GrabCAD

Dimmable Explosion Proof, Waterproof Fluorescent Light -Paint Booth, Rigs - 2 Lamp - 4 foot

by GrabCAD

Last crawled date: 1 year, 10 months ago

https://www.larsonelectronics.com/product/70018/dimmable-explosion-proof-waterproof-fluorescent-light-paint-booth-rigs-2-lamp-4-foot

Made in the USA

The Larson Electronics EPL-48-2L-T5HO-D Dimmable Explosion Proof Fluorescent Light Fixture is NRTL Listed for United States and Canada, Class 1 Division 1 and Class 1 Division 2 for hazardous locations where flammable chemical/petrochemical vapors exist or have the potential to exist. The unit carries a T6 temperature rating, it is also approved for Paint Spray Booths.

Click here to see the LED version of this light

The EPL-48-2L-T5HO-D fixture is a 4 foot long, 2 lamp, Class 1 Division 1 and Class 2 Division 1&2 explosion proof dimmable fluorescent light which is also approved for use in paint spray booth applications. This T6 temperature rated fixture comes standard with two T5HO fluorescent lamps. The lamps are protected by heat and impact resistant Pyrex tubes and the fixture is constructed of copper free aluminum alloy. The lamp reflectors are corrosion resistant heavy gauge aluminum and coated with a high gloss reflective finish.This fixture is multi-voltage capable and is equipped with an Advance Mark 7 dimming ballast. The EPL-48-2L-T5HO-D provides operators in hazardous locations with a reliable and affordable lighting solution that provides the best explosion proof protection available without sacrificing light quality or fixture durability.

We offer a choice of bulbs with all of our explosion proof fluorescent fixtures. However, this fixture standardize on the T-5HO bulbs mostly for longevity and high output. Many of our customers, including Naval bases, shipyards, oil rigs and petrochemical processing plants operate in very cold conditions, and T12HO bulbs operate well in those environments. Larson Electronics offers a T12VHO lamp option, 110 watt Very High Output lamps make this fixture an ideal replacement for 400 watt metal halide surface mount fixtures in hazardous location areas requiring Class 1 Division 1 rated lights. *However, the 110 watt T12VHO lamp configuration is not appropriate for paint spray booth applications. Please click here for the EPL-48-2L-T12VHO model.

Energy Consumption Comparison

T5HO T8 LED

Wattage 108 watts 64 watts 48 watts

Amp Draw @ 120V AC 0.9 amps 0.54 amps 0.4 amps

Amp Draw @ 277V AC 0.39 amps 0.24 amps 0.18 amps

Amp Draw @ 12V DC 9 amps 5.34 amps 4 amps

Amp Draw @ 24V DC 4.5 amps 2.67 amps 2 amps

Lamp Life Expectancy 20,000 hours 24,000 hours 50,000 hours

Color Temperature 5000K / 4100K 4100K 5300K

Operation cost per year

(8hs/day @ 11c/kWh) $34.69 $20.56 $15.42

Mounting Options: Unless otherwise specified, our standard, most popular configuration is the bracket end mounting shown enlarged below. We also offer a pendant mount for those needing to suspend the fixture away from the ceiling surface (i.e. suspend from pipe or conduit). Additional mounting configurations can be customized to meet the requirements on the application. Please contact us for special mounting configurations.

Adjustable Surface Mount Brackets: Each bracket is cinched to the bracket mounting peg on each side of the light. The angle of the bracket is set by tightening two cap screws on either side of the bracket. The cap screws act as a set screw. The bracket itself is mounted via a single bolt hole at the top the bracket. There are two brackets, one on each end of the light. Once the brackets are mounted to a surface (ceiling, floor or wall), the light fixture can be removed from the brackets by loosening the cap screws that hold the bracket to the mounting peg.

Suspension Mounting: Pendant mount fixtures hang from the ceiling and are suspended by rigid pipe. Each fixture features a 1/2” NPT junction box on one end, and a 1/2” NPT adjustable L-bracket on the other end of the fixture. Operators bring rigid pipe down to the threaded mounting hubs. Wiring is fed down through the rigid pipe to the junction box and tied in to the fixture’s lead wires, completing the electrical connection. The adjustable L-shape mounting bracket provides support for the opposite end of the fixture.

Made in USA Quality

1. Each unit dialectically tested.

2. Fixture arrives assembled and lamped to reduce installation time and cost. Adjustable mounting brackets enable the operator to choose any mounting angle for the fixture, where other models may only offer one or three choices.

3. Fixture constructed of extruded corrosion resistant copper free aluminum alloy.

4. Over-sized, finned ballast housing for 800 mA fixtures provides more heat dissipation and extends ballast life. Larger ballast box accommodates High Output lamp ballasts. Ballast housing easily accessible and externally mounted. Top and bottom covers secured with nuts and bolts, instead of threaded through holes, which can be damaged with dirt.

5. Heavy gauge extruded aluminum reflectors with high gloss reflective finish. Resists dents and corrosion.

6. A wrench is used to unscrew the end caps for relamping the fixture, while other models require the “tap and knock off” method to loosen the end cap.

7. Explosion proof, impact and heat resistant Pyrex tubes provide lamp protection.

Lamp Options

F54-T5/850/HO – 54 watt, 5000 lumens per bulb, 20,000 hours life, 5000 Kelvin color, CRI 85 RHA-UNV-254-LT5 Ballast is THD<10% and HPF .98 (Suffix –50KT5)

F54-T5/841/HO - 54 watt, 4450 lumens per bulb, 20,000 hour life, 4100 Kelvin color, CRI 85 (Suffix -41KT5)

Made in the USA

The Larson Electronics EPL-48-2L-T5HO-D Dimmable Explosion Proof Fluorescent Light Fixture is NRTL Listed for United States and Canada, Class 1 Division 1 and Class 1 Division 2 for hazardous locations where flammable chemical/petrochemical vapors exist or have the potential to exist. The unit carries a T6 temperature rating, it is also approved for Paint Spray Booths.

Click here to see the LED version of this light

The EPL-48-2L-T5HO-D fixture is a 4 foot long, 2 lamp, Class 1 Division 1 and Class 2 Division 1&2 explosion proof dimmable fluorescent light which is also approved for use in paint spray booth applications. This T6 temperature rated fixture comes standard with two T5HO fluorescent lamps. The lamps are protected by heat and impact resistant Pyrex tubes and the fixture is constructed of copper free aluminum alloy. The lamp reflectors are corrosion resistant heavy gauge aluminum and coated with a high gloss reflective finish.This fixture is multi-voltage capable and is equipped with an Advance Mark 7 dimming ballast. The EPL-48-2L-T5HO-D provides operators in hazardous locations with a reliable and affordable lighting solution that provides the best explosion proof protection available without sacrificing light quality or fixture durability.

We offer a choice of bulbs with all of our explosion proof fluorescent fixtures. However, this fixture standardize on the T-5HO bulbs mostly for longevity and high output. Many of our customers, including Naval bases, shipyards, oil rigs and petrochemical processing plants operate in very cold conditions, and T12HO bulbs operate well in those environments. Larson Electronics offers a T12VHO lamp option, 110 watt Very High Output lamps make this fixture an ideal replacement for 400 watt metal halide surface mount fixtures in hazardous location areas requiring Class 1 Division 1 rated lights. *However, the 110 watt T12VHO lamp configuration is not appropriate for paint spray booth applications. Please click here for the EPL-48-2L-T12VHO model.

Energy Consumption Comparison

T5HO T8 LED

Wattage 108 watts 64 watts 48 watts

Amp Draw @ 120V AC 0.9 amps 0.54 amps 0.4 amps

Amp Draw @ 277V AC 0.39 amps 0.24 amps 0.18 amps

Amp Draw @ 12V DC 9 amps 5.34 amps 4 amps

Amp Draw @ 24V DC 4.5 amps 2.67 amps 2 amps

Lamp Life Expectancy 20,000 hours 24,000 hours 50,000 hours

Color Temperature 5000K / 4100K 4100K 5300K

Operation cost per year

(8hs/day @ 11c/kWh) $34.69 $20.56 $15.42

Mounting Options: Unless otherwise specified, our standard, most popular configuration is the bracket end mounting shown enlarged below. We also offer a pendant mount for those needing to suspend the fixture away from the ceiling surface (i.e. suspend from pipe or conduit). Additional mounting configurations can be customized to meet the requirements on the application. Please contact us for special mounting configurations.

Adjustable Surface Mount Brackets: Each bracket is cinched to the bracket mounting peg on each side of the light. The angle of the bracket is set by tightening two cap screws on either side of the bracket. The cap screws act as a set screw. The bracket itself is mounted via a single bolt hole at the top the bracket. There are two brackets, one on each end of the light. Once the brackets are mounted to a surface (ceiling, floor or wall), the light fixture can be removed from the brackets by loosening the cap screws that hold the bracket to the mounting peg.

Suspension Mounting: Pendant mount fixtures hang from the ceiling and are suspended by rigid pipe. Each fixture features a 1/2” NPT junction box on one end, and a 1/2” NPT adjustable L-bracket on the other end of the fixture. Operators bring rigid pipe down to the threaded mounting hubs. Wiring is fed down through the rigid pipe to the junction box and tied in to the fixture’s lead wires, completing the electrical connection. The adjustable L-shape mounting bracket provides support for the opposite end of the fixture.

Made in USA Quality

1. Each unit dialectically tested.

2. Fixture arrives assembled and lamped to reduce installation time and cost. Adjustable mounting brackets enable the operator to choose any mounting angle for the fixture, where other models may only offer one or three choices.

3. Fixture constructed of extruded corrosion resistant copper free aluminum alloy.

4. Over-sized, finned ballast housing for 800 mA fixtures provides more heat dissipation and extends ballast life. Larger ballast box accommodates High Output lamp ballasts. Ballast housing easily accessible and externally mounted. Top and bottom covers secured with nuts and bolts, instead of threaded through holes, which can be damaged with dirt.

5. Heavy gauge extruded aluminum reflectors with high gloss reflective finish. Resists dents and corrosion.

6. A wrench is used to unscrew the end caps for relamping the fixture, while other models require the “tap and knock off” method to loosen the end cap.

7. Explosion proof, impact and heat resistant Pyrex tubes provide lamp protection.

Lamp Options

F54-T5/850/HO – 54 watt, 5000 lumens per bulb, 20,000 hours life, 5000 Kelvin color, CRI 85 RHA-UNV-254-LT5 Ballast is THD<10% and HPF .98 (Suffix –50KT5)

F54-T5/841/HO - 54 watt, 4450 lumens per bulb, 20,000 hour life, 4100 Kelvin color, CRI 85 (Suffix -41KT5)

Similar models

grabcad

free

Explosion Proof Fluorescent Lights for Paint Booths, Oil Rigs, Boats -2 foot - 2 lamp -Multi-voltage

... shows the access caps for changing the bulbs. the second picture shows the bracket at the opposite end of the fluorescent light.

grabcad

free

Surface Mount Explosion Proof, Waterproof Fluorescent Lights - T12 Very High Output - Oil Rigs - 2 L

... paint spray booths. for other lamp optoins please see our epl-48-2l fixture that is approved for paint spray booth applications.

grabcad

free

Replacement Mounting Bracket for the Two Lamp EPL-48 and EPL-24 series Explosion Proof Lights

...ght fixtures.

each light fixture requires two (2) surface mount brackets, or (1) pendant mount bracket. choose mount type below.

grabcad

free

Explosion Proof, Waterproof Fluorescent Lights - 2 Lamp - 4 Foot - Pendant and Surface Mount

...ns) - 60 watt, 4050 lumens per bulbs - this bulb, ballast and wiring configuration is designed for applications to 165 degrees c.

grabcad

free

Dimmable T8 Explosion Proof, Waterproof Fluorescent Light -Paint Booth, Rigs - 2 Lamp - 4 foot

... provide lamp protection.

lamp options

f32-t8/841 - 32 watt, 2,900 lumens per bulb, 24,000 hour life, 4100 kelvin color, cri 85

grabcad

free

Surface Mount Explosion Proof, Waterproof Fluorescent Lights - T12 Hotbox Configuration

...s to 165 degrees f.

for other lamp optoins please see our epl-48-2l fixture that is approved for paint spray booth applications.

grabcad

free

EPL-48-1L Surface Mount Explosion Proof, Waterproof Fluorescent Lights -Paint Booth, Rigs - 1 Lamp

...h operators requiring a brighter color light than a traditional "cool white", this bulb can be useful. (suffix –t12dho)

grabcad

free

Explosion Proof Light - Waterproof Fluorescent Light Fixture - Paint Spray Booth, Rigs - 4 foot, 2 l

...ns) - 60 watt, 4050 lumens per bulbs - this bulb, ballast and wiring configuration is designed for applications to 165 degrees c.

grabcad

free

Explosion Proof Emergency Fluorescent light Combination - 4 foot - 2 T5HO lamps - Class I, Div I

...ubes provide lamp protection.

lamps

f54-t5/850/ho – 54 watt, 5000 lumens per bulb, 20,000 hours life, 5000 kelvin color, cri 85

grabcad

free

45 Degree Surface Mount Explosion Proof Emergency Fluorescent light Combination - 4 foot - 2 T5HO

...bes provide lamp protection.

lamps

f54-t5/850/ho – 354 watt, 5000 lumens per bulb, 20,000 hours life, 5000 kelvin color, cri 85

Dimmable

turbosquid

$22

Dimmable Modern Minimalist Cheap Round

...minimalist cheap round for download as max, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1554250)

turbosquid

$10

Hasled dimmable LED lamp with colour changing base

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Kreon / Carde

...kreon / carde 3ddd kreon kr963763 | cadre 1200 dimmable ...

3ddd

$1

Modular Medard

...brand modular type surface mounted lamp socket gu10 (ø50) dimmable no orientable yes voltage 230v...

3ddd

$1

Prandina / la belle

...diffuser. opal white roto-moulded lowe diffuser. electronic or digital dimmable ...

3ddd

free

подвесной светильник Talo

...лакированный материал плафона: поликарбонат плафоны: серый лампы: g5 non dimmable х 2 max 54/80w высота: min 100 см -...

3ddd

free

Светильники HEXA (Bosma)

...светильники hexa (bosma) 3ddd bosma , dimmable неха 01 (bosma) / hexa 04 (bosma) серия функциональных...

3ddd

$1

On Line by Eden Design

...ceiling. on one and the same track, two separate dimmable circuits are available. an innovative and state-of-the-art magnet and...

3ddd

free

Hay WH Rope Trick

...a downward reading light and a diffused uplighter, both dimmable dimensions: w 18 x d 33 x h 180...

3d_export

$5

ceiling light

...be adjusted independently to create a unique composition.<br>details<br>features: triac dimmable led illumination compatible with lutron diva and maestro.<br>dimensions: l69...

Fluorescent

3d_ocean

$6

Energy Bulb Fluorescent

...energy bulb fluorescent

3docean

bulb eco ecological energy bulb fluorescent lamp light lighting

energy bulb fluorescent.

turbosquid

free

Fluorescent lamp

...bosquid

free 3d model fluorescent lamp for download as blend on turbosquid: 3d models for games, architecture, videos. (1313789)

3d_export

$5

Fluorescent 3D Model

...fluorescent 3d model

3dexport

florasan light lamb fluorescent bulb white high poly

fluorescent 3d model husky 49990 3dexport

turbosquid

$14

Fluorescence Microscope

...l fluorescence microscope for download as blend, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1610738)

turbosquid

$2

Fluorescent light

... 3d model fluorescent light for download as max, max, and fbx on turbosquid: 3d models for games, architecture, videos. (1531043)

turbosquid

$39

Fluorescent Bulb

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Bulb fluorescent

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Bulb fluorescent

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$6

fluorescent bulb

...seful light much more efficiently than incandescent lamps or bulbs.<br>modeled in solidworks.<br>rendered in keyshot.

3d_export

$5

Fluorescent light bulb

...fluorescent light bulb

3dexport

realistic 3d model of fluorescent light bulb with v-ray materials.

Waterproof

turbosquid

$4

Solar LED Light Waterproof

... model solar led light waterproof for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1458407)

turbosquid

$3

WATERPROOF WALL PLUG NO GROUNDED

...proof wall plug no grounded for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1369549)

3d_ocean

$15

GoPro HERO4 Black + waterproof case

... 3d max. you get 3d model with 16 v-ray textured materials and ready to use scene. also you get 4 high resolution 1920...

turbosquid

$13

6 Inch Shearling Boot Waterproof Boots

...rling boot waterproof boots for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1713226)

3d_export

$10

Waterproof Fabric Sofa

...xture format: .png .jpg<br>resolution: 1024*1024<br>pbr in substance painter<br>formats: .obj .gltf .fbx .blend

3d_export

$10

Waterproof leather sofa

...xture format: .png .jpg<br>resolution: 1024*1024<br>pbr in substance painter<br>formats: .obj .gltf .fbx .blend

3d_export

$10

Marble bathroom waterproof adsorption watch

...~ 100,000 model parts: 1 texture format: .png .jpg resolution: 1024*1024 pbr in substance painter formats: .obj .gltf .fbx .blend

3d_export

$10

Retro bathroom waterproof watch

...painter available for all software<br>ue4. ue5. blender. maya. 3d max. unity. c4d.<br>formats: .obj .gltf .fbx .blend

3d_export

$10

Retro bathroom waterproof watch

...painter available for all software<br>ue4. ue5. blender. maya. 3d max. unity. c4d.<br>formats: .obj .gltf .fbx .blend

3d_export

$10

Macaron bathroom waterproof watch

...painter available for all software<br>ue4. ue5. blender. maya. 3d max. unity. c4d.<br>formats: .obj .gltf .fbx .blend

Proof

turbosquid

$6

bullet proof jacket

...el bullet proof jacket for download as 3ds, obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1193147)

turbosquid

$1

Sound Proofing Foam

... sound proofing foam for download as ige, obj, stl, and sldpr on turbosquid: 3d models for games, architecture, videos. (1289027)

turbosquid

$149

Bullet Proof Vest with molle attachments

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$40

chevrolet nova ss 70 death proof

...chevrolet nova ss 70 death proof

3dexport

3d_export

$9

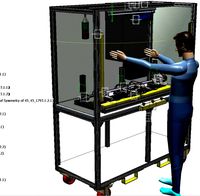

of automobile component error proofing system

...cific product defects; the other is to check the products one by one through cheap means to determine whether they are qualified.

3d_export

$16

yb2 high voltage explosion proof series three phase asynchronous motor 9 specifications in total

...cifications in total

3dexport

yb2 high voltage explosion proof series three phase asynchronous motor (9 specifications in total)

turbosquid

$2

Replacement RC Car Shock Proof Plank SJ11 Accessory Spare Parts 15-SJ11 for GPTOYS S911 S912 And Others

...1 for gptoys s911 s912 and others for download as obj and stl on turbosquid: 3d models for games, architecture, videos. (1193732)

3d_ocean

$1

Insulation Felt Seamless Pattern Background

...background 3docean background carpet ceilings closeup cloth cover dust proof fabric felt fiber fleece gray insulation insulation felt material...

3d_export

$20

Passport Collection 3D Model

...3dexport passport us usa united states travel document citizenship proof booklet realistic textures russia uk great britain france collection...

3d_ocean

$6

Duck

...3docean 3d printing animals bird car chrome creative death proof duck duck emblem metal model sculpture soot souvenirs trinkets...

Explosion

3d_export

$6

explosion

...explosion

3dexport

3 d of explosion

3d_export

$10

explosion

...explosion

3dexport

3d model of explosion for 3d printing

turbosquid

$5

Explosion

...rbosquid

royalty free 3d model explosion for download as max on turbosquid: 3d models for games, architecture, videos. (1202603)

3d_export

$10

Explosion

...explosion

3dexport

turbosquid

$14

Explosion

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Explosive

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$3

Explosive Barrel

...explosive barrel 3docean barrel decoration explosion explosive industrial low low poly metal object old poly...

3ddd

free

KOLARZ Serie Explosion

... serie explosion , австрия

kolarz serie explosion 0109.118.5.kot. врай. текстуры.

3d_export

$5

atomic bomb explosion

...atomic bomb explosion

3dexport

atomic bomb explosion

turbosquid

$1

explosives pack

...squid

royalty free 3d model explosives pack for download as on turbosquid: 3d models for games, architecture, videos. (1316376)

Booth

3d_export

$10

Booth Devassa

...booth devassa

3dexport

booth 10x10

3d_export

$10

Booth VENEZA

...booth veneza

3dexport

booth 12x10

3d_export

$10

Booth MSD

...booth msd

3dexport

booth 8.00x6.00

3d_export

$10

Booth Oncoclincas

...booth oncoclincas

3dexport

booth 14.00x11.00

3d_export

$10

Booth SOLINFTEC

...booth solinftec

3dexport

booth 11.00x5.00

3d_export

$7

Booth Janssen

...booth janssen

3dexport

booth 6.00x6.00

3d_export

$7

Booth Astellas

...booth astellas

3dexport

booth 6.00x6.00

3d_export

$7

Booth Galvani

...booth galvani

3dexport

booth 4.00x4.50

3d_export

$5

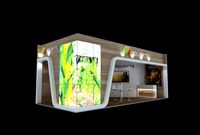

exhibition booth

...exhibition booth

3dexport

exhibition booth

3d_export

$5

Booth Camil

...booth camil

3dexport

booth 6x3

Foot

3ddd

$1

Foot cream

...foot cream

3ddd

foot cream , крем

foot cream

archibase_planet

free

Foot

...foot

archibase planet

footboard step pedestal

foot - 3d model (*.gsm+*.3ds) for interior 3d visualization.

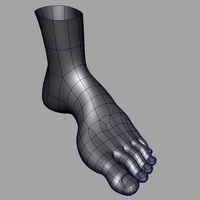

3d_ocean

$2

Foot

... human foot you can use it on your own character or for further details. it has multiple file formats fbx, obj and mb (maya 2009)

turbosquid

$19

Foot

...squid

royalty free 3d model foot for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1320812)

3d_export

$5

screw foot

...screw foot

3dexport

screw foot

3d_export

$5

long foot

...long foot

3dexport

long foot

3d_export

$5

screw foot

...screw foot

3dexport

screw foot

3d_export

$5

short foot

...short foot

3dexport

short foot

3d_export

free

foot fetish

...foot fetish

3dexport

foot fetish

3d_export

$10

foot massager

...foot massager

3dexport

foot massager blender3d

Rigs

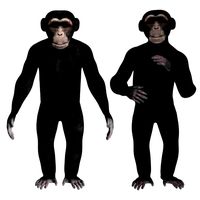

3d_export

$25

rigged chimpanzee

...rigged chimpanzee

3dexport

rigged chimpanzee

3d_export

$25

rigged wolf

...rigged wolf

3dexport

rigged wolf

3d_export

$25

rigged cicada

...rigged cicada

3dexport

rigged cicada

3d_export

$20

triceratops rigged

...triceratops rigged

3dexport

triceratops rigged

3d_export

$20

rigged horse

...rigged horse

3dexport

rigged horse

3d_export

$15

rigged cheetah

...rigged cheetah

3dexport

rigged cheetah

3d_ocean

$16

Rigged Mannequinn

...es .this rig contains two textures.however it is not uv mapped. the parts and the rig controls are named with proper naming co...

3d_ocean

$35

Rigged Bicycle

...rigged bicycle

3docean

bicycle cycle rigged bicycle slim tire

rigged bicycle ready for animation..

turbosquid

$40

knight-rigged RIGGED

...ree 3d model knight-skeleton for download as ma, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1576606)

turbosquid

$2

rig

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Paint

archibase_planet

free

Paints

...paints

archibase planet

paints paint

paints n241211 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Paint

...paint

archibase planet

jar of paint paint can

paint - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

paint

...paint

3ddd

paint

archibase_planet

free

Paint

...paint

archibase planet

paint

paint - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Painting

...painting

3ddd

картина

painting in double wooden frame decorated antique

3ddd

$1

The collection of paintings

...

картина , фото

collection of modern and contemporary paintings.

contemporary paintings.

turbosquid

$1

Painting

...ee 3d model painting for download as 3ds, obj, md3, and blend on turbosquid: 3d models for games, architecture, videos. (1207611)

turbosquid

free

Painting

... 3d model painting for download as ma, 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1219609)

3ddd

$1

PAINTINGS

...paintings

3ddd

панно

размеры:

1170х900

3ddd

$1

Paintings Frame

...paintings frame

3ddd

картины

paintings frame

Lamp

archibase_planet

free

Lamp

...lamp

archibase planet

lamp reading lamp table lamp

lamp - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Lamp

...lamp

archibase planet

lamp reading lamp table lamp

lamp - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Lamp

...lamp

archibase planet

lamp table lamp reading lamp

lamp - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Lamp

...lamp

archibase planet

lamp table lamp reading lamp

lamp - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Lamp

...lamp

archibase planet

lamp reading lamp table lamp

lamp - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Lamp

...lamp

archibase planet

lamp reading lamp table lamp

lamp - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Lamp

...lamp

archibase planet

lamp table lamp reading lamp

lamp - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Lamp

...lamp

archibase planet

lamp table lamp reading lamp

lamp - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Lamp

...lamp

archibase planet

lamp reading lamp table lamp lantern

lamp - 3d model (*.3ds) for interior 3d visualization.

3d_ocean

$6

Lamp

...lamp

3docean

lamp

a high quality lamp.

Light

archibase_planet

free

Light

...light

archibase planet

lamp lighting light

light - s2 - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

light luminaire lighting

light l0465 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

lighting

...lighting

3dexport

lighting

3d_export

$5

lighting

...lighting

3dexport

lighting in livingroom

turbosquid

$3

Lighting Tree with Lights

...d model lighting tree with lights for download as max and 3ds on turbosquid: 3d models for games, architecture, videos. (1585507)

archibase_planet

free

Light

...light

archibase planet

luster lighting solution

light - s - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

luster lamp lighting

light 1 - 3d model for interior 3d visualization.

archibase_planet

free

Lights

...lights

archibase planet

surgical lights surgical lamp

surgical lights (floor) - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

lighting luminaire candlelight

light l0463 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$18

street light-lighting-light-xia bing

...

3dexport

street light-lighting-light-xia bing<br>max 2015 v-ray 3 max 2015<br>textures<br>all files in zip...

4

turbosquid

$9

Office Chair 4-4

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

doors- 4

...doors- 4

3dexport

doors 4

3d_export

$5

hinge 4

...hinge 4

3dexport

hinge 4

3ddd

$1

Штора №4

...штора №4

3ddd

штора №4

3d_export

free

playstation 4

...playstation 4

3dexport

playstation 4

3ddd

$1

nexus 4

...nexus 4

3ddd

lg , телефон

nexus 4

3ddd

$1

4 Poufs

...4 poufs

3ddd

пуф

4 soft poufs

turbosquid

$12

Calligraphic Digit 4 Number 4

...hic digit 4 number 4 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1389332)

3ddd

$1

Dauphin 4+

...dauphin 4+

3ddd

кресло

dauphin 4+ конференц кресло

3ddd

$1

iPhone 4

...

3ddd

apple , iphone , телефон

модель iphone 4.

2

design_connected

$11

No 2

...no 2

designconnected

sibast no 2 computer generated 3d model. designed by sibast, helge.

turbosquid

$99

Smilodon 2 Pose 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Barrel Barricade 2-2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$6

Wall Trophy (2) (2)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Tire label 2 of 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Кровать, 2 тумбочки, 2 светильника

...кровать, 2 тумбочки, 2 светильника

3ddd

кровать, 2 тумбочки, 2 светильника

нормальное качество

формат 3ds max

без текстур

3ddd

free

Кровать, 2 тумбочки, 2 светильника

...кровать, 2 тумбочки, 2 светильника

3ddd

кровать, 2 тумбочки, 2 светильника

нормальное качество

формат 3ds max

без текстур

turbosquid

$19

Loft wooden square box chandelier (2) (2) (2)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

ALPEREN-2

...alperen-2

3ddd

комод , alperen-2

комод с зеркалом alperen-2

design_connected

$27

Confluences 2 2-Seater Sofa

... 2-seater sofa

designconnected

ligne roset confluences 2 2-seater sofa computer generated 3d model. designed by nigro, philippe.