Thingiverse

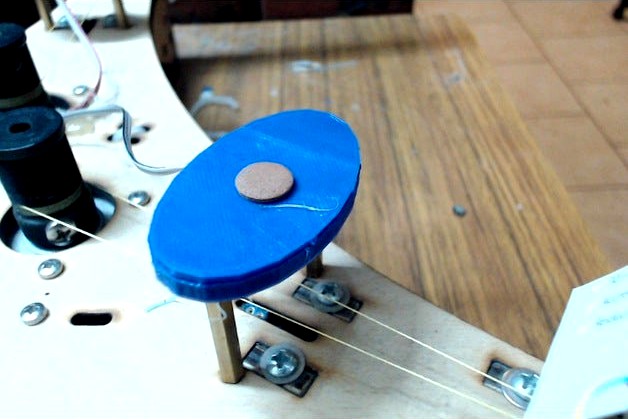

Deltaprintr KS Piezo Bed leveling by dendad51

by Thingiverse

Last crawled date: 4 years, 4 months ago

After battling for a number of years with the bed leveling Force Sense resistors on my Deltaprintr KS, I decided to have a go at Piezoing it.

The FSRs have worked well, but the second one has failed. I could replace it from a spare, but maybe it is time for a change.

So far, I have not finished this but in the next few days I hope to.

The parts are printed at 0.1mm layers, 100% infill.

27mm Piezo disks are used.

The PiezoBase part has support touching the build plate.

If you don't want to build your own electronics, have a look at...https://www.precisionpiezo.co.uk/

He has done a great job!

Files to edit here....https://www.tinkercad.com/things/1Rzp7yWNVPR-deltaprintrpiezo

When I get it going I'll post circuits and more pictures.

EDIT: It is still a project.

I've added a mod for the top part to have a pushbutton in it. And removed the unused version of the top.

Another EDIT: This works well :) Now I have to clean it up and post the circuit I used.

Also, I have to put a non slip surface on the pushbutton as the acrylic disk base slides around on the PLA.

EDIT: Added some felt pads to the buttons for non slip.

And have a concrete paver under the printer for a bit more stability.

The FSRs have worked well, but the second one has failed. I could replace it from a spare, but maybe it is time for a change.

So far, I have not finished this but in the next few days I hope to.

The parts are printed at 0.1mm layers, 100% infill.

27mm Piezo disks are used.

The PiezoBase part has support touching the build plate.

If you don't want to build your own electronics, have a look at...https://www.precisionpiezo.co.uk/

He has done a great job!

Files to edit here....https://www.tinkercad.com/things/1Rzp7yWNVPR-deltaprintrpiezo

When I get it going I'll post circuits and more pictures.

EDIT: It is still a project.

I've added a mod for the top part to have a pushbutton in it. And removed the unused version of the top.

Another EDIT: This works well :) Now I have to clean it up and post the circuit I used.

Also, I have to put a non slip surface on the pushbutton as the acrylic disk base slides around on the PLA.

EDIT: Added some felt pads to the buttons for non slip.

And have a concrete paver under the printer for a bit more stability.