Thingiverse

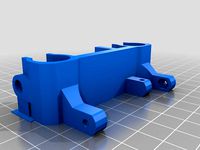

Delta Roller by cwaa

by Thingiverse

Last crawled date: 3 years, 1 month ago

My first printer was a Voxel OX from Open Builds. Its been running for two years and I have been thinking about a large delta build. For stability I wanted no plastic parts in the frame. I have followed other builds and for this size printer most are using materials custom cut on a CNC or water jet. I could not justify a $20 13" x 13" x.125 build plate being custom cut for $150. My top and bottom plates together cost $40 and would have cost another $200 to have them professionally cut. So the basis of my build is to cut all of my materials myself and use drill jigs to give me the necessary accuracy for this build. My tools include a 12" radial arm saw, a 10" table saw, a jig saw and a scroll saw, along with a drill press and misc. hand tools. Right now I am in assembly having cut my plates and just received the v-slot materials. The total out of pocket costs for the frame material excluding freight is less than $200.

When I began looking at this build, I wanted a wide rod spacing to enhance effector stability. I started out with 2080 uprights in my design and that gave me 100 mm between rods. I reduced that to 2060 after some conversations with others. Now the rod spacing is 80mm to give the carriage as much stability as possible. Also using 4 wheels per carriage while most use only 3 on a 2020 upright. When it came to the joints, I simple reverted to my structural background. The only other design that seemed strong enough was those using metal cast vertices, but they limit your choice in uprights. The corners have 9 bolts holding the upright, to the plate and the plate to the horizontal brace. Its like having a 100 mm corner brace. The plates and braces form a box at the bottom and top that is extremely ridged and flat. The horizontal braces not only brace the upright, but pull the plates into a flat position. I am building the frame without tightening the bolts from the horizontal braces to the uprights. After everything is assembled and check for square and alignment, I will slowly tighten the horizontal bolts both top and bottom and that will "lock" the frame in place. The power supply and SSR for the heated bed go into the bottom covered by a fireproof panel. There are two fans and one power inlet built into the lower horizontal braces. The electronics will rest on the top plate as will the motors. If I enclose the printer, I want the electronics outside of the heated area. My choices for controller is another Smoothie board, Duet Network, or Azteeg X5 mini.

When I began looking at this build, I wanted a wide rod spacing to enhance effector stability. I started out with 2080 uprights in my design and that gave me 100 mm between rods. I reduced that to 2060 after some conversations with others. Now the rod spacing is 80mm to give the carriage as much stability as possible. Also using 4 wheels per carriage while most use only 3 on a 2020 upright. When it came to the joints, I simple reverted to my structural background. The only other design that seemed strong enough was those using metal cast vertices, but they limit your choice in uprights. The corners have 9 bolts holding the upright, to the plate and the plate to the horizontal brace. Its like having a 100 mm corner brace. The plates and braces form a box at the bottom and top that is extremely ridged and flat. The horizontal braces not only brace the upright, but pull the plates into a flat position. I am building the frame without tightening the bolts from the horizontal braces to the uprights. After everything is assembled and check for square and alignment, I will slowly tighten the horizontal bolts both top and bottom and that will "lock" the frame in place. The power supply and SSR for the heated bed go into the bottom covered by a fireproof panel. There are two fans and one power inlet built into the lower horizontal braces. The electronics will rest on the top plate as will the motors. If I enclose the printer, I want the electronics outside of the heated area. My choices for controller is another Smoothie board, Duet Network, or Azteeg X5 mini.

Similar models

thingiverse

free

Magnet Delta Rod JIG by mpires

...magnet delta rod jig by mpires

thingiverse

magnet jig.

i did this "jig" to build my delta m6 carbon fiber rods.

thingiverse

free

Rostock Modded Parts - Carriage, Platform (for Ball Links); Belt Spreader; Corner Support by piit79

... idler bracket can be put above for belt tightening)

-- bottom belt spreader

-- bottom corner support (for better case stability)

thingiverse

free

Bolted Prusa Framed Stabilizer by Aerotayl

...nterfere with x axis motor and not allow for maximum height. i have removed the brace from that side and still use three braces.

thingiverse

free

Parameterized clamp to brace printer to a bottom wood plate by avri

...oden plate

customize to your printer using the scad file. the current settings are for my printer - a makerfarm prusa i3 8"

thingiverse

free

Prusa i3 Z Axis Stabilizer for board mount by mprobot

...crews into the board that the printer is mounted on.

requires one 5/16" x 36" rod cut in half, 8 nuts, and 4 screws.

thingiverse

free

Delta/Kossel Belt adjustPlatform by yngbra94

...on the top of the 40x40mm aluminium profile.

since the profile i at rest and the top platform i loose, the belts will be tighten.

thingiverse

free

5/16 threaded rod Z-brace for Tevo Tarantula by teikjoon

...e brackets are not load bearing, they just need to be stiff enough to prevent the z gantry from oscillating as the hot end moves!

thingiverse

free

Tevo Tornado Rear Frame Mount

...

i used one of the 10" rod pieces left over on the top left frame with a support for my spool holder (will publish soon).

thingiverse

free

Kossel Rod Jig by xile6

...ame.

picture is my carbon rods ,which im replacing because they crack, but have metal ones on the way. thats why i made this jig.

thingiverse

free

Z Brace for 3D Printer by katolystic

...er platform. fits any 1/2" tube. the brace is made to stabilize and prevent the forward and backward swing of the top frame.

Cwaa

thingiverse

free

Bicolored dice by cwaa

...bicolored dice by cwaa

thingiverse

this is a large di made with two colors on my custom printer.

thingiverse

free

Monarch Butterfly by cwaa

...monarch butterfly by cwaa

thingiverse

this is gcode for a two color printer. i used abs @ 265 c and a bed at 120 c.

thingiverse

free

PiTFT/camera by cwaa

...mera by cwaa

thingiverse

i am experimenting with a pi 3 b and a 2.8 capacitive screen hooked to the pi camera in one enclosure.

thingiverse

free

Piezo mount for Prometheus Hot end by cwaa

...piezo mount for prometheus hot end by cwaa

thingiverse

this is a design for the j-head of the prometheus hot end.

thingiverse

free

3D and Carbon Drone by cwaa

...o a h frame that i didn't like and so i have this current design. i have yet to up load files as this is a work in progress.

thingiverse

free

Voxel OX single Z axis conversion by cwaa

...out $9.00. you can get them cheaper, but they take a month to arrive.

so if you have a voxel ox and want convert it....have fun.

Delta

design_connected

$16

Delta

...delta

designconnected

arflex international spa delta computer generated 3d model. designed by koivisto, eero.

design_connected

$16

Delta

...delta

designconnected

lj lamps delta computer generated 3d model. designed by janowski-lenhart, sasha.

design_connected

$13

Delta

...delta

designconnected

emu group delta armchairs computer generated 3d model. designed by marin chiaramonte .

3ddd

$1

Delta Light

...delta light

3ddd

delta light , you-turn reo 3033

точечний светильник delta light

3ddd

$1

Blanco / delta

...blanco / delta

3ddd

blanco , мойка

мойка blanco delta со смесителем

3ddd

$1

Delta Light Spot

...delta light spot

3ddd

delta light

светильник фирмы delta light

3ddd

free

Bianchi Delta LVMDLT200100

...i delta lvmdlt200100

3ddd

bianchi delta , смеситель

смеситель bianchi delta lvmdlt200100

design_connected

free

Delta 190

...delta 190

designconnected

free 3d model of delta 190 by zanotta designed by progetti, emaf.

design_connected

$27

Delta 211

...delta 211

designconnected

zanotta delta 211 computer generated 3d model. designed by progetti, emaf.

design_connected

$27

Delta 234

...delta 234

designconnected

zanotta delta 234 computer generated 3d model. designed by progetti, emaf.

Roller

turbosquid

$26

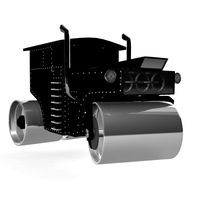

Roller A

...urbosquid

royalty free 3d model roller a for download as fbx on turbosquid: 3d models for games, architecture, videos. (1350603)

turbosquid

$3

Roller

...oyalty free 3d model roller for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1460818)

3ddd

$1

edilkamin roller

...edilkamin roller

3ddd

камин

edilkamin roller 360

3ddd

$1

Roller Blinds

...roller blinds

3ddd

рулонная

roller blinds black out finish

turbosquid

$50

Roller

... roller for download as max, max, c4d, max, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1700762)

3d_export

$10

rollers

...lers

3dexport

this is low-poly model of rollers.<br>model:<br>- low-poly<br>- textured<br>- uv unwrapped

3d_export

$28

Roller 3D Model

...roller 3d model

3dexport

roller construction boss evil

roller 3d model adagio15740837 50561 3dexport

3d_export

$6

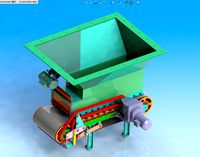

hopper roller conveyor

...hopper roller conveyor

3dexport

hopper roller conveyor

3d_export

$12

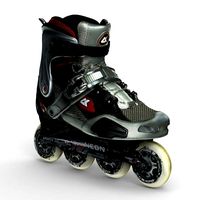

roller skates

...roller skates

3dexport

3d_ocean

$19

roller skate

...can scanned skates skating sport

3d scan of roller skate. the model has been retopologized and made fully compatible with zbrush.