problem is also compounded because I run 3mm filament into a 0.35mm j-head hot end. Not the highest flowing hot end, and a small nozzle to be squeezing plastic out of.

The second thing that plagues large bowden extruder printers is retraction. Because my bowden tube is 800mm long, I need a lot of retraction to avoid stringing. Lots of retraction means lots of running back and forward over the same poor piece of filament, which leads to grinding, slipping, and under extrusion. Ideally I would be running about 8mm of retraction, with 3mm filament 8mm is a lot of extrusion out the hot end before I get a fresh piece of filament to grip.

I soon established that my primary limiting factor was grip on the filament. To print fast I had to put a lot of spring pressure on the drive roller, which means when you retract back over the same piece of filament it gets destroyed. The fix? More teeth. By gripping the filament from both sides you get twice as many teeth holding it so can use less pressure and get the same grip. With nice sharp hobbed bolts I can make my stepper slip before the filament does, grip is not a problem with this arrangement!

The gear ratio is only 1:2.5 which is less than most Wades extruders, but there is a trade off between gear ratio and how big those gears get. With a decent spec motor you should still have plenty of torque (I use a 42BYGHM809).

This is now the second version, clearly the first one worked well enough that I decided to keep working on the concept. The second one works even better! I can print faster, retract faster, and have less problems grinding filament with lots of retraction on small models. I would love to see a few more out there and see if they work well for anyone else too.

It was intended for use with 3mm filament and a bowden setup. I guess theres no reason you couldn't use it as a direct extruder, but you would need a fairly large printer for it not to look silly (its pretty bulky). If you run 1.75mm filament then you probably dont need it, but I dont know anything about printing with 1.75 filament so feel free to correct me and give it a go!

Bear with me, this is a work in progress. Any questions, just post a comment I'll do my best to answer.

For anyone who wants to push their extruder to its limits I consider this article to be mandatory reading:http://www.extrudable.me/2013/04/18/exploring-extrusion-variability-and-limits/

Note that he is using a 0.6 nozzle, so his results may not be directly comparable to your setup. I intend to perform a similar test for my setup, but I haven't had time yet.

https://www.youtube.com/watch?v=0AV3KpuHrKAhttps://www.youtube.com/watch?v=WPuSdkbF-h0

New files added for use with MK8 drive gears. Unfortunately I would have had to compromise the design too much to make a version which can do both MK7 and MK8 gears, so theres two slightly different parts with slight changes to the geometry. The smaller diameter MK8 drive gears will give a slightly higher gear ratio, so more force on the filament, however they will also have slightly less grip as there will be less teeth in contact.

UPDATE 06-01-16:

Some updates to the V2 extruder frame and pivot arm. All the geometry is the same but there are now better mounting holes, a filament guide above the drive gears, some levers to grab to make it easier to change filament!

UPDATE 13-10-15:

I have left the MK1 files there in case anyone wants to remix or modify them, but MK2 is superior in many ways so if your building one for the first time, MK2 should be the one to build.

Lots of updates, now using off the shelf MK7 drive gears so you don't need to hob anything (unless you want to), its easier to print, there are bearings on the pivot arm, and the drive gears are now located in between the shaft bearings so you can apply much more clamping force without the arm or frame twisting!

There are many extruder designs out there already, why do we need another one?

Well, you might not. If you are running a small printer, with a direct extruder, then this is not for you. If you are running a small printer with a direct drive bowden extruder, then its still probably not for you. This is aimed at BIG printers, with the aim of going FAST.

I run a relatively large delta printer, not the largest out there by any means, but large enough to get some pretty large volume prints on the plate. And the problem you soon discover with large prints is that they take AAAGGGEEESSS. My problem is also compounded because I run 3mm filament into a 0.35mm j-head hot end. Not the highest flowing hot end, and a small nozzle to be squeezing plastic out of.

The second thing that plagues large bowden extruder printers is retraction. Because my bowden tube is 800mm long, I need a lot of retraction to avoid stringing. Lots of retraction means lots of running back and forward over the same poor piece of filament, which leads to grinding, slipping, and under extrusion. Ideally I would be running about 8mm of retraction, with 3mm filament 8mm is a lot of extrusion out the hot end before I get a fresh piece of filament to grip.

I soon established that my primary limiting factor was grip on the filament. To print fast I had to put a lot of spring pressure on the drive roller, which means when you retract back over the same piece of filament it gets destroyed. The fix? More teeth. By gripping the filament from both sides you get twice as many teeth holding it so can use less pressure and get the same grip. With nice sharp hobbed bolts I can make my stepper slip before the filament does, grip is not a problem with this arrangement!

The gear ratio is only 1:2.5 which is less than most Wades extruders, but there is a trade off between gear ratio and how big those gears get. With a decent spec motor you should still have plenty of torque (I use a 42BYGHM809).

This is now the second version, clearly the first one worked well enough that I decided to keep working on the concept. The second one works even better! I can print faster, retract faster, and have less problems grinding filament with lots of retraction on small models. I would love to see a few more out there and see if they work well for anyone else too.

It was intended for use with 3mm filament and a bowden setup. I guess theres no reason you couldn't use it as a direct extruder, but you would need a fairly large printer for it not to look silly (its pretty bulky). If you run 1.75mm filament then you probably dont need it, but I dont know anything about printing with 1.75 filament so feel free to correct me and give it a go!

Bear with me, this is a work in progress. Any questions, just post a comment I'll do my best to answer.

For anyone who wants to push their extruder to its limits I consider this article to be mandatory reading:http://www.extrudable.me/2013/04/18/exploring-extrusion-variability-and-limits/

Note that he is using a 0.6 nozzle, so his results may not be directly comparable to your setup. I intend to perform a similar test for my setup, but I haven't had time yet.

https://www.youtube.com/watch?v=0AV3KpuHrKAhttps://www.youtube.com/watch?v=WPuSdkbF-h0

Similar models

thingiverse

free

Makerbot MK8 1.75mm Filament all-Metal Bowden Extruder Wire feeder Ultimate Upgrade by Vanadusan

...ations search on www.instructables.com for: mk8 metal bowden extruder wire feeder ultimate upgrade)

i am sorry for my english ;)

thingiverse

free

Mk8 Extruder for Nema17 with BI v2.5 mount by HadesCorps

... the same as my previous design.

i will update more bowden mounting versions soon and improve instruction so lookout for updates.

thingiverse

free

HE+ Dual Drive Bowden Extruder by the_mechanical

...clamp for bowden 6mm, don't know the dimensions for 4mm clamp. if the outer dimesion is the same it will work, otherwise not.

thingiverse

free

Geared bowden extruder for mk8 and flexible filament by condac

...lament, this i have not really done in a way i am satisfied with yet so there will be some upgrade to make it better in that way.

grabcad

free

MK8 drive gear

...mk8 drive gear

grabcad

drive gear mounted inside 3d printer 1.75mm filament extruder.

thingiverse

free

Filamentguide for MK8 direct drive extruder for plexible filaments by chrisdruckt

...to hot.

credits are not on my side, as i have seen some images of parts like that while googling for tips on how to use filaflex.

thingiverse

free

Base for "Compact Bowden Extruder" modded for flexible Filament by Backenfutter

... 9mm diameter and constructed it for this size. didn´t tested it with a 8mm wheel. if you tested it, let me know if it works too,

thingiverse

free

MiniExtruder MK8 for Kossel by Kristong-S

...rtripper.com/1676/3d-printer-extruder-filament-drive-gear-review-benchmark/

so i try to make mini extruder use mk8 hobbed gear..

thingiverse

free

Fishbone gears for k8200 by ProtoMosh

...ng model of version 2.1

update:

i found way too many holes in big_gear so i deleted it and i will upload when i get it fixed.

thingiverse

free

inverted bulldog extruder with mk8 drive gear with filament guide by justsomeone

...lock to use m3x16 screws.(in my setup 3mm thickness steel plate is between with main block and the stepper)

i hope u may like it.

Invent3D

thingiverse

free

Curved Wine Holder Hexfill by invent3d

...erse

remix of the curved wine holder with a hexagon infill. wall thickness is 0.8mm so optimised for 2 shells on a 0.4mm nozzle.

thingiverse

free

Raspberry Pi VGA 666 Adapter by invent3d

...y invent3d

thingiverse

model of a raspberry pi vga adapter, could be useful if you want to check clearances in an enclosure etc.

thingiverse

free

Improved Tantillus Corners by invent3d

... increased for better strength

fillets added to prevent corner stresses (and make it look nicer)

geometry generally tidied up

thingiverse

free

Raspberry Pi VGA Case by invent3d

...id assembled with m3 cap screws. mounting holes are 75 x 100mm so will mount to either 75mm or 100mm vesa mounts (2 screws only).

thingiverse

free

Curvy Tablet Stand by invent3d

...e the gap under the tablet to hold a low profile usb hub.

edit:

new version up. should be a bit stronger to hold heavier tablets.

thingiverse

free

Smoothieboard Case by invent3d

...ries it for me.

the slots in the lid should be over the drivers, the rising hot air is what will pull fresh air in at the back.

thingiverse

free

Replicator 2 Big Foot by invent3d

...nder the feet on my machine and it seems to work really well. if you try something different that works, comment and let me know!

thingiverse

free

Improved Tantillus Herringbone Gears by invent3d

... improved strength

flipped the driven gear so they both sit the same way round on the shafts

generally tidied up the geometry

thingiverse

free

Replicator 2X Silicone Insulator by invent3d

... its a press together mould it should work ok with rtv.

thanks to martin_s for the idea!https://www.thingiverse.com/thing:1655134

thingiverse

free

Printable Sports Car wheel by invent3d

...erse here: http://www.thingiverse.com/thing:281782

you need to scale the front wheels about 95% of the rear to fit on that model.

Bowden

turbosquid

$199

Vintage Ben Bowden Spacelander bike

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Manooi Artica

...and pendants in various sizes and forms. suspension: galvanized bowden - dia. 1,5 mm. bulb: max 60 w -...

thingiverse

free

Remix Compact Bowden extruder - m6 bowden couplers and bowden tube pass-through

...ouplers and bowden tube pass-through

thingiverse

remix compact bowden extruder - m6 bowden couplers and bowden tube pass-through

thingiverse

free

Bowden Extruder

...bowden extruder

thingiverse

i have created bowden extruder for flsun delta 3d printer.

thingiverse

free

bowden 3mm by spee_D

...bowden 3mm by spee_d

thingiverse

for bowden 3mm

thingiverse

free

Bowden Tube Cutter

...bowden tube cutter

thingiverse

bowden tube cutter

thingiverse

free

Customizable Bowden Clip

...customizable bowden clip

thingiverse

customizable bowden clip

thingiverse

free

Bowden Oiler by fcheshire

...bowden oiler by fcheshire

thingiverse

inline bowden oiler

thingiverse

free

Bowden adapter by helkaroui

...bowden adapter by helkaroui

thingiverse

this is a fixed bowden adapter

thingiverse

free

Adventure3 Bowden Clip

...adventure3 bowden clip

thingiverse

adventure3 bowden clip

Dual

turbosquid

free

Dual Pistols

...ls

turbosquid

free 3d model dual pistols for download as fbx on turbosquid: 3d models for games, architecture, videos. (1320360)

turbosquid

$2

Dual Axe

...urbosquid

royalty free 3d model dual axe for download as fbx on turbosquid: 3d models for games, architecture, videos. (1332372)

turbosquid

$10

Dual Lesaths

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

плитка Dual Bianco (Испания)

...й плитки venis dual (испания). технические качества: устойчивость к стирания, отличная геометрия, отсутствие проблем при укладке.

turbosquid

$35

Dual Mesh Fonts

...ree 3d model dual mesh fonts for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1352989)

turbosquid

$29

Dual Flask with Bungs

...del dual flask with bungs for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1210512)

turbosquid

$19

Dual Socket Plug

...3d model dual socket plug for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1303912)

turbosquid

$13

Dual Adjustable Pulley

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Amoi N809 Dual

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Dual Turret Tank

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Drive

turbosquid

$90

Drive

...turbosquid

royalty free 3d model drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1654393)

3d_export

$10

cycloidal drive

...cycloidal drive

3dexport

cycloidal drive

3d_ocean

$5

Flash Drive

...h drive included : – materials – scene ( lighs / room ) – .c4d + .obj for any questions please feel free to contact me thank you.

3d_ocean

$5

Usb drive

...s shaders and a lighting setup. it also has a small animation of it going in and out. i saved it out as both a .blend file and...

3d_ocean

$5

Pen Drive

...est computer drive game model good low poly new pen pen drive textured unwrapped uv very low poly

a very beautiful low poly model

3d_ocean

$10

External hard drive

... is a detailed model of a trekstor external hard drive. you can easily modify the label on the top. simply edit the text objects.

turbosquid

$60

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1254314)

turbosquid

$50

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1263524)

turbosquid

$45

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1287060)

turbosquid

$40

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1261902)

Extruder

3ddd

$1

Extruded Chair

...extruded chair

3ddd

extruded , tom dixon

inspired by tom dixon extruded chair

turbosquid

$15

Extruded Table

... extruded table for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1634137)

turbosquid

$2

3D Printer Extruder

...d

royalty free 3d model 3d printer extruder for download as on turbosquid: 3d models for games, architecture, videos. (1537359)

turbosquid

$1

Zombie extruded text

...oyalty free 3d model zombie extruded text for download as obj on turbosquid: 3d models for games, architecture, videos. (1322198)

turbosquid

$4

Extruder conical screw

...el extruder conical screw for download as sldpr, ige, and stl on turbosquid: 3d models for games, architecture, videos. (1524433)

turbosquid

$50

3d PRINTER - Extruder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Extruded Table 2

...xtruded table 2 for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1621846)

turbosquid

$10

Maya Extrude Tool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

world earth extrude map

...world earth extrude map

3dexport

3ddd

$1

Simply Elegant Extruded Tree Coffee Table Design

...ble by link studios. the silhouette of a tree is visible at one angle, extruded from the surface to create the support structure.