Thingiverse

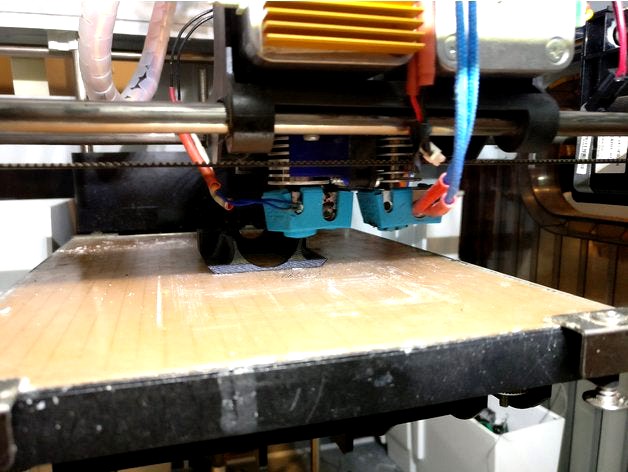

Da Vinci 2.0: Quick! E3d V6 conversion by ebat

by Thingiverse

Last crawled date: 3 years ago

These two small parts (cap and mount) can be used to convert your da vinci 2.0 duo to a single extruder E3d V6 without having to print an entirely carriage.

The cap does not need supports and I chose to print the mount with supports to minimize clean up. I also removed the second stepper motor on the carriage which has reduced weight significantly and has allowed me to print at 80mm/s without resonance in the x or y direction.

In Repetier EEPROM setting, I changed the lowered max z-axis by the difference in height between the original and the new nozzle. There is an optical end-stop sensor for the z-axis which is used to home the z-axis. there is a piece of metal on the bed which trips the end stop. I glued a piece of paper on to this, metal tab, to effectively extend the tab the distance of the which you changed the max z-axis travel. Sorry I don't have any pictures of this at the moment, I'm away from home for the next two weeks. You'll have to poke around your printer settings and take a look at the end stop to figure out what I mean.

also there is a small support in the bottom of the carriage which needs to be cut off to allow room for the cold end fan. The fan is 12v so I chose to run a line from the PSU which is turned on with the printer.

required materials:

about 10m of T-glase or ABS

2x m6x16mm (maybe 20mm?)

2x m6 nuts or nutserts

Version 2 of the mount is untested but should add extra stability to hot end although I haven't seen any need for it. If you test it, please let me know.

I have plans to convert to bowden to decrease weight further. Will update once I find the time.

The cap does not need supports and I chose to print the mount with supports to minimize clean up. I also removed the second stepper motor on the carriage which has reduced weight significantly and has allowed me to print at 80mm/s without resonance in the x or y direction.

In Repetier EEPROM setting, I changed the lowered max z-axis by the difference in height between the original and the new nozzle. There is an optical end-stop sensor for the z-axis which is used to home the z-axis. there is a piece of metal on the bed which trips the end stop. I glued a piece of paper on to this, metal tab, to effectively extend the tab the distance of the which you changed the max z-axis travel. Sorry I don't have any pictures of this at the moment, I'm away from home for the next two weeks. You'll have to poke around your printer settings and take a look at the end stop to figure out what I mean.

also there is a small support in the bottom of the carriage which needs to be cut off to allow room for the cold end fan. The fan is 12v so I chose to run a line from the PSU which is turned on with the printer.

required materials:

about 10m of T-glase or ABS

2x m6x16mm (maybe 20mm?)

2x m6 nuts or nutserts

Version 2 of the mount is untested but should add extra stability to hot end although I haven't seen any need for it. If you test it, please let me know.

I have plans to convert to bowden to decrease weight further. Will update once I find the time.

Similar models

thingiverse

free

Tarantula E3d V6 carriage MGN12H with BLtouch

...heels, so you cant print on full surface, but in future i will do a full mgn12 conversion for the z axis and then it should work.

thingiverse

free

Da Vinci Z-home replacement flag for E3D nozzle by prpickett

...er the z-home position of the da vinci 1.0 printer approximately 20mm.this reduces the chance of crashing into the e3d v6 nozzle.

thingiverse

free

Robo3D E3D LED Ring Mount by SoLongSidekick

...mm led ring mount that attaches to the x axis carriage of the robo3d r1. if you have a print bed fan you won't need supports.

thingiverse

free

E3D V6 2-in-1 fan duct - Remix by ant0ny

....

added clone e3dv6 2-1 which fits on the 24 - 25mm body. 1 is 2mm shorter than the other. doesn't have the holding tabs yet.

thingiverse

free

Dual E3D bowden coldend with 50mm fan cooling print and hotends by Nilz

... the e3d fans and don't want to cool the print, and a version which can hold an inductive sensor as an accurate z-endswitch .

thingiverse

free

HOTEND MOUNT for Airwolf HD2x... Convert to E3D v6 + Volcano by jbswaff

... endstop_support.stl on the y axis rod for the front endstop. this keeps the e3dv6's fans from hitting the belt.

revision 3

thingiverse

free

Reworked BLV MGN AM8 E3D V6 Carriage

... top to attach the x axis belt.

the rest of the parts to mount the fans can be found at https://www.thingiverse.com/thing:2567757

thingiverse

free

X axis carriage by Brennenenenenen

... it also has the 8 holes to mount linear bearings. the second file is also the e3d v6 and is needed to hold the hot end in place.

thingiverse

free

X5S Direct drive mount for Linear Rail by lookupatnight

...d e3d v6 hot end higher than my other designs.

the e3d v6 just clears the bottom of the carriage. this mount is pretty solid!

thingiverse

free

DaVinci E3D v6 dobuble fan carriage. by firecardenal

...ket and glued on its place.

the mk8, mk9, and mk10 motor mount are compatible but be sure to have the correct side filament hole.

Ebat

thingiverse

free

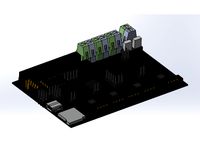

SKR MINI E3 V2.0 by ebat

...skr mini e3 v2.0 by ebat

thingiverse

step is straight from bigtreetech's github. solidworks models were converted from this

thingiverse

free

Tardis USB Case! by ebat

...oth side and glued a small pin in the bottom to keep the usb plug from getting bent in case a triple point bend is applied to it.

thingiverse

free

TR8 trapezoid nut for prusa by ebat

...rances and have not tested this i recommend using a little bit of x and y scaling and testing fit. let me know what works for you

thingiverse

free

Porsche 944 Sunroof Clip Retaining bracket by ebat

...'m too lazy to explain or post a picture. if you broke anything plastic on your sunroof, chances are that this is that piece.

thingiverse

free

Bear Prusa Rod Holder y axis 10mm by ebat

...his is the bear prusa y-axis rod holder opened up to accept a 10mm rod. i used this on my tornado/cr-10 conversion to linear rods

thingiverse

free

Prusa Einsy Base for SKR Mini v2.0 by ebat

...reful of screw head clearance between the bear, you may want to put a piece of electrical tape between it and the board. cheers!

thingiverse

free

CR-10 Heavy Duty E3D V6 - STOCK COOLING FAN MOUNT by ebat

...ket allows you to use the stock cooling fan with the the cr-10 heavy duty mount by chitohttps://www.thingiverse.com/thing:2494642

thingiverse

free

Gauge Vent A4 B5 Audi by ebat

...ternal holes on the small size, so those holes are 20 thous. larger than measured. i included the solid part file if you want it.

thingiverse

free

Da Vinci 2.0/1.0 PLA Heatsink Mod by ebat

... or longevity is an issue (pla is biodegradable).

as for the model of marvin, thingiverse required i added an stl to post this.

Vinci

3d_export

$9

clcok vinci

...clcok vinci

3dexport

clcok vinci

3ddd

$1

willisau vinci chair

...willisau vinci chair

3ddd

willisau , vinci

vinci chair from willisau ag.

design_connected

$13

Vinci chair

...vinci chair

designconnected

willisau vinci chair computer generated 3d model. designed by ballendat, martin.

3ddd

$1

BOVA-комод-vinci

...bova-комод-vinci

3ddd

bova , комод

bova-комод-vinci

3ddd

$1

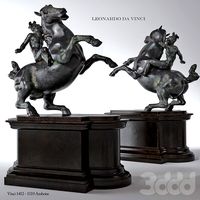

leonardo da vinci

...leonardo da vinci

3ddd

всадник , лошадь

leonardo da vinci

3d_export

$25

a - leonardo da vinci

...a - leonardo da vinci

3dexport

a - leonardo da vinci<br>antiquity

turbosquid

$10

Pouf Vinci

...ty free 3d model pouf vinci for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1507069)

turbosquid

$30

Da Vinci

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$25

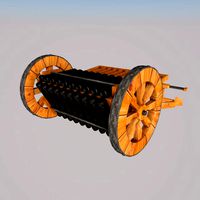

machine- leonardo da vinci

...machine- leonardo da vinci

3dexport

machine- leonardo da vinci

3d_export

$25

mortar - leonardo da vinci

...mortar - leonardo da vinci

3dexport

mortar - leonardo da vinci

E3D

turbosquid

$23

E3D - Google Home

... 3d model e3d - google home for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1192509)

cg_studio

free

e3d model

...e3d model

cgstudio

- e 3d model, royalty free license available, instant download after purchase.

turbosquid

$2

Syringe C4D (E3D Ready)

...lty free 3d model syringe c4d (e3d ready) for download as c4d on turbosquid: 3d models for games, architecture, videos. (1336720)

turbosquid

$12

Microphone USB E3D and C4D

...ree 3d model microphone usb e3d & c4d for download as c4d on turbosquid: 3d models for games, architecture, videos. (1568216)

turbosquid

$29

E3D - OnePlus 6 Black

...model e3d - oneplus 6 black for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1358534)

turbosquid

$29

E3D - Motorola One 2018

...del e3d - motorola one 2018 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1358533)

turbosquid

$29

E3D - Disney MagicBands 2

...l e3d - disney magicbands 2 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1355515)

turbosquid

$29

E3D - Samsung Z4 Smartphone

...e3d - samsung z4 smartphone for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1182179)

turbosquid

$23

E3D - Razer Phone model

...del e3d - razer phone model for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1231207)

turbosquid

$23

E3D - Alcatel Idol 5

... model e3d - alcatel idol 5 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1212799)

V6

3d_export

$100

v6 engine

...engine

3dexport

complete v6 engine modeled on solidworks 2017 along with .stl, .sldprt and .sldasm of all th parts and assembly.

3d_export

$10

V6 engine

... the first v6 engines were designed and produced independently by marmon motor car company, deutz gasmotoren fabrik and delahaye.

3d_export

$35

v6 engine

...s a complete model of a v6 engine containing over 400 components. you can contact me for a video of all the components assembling

3d_export

$10

v6 engine

...v6 engine

3dexport

turbosquid

$25

Bed1001-v6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$22

Chair2-v6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

V6.mb

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$20

V6 engine

...rovided in this package is all the parts in sldprt format and assembly in sldasm format. i can also convert the format on demand.

3ddd

$1

Стол V6

...6" в стиле дизельпанк изготовлен из блока двигателя, 4х поршней и 4х шатунов.

столешница изготовлена из стекла толщиной 8мм.

cg_studio

$199

V6 VVTi3d model

...v6 vvti3d model

cgstudio

.3ds - v6 vvti 3d model, royalty free license available, instant download after purchase.

Conversion

3ddd

$1

Conversation Seat

...шетка

the conversation seat made in englandhttp://www.squintlimited.com/products/the_conversation_seat/gold

+ max 2011

3d_export

$10

Converse 3D Model

...converse 3d model

3dexport

converse shoe pc unix mac

converse 3d model electropainter17075 38067 3dexport

turbosquid

$100

converse-shoe

...quid

royalty free 3d model converse-shoe for download as c4d on turbosquid: 3d models for games, architecture, videos. (1398427)

turbosquid

$10

Conversation Furniture

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$7

Converse Allstars

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$16

Conversation Club Chair

...conversation club chair

designconnected

donghia conversation club chair chairs computer generated 3d model. designed by n/a.

design_connected

$27

Hemicycle Conversation Chair

...rsation chair

designconnected

ligne roset hemicycle conversation chair computer generated 3d model. designed by nigro, philippe.

3d_export

$24

Converse keds 3D Model

...converse keds 3d model

3dexport

converse all star ked shoe clothes sports

converse keds 3d model vermi1ion 26201 3dexport

3ddd

$1

Converse All-Star Shoes

...converse all-star shoes

3ddd

кеды , обувь

converse all-star shoes

design_connected

$18

CONVERSE Jack Purcell Sneakers

...converse jack purcell sneakers

designconnected

converse jack purcell sneakers computer generated 3d model.

Quick

3ddd

$1

Quick-Step / Quadra

...quick-step / quadra

3ddd

quick step

ламинат quick-step, серия quadra. сайт источник -http://www.quick-step.com

3ddd

$1

Quick-Step / Lagune

...quick-step / lagune

3ddd

quick step

ламинат quick-step, серия lagune. сайт источник -http://www.quick-step.com

3ddd

$1

Quick-Step / Classic

...quick-step / classic

3ddd

quick step

ламинат quick-step, серия classic. сайт источник -http://www.quick-step.com

3ddd

$1

Quick-Step / Arte

...quick-step / arte

3ddd

quick step

ламинат quick-step, серия arte. сайт источник -http://www.quick-step.com

3ddd

$1

Quick-Step / Vogue

...quick-step / vogue

3ddd

quick step

ламинат quick-step, серия vogue. сайт источник -http://www.quick-step.com

3ddd

$1

Quick-Step / Rustic

...quick-step / rustic

3ddd

quick step

ламинат quick-step, серия rustic. сайт источник -http://www.quick-step.com

3ddd

$1

Quick-Step / Eligna

...quick-step / eligna

3ddd

quick step

ламинат quick-step, серия eligna. сайт источник -http://www.quick-step.com

turbosquid

$3

Quick Ball

...lty free 3d model quick ball for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1521597)

3ddd

free

Quick-Step / Elite

... ламинат

ламинат quick-step, серия elite. сайт источник -http://www.quick-step.com

turbosquid

$10

Quick Chrome

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

0

turbosquid

$12

Calligraphic Digit 0 Number 0

...hic digit 0 number 0 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1389318)

3d_export

$6

set-0

...set-0

3dexport

turbosquid

$6

hedge 0

...yalty free 3d model hedge 0 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1450353)

turbosquid

$5

Nuber 0

...oyalty free 3d model nuber 0 for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1564674)

turbosquid

$22

0.jpg

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Steam Locomotive Fowler 4F 0-6-0

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Liquid Number 0

... model liquid number 0 for download as c4d, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1689919)

turbosquid

$45

Dragon360_perspShape_tmp.0.jpg

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Rocks Debris 0

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$18

wood-guardrail-fence 0

...wood-guardrail-fence 0

3dexport

wood-guardrail-fence 0<br>3ds max 2015

Da

3ddd

$1

Luce da Vivere

...luce da vivere

3ddd

luce da vivere

luce da vivere mary 387/6+3

3ddd

$1

Luce da Vivere

...luce da vivere

3ddd

luce da vivere

luce da vivere

cristalline 494/12 rosso/cromo

turbosquid

$6

Cabinet DA

...ty free 3d model cabinet da for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1637312)

turbosquid

$6

Bookcase DA

... free 3d model bookcase da for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1639996)

turbosquid

$5

Wardrobe DA

...y free 3d model wardrobe da for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1661117)

turbosquid

$5

Partition DA

... free 3d model partition da for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1640359)

3ddd

$1

Ecstacity_LAMPADA DA TERRA

...ecstacity_lampada da terra

3ddd

ecstacity

торшер ecstacity_lampada da terra

3ddd

$1

leonardo da vinci

...leonardo da vinci

3ddd

всадник , лошадь

leonardo da vinci

turbosquid

$60

DA-ExoticWeapons

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$32

DA-SpikedChainMace

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

2

design_connected

$11

No 2

...no 2

designconnected

sibast no 2 computer generated 3d model. designed by sibast, helge.

turbosquid

$6

Cliff Rock 2-2

...uid

royalty free 3d model cliff rock 2-2 for download as obj on turbosquid: 3d models for games, architecture, videos. (1619161)

turbosquid

$29

Book variation 2 2

...3d model book variation 2 2 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1366868)

turbosquid

$22

Classic baluster (2) (2)

...assic baluster (2) (2) for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1483789)

turbosquid

$99

Smilodon 2 Pose 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Barrel Barricade 2-2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$6

Wall Trophy (2) (2)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Tire label 2 of 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Кровать, 2 тумбочки, 2 светильника

...кровать, 2 тумбочки, 2 светильника

3ddd

кровать, 2 тумбочки, 2 светильника

нормальное качество

формат 3ds max

без текстур

3ddd

free

Кровать, 2 тумбочки, 2 светильника

...кровать, 2 тумбочки, 2 светильника

3ddd

кровать, 2 тумбочки, 2 светильника

нормальное качество

формат 3ds max

без текстур