GrabCAD

DFLEX = "DISPOSITIVO FLEXÍVEL" PARA ACIONAMENTO DE CARGAS DIVERSAS.

by GrabCAD

Last crawled date: 1 year, 10 months ago

PRODUTO IDEALIZADO E REGISTRADO: DFLEX = "DISPOSITIVO FLEXÍVEL" PARA ACIONAMENTO DE CARGAS DIVERSAS.

DEFINIÇÃO: DFLEX - CONJUNTO DE ACOPLAMENTOS (ACOPLAGEM MOTORA, ACOPLAGEM MOVIDA) PARA GANHO

DE POTÊNCIA EM EQUIPAMENTOS MECÂNICOS, ELETROMECÂNICOS, ELÉTRICOS, ELETRÔNICOS E TAMBÉM

MICRO-ELETRÔNICOS, DE USO GERAL, PARA GANHO E/OU MULTIPLICAÇÃO DE POTÊNCIA, BASEADO NO

PRINCÍPIO DA ALAVANCA E TAMBÉM NO PRINCÍPIO DE PASCAL.

PRINCÍPIO DA ALAVANCA:

QUANDO SE APLICA UMA DETERMINADA FORÇA, CUIDADOSAMENTE DIRECIONADA PARA UMA OU MAIS DIREÇÔES

E/OU EM UMA OU MAIS EXTREMIDADES DE UMA OU MAIS PEÇAS PROJETADAS QUALQUER, (RODAS, EIXOS,

FERRAMENTAS, ETC...), E QUE ORA SE DENOMINA DE CIRCUITO DE ENTRADA (ACOPLAGEM MOTORA), E TAMBÉM

QUANTO MAIOR FOR O DIÂMETRO OU RÁIO DA CIRCUNFERÉNCIA QUE SERÁ USADO NO DETERMINADO PROJETO,

E QUE ORA SE DENOMINA DE CIRCUITO DE SAÍDA (ACOPLAGEM MOVIDA), MENOR SERÁ O ESFORÇO PARA GIRAR

(ROTACIONAR) O CENTRO DE TRABALHO DESTE CIRCUITO DE SAÍDA E A POTÊNCIA RESULTANTE ENTÃO SERÁ

MAIOR, GANHANDO-SE ASSIM POTÊNCIA EXTRA POR MENOR ESFORÇO APLICADO NA SAÍDA DO CONJUNTO DE

ACOPLAMENTOS DFLEX (ACOPLAGEM MOTORA E ACOPLAGEM MOVIDA).

O SISTEMA IDEALIZADO DO CONJUNTO DE ACOPLAMENTO DFLEX FAZ USO DE PEÇAS (GAIOLAS) COM DESIGNS

ESPECIAIS QUE ACOPLAM E SERVEM DE GUIAS DE MOVIMENTO PARA AS DEMAIS PEÇAS DO MESMO CONJUNTO,

CITO: GRUPO COM CARRO DE MOVIMENTAÇÃO PARA ROLAMENTOS DE TAMANHOS DIVERSOS MAIS ROLETES E/OU

PISTÕES MECÂNICOS E/OU PISTÕES HIDRÁULICOS.

PRINCÍPIO DE PASCAL:

SE APLICARÁ QUANDO DETERMINADO PROJETO IRÁ USAR PISTÕES HIDRÁULICOS.

(ACOPLAGEM MOTORA, ACOPLAGEM MOVIDA - PRINCIPIO DE PASCAL >> PISTÕES HIDRÁULICOS).

DESCRIMINAÇÃO:

O CONJUNTO DFLEX DE USO BÁSICO FOI IDEALIZADO PARA ACOPLAMENTO DIRETO, DISCRIMINADO ENTRE A ACOPLAGEM

MOTORA E A ACOPLAGEM MOVIDA, QUE POR SUA VEZ ACIONARÃO UM SISTEMA OU MAIS SISTEMAS DE CARGAS DIVERSAS,

DIRETAMENTE NA SAÍDA E/OU ENTRADA DE EIXO(S) DESTE(S) SISTEMA(S) QUE POSSA(M) ESTAR SENDO INTERLIGADO(S).

PODE SER USADO EM TODO TIPO DE SAÍDAS E ENTRADAS DE POTÊNCIA PARA ALIMENTAR CARGAS DIVERSAS:

PARA USO EM TODO TIPO DE DISPOSITIVOS, COMO EM EIXOS DE MÁQUINAS, MOTORES E VEÍCULOS DE TODOS OS TIPOS,

INCLUINDO TRENS, AVIÕES, NAVIOS E MÁQUINAS ESPECÍFICAS, DE TODOS OS TAMANHOS E DE FUNÇÕES VARIADAS.

VANTAGENS:

SISTEMA(S) COMPACTO(S), COM ALTO GANHO DE POTÊNCIA, COM CUSTO DE IMPLEMENTAÇÃO MUITO BAIXO (POUCA MASSA),

PRINCIPALMENTE QUANDO SE FOR UTILIZAR PISTÕES HIDRÁULICOS, RESULTANDO EM GRANDE ECONOMIA DE CAPITAL

NA AQUISIÇÃO E INSTALAÇÃO DE MOTORES, EQUIPAMENTOS E MAQUINÁRIOS DIVERSOS.

MAQUINARIA E MOTORES DE CUSTO MUITO MAIS BAIXO PODERÃO SER USADOS COM VANTAGENS E COM GANHOS

EXTRAORDINÁRIOS DE POTÊNCIA EM TODO TIPO DE APLICAÇÕES, PARA MOVIMENTAÇÃO PRIMÁRIA, SECUNDÁRIA

OU MESMO TERCIÁRIA, DE CARGAS E SISTEMAS DIVERSOS, APÓS A INSTALAÇÃO DO(S) CONJUNTO(S) DE

ACOPLAMENTOS DFLEX, EM SISTEMAS ESPECÍFICOS.

ATÉ A PRESENTE DATA, NÃO EXISTE NADA IGUAL, PODE-SE TER GANHOS EXTRAORDINÁRIOS DE POTÊNCIA, FAZENDO USO

DE UM OU MAIS CONJUNTOS DE ACOPLAMENTOS DFLEX, QUE PODEM SER LIGADOS EM CASCATA, CRIANDO GRUPOS DE CONJUNTOS

DFLEX (ACOPLAGENS MOTORA E MOVIDA), ALAVANCANDO AINDA MAIS A POTÊNCIA FINAL, COM A OPÇÃO DE SE UTILIZAR

ROLETES E/OU PISTÔES MECÂNICOS E/OU PISTÕES HIDRÁULICOS, CONFORME O PROJETO DESEJADO.

HAVERÁ VANTAGENS TAMBÉM NO MENOR TAMANHO DOS SISTEMAS PROJETADOS, COMPARATIVAMENTE AOS MAQUINÁRIOS COMPLEXOS

QUE EXISTEM ATUALMENTE, ONDE O TAMANHO DO PROJETO FINAL AS VEZES DEIXA A DESEJAR.

O TEMPO DE DESENVOLVIMENTO DE PROJETO(S) TAMBÉM PODERÁ SER REDUZIDO DRÁSTICAMENTE, O QUE É MUITO IMPORTANTE.

ROLETES, PISTÕES MECÂNICOS E PISTÕES HIDRÁULICOS:

PISTÕES HIDRÁULICOS ESPECIAIS FORAM DESENVOLVIDOS PARA USO COM OS ACOPLAMENTOS DFLEX, PODENDO-SE USAR

SENSORES DE PRESSÃO PIEZOELÉTRICOS, OPCIONALMENTE, (MELHORA A VELOCIDADE DE RESPOSTA DOS MESMOS)

OS ROLAMENTOS DO TIPO MINIATURA DEVERÃO SER PREFERENCIALMENTE USADOS, POIS SÃO PEQUENOS E EFICIÊNTES

E FACILITAM A IMPLEMENTAÇÃO DE PROJETOS MAIS COMPACTOS.

PISTÕES MECÂNICOS TAMBÉM COM ROLAMENTOS, PODEM SER UMA OUTRA OPÇÃO, PARA MÉDIAS POTÊNCIAS.

ROLETES QUE NÃO USAM ROLAMENTOS PODEM SER USADOS PARA APLICAÇÕES DE MENOR POTÊNCIA E SISTEMAS MENORES.

ROLETES, PISTÕES HIDRÁULICOS E MECÂNICOS SÃO OS COMPONENTES QUE FAZEM A INTERLIGAÇÃO ENTRE A ACOPLAGEM

MOTORA E A ACOPLAGEM MOVIDA.

EXEMPLO:

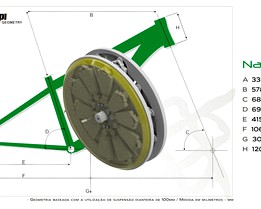

UM EXEMPLO PRÁTICO DE APLICAÇÃO IMEDIATA DESTE SISTEMA SERÁ A IMPLEMENTAÇÃO DO MESMO JUNTO A PROJETOS DE

BICICLETAS, ONDE SE PODE FIXAR O CONJUNTO DE ACOPLAMENTO DFLEX NO LUGAR DA CORÔA MOTRIZ, QUE GANHARÁ TORQUE

E VELOCIDADE EXTRA, RESULTANDO EM PEDALADAS MUITO MAIS FORTES E EXIGINDO MUITO MENOS ESFORÇOS POR PARTE DO

CICLISTA. SERÁ FÁCIL SUBIR MONTANHAS Á TODA VELOCIDADE, COM MUITO POUCO ESFORÇO E MUITA DIVERSÃO!

ESQUEMAS:

O CONJUNTO DE ACOPLAMENTO DFLEX TEM ESQUEMAS PARA DOIS, TRÊS E ATÉ MAIS DE QUATRO MODOS DE ACOPLAGEM MOTORA

E MOVIDA, PODENDO SER PARA PEQUENA, MEDIA OU PARA GRANDES CARGAS.

A ACOPLAGEM MOVIDA PODERÁ SER TAMBÉM CONFIGURADA CONFORME NECESSIDADE ESPECÍFICA, TAMBÉM COM ESQUEMA DE DOIS,

TRÊS OU MAIS MODOS DE ACOPLAMENTOS, COM USO DE ROLETES PARA PEQUENAS CARGAS, COM OU SEM ROLAMENTOS,

(TIPO MINIATURA, PREFERENCIALMENTE), E QUE TAMBÉM PODEM SER USADOS JUNTO A PISTÕES MECÂNICOS E/OU PISTÕES

HIDRÁULICOS, PARA CARGAS MÉDIAS E GRANDES.

COMBINANDO-SE DISTINTAS QUANTIDADES DE ROLETES E/OU PISTÕES E CONFORME O ESQUEMA DE ACOPLAGEM ESCOLHIDO, PODE-SE

DEFINIR SE DETERMINADA APLICAÇÃO SERÁ PARA BAIXA, MÉDIA OU ALTA ROTAÇÃO E/OU TORQUE, NUMA RAZÃO PREVISÍVEL EM FUNÇÃO

DO FATOR DE DESLIZAMENTO DOS ROLAMENTOS APLICADOS AO CONJUNTO DE ACOPLAMENTO DFLEX E TAMBÉM NA QUANTIDADE DE ROLETES

E PISTÕES QUE SERÃO UTILIZADOS NESTE(S) CONJUNTO(S) DE ACOPLAMENTO QUE ESTA(ÃO) SENDO PROJETADO(S) PARA UMA DETERMINADA

FINALIDADE.

USO DE MATERIAIS PARA FABRICAÇÃO DO CONJUNTO DE ACOPLAMENTO DFLEX:

ACOPLAGEM MOTORA:

PODE-SE USAR PLÁSTICOS E TAMBÉM METAIS COMO O ALUMÍNIO, BRONZE E LATÃO, ENTRE OUTROS, DEPENDERÁ DA APLICAÇÃO DESEJADA.

USANDO-SE PISTÕES HIDRÁULICOS NÃO HAVERÁ NECESSIDADE DE MATERIAIS DE CUSTO ELEVADO, PLÁSTICOS INDUSTRIAIS OU MESMO

ALUMÍNIOS DIVERSOS PODEM SERVIR, VISTO QUE TODA A POTÊNCIA DESEJADA SERÁ EXTRAÍDA DIRETAMENTE DA ACOPLAGEM MOVIDA.

ACOPLAGEM MOVIDA:

NESTE CASO, CONFORME A POTÊNCIA REQUERIDA, DEVE-SE USAR MATERIAIS MAIS RESISTENTES PARA MELHOR EFICIÊNCIA E COM UMA

MAIOR RESISTÊNCA Á FADIGA DOS ROLAMENTOS QUE SERÃO USADOS, VISTO QUE A MARGEM DO FATOR DE DESLIZAMENTO DOS ROLAMENTOS

NESTA APLICAÇÃO (POTÊNCIA DE SAÍDA) É UM POUCO EXTREITA.

MATERIAIS COMO OS AÇOS ESPECIAIS DEVEM SER OS ESCOLHIDOS TANTO PARA A GAIOLA DA ACOPLAGEM MOVIDA EM SI, COMO TAMBÉM

PARA OS ROLAMENTOS QUE SERÃO USADOS.

MATERIAIS COMO O TITÂNIO, TUNGSTÊNIO, MOLIBIDENO, OU MESMO LIGAS ESPECIAIS ESPECÍFICAS TAMBÉM PODERÃO SER UMA BOA

OPÇÃO, PRINCIPALMENTE PARA PEÇAS MAIORES QUE IRÃO EXIGIR GRANDES ESFORÇOS.

CUSTOS MAIS BAIXOS DE PROJETO(S):

PARA QUE SE CONSIGA CUSTOS MAIS BAIXOS DO(S) PROJETO(S), VÁRIOS CONJUNTOS DE ACLOPLAMENTOS DFLEX, CONECTADOS EM CASCATA

E FIXADOS JUNTO A MOTORES MENORES E DE POTÊNCIA MAIS BAIXA, PODERÁ SER UMA ÓTIMA ALTERNATIVA PARA APLICAÇÕES DE BAIXO

CUSTO E DE TAMANHO MENOR.

PARA PROJETOS DE APLICAÇÃO SIMPLES E DE TAMANHO MUITO PEQUENO E QUE SERÃO USADOS EM SISTEMAS ELETRÔNICOS E

MICRO-ELETRONICOS, ROLETES E/OU PISTÕES MECÂNICOS QUE ACIONARÃO ENGRENAGENS E EIXOS PEQUENOS, MESMO FEITOS DE PLÁSTICO

(PETG,ABS,PLA, ETC...) SERÃO UMA ÓTIMA OPÇÃO.

CUIDADOS ESPECIAIS:

CUIDADOS ESPECIAIS DEVEM SER TOMADOS EM RELAÇÃO AO DIÂMETRO DO EIXO DOS ROLAMENTOS QUE SERÃO USADOS PARA O GIRO

DENTRO DA ACOPLAGEM MOVIDA, POIS DURANTE O USO SERÃO MUITO SOLICITADOS, INDESCRIMINADAMENTE.

OS FATORES DE RESISTÊNCIA, DE AQUECIMENTO, LUBRIFICAÇÃO E VEDAÇÃO DOS MESMOS DEVEM SER LEVADOS EM CONSIDERAÇÃO NA

ESCOLHA DESTES ROLAMENTOS.

A BORDA EXTERNA DAS GAIOLAS DE ACOPLAMENTO, PRINCIPALMENTE DA ACOPLAGEM MOVIDA, DEVEM SER LARGAS O SUFICIENTE E BEM

RESISTENTES, POIS É O LOCAL AONDE ACONTECERÁ AS MAIORES PRESSÕES DE FUNCIONAMENTO DO CONJUNTO COMO UM TODO.

IDEALIZADOR:

SAULO RODRIGUES DE QUEVEDO

EMAIL: INOVASTAR@HOTMAIL.COM

LINKEDIN:

HTTPS://WWW.LINKEDIN.COM/IN/SAULO-QUEVEDO/

GRABCAD:

HTTPS://GRABCAD.COM/SAULO.RODRIGUES.DE.QUEVEDO-1/MODELS

FACEBOOK:

HTTPS://WWW.FACEBOOK.COM/SAULO.QUEVEDO.INVENTOR

INNOVATING TECHNOLOGICAL PROJECTS AND SOLUTIONS.

COMPANY:

https://1drv.ms/u/s!Ag0XjIMwxxU1hq12fG4YefTLvOB-xQ?e=mFYMOX

ESPANHOL:

PRODUCTO IDEALIZADO: DFLEX = "DISPOSITIVO FLEXIBLE" PARA CONDUCIR CARGAS VARIAS.

DEFINICIÓN: DFLEX - JUEGO DE ACOPLAMIENTO (ACOPLAMIENTO DE MOTOR, ACOPLAMIENTO MOVIDO) PARA GANANCIA

DE POTENCIA EN EQUIPOS MECÁNICOS, ELECTROMECÁNICOS, ELÉCTRICOS, ELECTRÓNICOS Y TAMBIÉN

MICRO-ELECTRÓNICA, DE USO GENERAL, PARA GANAR Y / O MULTIPLICAR LA ENERGÍA, BASADA EN

EL PRINCIPIO DE PALANCA Y TAMBIÉN EL PRINCIPIO PASCAL.

PRINCIPIO DE APOYO:

CUANDO SE APLICA CIERTA FUERZA, DIRIGIDA CUIDADOSAMENTE A UNA O MÁS DIRECCIONES

Y / O EN UNO O MÁS EXTREMO DE UNA O MÁS PIEZAS PROYECTADAS CUALQUIERA (RUEDAS, EJES,

HERRAMIENTAS, ETC ...), Y QUE SE NOMBRA EN CIRCUITO DE ENTRADA (ACOPLAMIENTO DE MOTOR), Y TAMBIÉN

Cuanto mayor sea el diámetro o radio de la circunferencia que se utilizará en el proyecto determinado,

Y QUE SE LLAMA CIRCUITO DE SALIDA (ACOPLAMIENTO MOVIDO), MENOS EL ESFUERZO PARA GIRAR

(ROTAR) EL CENTRO DE TRABAJO DE ESTE CIRCUITO DE SALIDA Y EL PODER RESULTANTE ENTONCES SERÁ

MAYOR, POR LO TANTO GANANDO PODER EXTRA POR MENOS ESFUERZO APLICADO EN LA SALIDA DEL CONJUNTO DE

ACOPLAMIENTOS DFLEX (ACOPLAMIENTO DE MOTOR Y ACOPLAMIENTO MOVIDO).

EL SISTEMA IDEALIZADO DEL CONJUNTO DE ACOPLAMIENTO DFLEX HACE USO DE PIEZAS (JAULAS) CON DISEÑOS

ESPECIALES QUE CUMPLEN Y SERVEN GUÍAS DE MOVIMIENTO PARA LAS OTRAS PARTES DEL MISMO CONJUNTO,

CITO: GRUPO CON CARRO DE MOVIMIENTO PARA RODAMIENTOS DE DIFERENTES TAMAÑOS MÁS RODILLOS Y / O

PISTONES MECÁNICOS Y / O PISTONES HIDRÁULICOS.

PRINCIPIO DE PASCAL:

APLICARÁ CUANDO UN PROYECTO UTILIZARÁ PISTONES HIDRÁULICOS.

(ACOPLAMIENTO DE MOTOR, ACOPLAMIENTO MOVIDO - PRINCIPIO PASCAL >> PISTONES HIDRÁULICOS).

DESCRIMINACIÓN

EL CONJUNTO DFLEX PARA USO BÁSICO FUE IDEALIZADO PARA ACOPLAMIENTO DIRECTO, DISCRIMINADO ENTRE ACOPLAMIENTO

ACOPLAMIENTO MOTOR Y MOVIDO, QUE A SU VEZ ACTIVARÁ UN SISTEMA O MÁS SISTEMAS DE CARGAS VARIAS,

DIRECTAMENTE EN LA SALIDA Y / O ENTRADA DEL EJE (S) DE ESTE (S) SISTEMA (S) QUE PUEDE (M) ESTAR CONECTADO (S).

SE PUEDE UTILIZAR EN TODO TIPO DE SALIDAS Y ENTRADAS DE ALIMENTACIÓN PARA ALIMENTAR CARGAS VARIAS:

PARA USO EN TODO TIPO DE DISPOSITIVOS, COMO EN EJES DE MÁQUINAS, MOTORES Y VEHÍCULOS DE TODO TIPO,

INCLUYENDO TRENES, AVIONES, BUQUES Y MÁQUINAS ESPECÍFICAS, DE TODOS LOS TAMAÑOS Y VARIAS FUNCIONES.

BENEFICIOS

SISTEMA (S) COMPACTO, CON ALTA GANANCIA DE POTENCIA, CON UN COSTE DE APLICACIÓN MUY BAJO (LITTLE MASS),

PRINCIPALMENTE CUANDO SE DEBEN USAR LOS PISTONES HIDRÁULICOS, RESULTANDO EN UNA ECONOMÍA DE GRAN CAPITAL

ADQUISICIÓN E INSTALACIÓN DE MOTORES, EQUIPOS Y MÁQUINAS VARIAS.

MÁQUINAS Y MOTORES DE BAJO COSTO PUEDEN SER UTILIZADOS CON VENTAJAS Y GANANCIAS

PODER EXTRAORDINARIO EN TODO TIPO DE APLICACIONES, PARA MOVIMIENTO PRIMARIO, SECUNDARIO

O EL MISMO TERCIARIO, DE CARGAS Y SISTEMAS VARIOS, DESPUÉS DE LA INSTALACIÓN DEL (S) CONJUNTO (S) DE

ACOPLAMIENTOS DFLEX, EN SISTEMAS ESPECÍFICOS.

HASTA ESTA FECHA, NO HAY NADA IGUAL, PUEDE TENER GANANCIAS EXTRAORDINARIAS DE PODER, HACIENDO USO

DE UNO O MÁS CONJUNTOS DE ACOPLAMIENTOS DFLEX, QUE SE PUEDEN CONECTAR EN CASCADA, CREANDO GRUPOS DE CONJUNTOS

DFLEX (MOTOR Y ACOPLAMIENTOS MOVIDOS), APROVECHANDO AÚN MÁS LA POTENCIA FINAL, CON LA OPCIÓN DE USAR

RODILLOS MECÁNICOS Y / O PISTONES Y / O PISTONES HIDRÁULICOS, SEGÚN EL DISEÑO DESEADO.

HABRÁ VENTAJAS TAMBIÉN EN EL TAMAÑO MÁS PEQUEÑO DE LOS SISTEMAS DISEÑADOS, COMPARATIVO CON LAS MÁQUINAS COMPLEJAS

QUE ACTUALMENTE EXISTEN, DONDE DEJAN A VECES EL TAMAÑO DEL PROYECTO FINAL.

EL PROYECTO (S) TIEMPO DE DESARROLLO TAMBIÉN PUEDE SER PROYECTO DE BORRADOR, QUE ES MUY IMPORTANTE.

RODILLOS, PISTONES MECÁNICOS Y PISTONES HIDRÁULICOS:

PISTONES HIDRÁULICOS ESPECIALES HAN SIDO DESARROLLADOS PARA SU USO CON ACOPLAMIENTOS DFLEX, Y PUEDEN SER USADOS

SENSORES DE PRESIÓN PIEZOELÉCTRICOS, OPCIONALMENTE (MEJORAN LA VELOCIDAD DE RESPUESTA DE LOS MISMOS)

LOS RODAMIENTOS DE TIPO MINIATURA DEBEN SER USADOS PREFERENTEMENTE, PORQUE SON PEQUEÑOS Y EFICIENTES

Y FACILITAR LA IMPLEMENTACIÓN DE PROYECTOS MÁS COMPACTOS.

PISTONES MECÁNICOS TAMBIÉN CON RODAMIENTOS, PUEDEN SER OTRA OPCIÓN, PARA PODERES MEDIOS.

LOS RODILLOS QUE NO UTILIZAN RODAMIENTOS SE PUEDEN UTILIZAR PARA APLICACIONES DE BAJA POTENCIA Y MENOS SISTEMAS.

RODILLOS, PISTONES HIDRÁULICOS Y MECÁNICOS SON LOS COMPONENTES QUE HACEN LA INTERCONEXIÓN ENTRE EL ACOPLAMIENTO

ACOPLAMIENTO MOTOR Y MOVIDO.

EJEMPLO:

UN EJEMPLO PRÁCTICO DE APLICACIÓN INMEDIATA DE ESTE SISTEMA SERÁ LA APLICACIÓN DE LOS MISMOS PROYECTOS DE

BICICLETAS, DONDE SE PUEDE FIJAR EL CONJUNTO DE ACOPLAMIENTO DFLEX EN EL LUGAR DE LA MOTOCICLETA, QUE GANARÁ EL PAR

Y VELOCIDAD ADICIONAL, RESULTANDO EN PEDALES MUCHO MÁS FUERTES Y REQUERIENDO MUCHO MENOS ESFUERZOS DEL

CICLISTA. ¡SERÁ FÁCIL MONTAR LAS MONTAÑAS A TODA VELOCIDAD, CON MUY POCO ESFUERZO Y MUCHA DIVERSIÓN!

Esquemas

EL JUEGO DE ACOPLAMIENTO DFLEX TIENE ESQUEMAS PARA DOS, TRES Y AÚN MÁS DE CUATRO MODOS DE ACOPLAMIENTO DE MOTOR

Y MOVIDO, PUEDE SER PARA CARGAS PEQUEÑAS, MEDIAS O GRANDES.

EL ACOPLAMIENTO MOVIDO TAMBIÉN PUEDE CONFIGURARSE DE ACUERDO CON NECESIDADES ESPECÍFICAS, TAMBIÉN CON DOS ESQUEMAS,

TRES O MÁS MODOS DE ACOPLAMIENTO, CON EL USO DE PEQUEÑAS CARGADORAS DE CARGA, CON O SIN RODAMIENTOS,

(TIPO MINIATURA, PREFERENCIALMENTE), Y QUE TAMBIÉN PUEDE UTILIZARSE CON PISTONES Y / O PISTONES MECÁNICOS

HIDRÁULICO, PARA CARGAS MEDIANAS Y GRANDES.

COMBINANDO DIFERENTES CANTIDADES DE RODILLOS Y / O PISTONES Y SEGÚN EL ESQUEMA DE ACOPLAMIENTO DE ELECCIÓN,

DEFINE SI CIERTA APLICACIÓN SERÁ BAJA, MEDIA O ALTA ROTACIÓN Y / O PAR, POR UNA RAZÓN PREVISTA EN FUNCIÓN

DEL FACTOR DESLIZANTE DE RODAMIENTOS APLICADOS A LA ASAMBLEA DE ACOPLAMIENTO DFLEX Y TAMBIÉN EN LA CANTIDAD DE RODILLOS

Y PISTONES QUE SE UTILIZARÁN EN ESTE (S) CONJUNTO (S) DE ACOPLAMIENTO DISEÑADO PARA UN PARTICULAR

OBJETIVO.

USO DE MATERIALES PARA FABRICAR EL CONJUNTO DE ACOPLAMIENTO DFLEX:

ACOPLAMIENTO DE MOTOR:

PLÁSTICOS Y METALES COMO EL ALUMINIO, SE PUEDEN USAR LATÓN Y LATÓN, ENTRE OTROS, DEPENDRÁN DE LA APLICACIÓN DESEADA.

UTILIZANDO PISTONES HIDRÁULICOS NO HABRÁ NECESIDAD DE MATERIALES DE ALTO COSTO, PLÁSTICOS INDUSTRIALES O MISMOS

ALUMINIOS VARIOS PUEDEN SERVIR, DESDE QUE TODA LA POTENCIA DESEADA SE EXTRACTARÁ DIRECTAMENTE DEL ACOPLAMIENTO MOVIDO.

ACOPLAMIENTO MOVIDO:

EN ESTE CASO, DE ACUERDO CON LA POTENCIA REQUERIDA, DEBEN USARSE MATERIALES MÁS RESISTENTES PARA MAYOR EFICIENCIA Y CON UN

MAYOR RESISTENCIA A LA FATIGA DE LOS RODAMIENTOS QUE SE UTILIZARÁN, DESDE LA GAMA DEL FACTOR DESLIZANTE DEL RODAMIENTO

ESTA APLICACIÓN (POTENCIA DE SALIDA) ES UN POCO EXTREMO.

MATERIALES COMO ACEROS ESPECIALES DEBEN SER ELEGIDOS COMO MUCHO PARA LA JAULA DE ACOPLAMIENTO MUDADA EN USTED MISMO

PARA USO DE RODAMIENTOS.

MATERIALES COMO TITANIO, TUNGSTENO, MOLIBIDENO O INCLUSO ALEACIONES ESPECIALES ESPECIALES TAMBIÉN PUEDEN SER BUENAS

OPCIÓN, PRINCIPALMENTE PARA PIEZAS MÁS GRANDES QUE REQUERIRÁN GRANDES ESFUERZOS.

COSTO MÁS BAJO DEL PROYECTO (S):

PARA ALCANZAR LOS BAJOS COSTOS DEL PROYECTO (S), VARIOS CONJUNTOS DE CONEXIONES DFLEX, CONECTADOS EN CASCADA

Y FIJO CON MOTORES MÁS BAJOS Y MÁS BAJOS, PUEDE SER UNA GRAN ALTERNATIVA PARA APLICACIONES BAJAS

COSTE Y MENOS TAMAÑO.

PARA PROYECTOS DE APLICACIÓN SENCILLOS Y MUY PEQUEÑOS PARA SER UTILIZADOS EN SISTEMAS ELECTRÓNICOS Y

MICRO-ELECTRÓNICA, RODILLOS Y / O PISTONES MECÁNICOS QUE ACCIONARÁN PEQUEÑOS ENGRANAJES Y EJES, INCLUSO HECHOS DE PLÁSTICO

(PETG, ABS, PLA, ETC ...) SERÁ UNA GRAN OPCIÓN.

CUIDADOS ESPECIALES:

CUIDADOS ESPECIALES DEBEN TOMARSE EN RELACIÓN CON EL DIÁMETRO DEL EJE DE LOS RODAMIENTOS QUE SE UTILIZARÁN PARA EL GIRO

DENTRO DEL ACOPLAMIENTO MOVIDO, DURANTE EL USO SERÁ MUY SOLICITADO, INDESCRIMINADAMENTE.

LA RESISTENCIA, CALEFACCIÓN, LUBRICACIÓN Y FACTORES DE SELLADO DE LOS MISMOS DEBEN TENERSE EN CUENTA EN EL

ELIGE DE ESTOS RODAMIENTOS.

EL BORDE EXTERNO DE LAS JAULAS DE ACOPLAMIENTO, PRINCIPALMENTE DE ACOPLAMIENTO MOVIDO, DEBE SER SUFICIENTEMENTE GRANDE Y BIEN

RESISTENTE, PORQUE ES EL LUGAR DONDE OCURRIRÁN LAS MAYORES PRESIONES DE FUNCIONAMIENTO DEL CONJUNTO.

IDEALIZADOR:

SAULO RODRIGUES DE QUEVEDO

CORREO ELECTRÓNICO: INOVASTAR@HOTMAIL.COM

LINKEDIN:

HTTPS://WWW.LINKEDIN.COM/IN/SAULO-QUEVEDO/

GRABCAD:

HTTPS://GRABCAD.COM/SAULO.RODRIGUES.DE.QUEVEDO-1/MODELS

FACEBOOK:

HTTPS://WWW.FACEBOOK.COM/SAULO.QUEVEDO.INVENTOR

INNOVANDO PROYECTOS TECNOLÓGICOS Y SOLUCIONES.

EMPRESA:

HTTPS://1DRV.MS/B/S!AG0XJIMWXXU1HOYTSHDVV2LPO2Y8SA

INOVASTAR PROJETOS E SOLUÇÕES TECNOLÓGICAS.

EMPRESA:

iNGLES:

IDEALIZED PRODUCT: DFLEX = "FLEXIBLE DEVICE" FOR DRIVING MISCELLANEOUS LOADS.

DEFINITION: DFLEX - COUPLING SET (MOTOR COUPLING, MOVED COUPLING) FOR GAIN

OF POWER IN MECHANICAL, ELECTROMECHANICAL, ELECTRICAL, ELECTRONIC AND ALSO EQUIPMENT

MICRO-ELECTRONICS, OF GENERAL USE, FOR GAINING AND / OR MULTIPLICATION OF POWER, BASED ON

THE LEVER PRINCIPLE AND ALSO THE PASCAL PRINCIPLE.

LEVERAGE PRINCIPLE:

WHEN A CERTAIN FORCE IS APPLIED, CAREFULLY DIRECTED TO ONE OR MORE DIRECTIONS

AND / OR ON ONE OR MORE END OF ONE OR MORE PROJECTED PARTS ANY, (WHEELS, AXLES,

TOOLS, ETC ...), AND WHICH IS NAMED INPUT CIRCUIT (MOTOR COUPLING), AND ALSO

THE GREATER THE DIAMETER OR RADIO OF THE CIRCUMFERENCE THAT WILL BE USED IN THE PARTICULAR PROJECT,

AND WHICH IS CALLED OUTPUT CIRCUIT (MOVED COUPLING), THE LESS THE EFFORT TO TURN

(ROTATE) THE WORK CENTER OF THIS OUTPUT CIRCUIT AND THE RESULTING POWER THEN WILL BE

GREATER, THEREFORE GAINING EXTRA POWER BY LESS EFFORT APPLIED AT THE OUTPUT OF THE SET OF

DFLEX COUPLINGS (MOTOR COUPLING AND MOVED COUPLING).

THE IDEALIZED SYSTEM OF THE DFLEX COUPLING ASSEMBLY MAKES USE OF PARTS (CAGES) WITH DESIGNS

SPECIALS THAT COUPLY AND SERVE MOVEMENT GUIDES FOR THE OTHER PARTS OF THE SAME SET,

CITO: GROUP WITH MOVEMENT CART FOR BEARINGS OF DIFFERENT SIZES PLUS ROLLERS AND / OR

MECHANICAL PISTONS AND / OR HYDRAULIC PISTONS.

PRINCIPLE OF PASCAL:

WILL APPLY WHEN A PROJECT WILL USE HYDRAULIC PISTONS.

(MOTOR COUPLING, MOVED COUPLING - PASCAL PRINCIPLE >> HYDRAULIC PISTONS).

DESCRIMINATION:

THE BASIC USE DFLEX SET HAS BEEN DESIGNED FOR DIRECT COUPLING, DISCRIMINATED BETWEEN COUPLING

MOTOR AND MOVED COUPLING, WHICH IN turn WILL ACTIVATE A SYSTEM OR MORE SYSTEMS OF MISCELLANEOUS LOADS,

DIRECTLY AT THE OUTPUT AND / OR INPUT OF AXLE (S) OF THIS (S) SYSTEM (S) THAT MAY (M) BE BEING CONNECTED (S).

CAN BE USED IN ALL TYPES OF POWER OUTPUTS AND INPUTS TO FEED MISCELLANEOUS LOADS:

FOR USE ON ALL TYPES OF DEVICES, AS ON AXLES OF MACHINES, ENGINES AND VEHICLES OF ALL TYPES,

INCLUDING TRAINS, PLANES, SHIPS AND SPECIFIC MACHINES, OF ALL SIZES AND VARIOUS FUNCTIONS.

BENEFITS:

COMPACT SYSTEM (S), WITH HIGH POWER GAIN, WITH VERY LOW IMPLEMENTATION COST (LITTLE MASS),

MAINLY WHEN HYDRAULIC PISTONS ARE TO BE USED, RESULTING IN LARGE CAPITAL ECONOMY

ACQUISITION AND INSTALLATION OF ENGINES, EQUIPMENT AND MISCELLANEOUS MACHINERY.

MUCH LOWER COST MACHINERY AND ENGINES CAN BE USED WITH ADVANTAGES AND GAINS

EXTRAORDINARY POWER IN ALL TYPES OF APPLICATIONS, FOR PRIMARY, SECONDARY MOVEMENT

OR SAME TERTIARY, OF MISCELLANEOUS LOADS AND SYSTEMS, AFTER THE INSTALLATION OF THE SET (S) OF

DFLEX COUPLINGS, IN SPECIFIC SYSTEMS.

UNTIL THIS DATE, THERE IS NOTHING EQUAL, YOU CAN HAVE EXTRAORDINARY GAINS OF POWER, MAKING USE

OF ONE OR MORE SETS OF DFLEX COUPLINGS, THAT CAN BE CONNECTED IN CASCADE, CREATING GROUPS OF SETS

DFLEX (MOTOR AND MOVED COUPLINGS), LEVERING EVEN MORE THE FINAL POWER, WITH THE OPTION TO USE

MECHANICAL ROLLERS AND / OR PISTONS AND / OR HYDRAULIC PISTONS, ACCORDING TO THE DESIRED DESIGN.

THERE WILL BE ADVANTAGES ALSO IN THE SMALLEST SIZE OF THE DESIGNED SYSTEMS, COMPARATIVE TO COMPLEX MACHINERIES

THAT CURRENTLY EXIST, WHERE THE SIZE OF THE FINAL PROJECT SOMETIMES LEAVE.

THE PROJECT (S) DEVELOPMENT TIME MAY ALSO BE DRAFTED DRAFT, WHICH IS VERY IMPORTANT.

ROLLERS, MECHANICAL PISTONS AND HYDRAULIC PISTONS:

SPECIAL HYDRAULIC PISTONS HAVE BEEN DEVELOPED FOR USE WITH DFLEX COUPLINGS, AND CAN BE USED

PIEZOELECTRIC PRESSURE SENSORS, OPTIONALLY, (IMPROVES THE RESPONSE SPEED OF THE SAME)

MINIATURE TYPE BEARINGS MUST BE PREFERENTIALLY USED, AS THEY ARE SMALL AND EFFICIENT

AND FACILITATE THE IMPLEMENTATION OF MORE COMPACT PROJECTS.

MECHANICAL PISTONS ALSO WITH BEARINGS, MAY BE ANOTHER OPTION, FOR MEDIUM POWERS.

ROLLERS THAT DO NOT USE BEARINGS CAN BE USED FOR LOWER POWER APPLICATIONS AND LESS SYSTEMS.

ROLLERS, HYDRAULIC AND MECHANICAL PISTONS ARE THE COMPONENTS THAT MAKE THE INTERCONNECTION BETWEEN THE COUPLING

MOTOR AND MOVED COUPLING.

EXAMPLE:

A PRACTICAL EXAMPLE OF IMMEDIATE APPLICATION OF THIS SYSTEM WILL BE THE IMPLEMENTATION OF THE SAME ALONG PROJECTS OF

BICYCLES, WHERE THE DFLEX COUPLING ASSEMBLY CAN BE FIXED IN THE PLACE OF THE MOTORCYCLE, THAT WILL WIN TORQUE

AND EXTRA SPEED, RESULTING IN MUCH STRONGER PEDALING AND REQUIRING MUCH LESS EFFORTS FROM THE

CYCLIST. IT WILL BE EASY TO MOUNTAIN MOUNTAINS AT ALL SPEED, WITH VERY LITTLE EFFORT AND LOTS OF FUN!

SCHEMES:

THE DFLEX COUPLING SET HAS SCHEMES FOR TWO, THREE AND EVEN MORE THAN FOUR MOTOR COUPLING MODES

AND MOVED, MAY BE FOR SMALL, MEDIUM OR LARGE LOADS.

MOVED COUPLING MAY ALSO BE CONFIGURED ACCORDING TO SPECIFIC NEEDS, ALSO WITH TWO SCHEME,

THREE OR MORE COUPLING MODES, WITH THE USE OF SMALL LOAD LOADERS, WITH OR WITHOUT BEARINGS,

(MINIATURE TYPE, PREFERENTIALLY), AND THAT CAN ALSO BE USED WITH MECHANICAL PISTONS AND / OR PISTONS

HYDRAULIC, FOR MEDIUM AND LARGE LOADS.

COMBINING DIFFERENT QUANTITIES OF ROLLERS AND / OR PISTONS AND ACCORDING TO THE CHOOSING COUPLING SCHEME,

DEFINE IF CERTAIN APPLICATION WILL BE LOW, MEDIUM OR HIGH ROTATION AND / OR TORQUE, FOR A FORECASTABLE REASON IN FUNCTION

OF THE SLIDING FACTOR OF BEARINGS APPLIED TO THE DFLEX COUPLING ASSEMBLY AND ALSO IN THE QUANTITY OF ROLLERS

AND PISTONS THAT WILL BE USED IN THIS COUPLING SET (S) THAT IS BEING DESIGNED FOR A PARTICULAR

GOAL.

USE OF MATERIALS FOR MANUFACTURING THE DFLEX COUPLING ASSEMBLY:

MOTOR COUPLING:

PLASTICS AND METALS LIKE ALUMINUM, BRASS AND BRASS CAN BE USED, AMONG OTHERS, WILL DEPEND ON THE DESIRED APPLICATION.

USING HYDRAULIC PISTONS THERE WILL BE NO NEED FOR HIGH COST MATERIALS, INDUSTRIAL PLASTICS OR SAME

MISCELLANEOUS ALUMINUMS CAN SERVE, SINCE ALL THE DESIRED POWER WILL BE EXTRACTED DIRECTLY FROM THE MOVED COUPLING.

MOVED COUPLING:

IN THIS CASE, ACCORDING TO THE REQUIRED POWER, MORE RESISTANT MATERIALS MUST BE USED FOR BETTER EFFICIENCY AND WITH A

GREATER RESISTANCE TO THE BEARINGS OF THE BEARINGS THAT WILL BE USED, SINCE THE MARGIN OF THE BEARING SLIDING FACTOR

THIS APPLICATION (OUTPUT POWER) IS A LITTLE EXTREME.

MATERIALS LIKE SPECIAL STEELS MUST BE CHOSEN AS MUCH FOR THE COUPLING CAGE MOVED IN YOURSELF, ALSO

FOR BEARINGS TO BE USED.

MATERIALS LIKE TITANIUM, TUNGSTEN, MOLYBIDENE, OR EVEN SPECIAL SPECIAL ALLOYS MAY ALSO BE GOOD

OPTION, MAINLY FOR LARGER PARTS THAT WILL REQUIRE GREAT EFFORTS.

LOWEST COST OF PROJECT (S):

IN ORDER TO ACHIEVE LOWER COSTS OF THE PROJECT (S), SEVERAL SETS OF DFLEX CONNECTIONS, CONNECTED IN CASCADE

AND FIXED WITH LOWER AND LOWER POWER ENGINES, MAY BE A GREAT ALTERNATIVE FOR LOW APPLICATIONS

COST AND LESS SIZE.

FOR SIMPLE AND VERY SMALL APPLICATION PROJECTS TO BE USED IN ELECTRONIC SYSTEMS AND

MICRO-ELECTRONICS, ROLLERS AND / OR MECHANICAL PISTONS THAT WILL DRIVE SMALL GEARS AND AXLES, EVEN MADE OF PLASTIC

(PETG, ABS, PLA, ETC ...) WILL BE A GREAT OPTION.

SPECIAL CARES:

SPECIAL CARES SHOULD BE TAKEN IN RELATION TO THE DIAMETER OF THE SHAFT OF THE BEARINGS THAT WILL BE USED FOR THE SPIN

WITHIN MOVED COUPLING, DURING USE WILL BE VERY REQUESTED, INDESCRIMINATELY.

THE RESISTANCE, HEATING, LUBRICATION AND SEALING FACTORS OF THE SAME MUST BE TAKEN INTO CONSIDERATION IN THE

CHOOSE FROM THESE BEARINGS.

THE EXTERNAL EDGE OF COUPLING CAGES, MAINLY OF MOVED COUPLING, MUST BE LARGE ENOUGH AND WELL

RESISTANT, BECAUSE IT IS THE PLACE WHERE THE GREATEST PRESSURES OF OPERATION OF THE SET AS A WHOLE WILL HAPPEN.

IDEALIZER:

SAULO RODRIGUES DE QUEVEDO

EMAIL: INOVASTAR@HOTMAIL.COM

LINKEDIN:

HTTPS://WWW.LINKEDIN.COM/IN/SAULO-QUEVEDO/

GRABCAD:

HTTPS://GRABCAD.COM/SAULO.RODRIGUES.DE.QUEVEDO-1/MODELS

FACEBOOK:

HTTPS://WWW.FACEBOOK.COM/SAULO.QUEVEDO.INVENTOR

INNOVATING TECHNOLOGICAL PROJECTS AND SOLUTIONS.

COMPANY:

https://1drv.ms/u/s!Ag0XjIMwxxU1hq12fG4YefTLvOB-xQ?e=mFYMOX

iNGLES:

IDEALIZED PRODUCT: DFLEX = "FLEXIBLE DEVICE" FOR DRIVING MISCELLANEOUS LOADS.

DEFINITION: DFLEX - COUPLING SET (MOTOR COUPLING, MOVED COUPLING) FOR GAIN

OF POWER IN MECHANICAL, ELECTROMECHANICAL, ELECTRICAL, ELECTRONIC AND ALSO EQUIPMENT

MICRO-ELECTRONICS, OF GENERAL USE, FOR GAINING AND / OR MULTIPLICATION OF POWER, BASED ON

THE LEVER PRINCIPLE AND ALSO THE PASCAL PRINCIPLE.

LEVERAGE PRINCIPLE:

WHEN A CERTAIN FORCE IS APPLIED, CAREFULLY DIRECTED TO ONE OR MORE DIRECTIONS

AND / OR ON ONE OR MORE END OF ONE OR MORE PROJECTED PARTS ANY, (WHEELS, AXLES,

TOOLS, ETC ...), AND WHICH IS NAMED INPUT CIRCUIT (MOTOR COUPLING), AND ALSO

THE GREATER THE DIAMETER OR RADIO OF THE CIRCUMFERENCE THAT WILL BE USED IN THE PARTICULAR PROJECT,

AND WHICH IS CALLED OUTPUT CIRCUIT (MOVED COUPLING), THE LESS THE EFFORT TO TURN

(ROTATE) THE WORK CENTER OF THIS OUTPUT CIRCUIT AND THE RESULTING POWER THEN WILL BE

GREATER, THEREFORE GAINING EXTRA POWER BY LESS EFFORT APPLIED AT THE OUTPUT OF THE SET OF

DFLEX COUPLINGS (MOTOR COUPLING AND MOVED COUPLING).

THE IDEALIZED SYSTEM OF THE DFLEX COUPLING ASSEMBLY MAKES USE OF PARTS (CAGES) WITH DESIGNS

SPECIALS THAT COUPLY AND SERVE MOVEMENT GUIDES FOR THE OTHER PARTS OF THE SAME SET,

CITO: GROUP WITH MOVEMENT CART FOR BEARINGS OF DIFFERENT SIZES PLUS ROLLERS AND / OR

MECHANICAL PISTONS AND / OR HYDRAULIC PISTONS.

PRINCIPLE OF PASCAL:

WILL APPLY WHEN A PROJECT WILL USE HYDRAULIC PISTONS.

(MOTOR COUPLING, MOVED COUPLING - PASCAL PRINCIPLE >> HYDRAULIC PISTONS).

DESCRIMINATION:

THE BASIC USE DFLEX SET HAS BEEN DESIGNED FOR DIRECT COUPLING, DISCRIMINATED BETWEEN COUPLING

MOTOR AND MOVED COUPLING, WHICH IN turn WILL ACTIVATE A SYSTEM OR MORE SYSTEMS OF MISCELLANEOUS LOADS,

DIRECTLY AT THE OUTPUT AND / OR INPUT OF AXLE (S) OF THIS (S) SYSTEM (S) THAT MAY (M) BE BEING CONNECTED (S).

CAN BE USED IN ALL TYPES OF POWER OUTPUTS AND INPUTS TO FEED MISCELLANEOUS LOADS:

FOR USE ON ALL TYPES OF DEVICES, AS ON AXLES OF MACHINES, ENGINES AND VEHICLES OF ALL TYPES,

INCLUDING TRAINS, PLANES, SHIPS AND SPECIFIC MACHINES, OF ALL SIZES AND VARIOUS FUNCTIONS.

BENEFITS:

COMPACT SYSTEM (S), WITH HIGH POWER GAIN, WITH VERY LOW IMPLEMENTATION COST (LITTLE MASS),

MAINLY WHEN HYDRAULIC PISTONS ARE TO BE USED, RESULTING IN LARGE CAPITAL ECONOMY

ACQUISITION AND INSTALLATION OF ENGINES, EQUIPMENT AND MISCELLANEOUS MACHINERY.

MUCH LOWER COST MACHINERY AND ENGINES CAN BE USED WITH ADVANTAGES AND GAINS

EXTRAORDINARY POWER IN ALL TYPES OF APPLICATIONS, FOR PRIMARY, SECONDARY MOVEMENT

OR SAME TERTIARY, OF MISCELLANEOUS LOADS AND SYSTEMS, AFTER THE INSTALLATION OF THE SET (S) OF

DFLEX COUPLINGS, IN SPECIFIC SYSTEMS.

UNTIL THIS DATE, THERE IS NOTHING EQUAL, YOU CAN HAVE EXTRAORDINARY GAINS OF POWER, MAKING USE

OF ONE OR MORE SETS OF DFLEX COUPLINGS, THAT CAN BE CONNECTED IN CASCADE, CREATING GROUPS OF SETS

DFLEX (MOTOR AND MOVED COUPLINGS), LEVERING EVEN MORE THE FINAL POWER, WITH THE OPTION TO USE

MECHANICAL ROLLERS AND / OR PISTONS AND / OR HYDRAULIC PISTONS, ACCORDING TO THE DESIRED DESIGN.

THERE WILL BE ADVANTAGES ALSO IN THE SMALLEST SIZE OF THE DESIGNED SYSTEMS, COMPARATIVE TO COMPLEX MACHINERIES

THAT CURRENTLY EXIST, WHERE THE SIZE OF THE FINAL PROJECT SOMETIMES LEAVE.

THE PROJECT (S) DEVELOPMENT TIME MAY ALSO BE DRAFTED DRAFT, WHICH IS VERY IMPORTANT.

ROLLERS, MECHANICAL PISTONS AND HYDRAULIC PISTONS:

SPECIAL HYDRAULIC PISTONS HAVE BEEN DEVELOPED FOR USE WITH DFLEX COUPLINGS, AND CAN BE USED

PIEZOELECTRIC PRESSURE SENSORS, OPTIONALLY, (IMPROVES THE RESPONSE SPEED OF THE SAME)

MINIATURE TYPE BEARINGS MUST BE PREFERENTIALLY USED, AS THEY ARE SMALL AND EFFICIENT

AND FACILITATE THE IMPLEMENTATION OF MORE COMPACT PROJECTS.

MECHANICAL PISTONS ALSO WITH BEARINGS, MAY BE ANOTHER OPTION, FOR MEDIUM POWERS.

ROLLERS THAT DO NOT USE BEARINGS CAN BE USED FOR LOWER POWER APPLICATIONS AND LESS SYSTEMS.

ROLLERS, HYDRAULIC AND MECHANICAL PISTONS ARE THE COMPONENTS THAT MAKE THE INTERCONNECTION BETWEEN THE COUPLING

MOTOR AND MOVED COUPLING.

EXAMPLE:

A PRACTICAL EXAMPLE OF IMMEDIATE APPLICATION OF THIS SYSTEM WILL BE THE IMPLEMENTATION OF THE SAME ALONG PROJECTS OF

BICYCLES, WHERE THE DFLEX COUPLING ASSEMBLY CAN BE FIXED IN THE PLACE OF THE MOTORCYCLE, THAT WILL WIN TORQUE

AND EXTRA SPEED, RESULTING IN MUCH STRONGER PEDALING AND REQUIRING MUCH LESS EFFORTS FROM THE

CYCLIST. IT WILL BE EASY TO MOUNTAIN MOUNTAINS AT ALL SPEED, WITH VERY LITTLE EFFORT AND LOTS OF FUN!

SCHEMES:

THE DFLEX COUPLING SET HAS SCHEMES FOR TWO, THREE AND EVEN MORE THAN FOUR MOTOR COUPLING MODES

AND MOVED, MAY BE FOR SMALL, MEDIUM OR LARGE LOADS.

MOVED COUPLING MAY ALSO BE CONFIGURED ACCORDING TO SPECIFIC NEEDS, ALSO WITH TWO SCHEME,

THREE OR MORE COUPLING MODES, WITH THE USE OF SMALL LOAD LOADERS, WITH OR WITHOUT BEARINGS,

(MINIATURE TYPE, PREFERENTIALLY), AND THAT CAN ALSO BE USED WITH MECHANICAL PISTONS AND / OR PISTONS

HYDRAULIC, FOR MEDIUM AND LARGE LOADS.

COMBINING DIFFERENT QUANTITIES OF ROLLERS AND / OR PISTONS AND ACCORDING TO THE CHOOSING COUPLING SCHEME,

DEFINE IF CERTAIN APPLICATION WILL BE LOW, MEDIUM OR HIGH ROTATION AND / OR TORQUE, FOR A FORECASTABLE REASON IN FUNCTION

OF THE SLIDING FACTOR OF BEARINGS APPLIED TO THE DFLEX COUPLING ASSEMBLY AND ALSO IN THE QUANTITY OF ROLLERS

AND PISTONS THAT WILL BE USED IN THIS COUPLING SET (S) THAT IS BEING DESIGNED FOR A PARTICULAR

GOAL.

USE OF MATERIALS FOR MANUFACTURING THE DFLEX COUPLING ASSEMBLY:

MOTOR COUPLING:

PLASTICS AND METALS LIKE ALUMINUM, BRASS AND BRASS CAN BE USED, AMONG OTHERS, WILL DEPEND ON THE DESIRED APPLICATION.

USING HYDRAULIC PISTONS THERE WILL BE NO NEED FOR HIGH COST MATERIALS, INDUSTRIAL PLASTICS OR SAME

MISCELLANEOUS ALUMINUMS CAN SERVE, SINCE ALL THE DESIRED POWER WILL BE EXTRACTED DIRECTLY FROM THE MOVED COUPLING.

MOVED COUPLING:

IN THIS CASE, ACCORDING TO THE REQUIRED POWER, MORE RESISTANT MATERIALS MUST BE USED FOR BETTER EFFICIENCY AND WITH A

GREATER RESISTANCE TO THE BEARINGS OF THE BEARINGS THAT WILL BE USED, SINCE THE MARGIN OF THE BEARING SLIDING FACTOR

THIS APPLICATION (OUTPUT POWER) IS A LITTLE EXTREME.

MATERIALS LIKE SPECIAL STEELS MUST BE CHOSEN AS MUCH FOR THE COUPLING CAGE MOVED IN YOURSELF, ALSO

FOR BEARINGS TO BE USED.

MATERIALS LIKE TITANIUM, TUNGSTEN, MOLYBIDENE, OR EVEN SPECIAL SPECIAL ALLOYS MAY ALSO BE GOOD

OPTION, MAINLY FOR LARGER PARTS THAT WILL REQUIRE GREAT EFFORTS.

LOWEST COST OF PROJECT (S):

IN ORDER TO ACHIEVE LOWER COSTS OF THE PROJECT (S), SEVERAL SETS OF DFLEX CONNECTIONS, CONNECTED IN CASCADE

AND FIXED WITH LOWER AND LOWER POWER ENGINES, MAY BE A GREAT ALTERNATIVE FOR LOW APPLICATIONS

COST AND LESS SIZE.

FOR SIMPLE AND VERY SMALL APPLICATION PROJECTS TO BE USED IN ELECTRONIC SYSTEMS AND

MICRO-ELECTRONICS, ROLLERS AND / OR MECHANICAL PISTONS THAT WILL DRIVE SMALL GEARS AND AXLES, EVEN MADE OF PLASTIC

(PETG, ABS, PLA, ETC ...) WILL BE A GREAT OPTION.

SPECIAL CARES:

SPECIAL CARES SHOULD BE TAKEN IN RELATION TO THE DIAMETER OF THE SHAFT OF THE BEARINGS THAT WILL BE USED FOR THE SPIN

WITHIN MOVED COUPLING, DURING USE WILL BE VERY REQUESTED, INDESCRIMINATELY.

THE RESISTANCE, HEATING, LUBRICATION AND SEALING FACTORS OF THE SAME MUST BE TAKEN INTO CONSIDERATION IN THE

CHOOSE FROM THESE BEARINGS.

THE EXTERNAL EDGE OF COUPLING CAGES, MAINLY OF MOVED COUPLING, MUST BE LARGE ENOUGH AND WELL

RESISTANT, BECAUSE IT IS THE PLACE WHERE THE GREATEST PRESSURES OF OPERATION OF THE SET AS A WHOLE WILL HAPPEN.

IDEALIZER:

SAULO RODRIGUES DE QUEVEDO

EMAIL: INOVASTAR@HOTMAIL.COM

LINKEDIN:

HTTPS://WWW.LINKEDIN.COM/IN/SAULO-QUEVEDO/

GRABCAD:

HTTPS://GRABCAD.COM/SAULO.RODRIGUES.DE.QUEVEDO-1/MODELS

FACEBOOK:

HTTPS://WWW.FACEBOOK.COM/SAULO.QUEVEDO.INVENTOR

INNOVATING TECHNOLOGICAL PROJECTS AND SOLUTIONS.

COMPANY:

https://1drv.ms/u/s!Ag0XjIMwxxU1hq12fG4YefTLvOB-xQ?e=mFYMOX

INGLISH:

IDEALIZED PRODUCT: DFLEX = "FLEXIBLE DEVICE" FOR DRIVING MISCELLANEOUS LOADS.

DEFINITION: DFLEX - COUPLING SET (MOTOR COUPLING, MOVED COUPLING) FOR GAIN

OF POWER IN MECHANICAL, ELECTROMECHANICAL, ELECTRICAL, ELECTRONIC AND ALSO EQUIPMENT

MICRO-ELECTRONICS, OF GENERAL USE, FOR GAINING AND / OR MULTIPLICATION OF POWER, BASED ON

THE LEVER PRINCIPLE AND ALSO THE PASCAL PRINCIPLE.

LEVERAGE PRINCIPLE:

WHEN A CERTAIN FORCE IS APPLIED, CAREFULLY DIRECTED TO ONE OR MORE DIRECTIONS

AND / OR ON ONE OR MORE END OF ONE OR MORE PROJECTED PARTS ANY, (WHEELS, AXLES,

TOOLS, ETC ...), AND WHICH IS NAMED INPUT CIRCUIT (MOTOR COUPLING), AND ALSO

THE GREATER THE DIAMETER OR RADIO OF THE CIRCUMFERENCE THAT WILL BE USED IN THE PARTICULAR PROJECT,

AND WHICH IS CALLED OUTPUT CIRCUIT (MOVED COUPLING), THE LESS THE EFFORT TO TURN

(ROTATE) THE WORK CENTER OF THIS OUTPUT CIRCUIT AND THE RESULTING POWER THEN WILL BE

GREATER, THEREFORE GAINING EXTRA POWER BY LESS EFFORT APPLIED AT THE OUTPUT OF THE SET OF

DFLEX COUPLINGS (MOTOR COUPLING AND MOVED COUPLING).

THE IDEALIZED SYSTEM OF THE DFLEX COUPLING ASSEMBLY MAKES USE OF PARTS (CAGES) WITH DESIGNS

SPECIALS THAT COUPLY AND SERVE MOVEMENT GUIDES FOR THE OTHER PARTS OF THE SAME SET,

CITO: GROUP WITH MOVEMENT CART FOR BEARINGS OF DIFFERENT SIZES PLUS ROLLERS AND / OR

MECHANICAL PISTONS AND / OR HYDRAULIC PISTONS.

PRINCIPLE OF PASCAL:

WILL APPLY WHEN A PROJECT WILL USE HYDRAULIC PISTONS.

(MOTOR COUPLING, MOVED COUPLING - PASCAL PRINCIPLE >> HYDRAULIC PISTONS).

DESCRIMINATION:

THE BASIC USE DFLEX SET HAS BEEN DESIGNED FOR DIRECT COUPLING, DISCRIMINATED BETWEEN COUPLING

MOTOR AND MOVED COUPLING, WHICH IN turn WILL ACTIVATE A SYSTEM OR MORE SYSTEMS OF MISCELLANEOUS LOADS,

DIRECTLY AT THE OUTPUT AND / OR INPUT OF AXLE (S) OF THIS (S) SYSTEM (S) THAT MAY (M) BE BEING CONNECTED (S).

CAN BE USED IN ALL TYPES OF POWER OUTPUTS AND INPUTS TO FEED MISCELLANEOUS LOADS:

FOR USE ON ALL TYPES OF DEVICES, AS ON AXLES OF MACHINES, ENGINES AND VEHICLES OF ALL TYPES,

INCLUDING TRAINS, PLANES, SHIPS AND SPECIFIC MACHINES, OF ALL SIZES AND VARIOUS FUNCTIONS.

BENEFITS:

COMPACT SYSTEM (S), WITH HIGH POWER GAIN, WITH VERY LOW IMPLEMENTATION COST (LITTLE MASS),

MAINLY WHEN HYDRAULIC PISTONS ARE TO BE USED, RESULTING IN LARGE CAPITAL ECONOMY

ACQUISITION AND INSTALLATION OF ENGINES, EQUIPMENT AND MISCELLANEOUS MACHINERY.

MUCH LOWER COST MACHINERY AND ENGINES CAN BE USED WITH ADVANTAGES AND GAINS

EXTRAORDINARY POWER IN ALL TYPES OF APPLICATIONS, FOR PRIMARY, SECONDARY MOVEMENT

OR SAME TERTIARY, OF MISCELLANEOUS LOADS AND SYSTEMS, AFTER THE INSTALLATION OF THE SET (S) OF

DFLEX COUPLINGS, IN SPECIFIC SYSTEMS.

UNTIL THIS DATE, THERE IS NOTHING EQUAL, YOU CAN HAVE EXTRAORDINARY GAINS OF POWER, MAKING USE

OF ONE OR MORE SETS OF DFLEX COUPLINGS, THAT CAN BE CONNECTED IN CASCADE, CREATING GROUPS OF SETS

DFLEX (MOTOR AND MOVED COUPLINGS), LEVERING EVEN MORE THE FINAL POWER, WITH THE OPTION TO USE

MECHANICAL ROLLERS AND / OR PISTONS AND / OR HYDRAULIC PISTONS, ACCORDING TO THE DESIRED DESIGN.

THERE WILL BE ADVANTAGES ALSO IN THE SMALLEST SIZE OF THE DESIGNED SYSTEMS, COMPARATIVE TO COMPLEX MACHINERIES

THAT CURRENTLY EXIST, WHERE THE SIZE OF THE FINAL PROJECT SOMETIMES LEAVE.

THE PROJECT (S) DEVELOPMENT TIME MAY ALSO BE DRAFTED DRAFT, WHICH IS VERY IMPORTANT.

ROLLERS, MECHANICAL PISTONS AND HYDRAULIC PISTONS:

SPECIAL HYDRAULIC PISTONS HAVE BEEN DEVELOPED FOR USE WITH DFLEX COUPLINGS, AND CAN BE USED

PIEZOELECTRIC PRESSURE SENSORS, OPTIONALLY, (IMPROVES THE RESPONSE SPEED OF THE SAME)

MINIATURE TYPE BEARINGS MUST BE PREFERENTIALLY USED, AS THEY ARE SMALL AND EFFICIENT

AND FACILITATE THE IMPLEMENTATION OF MORE COMPACT PROJECTS.

MECHANICAL PISTONS ALSO WITH BEARINGS, MAY BE ANOTHER OPTION, FOR MEDIUM POWERS.

ROLLERS THAT DO NOT USE BEARINGS CAN BE USED FOR LOWER POWER APPLICATIONS AND LESS SYSTEMS.

ROLLERS, HYDRAULIC AND MECHANICAL PISTONS ARE THE COMPONENTS THAT MAKE THE INTERCONNECTION BETWEEN THE COUPLING

MOTOR AND MOVED COUPLING.

EXAMPLE:

A PRACTICAL EXAMPLE OF IMMEDIATE APPLICATION OF THIS SYSTEM WILL BE THE IMPLEMENTATION OF THE SAME ALONG PROJECTS OF

BICYCLES, WHERE THE DFLEX COUPLING ASSEMBLY CAN BE FIXED IN THE PLACE OF THE MOTORCYCLE, THAT WILL WIN TORQUE

AND EXTRA SPEED, RESULTING IN MUCH STRONGER PEDALING AND REQUIRING MUCH LESS EFFORTS FROM THE

CYCLIST. IT WILL BE EASY TO MOUNTAIN MOUNTAINS AT ALL SPEED, WITH VERY LITTLE EFFORT AND LOTS OF FUN!

SCHEMES:

THE DFLEX COUPLING SET HAS SCHEMES FOR TWO, THREE AND EVEN MORE THAN FOUR MOTOR COUPLING MODES

AND MOVED, MAY BE FOR SMALL, MEDIUM OR LARGE LOADS.

MOVED COUPLING MAY ALSO BE CONFIGURED ACCORDING TO SPECIFIC NEEDS, ALSO WITH TWO SCHEME,

THREE OR MORE COUPLING MODES, WITH THE USE OF SMALL LOAD LOADERS, WITH OR WITHOUT BEARINGS,

(MINIATURE TYPE, PREFERENTIALLY), AND THAT CAN ALSO BE USED WITH MECHANICAL PISTONS AND / OR PISTONS

HYDRAULIC, FOR MEDIUM AND LARGE LOADS.

COMBINING DIFFERENT QUANTITIES OF ROLLERS AND / OR PISTONS AND ACCORDING TO THE CHOOSING COUPLING SCHEME,

DEFINE IF CERTAIN APPLICATION WILL BE LOW, MEDIUM OR HIGH ROTATION AND / OR TORQUE, FOR A FORECASTABLE REASON IN FUNCTION

OF THE SLIDING FACTOR OF BEARINGS APPLIED TO THE DFLEX COUPLING ASSEMBLY AND ALSO IN THE QUANTITY OF ROLLERS

AND PISTONS THAT WILL BE USED IN THIS COUPLING SET (S) THAT IS BEING DESIGNED FOR A PARTICULAR

GOAL.

USE OF MATERIALS FOR MANUFACTURING THE DFLEX COUPLING ASSEMBLY:

MOTOR COUPLING:

PLASTICS AND METALS LIKE ALUMINUM, BRASS AND BRASS CAN BE USED, AMONG OTHERS, WILL DEPEND ON THE DESIRED APPLICATION.

USING HYDRAULIC PISTONS THERE WILL BE NO NEED FOR HIGH COST MATERIALS, INDUSTRIAL PLASTICS OR SAME

MISCELLANEOUS ALUMINUMS CAN SERVE, SINCE ALL THE DESIRED POWER WILL BE EXTRACTED DIRECTLY FROM THE MOVED COUPLING.

MOVED COUPLING:

IN THIS CASE, ACCORDING TO THE REQUIRED POWER, MORE RESISTANT MATERIALS MUST BE USED FOR BETTER EFFICIENCY AND WITH A

GREATER RESISTANCE TO THE BEARINGS OF THE BEARINGS THAT WILL BE USED, SINCE THE MARGIN OF THE BEARING SLIDING FACTOR

THIS APPLICATION (OUTPUT POWER) IS A LITTLE EXTREME.

MATERIALS LIKE SPECIAL STEELS MUST BE CHOSEN AS MUCH FOR THE COUPLING CAGE MOVED IN YOURSELF, ALSO

FOR BEARINGS TO BE USED.

MATERIALS LIKE TITANIUM, TUNGSTEN, MOLYBIDENE, OR EVEN SPECIAL SPECIAL ALLOYS MAY ALSO BE GOOD

OPTION, MAINLY FOR LARGER PARTS THAT WILL REQUIRE GREAT EFFORTS.

LOWEST COST OF PROJECT (S):

IN ORDER TO ACHIEVE LOWER COSTS OF THE PROJECT (S), SEVERAL SETS OF DFLEX CONNECTIONS, CONNECTED IN CASCADE

AND FIXED WITH LOWER AND LOWER POWER ENGINES, MAY BE A GREAT ALTERNATIVE FOR LOW APPLICATIONS

COST AND LESS SIZE.

FOR SIMPLE AND VERY SMALL APPLICATION PROJECTS TO BE USED IN ELECTRONIC SYSTEMS AND

MICRO-ELECTRONICS, ROLLERS AND / OR MECHANICAL PISTONS THAT WILL DRIVE SMALL GEARS AND AXLES, EVEN MADE OF PLASTIC

(PETG, ABS, PLA, ETC ...) WILL BE A GREAT OPTION.

SPECIAL CARES:

SPECIAL CARES SHOULD BE TAKEN IN RELATION TO THE DIAMETER OF THE SHAFT OF THE BEARINGS THAT WILL BE USED FOR THE SPIN

WITHIN MOVED COUPLING, DURING USE WILL BE VERY REQUESTED, INDESCRIMINATELY.

THE RESISTANCE, HEATING, LUBRICATION AND SEALING FACTORS OF THE SAME MUST BE TAKEN INTO CONSIDERATION IN THE

CHOOSE FROM THESE BEARINGS.

THE EXTERNAL EDGE OF COUPLING CAGES, MAINLY OF MOVED COUPLING, MUST BE LARGE ENOUGH AND WELL

RESISTANT, BECAUSE IT IS THE PLACE WHERE THE GREATEST PRESSURES OF OPERATION OF THE SET AS A WHOLE WILL HAPPEN.

IDEALIZER:

SAULO RODRIGUES DE QUEVEDO

EMAIL: INOVASTAR@HOTMAIL.COM

LINKEDIN:

HTTPS://WWW.LINKEDIN.COM/IN/SAULO-QUEVEDO/

GRABCAD:

HTTPS://GRABCAD.COM/SAULO.RODRIGUES.DE.QUEVEDO-1/MODELS

FACEBOOK:

HTTPS://WWW.FACEBOOK.COM/SAULO.QUEVEDO.INVENTOR

INNOVATING TECHNOLOGICAL PROJECTS AND SOLUTIONS.

COMPANY:

iNGLES:

IDEALIZED PRODUCT: DFLEX = "FLEXIBLE DEVICE" FOR DRIVING MISCELLANEOUS LOADS.

DEFINITION: DFLEX - COUPLING SET (MOTOR COUPLING, MOVED COUPLING) FOR GAIN

OF POWER IN MECHANICAL, ELECTROMECHANICAL, ELECTRICAL, ELECTRONIC AND ALSO EQUIPMENT

MICRO-ELECTRONICS, OF GENERAL USE, FOR GAINING AND / OR MULTIPLICATION OF POWER, BASED ON

THE LEVER PRINCIPLE AND ALSO THE PASCAL PRINCIPLE.

LEVERAGE PRINCIPLE:

WHEN A CERTAIN FORCE IS APPLIED, CAREFULLY DIRECTED TO ONE OR MORE DIRECTIONS

AND / OR ON ONE OR MORE END OF ONE OR MORE PROJECTED PARTS ANY, (WHEELS, AXLES,

TOOLS, ETC ...), AND WHICH IS NAMED INPUT CIRCUIT (MOTOR COUPLING), AND ALSO

THE GREATER THE DIAMETER OR RADIO OF THE CIRCUMFERENCE THAT WILL BE USED IN THE PARTICULAR PROJECT,

AND WHICH IS CALLED OUTPUT CIRCUIT (MOVED COUPLING), THE LESS THE EFFORT TO TURN

(ROTATE) THE WORK CENTER OF THIS OUTPUT CIRCUIT AND THE RESULTING POWER THEN WILL BE

GREATER, THEREFORE GAINING EXTRA POWER BY LESS EFFORT APPLIED AT THE OUTPUT OF THE SET OF

DFLEX COUPLINGS (MOTOR COUPLING AND MOVED COUPLING).

THE IDEALIZED SYSTEM OF THE DFLEX COUPLING ASSEMBLY MAKES USE OF PARTS (CAGES) WITH DESIGNS

SPECIALS THAT COUPLY AND SERVE MOVEMENT GUIDES FOR THE OTHER PARTS OF THE SAME SET,

CITO: GROUP WITH MOVEMENT CART FOR BEARINGS OF DIFFERENT SIZES PLUS ROLLERS AND / OR

MECHANICAL PISTONS AND / OR HYDRAULIC PISTONS.

PRINCIPLE OF PASCAL:

WILL APPLY WHEN A PROJECT WILL USE HYDRAULIC PISTONS.

(MOTOR COUPLING, MOVED COUPLING - PASCAL PRINCIPLE >> HYDRAULIC PISTONS).

DESCRIMINATION:

THE BASIC USE DFLEX SET HAS BEEN DESIGNED FOR DIRECT COUPLING, DISCRIMINATED BETWEEN COUPLING

MOTOR AND MOVED COUPLING, WHICH IN turn WILL ACTIVATE A SYSTEM OR MORE SYSTEMS OF MISCELLANEOUS LOADS,

DIRECTLY AT THE OUTPUT AND / OR INPUT OF AXLE (S) OF THIS (S) SYSTEM (S) THAT MAY (M) BE BEING CONNECTED (S).

CAN BE USED IN ALL TYPES OF POWER OUTPUTS AND INPUTS TO FEED MISCELLANEOUS LOADS:

FOR USE ON ALL TYPES OF DEVICES, AS ON AXLES OF MACHINES, ENGINES AND VEHICLES OF ALL TYPES,

INCLUDING TRAINS, PLANES, SHIPS AND SPECIFIC MACHINES, OF ALL SIZES AND VARIOUS FUNCTIONS.

BENEFITS:

COMPACT SYSTEM (S), WITH HIGH POWER GAIN, WITH VERY LOW IMPLEMENTATION COST (LITTLE MASS),

MAINLY WHEN HYDRAULIC PISTONS ARE TO BE USED, RESULTING IN LARGE CAPITAL ECONOMY

ACQUISITION AND INSTALLATION OF ENGINES, EQUIPMENT AND MISCELLANEOUS MACHINERY.

MUCH LOWER COST MACHINERY AND ENGINES CAN BE USED WITH ADVANTAGES AND GAINS

EXTRAORDINARY POWER IN ALL TYPES OF APPLICATIONS, FOR PRIMARY, SECONDARY MOVEMENT

OR SAME TERTIARY, OF MISCELLANEOUS LOADS AND SYSTEMS, AFTER THE INSTALLATION OF THE SET (S) OF

DFLEX COUPLINGS, IN SPECIFIC SYSTEMS.

UNTIL THIS DATE, THERE IS NOTHING EQUAL, YOU CAN HAVE EXTRAORDINARY GAINS OF POWER, MAKING USE

OF ONE OR MORE SETS OF DFLEX COUPLINGS, THAT CAN BE CONNECTED IN CASCADE, CREATING GROUPS OF SETS

DFLEX (MOTOR AND MOVED COUPLINGS), LEVERING EVEN MORE THE FINAL POWER, WITH THE OPTION TO USE

MECHANICAL ROLLERS AND / OR PISTONS AND / OR HYDRAULIC PISTONS, ACCORDING TO THE DESIRED DESIGN.

THERE WILL BE ADVANTAGES ALSO IN THE SMALLEST SIZE OF THE DESIGNED SYSTEMS, COMPARATIVE TO COMPLEX MACHINERIES

THAT CURRENTLY EXIST, WHERE THE SIZE OF THE FINAL PROJECT SOMETIMES LEAVE.

THE PROJECT (S) DEVELOPMENT TIME MAY ALSO BE DRAFTED DRAFT, WHICH IS VERY IMPORTANT.

ROLLERS, MECHANICAL PISTONS AND HYDRAULIC PISTONS:

SPECIAL HYDRAULIC PISTONS HAVE BEEN DEVELOPED FOR USE WITH DFLEX COUPLINGS, AND CAN BE USED

PIEZOELECTRIC PRESSURE SENSORS, OPTIONALLY, (IMPROVES THE RESPONSE SPEED OF THE SAME)

MINIATURE TYPE BEARINGS MUST BE PREFERENTIALLY USED, AS THEY ARE SMALL AND EFFICIENT

AND FACILITATE THE IMPLEMENTATION OF MORE COMPACT PROJECTS.

MECHANICAL PISTONS ALSO WITH BEARINGS, MAY BE ANOTHER OPTION, FOR MEDIUM POWERS.

ROLLERS THAT DO NOT USE BEARINGS CAN BE USED FOR LOWER POWER APPLICATIONS AND LESS SYSTEMS.

ROLLERS, HYDRAULIC AND MECHANICAL PISTONS ARE THE COMPONENTS THAT MAKE THE INTERCONNECTION BETWEEN THE COUPLING

MOTOR AND MOVED COUPLING.

EXAMPLE:

A PRACTICAL EXAMPLE OF IMMEDIATE APPLICATION OF THIS SYSTEM WILL BE THE IMPLEMENTATION OF THE SAME ALONG PROJECTS OF

BICYCLES, WHERE THE DFLEX COUPLING ASSEMBLY CAN BE FIXED IN THE PLACE OF THE MOTORCYCLE, THAT WILL WIN TORQUE

AND EXTRA SPEED, RESULTING IN MUCH STRONGER PEDALING AND REQUIRING MUCH LESS EFFORTS FROM THE

CYCLIST. IT WILL BE EASY TO MOUNTAIN MOUNTAINS AT ALL SPEED, WITH VERY LITTLE EFFORT AND LOTS OF FUN!

SCHEMES:

THE DFLEX COUPLING SET HAS SCHEMES FOR TWO, THREE AND EVEN MORE THAN FOUR MOTOR COUPLING MODES

AND MOVED, MAY BE FOR SMALL, MEDIUM OR LARGE LOADS.

MOVED COUPLING MAY ALSO BE CONFIGURED ACCORDING TO SPECIFIC NEEDS, ALSO WITH TWO SCHEME,

THREE OR MORE COUPLING MODES, WITH THE USE OF SMALL LOAD LOADERS, WITH OR WITHOUT BEARINGS,

(MINIATURE TYPE, PREFERENTIALLY), AND THAT CAN ALSO BE USED WITH MECHANICAL PISTONS AND / OR PISTONS

HYDRAULIC, FOR MEDIUM AND LARGE LOADS.

COMBINING DIFFERENT QUANTITIES OF ROLLERS AND / OR PISTONS AND ACCORDING TO THE CHOOSING COUPLING SCHEME,

DEFINE IF CERTAIN APPLICATION WILL BE LOW, MEDIUM OR HIGH ROTATION AND / OR TORQUE, FOR A FORECASTABLE REASON IN FUNCTION

OF THE SLIDING FACTOR OF BEARINGS APPLIED TO THE DFLEX COUPLING ASSEMBLY AND ALSO IN THE QUANTITY OF ROLLERS

AND PISTONS THAT WILL BE USED IN THIS COUPLING SET (S) THAT IS BEING DESIGNED FOR A PARTICULAR

GOAL.

USE OF MATERIALS FOR MANUFACTURING THE DFLEX COUPLING ASSEMBLY:

MOTOR COUPLING:

PLASTICS AND METALS LIKE ALUMINUM, BRASS AND BRASS CAN BE USED, AMONG OTHERS, WILL DEPEND ON THE DESIRED APPLICATION.

USING HYDRAULIC PISTONS THERE WILL BE NO NEED FOR HIGH COST MATERIALS, INDUSTRIAL PLASTICS OR SAME

MISCELLANEOUS ALUMINUMS CAN SERVE, SINCE ALL THE DESIRED POWER WILL BE EXTRACTED DIRECTLY FROM THE MOVED COUPLING.

MOVED COUPLING:

IN THIS CASE, ACCORDING TO THE REQUIRED POWER, MORE RESISTANT MATERIALS MUST BE USED FOR BETTER EFFICIENCY AND WITH A

GREATER RESISTANCE TO THE BEARINGS OF THE BEARINGS THAT WILL BE USED, SINCE THE MARGIN OF THE BEARING SLIDING FACTOR

THIS APPLICATION (OUTPUT POWER) IS A LITTLE EXTREME.

MATERIALS LIKE SPECIAL STEELS MUST BE CHOSEN AS MUCH FOR THE COUPLING CAGE MOVED IN YOURSELF, ALSO

FOR BEARINGS TO BE USED.

MATERIALS LIKE TITANIUM, TUNGSTEN, MOLYBIDENE, OR EVEN SPECIAL SPECIAL ALLOYS MAY ALSO BE GOOD

OPTION, MAINLY FOR LARGER PARTS THAT WILL REQUIRE GREAT EFFORTS.

LOWEST COST OF PROJECT (S):

IN ORDER TO ACHIEVE LOWER COSTS OF THE PROJECT (S), SEVERAL SETS OF DFLEX CONNECTIONS, CONNECTED IN CASCADE

AND FIXED WITH LOWER AND LOWER POWER ENGINES, MAY BE A GREAT ALTERNATIVE FOR LOW APPLICATIONS

COST AND LESS SIZE.

FOR SIMPLE AND VERY SMALL APPLICATION PROJECTS TO BE USED IN ELECTRONIC SYSTEMS AND

MICRO-ELECTRONICS, ROLLERS AND / OR MECHANICAL PISTONS THAT WILL DRIVE SMALL GEARS AND AXLES, EVEN MADE OF PLASTIC

(PETG, ABS, PLA, ETC ...) WILL BE A GREAT OPTION.

SPECIAL CARES:

SPECIAL CARES SHOULD BE TAKEN IN RELATION TO THE DIAMETER OF THE SHAFT OF THE BEARINGS THAT WILL BE USED FOR THE SPIN

WITHIN MOVED COUPLING, DURING USE WILL BE VERY REQUESTED, INDESCRIMINATELY.

THE RESISTANCE, HEATING, LUBRICATION AND SEALING FACTORS OF THE SAME MUST BE TAKEN INTO CONSIDERATION IN THE

CHOOSE FROM THESE BEARINGS.

THE EXTERNAL EDGE OF COUPLING CAGES, MAINLY OF MOVED COUPLING, MUST BE LARGE ENOUGH AND WELL

RESISTANT, BECAUSE IT IS THE PLACE WHERE THE GREATEST PRESSURES OF OPERATION OF THE SET AS A WHOLE WILL HAPPEN.

IDEALIZER:

SAULO RODRIGUES DE QUEVEDO

EMAIL: INOVASTAR@HOTMAIL.COM

LINKEDIN:

HTTPS://WWW.LINKEDIN.COM/IN/SAULO-QUEVEDO/

GRABCAD:

HTTPS://GRABCAD.COM/SAULO.RODRIGUES.DE.QUEVEDO-1/MODELS

FACEBOOK:

HTTPS://WWW.FACEBOOK.COM/SAULO.QUEVEDO.INVENTOR

INNOVATING TECHNOLOGICAL PROJECTS AND SOLUTIONS.

COMPANY:

https://1drv.ms/u/s!Ag0XjIMwxxU1hq12fG4YefTLvOB-xQ?e=mFYMOX

DEFINIÇÃO: DFLEX - CONJUNTO DE ACOPLAMENTOS (ACOPLAGEM MOTORA, ACOPLAGEM MOVIDA) PARA GANHO

DE POTÊNCIA EM EQUIPAMENTOS MECÂNICOS, ELETROMECÂNICOS, ELÉTRICOS, ELETRÔNICOS E TAMBÉM

MICRO-ELETRÔNICOS, DE USO GERAL, PARA GANHO E/OU MULTIPLICAÇÃO DE POTÊNCIA, BASEADO NO

PRINCÍPIO DA ALAVANCA E TAMBÉM NO PRINCÍPIO DE PASCAL.

PRINCÍPIO DA ALAVANCA:

QUANDO SE APLICA UMA DETERMINADA FORÇA, CUIDADOSAMENTE DIRECIONADA PARA UMA OU MAIS DIREÇÔES

E/OU EM UMA OU MAIS EXTREMIDADES DE UMA OU MAIS PEÇAS PROJETADAS QUALQUER, (RODAS, EIXOS,

FERRAMENTAS, ETC...), E QUE ORA SE DENOMINA DE CIRCUITO DE ENTRADA (ACOPLAGEM MOTORA), E TAMBÉM

QUANTO MAIOR FOR O DIÂMETRO OU RÁIO DA CIRCUNFERÉNCIA QUE SERÁ USADO NO DETERMINADO PROJETO,

E QUE ORA SE DENOMINA DE CIRCUITO DE SAÍDA (ACOPLAGEM MOVIDA), MENOR SERÁ O ESFORÇO PARA GIRAR

(ROTACIONAR) O CENTRO DE TRABALHO DESTE CIRCUITO DE SAÍDA E A POTÊNCIA RESULTANTE ENTÃO SERÁ

MAIOR, GANHANDO-SE ASSIM POTÊNCIA EXTRA POR MENOR ESFORÇO APLICADO NA SAÍDA DO CONJUNTO DE

ACOPLAMENTOS DFLEX (ACOPLAGEM MOTORA E ACOPLAGEM MOVIDA).

O SISTEMA IDEALIZADO DO CONJUNTO DE ACOPLAMENTO DFLEX FAZ USO DE PEÇAS (GAIOLAS) COM DESIGNS

ESPECIAIS QUE ACOPLAM E SERVEM DE GUIAS DE MOVIMENTO PARA AS DEMAIS PEÇAS DO MESMO CONJUNTO,

CITO: GRUPO COM CARRO DE MOVIMENTAÇÃO PARA ROLAMENTOS DE TAMANHOS DIVERSOS MAIS ROLETES E/OU

PISTÕES MECÂNICOS E/OU PISTÕES HIDRÁULICOS.

PRINCÍPIO DE PASCAL:

SE APLICARÁ QUANDO DETERMINADO PROJETO IRÁ USAR PISTÕES HIDRÁULICOS.

(ACOPLAGEM MOTORA, ACOPLAGEM MOVIDA - PRINCIPIO DE PASCAL >> PISTÕES HIDRÁULICOS).

DESCRIMINAÇÃO:

O CONJUNTO DFLEX DE USO BÁSICO FOI IDEALIZADO PARA ACOPLAMENTO DIRETO, DISCRIMINADO ENTRE A ACOPLAGEM

MOTORA E A ACOPLAGEM MOVIDA, QUE POR SUA VEZ ACIONARÃO UM SISTEMA OU MAIS SISTEMAS DE CARGAS DIVERSAS,

DIRETAMENTE NA SAÍDA E/OU ENTRADA DE EIXO(S) DESTE(S) SISTEMA(S) QUE POSSA(M) ESTAR SENDO INTERLIGADO(S).

PODE SER USADO EM TODO TIPO DE SAÍDAS E ENTRADAS DE POTÊNCIA PARA ALIMENTAR CARGAS DIVERSAS:

PARA USO EM TODO TIPO DE DISPOSITIVOS, COMO EM EIXOS DE MÁQUINAS, MOTORES E VEÍCULOS DE TODOS OS TIPOS,

INCLUINDO TRENS, AVIÕES, NAVIOS E MÁQUINAS ESPECÍFICAS, DE TODOS OS TAMANHOS E DE FUNÇÕES VARIADAS.

VANTAGENS:

SISTEMA(S) COMPACTO(S), COM ALTO GANHO DE POTÊNCIA, COM CUSTO DE IMPLEMENTAÇÃO MUITO BAIXO (POUCA MASSA),

PRINCIPALMENTE QUANDO SE FOR UTILIZAR PISTÕES HIDRÁULICOS, RESULTANDO EM GRANDE ECONOMIA DE CAPITAL

NA AQUISIÇÃO E INSTALAÇÃO DE MOTORES, EQUIPAMENTOS E MAQUINÁRIOS DIVERSOS.

MAQUINARIA E MOTORES DE CUSTO MUITO MAIS BAIXO PODERÃO SER USADOS COM VANTAGENS E COM GANHOS

EXTRAORDINÁRIOS DE POTÊNCIA EM TODO TIPO DE APLICAÇÕES, PARA MOVIMENTAÇÃO PRIMÁRIA, SECUNDÁRIA

OU MESMO TERCIÁRIA, DE CARGAS E SISTEMAS DIVERSOS, APÓS A INSTALAÇÃO DO(S) CONJUNTO(S) DE

ACOPLAMENTOS DFLEX, EM SISTEMAS ESPECÍFICOS.

ATÉ A PRESENTE DATA, NÃO EXISTE NADA IGUAL, PODE-SE TER GANHOS EXTRAORDINÁRIOS DE POTÊNCIA, FAZENDO USO

DE UM OU MAIS CONJUNTOS DE ACOPLAMENTOS DFLEX, QUE PODEM SER LIGADOS EM CASCATA, CRIANDO GRUPOS DE CONJUNTOS

DFLEX (ACOPLAGENS MOTORA E MOVIDA), ALAVANCANDO AINDA MAIS A POTÊNCIA FINAL, COM A OPÇÃO DE SE UTILIZAR

ROLETES E/OU PISTÔES MECÂNICOS E/OU PISTÕES HIDRÁULICOS, CONFORME O PROJETO DESEJADO.

HAVERÁ VANTAGENS TAMBÉM NO MENOR TAMANHO DOS SISTEMAS PROJETADOS, COMPARATIVAMENTE AOS MAQUINÁRIOS COMPLEXOS

QUE EXISTEM ATUALMENTE, ONDE O TAMANHO DO PROJETO FINAL AS VEZES DEIXA A DESEJAR.

O TEMPO DE DESENVOLVIMENTO DE PROJETO(S) TAMBÉM PODERÁ SER REDUZIDO DRÁSTICAMENTE, O QUE É MUITO IMPORTANTE.

ROLETES, PISTÕES MECÂNICOS E PISTÕES HIDRÁULICOS:

PISTÕES HIDRÁULICOS ESPECIAIS FORAM DESENVOLVIDOS PARA USO COM OS ACOPLAMENTOS DFLEX, PODENDO-SE USAR

SENSORES DE PRESSÃO PIEZOELÉTRICOS, OPCIONALMENTE, (MELHORA A VELOCIDADE DE RESPOSTA DOS MESMOS)

OS ROLAMENTOS DO TIPO MINIATURA DEVERÃO SER PREFERENCIALMENTE USADOS, POIS SÃO PEQUENOS E EFICIÊNTES

E FACILITAM A IMPLEMENTAÇÃO DE PROJETOS MAIS COMPACTOS.

PISTÕES MECÂNICOS TAMBÉM COM ROLAMENTOS, PODEM SER UMA OUTRA OPÇÃO, PARA MÉDIAS POTÊNCIAS.

ROLETES QUE NÃO USAM ROLAMENTOS PODEM SER USADOS PARA APLICAÇÕES DE MENOR POTÊNCIA E SISTEMAS MENORES.

ROLETES, PISTÕES HIDRÁULICOS E MECÂNICOS SÃO OS COMPONENTES QUE FAZEM A INTERLIGAÇÃO ENTRE A ACOPLAGEM

MOTORA E A ACOPLAGEM MOVIDA.

EXEMPLO:

UM EXEMPLO PRÁTICO DE APLICAÇÃO IMEDIATA DESTE SISTEMA SERÁ A IMPLEMENTAÇÃO DO MESMO JUNTO A PROJETOS DE

BICICLETAS, ONDE SE PODE FIXAR O CONJUNTO DE ACOPLAMENTO DFLEX NO LUGAR DA CORÔA MOTRIZ, QUE GANHARÁ TORQUE

E VELOCIDADE EXTRA, RESULTANDO EM PEDALADAS MUITO MAIS FORTES E EXIGINDO MUITO MENOS ESFORÇOS POR PARTE DO

CICLISTA. SERÁ FÁCIL SUBIR MONTANHAS Á TODA VELOCIDADE, COM MUITO POUCO ESFORÇO E MUITA DIVERSÃO!

ESQUEMAS:

O CONJUNTO DE ACOPLAMENTO DFLEX TEM ESQUEMAS PARA DOIS, TRÊS E ATÉ MAIS DE QUATRO MODOS DE ACOPLAGEM MOTORA

E MOVIDA, PODENDO SER PARA PEQUENA, MEDIA OU PARA GRANDES CARGAS.

A ACOPLAGEM MOVIDA PODERÁ SER TAMBÉM CONFIGURADA CONFORME NECESSIDADE ESPECÍFICA, TAMBÉM COM ESQUEMA DE DOIS,

TRÊS OU MAIS MODOS DE ACOPLAMENTOS, COM USO DE ROLETES PARA PEQUENAS CARGAS, COM OU SEM ROLAMENTOS,

(TIPO MINIATURA, PREFERENCIALMENTE), E QUE TAMBÉM PODEM SER USADOS JUNTO A PISTÕES MECÂNICOS E/OU PISTÕES

HIDRÁULICOS, PARA CARGAS MÉDIAS E GRANDES.

COMBINANDO-SE DISTINTAS QUANTIDADES DE ROLETES E/OU PISTÕES E CONFORME O ESQUEMA DE ACOPLAGEM ESCOLHIDO, PODE-SE

DEFINIR SE DETERMINADA APLICAÇÃO SERÁ PARA BAIXA, MÉDIA OU ALTA ROTAÇÃO E/OU TORQUE, NUMA RAZÃO PREVISÍVEL EM FUNÇÃO

DO FATOR DE DESLIZAMENTO DOS ROLAMENTOS APLICADOS AO CONJUNTO DE ACOPLAMENTO DFLEX E TAMBÉM NA QUANTIDADE DE ROLETES

E PISTÕES QUE SERÃO UTILIZADOS NESTE(S) CONJUNTO(S) DE ACOPLAMENTO QUE ESTA(ÃO) SENDO PROJETADO(S) PARA UMA DETERMINADA

FINALIDADE.

USO DE MATERIAIS PARA FABRICAÇÃO DO CONJUNTO DE ACOPLAMENTO DFLEX:

ACOPLAGEM MOTORA:

PODE-SE USAR PLÁSTICOS E TAMBÉM METAIS COMO O ALUMÍNIO, BRONZE E LATÃO, ENTRE OUTROS, DEPENDERÁ DA APLICAÇÃO DESEJADA.

USANDO-SE PISTÕES HIDRÁULICOS NÃO HAVERÁ NECESSIDADE DE MATERIAIS DE CUSTO ELEVADO, PLÁSTICOS INDUSTRIAIS OU MESMO

ALUMÍNIOS DIVERSOS PODEM SERVIR, VISTO QUE TODA A POTÊNCIA DESEJADA SERÁ EXTRAÍDA DIRETAMENTE DA ACOPLAGEM MOVIDA.

ACOPLAGEM MOVIDA:

NESTE CASO, CONFORME A POTÊNCIA REQUERIDA, DEVE-SE USAR MATERIAIS MAIS RESISTENTES PARA MELHOR EFICIÊNCIA E COM UMA

MAIOR RESISTÊNCA Á FADIGA DOS ROLAMENTOS QUE SERÃO USADOS, VISTO QUE A MARGEM DO FATOR DE DESLIZAMENTO DOS ROLAMENTOS

NESTA APLICAÇÃO (POTÊNCIA DE SAÍDA) É UM POUCO EXTREITA.

MATERIAIS COMO OS AÇOS ESPECIAIS DEVEM SER OS ESCOLHIDOS TANTO PARA A GAIOLA DA ACOPLAGEM MOVIDA EM SI, COMO TAMBÉM

PARA OS ROLAMENTOS QUE SERÃO USADOS.

MATERIAIS COMO O TITÂNIO, TUNGSTÊNIO, MOLIBIDENO, OU MESMO LIGAS ESPECIAIS ESPECÍFICAS TAMBÉM PODERÃO SER UMA BOA

OPÇÃO, PRINCIPALMENTE PARA PEÇAS MAIORES QUE IRÃO EXIGIR GRANDES ESFORÇOS.

CUSTOS MAIS BAIXOS DE PROJETO(S):

PARA QUE SE CONSIGA CUSTOS MAIS BAIXOS DO(S) PROJETO(S), VÁRIOS CONJUNTOS DE ACLOPLAMENTOS DFLEX, CONECTADOS EM CASCATA

E FIXADOS JUNTO A MOTORES MENORES E DE POTÊNCIA MAIS BAIXA, PODERÁ SER UMA ÓTIMA ALTERNATIVA PARA APLICAÇÕES DE BAIXO

CUSTO E DE TAMANHO MENOR.

PARA PROJETOS DE APLICAÇÃO SIMPLES E DE TAMANHO MUITO PEQUENO E QUE SERÃO USADOS EM SISTEMAS ELETRÔNICOS E

MICRO-ELETRONICOS, ROLETES E/OU PISTÕES MECÂNICOS QUE ACIONARÃO ENGRENAGENS E EIXOS PEQUENOS, MESMO FEITOS DE PLÁSTICO

(PETG,ABS,PLA, ETC...) SERÃO UMA ÓTIMA OPÇÃO.

CUIDADOS ESPECIAIS:

CUIDADOS ESPECIAIS DEVEM SER TOMADOS EM RELAÇÃO AO DIÂMETRO DO EIXO DOS ROLAMENTOS QUE SERÃO USADOS PARA O GIRO

DENTRO DA ACOPLAGEM MOVIDA, POIS DURANTE O USO SERÃO MUITO SOLICITADOS, INDESCRIMINADAMENTE.

OS FATORES DE RESISTÊNCIA, DE AQUECIMENTO, LUBRIFICAÇÃO E VEDAÇÃO DOS MESMOS DEVEM SER LEVADOS EM CONSIDERAÇÃO NA

ESCOLHA DESTES ROLAMENTOS.

A BORDA EXTERNA DAS GAIOLAS DE ACOPLAMENTO, PRINCIPALMENTE DA ACOPLAGEM MOVIDA, DEVEM SER LARGAS O SUFICIENTE E BEM

RESISTENTES, POIS É O LOCAL AONDE ACONTECERÁ AS MAIORES PRESSÕES DE FUNCIONAMENTO DO CONJUNTO COMO UM TODO.

IDEALIZADOR:

SAULO RODRIGUES DE QUEVEDO

EMAIL: INOVASTAR@HOTMAIL.COM

LINKEDIN:

HTTPS://WWW.LINKEDIN.COM/IN/SAULO-QUEVEDO/

GRABCAD:

HTTPS://GRABCAD.COM/SAULO.RODRIGUES.DE.QUEVEDO-1/MODELS

FACEBOOK:

HTTPS://WWW.FACEBOOK.COM/SAULO.QUEVEDO.INVENTOR

INNOVATING TECHNOLOGICAL PROJECTS AND SOLUTIONS.

COMPANY:

https://1drv.ms/u/s!Ag0XjIMwxxU1hq12fG4YefTLvOB-xQ?e=mFYMOX

ESPANHOL:

PRODUCTO IDEALIZADO: DFLEX = "DISPOSITIVO FLEXIBLE" PARA CONDUCIR CARGAS VARIAS.

DEFINICIÓN: DFLEX - JUEGO DE ACOPLAMIENTO (ACOPLAMIENTO DE MOTOR, ACOPLAMIENTO MOVIDO) PARA GANANCIA

DE POTENCIA EN EQUIPOS MECÁNICOS, ELECTROMECÁNICOS, ELÉCTRICOS, ELECTRÓNICOS Y TAMBIÉN

MICRO-ELECTRÓNICA, DE USO GENERAL, PARA GANAR Y / O MULTIPLICAR LA ENERGÍA, BASADA EN

EL PRINCIPIO DE PALANCA Y TAMBIÉN EL PRINCIPIO PASCAL.

PRINCIPIO DE APOYO:

CUANDO SE APLICA CIERTA FUERZA, DIRIGIDA CUIDADOSAMENTE A UNA O MÁS DIRECCIONES

Y / O EN UNO O MÁS EXTREMO DE UNA O MÁS PIEZAS PROYECTADAS CUALQUIERA (RUEDAS, EJES,

HERRAMIENTAS, ETC ...), Y QUE SE NOMBRA EN CIRCUITO DE ENTRADA (ACOPLAMIENTO DE MOTOR), Y TAMBIÉN

Cuanto mayor sea el diámetro o radio de la circunferencia que se utilizará en el proyecto determinado,

Y QUE SE LLAMA CIRCUITO DE SALIDA (ACOPLAMIENTO MOVIDO), MENOS EL ESFUERZO PARA GIRAR

(ROTAR) EL CENTRO DE TRABAJO DE ESTE CIRCUITO DE SALIDA Y EL PODER RESULTANTE ENTONCES SERÁ

MAYOR, POR LO TANTO GANANDO PODER EXTRA POR MENOS ESFUERZO APLICADO EN LA SALIDA DEL CONJUNTO DE

ACOPLAMIENTOS DFLEX (ACOPLAMIENTO DE MOTOR Y ACOPLAMIENTO MOVIDO).

EL SISTEMA IDEALIZADO DEL CONJUNTO DE ACOPLAMIENTO DFLEX HACE USO DE PIEZAS (JAULAS) CON DISEÑOS

ESPECIALES QUE CUMPLEN Y SERVEN GUÍAS DE MOVIMIENTO PARA LAS OTRAS PARTES DEL MISMO CONJUNTO,

CITO: GRUPO CON CARRO DE MOVIMIENTO PARA RODAMIENTOS DE DIFERENTES TAMAÑOS MÁS RODILLOS Y / O

PISTONES MECÁNICOS Y / O PISTONES HIDRÁULICOS.

PRINCIPIO DE PASCAL:

APLICARÁ CUANDO UN PROYECTO UTILIZARÁ PISTONES HIDRÁULICOS.

(ACOPLAMIENTO DE MOTOR, ACOPLAMIENTO MOVIDO - PRINCIPIO PASCAL >> PISTONES HIDRÁULICOS).

DESCRIMINACIÓN

EL CONJUNTO DFLEX PARA USO BÁSICO FUE IDEALIZADO PARA ACOPLAMIENTO DIRECTO, DISCRIMINADO ENTRE ACOPLAMIENTO

ACOPLAMIENTO MOTOR Y MOVIDO, QUE A SU VEZ ACTIVARÁ UN SISTEMA O MÁS SISTEMAS DE CARGAS VARIAS,

DIRECTAMENTE EN LA SALIDA Y / O ENTRADA DEL EJE (S) DE ESTE (S) SISTEMA (S) QUE PUEDE (M) ESTAR CONECTADO (S).

SE PUEDE UTILIZAR EN TODO TIPO DE SALIDAS Y ENTRADAS DE ALIMENTACIÓN PARA ALIMENTAR CARGAS VARIAS:

PARA USO EN TODO TIPO DE DISPOSITIVOS, COMO EN EJES DE MÁQUINAS, MOTORES Y VEHÍCULOS DE TODO TIPO,

INCLUYENDO TRENES, AVIONES, BUQUES Y MÁQUINAS ESPECÍFICAS, DE TODOS LOS TAMAÑOS Y VARIAS FUNCIONES.

BENEFICIOS

SISTEMA (S) COMPACTO, CON ALTA GANANCIA DE POTENCIA, CON UN COSTE DE APLICACIÓN MUY BAJO (LITTLE MASS),

PRINCIPALMENTE CUANDO SE DEBEN USAR LOS PISTONES HIDRÁULICOS, RESULTANDO EN UNA ECONOMÍA DE GRAN CAPITAL

ADQUISICIÓN E INSTALACIÓN DE MOTORES, EQUIPOS Y MÁQUINAS VARIAS.

MÁQUINAS Y MOTORES DE BAJO COSTO PUEDEN SER UTILIZADOS CON VENTAJAS Y GANANCIAS

PODER EXTRAORDINARIO EN TODO TIPO DE APLICACIONES, PARA MOVIMIENTO PRIMARIO, SECUNDARIO

O EL MISMO TERCIARIO, DE CARGAS Y SISTEMAS VARIOS, DESPUÉS DE LA INSTALACIÓN DEL (S) CONJUNTO (S) DE

ACOPLAMIENTOS DFLEX, EN SISTEMAS ESPECÍFICOS.

HASTA ESTA FECHA, NO HAY NADA IGUAL, PUEDE TENER GANANCIAS EXTRAORDINARIAS DE PODER, HACIENDO USO

DE UNO O MÁS CONJUNTOS DE ACOPLAMIENTOS DFLEX, QUE SE PUEDEN CONECTAR EN CASCADA, CREANDO GRUPOS DE CONJUNTOS

DFLEX (MOTOR Y ACOPLAMIENTOS MOVIDOS), APROVECHANDO AÚN MÁS LA POTENCIA FINAL, CON LA OPCIÓN DE USAR

RODILLOS MECÁNICOS Y / O PISTONES Y / O PISTONES HIDRÁULICOS, SEGÚN EL DISEÑO DESEADO.

HABRÁ VENTAJAS TAMBIÉN EN EL TAMAÑO MÁS PEQUEÑO DE LOS SISTEMAS DISEÑADOS, COMPARATIVO CON LAS MÁQUINAS COMPLEJAS

QUE ACTUALMENTE EXISTEN, DONDE DEJAN A VECES EL TAMAÑO DEL PROYECTO FINAL.

EL PROYECTO (S) TIEMPO DE DESARROLLO TAMBIÉN PUEDE SER PROYECTO DE BORRADOR, QUE ES MUY IMPORTANTE.

RODILLOS, PISTONES MECÁNICOS Y PISTONES HIDRÁULICOS:

PISTONES HIDRÁULICOS ESPECIALES HAN SIDO DESARROLLADOS PARA SU USO CON ACOPLAMIENTOS DFLEX, Y PUEDEN SER USADOS

SENSORES DE PRESIÓN PIEZOELÉCTRICOS, OPCIONALMENTE (MEJORAN LA VELOCIDAD DE RESPUESTA DE LOS MISMOS)

LOS RODAMIENTOS DE TIPO MINIATURA DEBEN SER USADOS PREFERENTEMENTE, PORQUE SON PEQUEÑOS Y EFICIENTES

Y FACILITAR LA IMPLEMENTACIÓN DE PROYECTOS MÁS COMPACTOS.

PISTONES MECÁNICOS TAMBIÉN CON RODAMIENTOS, PUEDEN SER OTRA OPCIÓN, PARA PODERES MEDIOS.

LOS RODILLOS QUE NO UTILIZAN RODAMIENTOS SE PUEDEN UTILIZAR PARA APLICACIONES DE BAJA POTENCIA Y MENOS SISTEMAS.

RODILLOS, PISTONES HIDRÁULICOS Y MECÁNICOS SON LOS COMPONENTES QUE HACEN LA INTERCONEXIÓN ENTRE EL ACOPLAMIENTO

ACOPLAMIENTO MOTOR Y MOVIDO.

EJEMPLO:

UN EJEMPLO PRÁCTICO DE APLICACIÓN INMEDIATA DE ESTE SISTEMA SERÁ LA APLICACIÓN DE LOS MISMOS PROYECTOS DE

BICICLETAS, DONDE SE PUEDE FIJAR EL CONJUNTO DE ACOPLAMIENTO DFLEX EN EL LUGAR DE LA MOTOCICLETA, QUE GANARÁ EL PAR

Y VELOCIDAD ADICIONAL, RESULTANDO EN PEDALES MUCHO MÁS FUERTES Y REQUERIENDO MUCHO MENOS ESFUERZOS DEL

CICLISTA. ¡SERÁ FÁCIL MONTAR LAS MONTAÑAS A TODA VELOCIDAD, CON MUY POCO ESFUERZO Y MUCHA DIVERSIÓN!

Esquemas

EL JUEGO DE ACOPLAMIENTO DFLEX TIENE ESQUEMAS PARA DOS, TRES Y AÚN MÁS DE CUATRO MODOS DE ACOPLAMIENTO DE MOTOR

Y MOVIDO, PUEDE SER PARA CARGAS PEQUEÑAS, MEDIAS O GRANDES.

EL ACOPLAMIENTO MOVIDO TAMBIÉN PUEDE CONFIGURARSE DE ACUERDO CON NECESIDADES ESPECÍFICAS, TAMBIÉN CON DOS ESQUEMAS,

TRES O MÁS MODOS DE ACOPLAMIENTO, CON EL USO DE PEQUEÑAS CARGADORAS DE CARGA, CON O SIN RODAMIENTOS,

(TIPO MINIATURA, PREFERENCIALMENTE), Y QUE TAMBIÉN PUEDE UTILIZARSE CON PISTONES Y / O PISTONES MECÁNICOS

HIDRÁULICO, PARA CARGAS MEDIANAS Y GRANDES.

COMBINANDO DIFERENTES CANTIDADES DE RODILLOS Y / O PISTONES Y SEGÚN EL ESQUEMA DE ACOPLAMIENTO DE ELECCIÓN,

DEFINE SI CIERTA APLICACIÓN SERÁ BAJA, MEDIA O ALTA ROTACIÓN Y / O PAR, POR UNA RAZÓN PREVISTA EN FUNCIÓN

DEL FACTOR DESLIZANTE DE RODAMIENTOS APLICADOS A LA ASAMBLEA DE ACOPLAMIENTO DFLEX Y TAMBIÉN EN LA CANTIDAD DE RODILLOS

Y PISTONES QUE SE UTILIZARÁN EN ESTE (S) CONJUNTO (S) DE ACOPLAMIENTO DISEÑADO PARA UN PARTICULAR

OBJETIVO.

USO DE MATERIALES PARA FABRICAR EL CONJUNTO DE ACOPLAMIENTO DFLEX:

ACOPLAMIENTO DE MOTOR:

PLÁSTICOS Y METALES COMO EL ALUMINIO, SE PUEDEN USAR LATÓN Y LATÓN, ENTRE OTROS, DEPENDRÁN DE LA APLICACIÓN DESEADA.

UTILIZANDO PISTONES HIDRÁULICOS NO HABRÁ NECESIDAD DE MATERIALES DE ALTO COSTO, PLÁSTICOS INDUSTRIALES O MISMOS

ALUMINIOS VARIOS PUEDEN SERVIR, DESDE QUE TODA LA POTENCIA DESEADA SE EXTRACTARÁ DIRECTAMENTE DEL ACOPLAMIENTO MOVIDO.

ACOPLAMIENTO MOVIDO:

EN ESTE CASO, DE ACUERDO CON LA POTENCIA REQUERIDA, DEBEN USARSE MATERIALES MÁS RESISTENTES PARA MAYOR EFICIENCIA Y CON UN

MAYOR RESISTENCIA A LA FATIGA DE LOS RODAMIENTOS QUE SE UTILIZARÁN, DESDE LA GAMA DEL FACTOR DESLIZANTE DEL RODAMIENTO

ESTA APLICACIÓN (POTENCIA DE SALIDA) ES UN POCO EXTREMO.

MATERIALES COMO ACEROS ESPECIALES DEBEN SER ELEGIDOS COMO MUCHO PARA LA JAULA DE ACOPLAMIENTO MUDADA EN USTED MISMO

PARA USO DE RODAMIENTOS.

MATERIALES COMO TITANIO, TUNGSTENO, MOLIBIDENO O INCLUSO ALEACIONES ESPECIALES ESPECIALES TAMBIÉN PUEDEN SER BUENAS

OPCIÓN, PRINCIPALMENTE PARA PIEZAS MÁS GRANDES QUE REQUERIRÁN GRANDES ESFUERZOS.

COSTO MÁS BAJO DEL PROYECTO (S):

PARA ALCANZAR LOS BAJOS COSTOS DEL PROYECTO (S), VARIOS CONJUNTOS DE CONEXIONES DFLEX, CONECTADOS EN CASCADA

Y FIJO CON MOTORES MÁS BAJOS Y MÁS BAJOS, PUEDE SER UNA GRAN ALTERNATIVA PARA APLICACIONES BAJAS

COSTE Y MENOS TAMAÑO.

PARA PROYECTOS DE APLICACIÓN SENCILLOS Y MUY PEQUEÑOS PARA SER UTILIZADOS EN SISTEMAS ELECTRÓNICOS Y

MICRO-ELECTRÓNICA, RODILLOS Y / O PISTONES MECÁNICOS QUE ACCIONARÁN PEQUEÑOS ENGRANAJES Y EJES, INCLUSO HECHOS DE PLÁSTICO

(PETG, ABS, PLA, ETC ...) SERÁ UNA GRAN OPCIÓN.

CUIDADOS ESPECIALES:

CUIDADOS ESPECIALES DEBEN TOMARSE EN RELACIÓN CON EL DIÁMETRO DEL EJE DE LOS RODAMIENTOS QUE SE UTILIZARÁN PARA EL GIRO

DENTRO DEL ACOPLAMIENTO MOVIDO, DURANTE EL USO SERÁ MUY SOLICITADO, INDESCRIMINADAMENTE.

LA RESISTENCIA, CALEFACCIÓN, LUBRICACIÓN Y FACTORES DE SELLADO DE LOS MISMOS DEBEN TENERSE EN CUENTA EN EL

ELIGE DE ESTOS RODAMIENTOS.

EL BORDE EXTERNO DE LAS JAULAS DE ACOPLAMIENTO, PRINCIPALMENTE DE ACOPLAMIENTO MOVIDO, DEBE SER SUFICIENTEMENTE GRANDE Y BIEN

RESISTENTE, PORQUE ES EL LUGAR DONDE OCURRIRÁN LAS MAYORES PRESIONES DE FUNCIONAMIENTO DEL CONJUNTO.

IDEALIZADOR:

SAULO RODRIGUES DE QUEVEDO

CORREO ELECTRÓNICO: INOVASTAR@HOTMAIL.COM

LINKEDIN:

HTTPS://WWW.LINKEDIN.COM/IN/SAULO-QUEVEDO/

GRABCAD:

HTTPS://GRABCAD.COM/SAULO.RODRIGUES.DE.QUEVEDO-1/MODELS

FACEBOOK:

HTTPS://WWW.FACEBOOK.COM/SAULO.QUEVEDO.INVENTOR

INNOVANDO PROYECTOS TECNOLÓGICOS Y SOLUCIONES.

EMPRESA:

HTTPS://1DRV.MS/B/S!AG0XJIMWXXU1HOYTSHDVV2LPO2Y8SA

INOVASTAR PROJETOS E SOLUÇÕES TECNOLÓGICAS.

EMPRESA:

iNGLES:

IDEALIZED PRODUCT: DFLEX = "FLEXIBLE DEVICE" FOR DRIVING MISCELLANEOUS LOADS.

DEFINITION: DFLEX - COUPLING SET (MOTOR COUPLING, MOVED COUPLING) FOR GAIN

OF POWER IN MECHANICAL, ELECTROMECHANICAL, ELECTRICAL, ELECTRONIC AND ALSO EQUIPMENT

MICRO-ELECTRONICS, OF GENERAL USE, FOR GAINING AND / OR MULTIPLICATION OF POWER, BASED ON

THE LEVER PRINCIPLE AND ALSO THE PASCAL PRINCIPLE.

LEVERAGE PRINCIPLE:

WHEN A CERTAIN FORCE IS APPLIED, CAREFULLY DIRECTED TO ONE OR MORE DIRECTIONS

AND / OR ON ONE OR MORE END OF ONE OR MORE PROJECTED PARTS ANY, (WHEELS, AXLES,

TOOLS, ETC ...), AND WHICH IS NAMED INPUT CIRCUIT (MOTOR COUPLING), AND ALSO

THE GREATER THE DIAMETER OR RADIO OF THE CIRCUMFERENCE THAT WILL BE USED IN THE PARTICULAR PROJECT,

AND WHICH IS CALLED OUTPUT CIRCUIT (MOVED COUPLING), THE LESS THE EFFORT TO TURN

(ROTATE) THE WORK CENTER OF THIS OUTPUT CIRCUIT AND THE RESULTING POWER THEN WILL BE

GREATER, THEREFORE GAINING EXTRA POWER BY LESS EFFORT APPLIED AT THE OUTPUT OF THE SET OF

DFLEX COUPLINGS (MOTOR COUPLING AND MOVED COUPLING).

THE IDEALIZED SYSTEM OF THE DFLEX COUPLING ASSEMBLY MAKES USE OF PARTS (CAGES) WITH DESIGNS

SPECIALS THAT COUPLY AND SERVE MOVEMENT GUIDES FOR THE OTHER PARTS OF THE SAME SET,

CITO: GROUP WITH MOVEMENT CART FOR BEARINGS OF DIFFERENT SIZES PLUS ROLLERS AND / OR

MECHANICAL PISTONS AND / OR HYDRAULIC PISTONS.

PRINCIPLE OF PASCAL:

WILL APPLY WHEN A PROJECT WILL USE HYDRAULIC PISTONS.

(MOTOR COUPLING, MOVED COUPLING - PASCAL PRINCIPLE >> HYDRAULIC PISTONS).

DESCRIMINATION:

THE BASIC USE DFLEX SET HAS BEEN DESIGNED FOR DIRECT COUPLING, DISCRIMINATED BETWEEN COUPLING

MOTOR AND MOVED COUPLING, WHICH IN turn WILL ACTIVATE A SYSTEM OR MORE SYSTEMS OF MISCELLANEOUS LOADS,

DIRECTLY AT THE OUTPUT AND / OR INPUT OF AXLE (S) OF THIS (S) SYSTEM (S) THAT MAY (M) BE BEING CONNECTED (S).

CAN BE USED IN ALL TYPES OF POWER OUTPUTS AND INPUTS TO FEED MISCELLANEOUS LOADS:

FOR USE ON ALL TYPES OF DEVICES, AS ON AXLES OF MACHINES, ENGINES AND VEHICLES OF ALL TYPES,

INCLUDING TRAINS, PLANES, SHIPS AND SPECIFIC MACHINES, OF ALL SIZES AND VARIOUS FUNCTIONS.

BENEFITS:

COMPACT SYSTEM (S), WITH HIGH POWER GAIN, WITH VERY LOW IMPLEMENTATION COST (LITTLE MASS),

MAINLY WHEN HYDRAULIC PISTONS ARE TO BE USED, RESULTING IN LARGE CAPITAL ECONOMY

ACQUISITION AND INSTALLATION OF ENGINES, EQUIPMENT AND MISCELLANEOUS MACHINERY.

MUCH LOWER COST MACHINERY AND ENGINES CAN BE USED WITH ADVANTAGES AND GAINS

EXTRAORDINARY POWER IN ALL TYPES OF APPLICATIONS, FOR PRIMARY, SECONDARY MOVEMENT

OR SAME TERTIARY, OF MISCELLANEOUS LOADS AND SYSTEMS, AFTER THE INSTALLATION OF THE SET (S) OF

DFLEX COUPLINGS, IN SPECIFIC SYSTEMS.

UNTIL THIS DATE, THERE IS NOTHING EQUAL, YOU CAN HAVE EXTRAORDINARY GAINS OF POWER, MAKING USE

OF ONE OR MORE SETS OF DFLEX COUPLINGS, THAT CAN BE CONNECTED IN CASCADE, CREATING GROUPS OF SETS

DFLEX (MOTOR AND MOVED COUPLINGS), LEVERING EVEN MORE THE FINAL POWER, WITH THE OPTION TO USE

MECHANICAL ROLLERS AND / OR PISTONS AND / OR HYDRAULIC PISTONS, ACCORDING TO THE DESIRED DESIGN.

THERE WILL BE ADVANTAGES ALSO IN THE SMALLEST SIZE OF THE DESIGNED SYSTEMS, COMPARATIVE TO COMPLEX MACHINERIES

THAT CURRENTLY EXIST, WHERE THE SIZE OF THE FINAL PROJECT SOMETIMES LEAVE.

THE PROJECT (S) DEVELOPMENT TIME MAY ALSO BE DRAFTED DRAFT, WHICH IS VERY IMPORTANT.

ROLLERS, MECHANICAL PISTONS AND HYDRAULIC PISTONS:

SPECIAL HYDRAULIC PISTONS HAVE BEEN DEVELOPED FOR USE WITH DFLEX COUPLINGS, AND CAN BE USED

PIEZOELECTRIC PRESSURE SENSORS, OPTIONALLY, (IMPROVES THE RESPONSE SPEED OF THE SAME)

MINIATURE TYPE BEARINGS MUST BE PREFERENTIALLY USED, AS THEY ARE SMALL AND EFFICIENT

AND FACILITATE THE IMPLEMENTATION OF MORE COMPACT PROJECTS.

MECHANICAL PISTONS ALSO WITH BEARINGS, MAY BE ANOTHER OPTION, FOR MEDIUM POWERS.

ROLLERS THAT DO NOT USE BEARINGS CAN BE USED FOR LOWER POWER APPLICATIONS AND LESS SYSTEMS.

ROLLERS, HYDRAULIC AND MECHANICAL PISTONS ARE THE COMPONENTS THAT MAKE THE INTERCONNECTION BETWEEN THE COUPLING

MOTOR AND MOVED COUPLING.

EXAMPLE:

A PRACTICAL EXAMPLE OF IMMEDIATE APPLICATION OF THIS SYSTEM WILL BE THE IMPLEMENTATION OF THE SAME ALONG PROJECTS OF

BICYCLES, WHERE THE DFLEX COUPLING ASSEMBLY CAN BE FIXED IN THE PLACE OF THE MOTORCYCLE, THAT WILL WIN TORQUE

AND EXTRA SPEED, RESULTING IN MUCH STRONGER PEDALING AND REQUIRING MUCH LESS EFFORTS FROM THE

CYCLIST. IT WILL BE EASY TO MOUNTAIN MOUNTAINS AT ALL SPEED, WITH VERY LITTLE EFFORT AND LOTS OF FUN!

SCHEMES:

THE DFLEX COUPLING SET HAS SCHEMES FOR TWO, THREE AND EVEN MORE THAN FOUR MOTOR COUPLING MODES

AND MOVED, MAY BE FOR SMALL, MEDIUM OR LARGE LOADS.

MOVED COUPLING MAY ALSO BE CONFIGURED ACCORDING TO SPECIFIC NEEDS, ALSO WITH TWO SCHEME,

THREE OR MORE COUPLING MODES, WITH THE USE OF SMALL LOAD LOADERS, WITH OR WITHOUT BEARINGS,

(MINIATURE TYPE, PREFERENTIALLY), AND THAT CAN ALSO BE USED WITH MECHANICAL PISTONS AND / OR PISTONS

HYDRAULIC, FOR MEDIUM AND LARGE LOADS.

COMBINING DIFFERENT QUANTITIES OF ROLLERS AND / OR PISTONS AND ACCORDING TO THE CHOOSING COUPLING SCHEME,

DEFINE IF CERTAIN APPLICATION WILL BE LOW, MEDIUM OR HIGH ROTATION AND / OR TORQUE, FOR A FORECASTABLE REASON IN FUNCTION

OF THE SLIDING FACTOR OF BEARINGS APPLIED TO THE DFLEX COUPLING ASSEMBLY AND ALSO IN THE QUANTITY OF ROLLERS

AND PISTONS THAT WILL BE USED IN THIS COUPLING SET (S) THAT IS BEING DESIGNED FOR A PARTICULAR

GOAL.

USE OF MATERIALS FOR MANUFACTURING THE DFLEX COUPLING ASSEMBLY:

MOTOR COUPLING:

PLASTICS AND METALS LIKE ALUMINUM, BRASS AND BRASS CAN BE USED, AMONG OTHERS, WILL DEPEND ON THE DESIRED APPLICATION.

USING HYDRAULIC PISTONS THERE WILL BE NO NEED FOR HIGH COST MATERIALS, INDUSTRIAL PLASTICS OR SAME

MISCELLANEOUS ALUMINUMS CAN SERVE, SINCE ALL THE DESIRED POWER WILL BE EXTRACTED DIRECTLY FROM THE MOVED COUPLING.

MOVED COUPLING:

IN THIS CASE, ACCORDING TO THE REQUIRED POWER, MORE RESISTANT MATERIALS MUST BE USED FOR BETTER EFFICIENCY AND WITH A

GREATER RESISTANCE TO THE BEARINGS OF THE BEARINGS THAT WILL BE USED, SINCE THE MARGIN OF THE BEARING SLIDING FACTOR

THIS APPLICATION (OUTPUT POWER) IS A LITTLE EXTREME.

MATERIALS LIKE SPECIAL STEELS MUST BE CHOSEN AS MUCH FOR THE COUPLING CAGE MOVED IN YOURSELF, ALSO

FOR BEARINGS TO BE USED.

MATERIALS LIKE TITANIUM, TUNGSTEN, MOLYBIDENE, OR EVEN SPECIAL SPECIAL ALLOYS MAY ALSO BE GOOD

OPTION, MAINLY FOR LARGER PARTS THAT WILL REQUIRE GREAT EFFORTS.

LOWEST COST OF PROJECT (S):

IN ORDER TO ACHIEVE LOWER COSTS OF THE PROJECT (S), SEVERAL SETS OF DFLEX CONNECTIONS, CONNECTED IN CASCADE

AND FIXED WITH LOWER AND LOWER POWER ENGINES, MAY BE A GREAT ALTERNATIVE FOR LOW APPLICATIONS

COST AND LESS SIZE.

FOR SIMPLE AND VERY SMALL APPLICATION PROJECTS TO BE USED IN ELECTRONIC SYSTEMS AND

MICRO-ELECTRONICS, ROLLERS AND / OR MECHANICAL PISTONS THAT WILL DRIVE SMALL GEARS AND AXLES, EVEN MADE OF PLASTIC

(PETG, ABS, PLA, ETC ...) WILL BE A GREAT OPTION.

SPECIAL CARES:

SPECIAL CARES SHOULD BE TAKEN IN RELATION TO THE DIAMETER OF THE SHAFT OF THE BEARINGS THAT WILL BE USED FOR THE SPIN

WITHIN MOVED COUPLING, DURING USE WILL BE VERY REQUESTED, INDESCRIMINATELY.

THE RESISTANCE, HEATING, LUBRICATION AND SEALING FACTORS OF THE SAME MUST BE TAKEN INTO CONSIDERATION IN THE

CHOOSE FROM THESE BEARINGS.

THE EXTERNAL EDGE OF COUPLING CAGES, MAINLY OF MOVED COUPLING, MUST BE LARGE ENOUGH AND WELL

RESISTANT, BECAUSE IT IS THE PLACE WHERE THE GREATEST PRESSURES OF OPERATION OF THE SET AS A WHOLE WILL HAPPEN.

IDEALIZER:

SAULO RODRIGUES DE QUEVEDO

EMAIL: INOVASTAR@HOTMAIL.COM

LINKEDIN:

HTTPS://WWW.LINKEDIN.COM/IN/SAULO-QUEVEDO/

GRABCAD:

HTTPS://GRABCAD.COM/SAULO.RODRIGUES.DE.QUEVEDO-1/MODELS

FACEBOOK:

HTTPS://WWW.FACEBOOK.COM/SAULO.QUEVEDO.INVENTOR

INNOVATING TECHNOLOGICAL PROJECTS AND SOLUTIONS.

COMPANY:

https://1drv.ms/u/s!Ag0XjIMwxxU1hq12fG4YefTLvOB-xQ?e=mFYMOX

iNGLES:

IDEALIZED PRODUCT: DFLEX = "FLEXIBLE DEVICE" FOR DRIVING MISCELLANEOUS LOADS.

DEFINITION: DFLEX - COUPLING SET (MOTOR COUPLING, MOVED COUPLING) FOR GAIN

OF POWER IN MECHANICAL, ELECTROMECHANICAL, ELECTRICAL, ELECTRONIC AND ALSO EQUIPMENT

MICRO-ELECTRONICS, OF GENERAL USE, FOR GAINING AND / OR MULTIPLICATION OF POWER, BASED ON

THE LEVER PRINCIPLE AND ALSO THE PASCAL PRINCIPLE.

LEVERAGE PRINCIPLE:

WHEN A CERTAIN FORCE IS APPLIED, CAREFULLY DIRECTED TO ONE OR MORE DIRECTIONS

AND / OR ON ONE OR MORE END OF ONE OR MORE PROJECTED PARTS ANY, (WHEELS, AXLES,

TOOLS, ETC ...), AND WHICH IS NAMED INPUT CIRCUIT (MOTOR COUPLING), AND ALSO

THE GREATER THE DIAMETER OR RADIO OF THE CIRCUMFERENCE THAT WILL BE USED IN THE PARTICULAR PROJECT,

AND WHICH IS CALLED OUTPUT CIRCUIT (MOVED COUPLING), THE LESS THE EFFORT TO TURN

(ROTATE) THE WORK CENTER OF THIS OUTPUT CIRCUIT AND THE RESULTING POWER THEN WILL BE

GREATER, THEREFORE GAINING EXTRA POWER BY LESS EFFORT APPLIED AT THE OUTPUT OF THE SET OF

DFLEX COUPLINGS (MOTOR COUPLING AND MOVED COUPLING).

THE IDEALIZED SYSTEM OF THE DFLEX COUPLING ASSEMBLY MAKES USE OF PARTS (CAGES) WITH DESIGNS

SPECIALS THAT COUPLY AND SERVE MOVEMENT GUIDES FOR THE OTHER PARTS OF THE SAME SET,

CITO: GROUP WITH MOVEMENT CART FOR BEARINGS OF DIFFERENT SIZES PLUS ROLLERS AND / OR

MECHANICAL PISTONS AND / OR HYDRAULIC PISTONS.

PRINCIPLE OF PASCAL:

WILL APPLY WHEN A PROJECT WILL USE HYDRAULIC PISTONS.

(MOTOR COUPLING, MOVED COUPLING - PASCAL PRINCIPLE >> HYDRAULIC PISTONS).

DESCRIMINATION:

THE BASIC USE DFLEX SET HAS BEEN DESIGNED FOR DIRECT COUPLING, DISCRIMINATED BETWEEN COUPLING

MOTOR AND MOVED COUPLING, WHICH IN turn WILL ACTIVATE A SYSTEM OR MORE SYSTEMS OF MISCELLANEOUS LOADS,