Thingiverse

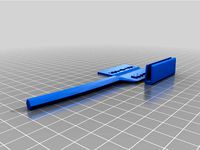

Double Edge Shaver (Yet Another) by hemocyanin

by Thingiverse

Last crawled date: 3 years ago

Here is yet another double edge shaver (see below for other examples). This one is completely made of plastic with the only metal part being the razor blade itself (this is not necessarily an advantage because the head of the shaver is not heavier than the handle -- I think of it as a disposable travel shaver).

Random videos on how to use a double edge shaver: Men; Women

---- Assembly ----

The photos demonstrate how it goes together. Because the bolt is plastic, don't torque it down too much or it will break off in the handle.

---- Printing Notes ----

Printing the handle, the base, and the bolt are all very straightforward and they print well in in ABS or PLA. The clamp however is next to impossible to print well in ABS. At least for me. I'd love some suggestions because I really prefer the look and feel of ABS.

The best solution I could find for printing the clamp, is to print it in PLA in a vertical orientation with a 100% fill rate. The issue I had with ABS was getting the outward edges perfectly flat. These edges need to be flat otherwise the razor blade tends to be depressed into a broad "U" profile, which means a close (maybe too close) shave in the center of the shaver, and a not-so-close shave at the ends.

---- Usage Notes ----

There are three razor base designs with differing comb lengths. The longer the comb, the less likely you'll get nicks, but the less close the shave. If you've never used a double edge shaver before, start with the long comb -- it is the safest.

---- Issues with the ####### Clamp ----

I thought this was going to be a fun quickie project, but I was so wrong. I had started with the bolt and the clamp as an integrated single piece. I had terrible trouble with automated support because it would encapsulate the bolt and while breaking off the support, it was about a 50/50 chance I'd break off the bolt too. I tried printing it sideways with support only for the bolt, but the part was incredibly weak and broke very easily. I tried printing it top side down, but that caused ugly and uneven edges. I tried printing with the edges directly on the build plate, but mine requires heat (PEI surfaced) and that caused warping.

I tried a horizontal orientation with custom supports. These snap off nicely without damaging the bolt, but the larger issue is that I still can not get a super flat outside edge. I even tried varying the amount of support along the length of the piece so that curl and sag would counterbalance -- no dice. I tried adding horizontal support to keep the edge from bowing out when it is but a single strand -- no luck.

I include those parts here as experimental -- for others to experiment with if they wish. I've put way more time into them than I want, and I've basically decided that a horizontally oriented integrated bolt clamp, has got me beat.

---- Final Notes ----

I always include my source files (in this case in freeCAD file format) so if you want to make it better or scavenge bits and pieces, you don't have to deal with the hassle of pure STL files.

The examples here were printed on a LulzBot Mini in ABS and PLA.

---- Other Shavers ---

Jan 20, 2013: http://www.thingiverse.com/thing:43568 (includes source)

Mar 12, 2013: http://www.thingiverse.com/thing:61169

Apr 09, 2015: http://www.thingiverse.com/thing:763815

And then there's this. You don't even need a printer, just some PVC pipe. It's pretty awesome in its purely utilitarian aesthetic: http://brettbeauregard.com/blog/2010/03/diy-safety-razor-handle/

If I've missed any, let me know, I'll add them.

Random videos on how to use a double edge shaver: Men; Women

---- Assembly ----

The photos demonstrate how it goes together. Because the bolt is plastic, don't torque it down too much or it will break off in the handle.

---- Printing Notes ----

Printing the handle, the base, and the bolt are all very straightforward and they print well in in ABS or PLA. The clamp however is next to impossible to print well in ABS. At least for me. I'd love some suggestions because I really prefer the look and feel of ABS.

The best solution I could find for printing the clamp, is to print it in PLA in a vertical orientation with a 100% fill rate. The issue I had with ABS was getting the outward edges perfectly flat. These edges need to be flat otherwise the razor blade tends to be depressed into a broad "U" profile, which means a close (maybe too close) shave in the center of the shaver, and a not-so-close shave at the ends.

---- Usage Notes ----

There are three razor base designs with differing comb lengths. The longer the comb, the less likely you'll get nicks, but the less close the shave. If you've never used a double edge shaver before, start with the long comb -- it is the safest.

---- Issues with the ####### Clamp ----

I thought this was going to be a fun quickie project, but I was so wrong. I had started with the bolt and the clamp as an integrated single piece. I had terrible trouble with automated support because it would encapsulate the bolt and while breaking off the support, it was about a 50/50 chance I'd break off the bolt too. I tried printing it sideways with support only for the bolt, but the part was incredibly weak and broke very easily. I tried printing it top side down, but that caused ugly and uneven edges. I tried printing with the edges directly on the build plate, but mine requires heat (PEI surfaced) and that caused warping.

I tried a horizontal orientation with custom supports. These snap off nicely without damaging the bolt, but the larger issue is that I still can not get a super flat outside edge. I even tried varying the amount of support along the length of the piece so that curl and sag would counterbalance -- no dice. I tried adding horizontal support to keep the edge from bowing out when it is but a single strand -- no luck.

I include those parts here as experimental -- for others to experiment with if they wish. I've put way more time into them than I want, and I've basically decided that a horizontally oriented integrated bolt clamp, has got me beat.

---- Final Notes ----

I always include my source files (in this case in freeCAD file format) so if you want to make it better or scavenge bits and pieces, you don't have to deal with the hassle of pure STL files.

The examples here were printed on a LulzBot Mini in ABS and PLA.

---- Other Shavers ---

Jan 20, 2013: http://www.thingiverse.com/thing:43568 (includes source)

Mar 12, 2013: http://www.thingiverse.com/thing:61169

Apr 09, 2015: http://www.thingiverse.com/thing:763815

And then there's this. You don't even need a printer, just some PVC pipe. It's pretty awesome in its purely utilitarian aesthetic: http://brettbeauregard.com/blog/2010/03/diy-safety-razor-handle/

If I've missed any, let me know, I'll add them.

Similar models

thingiverse

free

Shaving brush and shaver mirror holder

...but holds well a medium shaving brush. the shaving razor hole has 13.5mm diameter and the shaving brush holder has 30mm diameter.

cg_trader

free

Fixed Razor

... (twist-to-open) and comb. (photo of original for comparison) razor comb barber cutter shave shaver architectural other furniture

3d_export

$15

Vintage Razor 3D Model

...dge bathroom shaving implement barbers classic cut sharp toiletry toilet trim beard

vintage razor 3d model firdz3d 87556 3dexport

thingiverse

free

Shaver Holder for 50mm Dia. Can by rtsandiego

...tsandiego

thingiverse

a shaver hanger that clips onto a 50mm diameter shaving cream canister. i printed in pla with no supports.

thingiverse

free

Modern Style Bathroom Caddy by Zakzakattackx

... the caddy on its side, i printed with supports ( i have not tried without supports)

post a pic if you printed it!

happy printing

cg_trader

$8

Shaving Cream and Razor

...red. shaving cream razor blade cosmetic health and beauty fashion and beauty shave lotion shaver gel beard beauty household other

3d_export

$20

Electric Shaver 3D Model

...aver 3d model

3dexport

razor shaver shaving shave washable electric beard bathroom

electric shaver 3d model matvic 82927 3dexport

thingiverse

free

Shaving Brush Stand for "Razorock Bruce" by MrPeter

...azor blade box: https://www.thingiverse.com/thing:3028913

shaving lathering mug / bowl: https://www.thingiverse.com/thing:3120393

thingiverse

free

Double side razor handle by Rafaello

...for you that enjoy to shave the old fashion way like me.

just use a classic double side edge blade and try not to cut your throat

thingiverse

free

stand for shave accessories

... things :)

assembled from two separate parts: the base and the vertical stand- should match many different hand shavers.

enjoy :)

Hemocyanin

turbosquid

$49

Hemocyanin

...

royalty free 3d model hemocyanin for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1238350)

turbosquid

$16

Hemocyanin

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$49

Hemocyanin Structure

...free 3d model hemocyanin structure for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1238351)

turbosquid

$16

Hemocyanin(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

thingiverse

free

Hole Test 6mm and 3mm Diameters by hemocyanin

...the 3d equivalent of hello world, but if you want to see how freecad works at the most basic level, it might be worth looking at.

thingiverse

free

Mallet, Weighted Head by hemocyanin

...handle up a tiny bit to correct that. you'll also probably want to flip the heads over so the wide end is on the buildplate.

thingiverse

free

SSD Adapter for Lenovo TS130 Series by hemocyanin

... the holes don't match up to your specific ssd, i have included the freecad source to make modification of the design easier.

thingiverse

free

Shoe for Hakko FX888D Iron Stand by hemocyanin

...ll enough in that.

i've included the freecad source file to make modifications easier if you want to customize or improve it.

thingiverse

free

Handle for thread making taps by hemocyanin

... i figure the extra holes are there to be used when i eventually strip a screw hole.

made with freecad -- source file included.

thingiverse

free

Screw Mount Cable Clamps by hemocyanin

...ke them stronger, but these are good enough for my purposes so i'm quitting here.

edit: fixed a small error in 10mm files.

Shaver

3d_ocean

$12

Electric Shaver

...electric shaver

3docean

electric electric shaver hair removal personal care shaver shaving

electric shaver created in 3ds max.

turbosquid

$1

shaver

...

turbosquid

royalty free 3d model shaver for download as fbx on turbosquid: 3d models for games, architecture, videos. (1706142)

turbosquid

$60

shaver

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$60

shaver

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

shaver

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Shavers

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$12

shaver

...urlers hairdresser kit razor shaver spray

subdivision models.in archive there are 3ds max file,obj ,and render the scene modo lxo

3d_export

$10

Shaver 3D Model

...shaver 3d model

3dexport

shaver shave accesories bathroom toilet handle knife

shaver 3d model gldesign 29246 3dexport

turbosquid

$9

Fabric Shaver

...ee 3d model fabric shaver for download as blend, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1522246)

turbosquid

$50

Philips shaver

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Double

3ddd

free

Double

...double

3ddd

double , sicis

диван double от итальянской фабрики sicis next art

3d_ocean

$5

double stairs

...double stairs

3docean

double stairs

double stairs

3d_export

$5

double handle

...double handle

3dexport

double handle

3d_export

$5

double fastener

...double fastener

3dexport

double fastener

3ddd

$1

double bed

...double bed

3ddd

двуспальная

double bed

design_connected

free

Chair Double

...chair double

designconnected

free 3d model of chair double

3ddd

$1

Double Leaves

...double leaves

3ddd

double leaves

кресло китайской фабрики double leaves. vray, 3dmax 2013, гамма 2.2, текстуры в комплекте.

3ddd

free

Люстра Double

...люстра double

3ddd

double , david chipperfield

2004

размеры в архиве

3d_export

free

couch - double

...couch - double

3dexport

couch double with texture and .psd files for personal customization

3d_export

$10

double layer double speed chain

...d chain

3dexport

double layer speed chain (design very detailed) 3d model drawing model file reference using solidworks software

Another

turbosquid

$15

ANOTHER BATHROOM

...quid

royalty free 3d model another bathroom for download as on turbosquid: 3d models for games, architecture, videos. (1171460)

turbosquid

$24

Another World

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$39

Another Red Curb

...ee 3d model another red curb for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1182913)

turbosquid

$9

Another Deberenn Sofa

...model another deberenn sofa for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1497850)

turbosquid

$2

Another picnic table

... model another picnic table for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1426381)

turbosquid

$15

door to another world

...oor to another world for download as 3ds, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1334842)

3d_export

free

another hacksaw

...another hacksaw

3dexport

. . . 3d model of a hacksaw. 3d model files: - 3ds max 2017 (scanline) - obj (low poly) . . .

turbosquid

$12

Another Country Side Table

... another country side table for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1496053)

turbosquid

$29

Furniture - "Another country" modern sofa

...another country" modern sofa for download as obj and c4d on turbosquid: 3d models for games, architecture, videos. (1186189)

3d_ocean

$29

Another Tron Light Cycle with the Rider and Trail

...ther tron light cycle with the rider and the light trail. high quality 3d model,all the materials and lights are included. the...

Edge

3ddd

free

EDGE

... часы

светильник edge

дизайнер: моторный александрhttp://www.djournal.com.ua/?p=2483

3ddd

$1

Edge

...edge

3ddd

edge

кухня-моноблок, без плинтуса, подвешивается на стену.

3ddd

$1

кровать EDGE

...кровать edge

3ddd

edge

кровать и тумбочки от компании edge

полигоны: 181 253

3ddd

free

EDGE светильник

...edge светильник

3ddd

edge , подвес

производитель польша

материал метал

3ddd

$1

Artemide Edge

...artemide edge

3ddd

artemide

люстра artemide edge. сделана по фото.

design_connected

free

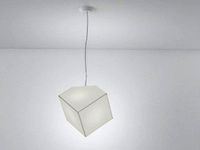

Edge pendant

...edge pendant

designconnected

free 3d model of edge pendant by fabbian designed by baldereschi, alessandra.

3ddd

$1

EDGE CHANDELIER

...lier фирмы holly hunt. официальный сайт:https://www.hollyhunt.com/showproduct.aspx?productid=3103&manufacturerid;=1

design_connected

$7

Edge 30

...edge 30

designconnected

artemide edge 30 computer generated 3d model. designed by mendini, alessandro.

3ddd

$1

Edge Seat

... банкетка

om website: beltafrajumar.com

designer: jacob pringiers

formats: 3ds, c4d, fbx, obj

3ddd

$1

бра Fabbian Edge

... edge

бра fabbian, модель edge, артикулы d77 d01 15 и edge d 77 d03 15. маленькое бра сделано более корректно