GrabCAD

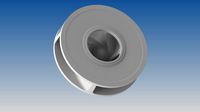

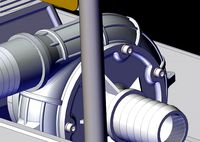

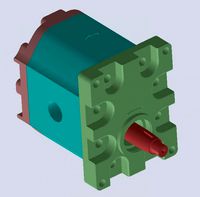

Double Closed Impeller Centrifugal Pump - AirBus Design

by GrabCAD

Last crawled date: 2 years ago

The key points I want to address with this pump are Low Cost, Simplicity, Reliability, Weight, Flow Rate, Size and a unique double closed impeller solution adding self-priming features as well as increased pressure throughput.

Pump should be orientated inlet port down, to saturate the bottom impeller chamber to enable self-priming.

Additionally, it was designed to be aesthetically pleasing with a spiral flow chamber (which is not entirely needed) but does provide some stylistic flare to a mundane competition. (may as well have some fun with it)

Professional renders were also made to satisfy the promotional and marketing intentions of the competition.

Technical Characteristics:

-No wearing parts

-Minimum 20,000hrs operation lifetime

-Steady and consistent flow

-Continuous working mode

-very quiet design, estimated 40DB(A)

-Targeted cost of <$30

-Operating Substance: Water (Glycol and Iso-Propanol Up To 50%+).

- Operating Temperature: 0 - 100 C

- Max. Pressure Difference: 4.2 Bar (Head: 40m) [with final geometry optimization likely >5Bar]

- Rated Flow Rate: 17 L/min (impeller design can be changed to target for 7-11L/min and increase max pressure @ 3000RPM]

- Blocked flow protection/Reversed polarity protection up to 6 Bar

- Nominal Voltage: 28VDC regulated to 24V for compatibility of motors

- Motor Max Power: 139W

- Inlet Port: 10mm

- Outlet Port: 6mm

- Weight: 0.8 - 1 kg.

- Overall Volume: <1L

- Priming Capability: Self Priming

- Mechanical Time Constant: 0.1 Sec.

Pump should be orientated inlet port down, to saturate the bottom impeller chamber to enable self-priming.

Additionally, it was designed to be aesthetically pleasing with a spiral flow chamber (which is not entirely needed) but does provide some stylistic flare to a mundane competition. (may as well have some fun with it)

Professional renders were also made to satisfy the promotional and marketing intentions of the competition.

Technical Characteristics:

-No wearing parts

-Minimum 20,000hrs operation lifetime

-Steady and consistent flow

-Continuous working mode

-very quiet design, estimated 40DB(A)

-Targeted cost of <$30

-Operating Substance: Water (Glycol and Iso-Propanol Up To 50%+).

- Operating Temperature: 0 - 100 C

- Max. Pressure Difference: 4.2 Bar (Head: 40m) [with final geometry optimization likely >5Bar]

- Rated Flow Rate: 17 L/min (impeller design can be changed to target for 7-11L/min and increase max pressure @ 3000RPM]

- Blocked flow protection/Reversed polarity protection up to 6 Bar

- Nominal Voltage: 28VDC regulated to 24V for compatibility of motors

- Motor Max Power: 139W

- Inlet Port: 10mm

- Outlet Port: 6mm

- Weight: 0.8 - 1 kg.

- Overall Volume: <1L

- Priming Capability: Self Priming

- Mechanical Time Constant: 0.1 Sec.

Similar models

grabcad

free

AIRBUS Water Pump

...10mm

- weight: 0.7 - 0.9 kg.

- overall volume: <1l

- priming capability: self priming

- mechanical time constant: 0.2 sec.

grabcad

free

Airbus External Gear Pump for Flying Product

...

- mechanical time constant: 0.1 sec.

----------------------------------------------

refer to included drawings for more details.

grabcad

free

Seko Duotek AF0030P

...d

air-operated double-diaphragm pump seko duotek af0030p.

flow rate: 35 l/min.

max delivery head: 80 m.

max air pressure: 8 bar.

grabcad

free

Closed Impeller Design In Solidworks

...the two shrouds. closed-impellers are installed on radial flow centrifugal pumps and can be either single inlet, or double inlet.

grabcad

free

PUMP IMPELLER

...e and flow of a fluid. it is the opposite of a turbine, which extracts energy from, and reduces the pressure of, a flowing fluid.

grabcad

free

Impeller for Centrifugal Pump

...impeller for centrifugal pump

grabcad

an impeller is a rotor used to increase the pressure and flow of a fluid.

grabcad

free

Centrifugal pump

...ws into the expanding casing. the pressure energy increases as the fluid moves from the suction side to the discharge side of the

grabcad

free

Centrifugal Pump Impeller Mk. II

...amount of pressurized particulate filled water from entering the shaft bearing area, in unison with the debris evacuation system.

grabcad

free

½" Wilden P1 Plastic Pump

...port sizes: ½" fnpt

wetted: polypropylene

diaphragms: teflon

flow rate to 56.8 lpm (15 gpm)

max pressure = 8.6 bar (125 psi)

grabcad

free

Enclosed Impeller

...the two shrouds. closed-impellers are installed on radial flow centrifugal pumps and can be either single inlet, or double inlet.

Impeller

turbosquid

$10

Impeller

...urbosquid

royalty free 3d model impeller for download as stl on turbosquid: 3d models for games, architecture, videos. (1311847)

3d_export

$5

impeller

...impeller

3dexport

3d_export

$5

impeller

...impeller

3dexport

3d_export

$15

Impeller 3D Model

...ller 3d model

3dexport

impeller pump centrifugal hydraulics system mechanical mechanics

impeller 3d model alex4721 39598 3dexport

turbosquid

$20

SLURRY PUMP IMPELLER

...oyalty free 3d model slurry pump impeller for download as ige on turbosquid: 3d models for games, architecture, videos. (1386992)

3d_export

$500

Centrifugal pump volute casing with impeller

...centrifugal pump volute casing with impeller

3dexport

volute casing with impeller and shroud plate

3d_export

$27

sc submersible slurry pump complete set of cad drawings 19

...processing drawing, pump body hydraulic drawing, motor end cover, impeller processing drawing, impeller hydraulic drawing, bearing body and other...

3d_export

$10

Fan Blade 3D Model

...3dexport fan blade mechanical household propeller plastic air wind impeller rotor runner airflow fans turbine fan blade 3d model...

3d_export

$19

Bladeless Fan oval 3D Model

...flextron ves bradex desk table interior office air multiplier impeller airfoil buffeting annular bladeless fan oval 3d model martimakflay...

3d_export

$19

Bladeless Fan circle 3D Model

...flextron ves bradex desk table interior office air multiplier impeller airfoil buffeting annular bladeless fan circle 3d model martimakflay...

Centrifugal

turbosquid

$209

Carpet centrifuge

...royalty free 3d model carpet centrifuge for download as sldas on turbosquid: 3d models for games, architecture, videos. (1445260)

turbosquid

$32

Centrifugal Pump

... free 3d model centrifugal pump for download as sldas and ige on turbosquid: 3d models for games, architecture, videos. (1643069)

3d_export

$12

Centrifugal Pump 3D Model

...centrifugal pump 3d model

3dexport

centrifugal pump

centrifugal pump 3d model fau 71172 3dexport

3d_export

$7

zy series centrifugal blower

...zy series centrifugal blower

3dexport

zy series centrifugal blower

3d_export

$20

Centrifugal pump 3D Model

... 3d model

3dexport

pump centrifugal turbomachinery turbo water machines industry

centrifugal pump 3d model qepasol 93421 3dexport

archive3d

free

Centrifuge 3D Model

...d

centrifuge spin dryer

dlc-213 n281107 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$8

Centrifuge Laboratory 3D Model

...oratory centrifuge

centrifuge laboratory 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl 3d1startup 105313 3dexport

3d_export

$7

centrifugal compressor

...ded, and also, step file and .stl files are also given so that anyone can operate this 3d model in any other designing softwares.

turbosquid

$120

Centrifugal Space Station

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$8

centrifugal fan 4-72-12 b4-72-12 no6 d c centrifugal fan

...centrifugal fan 4-72-12 b4-72-12 no6 d c centrifugal fan

3dexport

[centrifugal fan] 4-72-12, b4-72-12, no6 d, c centrifugal fan

Airbus

3d_ocean

$29

Airbus-330

...airbus-330

3docean

airbus airbus-330 aircraft

this is a model of airbus-330, wish you like.

3d_export

$30

Airbus A380

...airbus a380

3dexport

airbus a380

3d_export

$17

AIRBUS A320

...airbus a320

3dexport

airbus a320

3d_export

$17

Airbus A320

...airbus a320

3dexport

airbus a320

3d_export

$17

Airbus A350

...airbus a350

3dexport

airbus a350

3d_export

$10

airbus-a320

...airbus-a320

3dexport

airbus-a320

3d_ocean

$29

Airbus-380

...iner manufactured by airbus. it is the world’s largest passenger airliner, and the airports at which it operates have upgraded...

turbosquid

$99

airbus

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$16

Airbus

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$9

AirBus

...nsport

low poly airbus model, modeled on cinema 4d r14,rendered by phisical sky render. including postproduction preset psd file.

Pump

3d_export

$5

pump

...pump

3dexport

pump

archibase_planet

free

Pump

...pump

archibase planet

petrol pump petrol station gas station

pump - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_ocean

$8

Pumps

...ps

3docean

girls heels high kicks pumps shoes stilettos womens

womens high heels, pumps or stilettos. polygon model – no textures

3ddd

free

Pump

...ump

3ddd

pump , versus

производитель: versus

модель: pumphttp://www.versus.as/

turbosquid

$3

Pumps

...s

turbosquid

royalty free 3d model pumps for download as skp on turbosquid: 3d models for games, architecture, videos. (1275250)

3d_export

$5

pump

...pump

3dexport

turbosquid

$39

Realistic Water pump SYLLENT PUMP

...realistic water pump syllent pump for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1312864)

turbosquid

$150

Pumpe

...yalty free 3d model pumpe for download as ige, blend, and stl on turbosquid: 3d models for games, architecture, videos. (1284318)

3d_export

$10

gear pump

...gear pump

3dexport

it is a gear pump in iges format

turbosquid

$19

Old Water Pumps Gas Pumps

...pumps gas pumps for download as 3ds, obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1207997)

Double

3ddd

free

Double

...double

3ddd

double , sicis

диван double от итальянской фабрики sicis next art

3d_ocean

$5

double stairs

...double stairs

3docean

double stairs

double stairs

3d_export

$5

double handle

...double handle

3dexport

double handle

3d_export

$5

double fastener

...double fastener

3dexport

double fastener

3ddd

$1

double bed

...double bed

3ddd

двуспальная

double bed

design_connected

free

Chair Double

...chair double

designconnected

free 3d model of chair double

3ddd

$1

Double Leaves

...double leaves

3ddd

double leaves

кресло китайской фабрики double leaves. vray, 3dmax 2013, гамма 2.2, текстуры в комплекте.

3ddd

free

Люстра Double

...люстра double

3ddd

double , david chipperfield

2004

размеры в архиве

3d_export

free

couch - double

...couch - double

3dexport

couch double with texture and .psd files for personal customization

3d_export

$10

double layer double speed chain

...d chain

3dexport

double layer speed chain (design very detailed) 3d model drawing model file reference using solidworks software

Closed

turbosquid

$35

Closed

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Closed baskets

...osquid

royalty free 3d model closed baskets for download as on turbosquid: 3d models for games, architecture, videos. (1683282)

turbosquid

$2

closed to dust

...uid

royalty free 3d model closed to dust for download as stl on turbosquid: 3d models for games, architecture, videos. (1403703)

turbosquid

$29

hands close

...e 3d model hands close for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1442051)

turbosquid

$29

Closed Pinecone

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

CLOSED~1.3DS

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Briefcase Closed

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$20

bank vault close

...bank vault close

3dexport

bank vault close

3d_export

$8

road closed sign

...road closed sign

3dexport

road closed sign

3d_export

$5

closed hand wheel

...closed hand wheel

3dexport

closed hand wheel

Design

3ddd

$1

LINE DESIGN (Doors Design)

...line design (doors design)

3ddd

дверь

modern doors design - line design concept

turbosquid

$5

designer

...alty free 3d model designer for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1422665)

3ddd

$1

VER DESIGN

...ver design

3ddd

ver design

кресло ver design

3ddd

$1

VER DESIGN

...ver design

3ddd

ver design

диван ver design

3ddd

$1

Bagno design

...bagno design

3ddd

bagno design , унитаз

санитария bagno design

3ddd

free

VER DESIGN

...ver design

3ddd

ver design , стеллаж

полка ver design

3ddd

$1

VER DESIGN

...ver design , лежак , шезлонг

шезлонг ver design

3d_export

free

designer

..., trees and much more. the model has 3 types of parts: - 4 cells - 6 cells - 8 cells the *.max file contains 5 colored materials.

3d_export

$19

level design

...level design

3dexport

you can use this design (level design) in your own game.

3d_export

$7

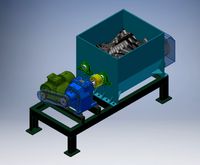

Crusher design

...crusher design

3dexport

crusher design