Thingiverse

Davinci Da Vinci 1.0 E3D Carriage and Extruder drop in replacement by nicksears

by Thingiverse

Last crawled date: 3 years ago

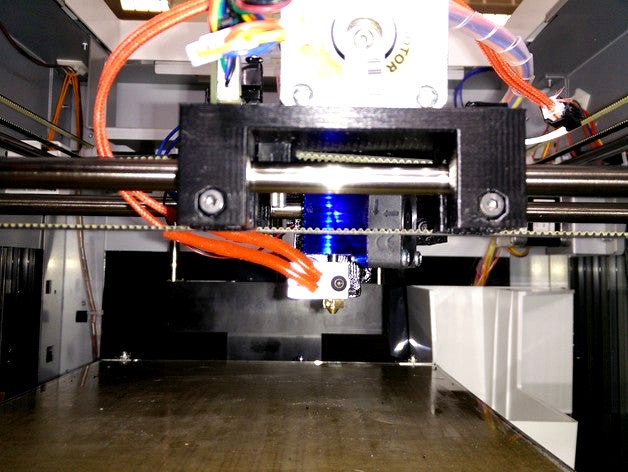

Update August 14th, added the LM8UU version, although I have NOT TESTED it. Also I included a picture showing how the level arm is NOT solid, rather is has a shell of support material that breaks away really easily.

Update, March 10th, 2015: updated minor parts of the assembly and added some final parts (z adapter for the optical switch, pin for the extruder lever arm). Added pictures of it in action. One of the best I think I've ever made. Eveything worked on the first try. Switching from a 40x40mm fan to 30x30mm made it fit much better and interfere less with the frame. Make sure to use a small screw with the z optical switch adapter (or use the minimalist one that just pushes on).

I'd love to hear input! Mines working great. I've printed Taulman Tritan and PCTPE, gold and silver PLA, Polycarbonate (still trying to get better adhesion - best I've gotten is with kapton with abs-juice at 110/280/45 bed/hotend/chamber)

Intro:

I wanted to print PLA (and nylon, PC, and flexible filaments) with my unlocked Davinci (luc's repetier firmware is great!)

I designed a drop in replacement that only needs some M3 hardware, an MK8 extruder gear, a 624 roller bearing, E3Dv6 hotend, and 5V fan (30x30x10 for the E3D itself, or 40x40x10 for print cooling with a permanent 12V power source for the E3D fan).

I made it so you can use the original brass sleeve bearings (I know they're not the greatest - I'm making a version that will use LM8UU's) but this minimizes bought parts.

Just print the carriage, extruder and accessories (belt clip, opto trigger, extruder arm, fan shroud, and fan connectors, board mount - sounds like a lot but it all fits on one plate) and should fit great. The brass sleeves fit well and can be tightened if your tolerances are better than mine.

You'll need to transplant the board from the original extruder - just wire up the fan, heater, thermistor and extruder the same way from the board.

As far as software goes, I'll be adding a version that uses an MK7 gear that should work with the stock extruder calibration, (maybe without any firmware changes!) but for now you'll need luc's repetier firmware with the following changes:

" #define EXT0_STEPS_PER_MM 165"

I've had issues with this and I just put M92 E165 in the start gcode

DO NOT change thermistor type, it is a 104gt-2 i the stock and e3d, but the temp table is custom for their resistor values.

"#define MAXTEMP 305 // to go up to 30"

"#define MAX_DEFECT_TEMPERATURE 325 //increased as well"

And finally you'll need either:

a 5v 30x30x10 fan instead of the e3d 12v fan

or a 5V 40x40x10mm fan for the print cooler

Davinci controls fans with 5v so in the original config, the same 5V just controls the e3d fan. If you want a fan to cool the prints, you'll need a 5v 40x40x10 fan so davinci can control it. You'll also need to change near the beginning of the configuration.h:

" #define REPURPOSE_FAN_TO_COOL_EXTRUSIONS 0 //Setting this to 1 will repurpose the main Extruder cooling fan to be controlled VIA M106/M107 "

Set this to 1 and davinci will control the print cooling fan, but you need to find a permanent power source for the e3d fan (12v for stock or 5v if you got one)/

Update, March 10th, 2015: updated minor parts of the assembly and added some final parts (z adapter for the optical switch, pin for the extruder lever arm). Added pictures of it in action. One of the best I think I've ever made. Eveything worked on the first try. Switching from a 40x40mm fan to 30x30mm made it fit much better and interfere less with the frame. Make sure to use a small screw with the z optical switch adapter (or use the minimalist one that just pushes on).

I'd love to hear input! Mines working great. I've printed Taulman Tritan and PCTPE, gold and silver PLA, Polycarbonate (still trying to get better adhesion - best I've gotten is with kapton with abs-juice at 110/280/45 bed/hotend/chamber)

Intro:

I wanted to print PLA (and nylon, PC, and flexible filaments) with my unlocked Davinci (luc's repetier firmware is great!)

I designed a drop in replacement that only needs some M3 hardware, an MK8 extruder gear, a 624 roller bearing, E3Dv6 hotend, and 5V fan (30x30x10 for the E3D itself, or 40x40x10 for print cooling with a permanent 12V power source for the E3D fan).

I made it so you can use the original brass sleeve bearings (I know they're not the greatest - I'm making a version that will use LM8UU's) but this minimizes bought parts.

Just print the carriage, extruder and accessories (belt clip, opto trigger, extruder arm, fan shroud, and fan connectors, board mount - sounds like a lot but it all fits on one plate) and should fit great. The brass sleeves fit well and can be tightened if your tolerances are better than mine.

You'll need to transplant the board from the original extruder - just wire up the fan, heater, thermistor and extruder the same way from the board.

As far as software goes, I'll be adding a version that uses an MK7 gear that should work with the stock extruder calibration, (maybe without any firmware changes!) but for now you'll need luc's repetier firmware with the following changes:

" #define EXT0_STEPS_PER_MM 165"

I've had issues with this and I just put M92 E165 in the start gcode

DO NOT change thermistor type, it is a 104gt-2 i the stock and e3d, but the temp table is custom for their resistor values.

"#define MAXTEMP 305 // to go up to 30"

"#define MAX_DEFECT_TEMPERATURE 325 //increased as well"

And finally you'll need either:

a 5v 30x30x10 fan instead of the e3d 12v fan

or a 5V 40x40x10mm fan for the print cooler

Davinci controls fans with 5v so in the original config, the same 5V just controls the e3d fan. If you want a fan to cool the prints, you'll need a 5v 40x40x10 fan so davinci can control it. You'll also need to change near the beginning of the configuration.h:

" #define REPURPOSE_FAN_TO_COOL_EXTRUSIONS 0 //Setting this to 1 will repurpose the main Extruder cooling fan to be controlled VIA M106/M107 "

Set this to 1 and davinci will control the print cooling fan, but you need to find a permanent power source for the e3d fan (12v for stock or 5v if you got one)/

Similar models

thingiverse

free

Layer cooling fan duct for DaVinci 1.0A and bouden E3D V6 by Hecot

...it and buy a fan of course :) here is how to change the software: https://github.com/luc-github/repetier-firmware-0.92/issues/152

thingiverse

free

DaVinci 1.0 E3D v6 Fan Shroud by JKHeadley

...raised 2.5mm on the bottom so that it doesn't hit the contact screws on the bed, though i haven't tested the new version.

thingiverse

free

DaVinci Firmware Upgrade (1.1.J to Repetier 0.92 Beta) by djnicolosi3148

...d just a simple cylinder for comparison because each layer gets printed exactly the same which shows z-axis banding very clearly.

thingiverse

free

XYZ Davinci E3D V6 40mm Cooling Fan Shroud by njmerola

...o make the fan functional, i needed to modify the configuration.h file. once i find the instructions i used, i will add the link.

thingiverse

free

Alpha Support for E3D by ebross

...lues at 230 and 40.

the e3d v6 is printing wonderfully, and i was able to print pla, abs, petg and ninja flex with great results.

thingiverse

free

FLSun Cube Part Cooling Fan

... doing it, i recommend you to make sure that thermal_protection_hotends and thermal_protection_bed are enabled in configuration.h

thingiverse

free

E3D V6 Hotend Mount - Single Version - with 40mm Fan - CTC / Makerbot Replicator / Flashforge by swestru

...mply unpluged everything from the second extruder and changed my onboard printer settings and my simplify3d slicer to 1 extruder.

thingiverse

free

XYZ Printing daVinci Jr 1.0 - Stock Hotend Compact Mount with Silent/Quiet Part Cooling Fan by kr15_uk

...tributed across the heatsink.

also part cooling fan outlet is in angle so it doesn't hit hotend itself but only printed part.

thingiverse

free

Swappable E3D v6 holder by rodens

...g radiator and 4010 two turbine fans for blowing the print site.

mirror the "blowing" part in slicer for print two part

thingiverse

free

Ubiquiti USG 40mm fan mount by gunpowder

...move the pcb and flip it over you'll see a few places to take 5v from, otherwise a 12v fan powered from the barrel connector.

Nicksears

thingiverse

free

smiley cube man body no support by nicksears

...pport by nicksears

thingiverse

i made a version of the smiley cube man's body that doesn't need support material.

enjoy!

thingiverse

free

individual buttons for Mmintbox by nicksears

... separate them, so modified the design to cut away the solid flat portion so it's usable as-printed. probably needs supports.

thingiverse

free

nicks peripump peristaltic pump by nicksears

... peripump itself definitely works (with a hand drill) but i'm currently assembling the gear reducer and will test it shortly.

thingiverse

free

McCormick salt or pepper grinder adapter (for drill, etc) by nicksears

...it with most printers for the actual diameter of ~42.75mm. adapted to 1/4" hexagonal bit to work with just about any drill.

thingiverse

free

plantronic voyager edge case by nicksears

...nt, but it allows you to remove easily. will add pictures when i can.

i've provided step and sldprt in case you want to edit.

thingiverse

free

nicks hysteresis calibrator by nicksears

...he file name (ie 0.5, 0.25mm). going in the opposite direction reverses this.

i tested this with a rather thick nozzle, so ymmv.

thingiverse

free

E3D clone M6 thread bowden to direct adapter by nicksears

...quests and i can make one that fits more recessed into the heatsink itself (but this will get complicated to screw it into place.

thingiverse

free

Magic chef replacement ice bucket by nicksears

...ing or rubber washer. if you are going to use the single piece version, i would verify the angle and let me know if it's off.

thingiverse

free

cubex e3d adapter for stock extruder by nicksears

... drawing of the e3d-v6 since it requires a model to post. let me know if you want one, i can ship you one for shipping cost ($7).

thingiverse

free

Nicks linear actuator paste extruder by nicksears

..., and holes for access to tighten the flag bolt - all so you can print two of them and mount them, side by side. (pictures soon).

Davinci

3ddd

$1

Torre DaVinci 03W

...: davinci 03w

dimensions:

730mm x 575mm x h770mmhttp://www.torre.it/products/contract/chairs-armchairs/da-vinci-03-112

3ddd

$1

Torre DaVinci 04W

...l: davinci 04

dimensions:

730mm x 575mm x h855mmhttp://www.torre.it/products/contract/chairs-armchairs/da-vinci-04-112

turbosquid

$9

Davinci Coin gold coin

...alty free 3d model davinci coin gold coin for download as max on turbosquid: 3d models for games, architecture, videos. (1495584)

turbosquid

$5

DaVinci Single Coffee Table

...free 3d model davinci single coffee table for download as max on turbosquid: 3d models for games, architecture, videos. (1540607)

3d_export

$10

Italdesign Davinci Asphalt 9

...at your discretion. instead of textures, blender materials are used, and the color of any part can be changed at your discretion.

3ddd

$1

Cattelan Italia / DaVinci

...75 см

глубина: 75 см

ширина: 140 см

схематичное изображениеhttp://www.ib-gallery.ru/off-line/mebel_file/25949/file.png

3d_export

$7

092 armchair davinci

...t includes four balls with different color materials (gray, brown, light brown, natural wood). on the end there is real plywood))

3d_export

$10

davinci machine

...aterials are logically named<br>the main format is in 3ds max 2009.<br>satisfcation garranteed..<br>thank you !

3ddd

free

Настенная мозаика DaVinci

...ерация turbosmooth), и простые кубики с фаской - 9000 полигонов.

габариты модели, шхвхг: 50см*50см*1,5см

размер ячейки: 2см*2см

3d_export

$29

Cryptex New 3D Model

...cryptex new 3d model 3dexport cryptex davinci da vinci code criptex enigma mystery riddle game device...

Vinci

3d_export

$9

clcok vinci

...clcok vinci

3dexport

clcok vinci

3ddd

$1

willisau vinci chair

...willisau vinci chair

3ddd

willisau , vinci

vinci chair from willisau ag.

design_connected

$13

Vinci chair

...vinci chair

designconnected

willisau vinci chair computer generated 3d model. designed by ballendat, martin.

3ddd

$1

BOVA-комод-vinci

...bova-комод-vinci

3ddd

bova , комод

bova-комод-vinci

3ddd

$1

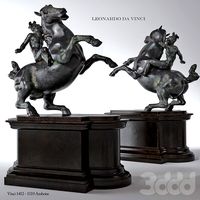

leonardo da vinci

...leonardo da vinci

3ddd

всадник , лошадь

leonardo da vinci

3d_export

$25

a - leonardo da vinci

...a - leonardo da vinci

3dexport

a - leonardo da vinci<br>antiquity

turbosquid

$10

Pouf Vinci

...ty free 3d model pouf vinci for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1507069)

turbosquid

$30

Da Vinci

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$25

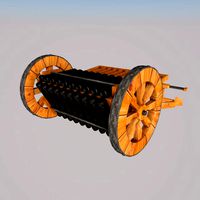

machine- leonardo da vinci

...machine- leonardo da vinci

3dexport

machine- leonardo da vinci

3d_export

$25

mortar - leonardo da vinci

...mortar - leonardo da vinci

3dexport

mortar - leonardo da vinci

E3D

turbosquid

$23

E3D - Google Home

... 3d model e3d - google home for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1192509)

cg_studio

free

e3d model

...e3d model

cgstudio

- e 3d model, royalty free license available, instant download after purchase.

turbosquid

$2

Syringe C4D (E3D Ready)

...lty free 3d model syringe c4d (e3d ready) for download as c4d on turbosquid: 3d models for games, architecture, videos. (1336720)

turbosquid

$12

Microphone USB E3D and C4D

...ree 3d model microphone usb e3d & c4d for download as c4d on turbosquid: 3d models for games, architecture, videos. (1568216)

turbosquid

$29

E3D - OnePlus 6 Black

...model e3d - oneplus 6 black for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1358534)

turbosquid

$29

E3D - Motorola One 2018

...del e3d - motorola one 2018 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1358533)

turbosquid

$29

E3D - Disney MagicBands 2

...l e3d - disney magicbands 2 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1355515)

turbosquid

$29

E3D - Samsung Z4 Smartphone

...e3d - samsung z4 smartphone for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1182179)

turbosquid

$23

E3D - Razer Phone model

...del e3d - razer phone model for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1231207)

turbosquid

$23

E3D - Alcatel Idol 5

... model e3d - alcatel idol 5 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1212799)

Carriage

archibase_planet

free

Carriage

...arriage

archibase planet

perambulator baby carriage pram

carriage n250908 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

free

carriage

...carriage

3dexport

old fashion carriage model, more files here:

turbosquid

$140

Carriage

...urbosquid

royalty free 3d model carriage for download as max on turbosquid: 3d models for games, architecture, videos. (1482052)

turbosquid

$25

Carriage

...urbosquid

royalty free 3d model carriage for download as max on turbosquid: 3d models for games, architecture, videos. (1285944)

3d_export

free

carriage

...carriage

3dexport

game cart

3d_ocean

$15

Barrel Carriage

...ieval oak old transport wheels wine wood

this model contains a barrel and a carriage. it is a medieval type of wood oak carriage.

turbosquid

$40

Carriage

...ty free 3d model carriage for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1290094)

turbosquid

free

Carriage

...yalty free 3d model carriage for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1239157)

3d_export

$5

Medieval carriage

...medieval carriage

3dexport

medieval carriage in fairy style

turbosquid

$58

Carriage

...d model carriage with scene for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1276262)

Extruder

3ddd

$1

Extruded Chair

...extruded chair

3ddd

extruded , tom dixon

inspired by tom dixon extruded chair

turbosquid

$15

Extruded Table

... extruded table for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1634137)

turbosquid

$2

3D Printer Extruder

...d

royalty free 3d model 3d printer extruder for download as on turbosquid: 3d models for games, architecture, videos. (1537359)

turbosquid

$1

Zombie extruded text

...oyalty free 3d model zombie extruded text for download as obj on turbosquid: 3d models for games, architecture, videos. (1322198)

turbosquid

$4

Extruder conical screw

...el extruder conical screw for download as sldpr, ige, and stl on turbosquid: 3d models for games, architecture, videos. (1524433)

turbosquid

$50

3d PRINTER - Extruder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Extruded Table 2

...xtruded table 2 for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1621846)

turbosquid

$10

Maya Extrude Tool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

world earth extrude map

...world earth extrude map

3dexport

3ddd

$1

Simply Elegant Extruded Tree Coffee Table Design

...ble by link studios. the silhouette of a tree is visible at one angle, extruded from the surface to create the support structure.

Drop

3ddd

$1

Писсуар Drop

...писсуар drop

3ddd

писсуар , drop

писсуар drop

3d_ocean

$1

Water Drop

...g drops fresh liquid rain refresh splash water water drop

3ds max 2010, 3ds max 2013 & obj model of water drop. vray 2.30.01

3ddd

$1

Drop, Faber

... , faber , вытяжка

вытяжка drop, компания faber

turbosquid

$5

Drop

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

cartoon blood drop - water drop - medicine drop

...od drop - water drop - medicine drop

3dexport

texture size:small size number of texture:3 texture format: png 1 texture= 1 model

3d_export

free

Nose Drops

...nose drops

3dexport

nose drops)

3ddd

$1

Mirror Drops

...mirror drops

3ddd

mirror drops 530х410 max2011

3ddd

$1

Зеркало Drops

... drops

зеркало drops 53x41

фабрика : kare design

артикул : 74419

материал : glass, aluminium

3ddd

$1

Acid Drop

... curiousa&curiousa

curiousa&curiousa;

acid drophttp://www.curiousa.co.uk/acid-drops

design_connected

$11

Drop Top

...drop top

designconnected

plumen drop top computer generated 3d model.

0

turbosquid

$12

Calligraphic Digit 0 Number 0

...hic digit 0 number 0 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1389318)

3d_export

$6

set-0

...set-0

3dexport

turbosquid

$6

hedge 0

...yalty free 3d model hedge 0 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1450353)

turbosquid

$5

Nuber 0

...oyalty free 3d model nuber 0 for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1564674)

turbosquid

$22

0.jpg

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Steam Locomotive Fowler 4F 0-6-0

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Liquid Number 0

... model liquid number 0 for download as c4d, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1689919)

turbosquid

$45

Dragon360_perspShape_tmp.0.jpg

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Rocks Debris 0

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$18

wood-guardrail-fence 0

...wood-guardrail-fence 0

3dexport

wood-guardrail-fence 0<br>3ds max 2015

Replacement

3d_export

$12

replaceable bristle

...replaceable bristle

3dexport

this is 3d printable replaceable bristle toothbrush.

3d_export

$34

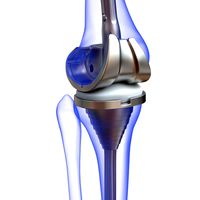

Knee Replacement

...h meets the lower leg. ... during a total knee replacement, the end of the femur bone is removed and replaced with a metal shell.

3d_export

$44

Hip Replacement

...omponents. the damaged femoral head is removed and replaced with a metal stem that is placed into the hollow center of the femur.

turbosquid

$59

Hip replacement

...el hip replacement for download as ma, c4d, lwo, lxo, and obj on turbosquid: 3d models for games, architecture, videos. (1520195)

turbosquid

$10

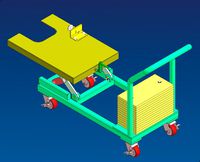

Module replacment station

...alty free 3d model module replacment station for download as on turbosquid: 3d models for games, architecture, videos. (1271271)

3d_export

$8

tool replacement gearbox

...tool replacement gearbox

3dexport

eccentric lifting mechanism, you can process according to available drawings.

turbosquid

$7

Globe Oil Atomizer Replacement Housing

... oil atomizer replacement housing for download as ige and stl on turbosquid: 3d models for games, architecture, videos. (1253839)

turbosquid

free

SLICE Ceramic Scapel (Replaceable Blade)

... (replaceable blade) for download as obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1363525)

3d_export

$19

Knee Replacement Implant

...ntimeter<br>__________________________<br>poly count :<br>polygon count - 217440<br>vertex count - 108776

turbosquid

$19

(Project) Bad odor filtering sytem with support rail and pulley that assure a comfortable gel filter element replacement.

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Da

3ddd

$1

Luce da Vivere

...luce da vivere

3ddd

luce da vivere

luce da vivere mary 387/6+3

3ddd

$1

Luce da Vivere

...luce da vivere

3ddd

luce da vivere

luce da vivere

cristalline 494/12 rosso/cromo

turbosquid

$6

Cabinet DA

...ty free 3d model cabinet da for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1637312)

turbosquid

$6

Bookcase DA

... free 3d model bookcase da for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1639996)

turbosquid

$5

Wardrobe DA

...y free 3d model wardrobe da for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1661117)

turbosquid

$5

Partition DA

... free 3d model partition da for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1640359)

3ddd

$1

Ecstacity_LAMPADA DA TERRA

...ecstacity_lampada da terra

3ddd

ecstacity

торшер ecstacity_lampada da terra

3ddd

$1

leonardo da vinci

...leonardo da vinci

3ddd

всадник , лошадь

leonardo da vinci

turbosquid

$60

DA-ExoticWeapons

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$32

DA-SpikedChainMace

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

1

turbosquid

$69

armchairs(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

ring 1+1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

RING 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

house 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Table 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$59

Formula 1(1)

...lty free 3d model formula 1 for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1567088)

design_connected

$11

No 1

...no 1

designconnected

sibast no 1 computer generated 3d model. designed by sibast, helge.

turbosquid

$2

desert house(1)(1)

...3d model desert house(1)(1) for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1055095)