Thingiverse

Customizable Filament Gland v2.1 by Commod0re

by Thingiverse

Last crawled date: 3 years, 1 month ago

v2.1 update 2020-05-10:

added M10 threaded inner plate variant, for use with PC4-M10 fittings; updated instructions and hardware list

added a couple of stls featuring the M10 inner variant

Storage box filament gland with two holes. This version has a customizable number of filament openings. This version also fixes two problems I had with the earlier version:

It's now much easier and faster to print, requiring no supports whatsoever

Filament moves through it much more easily than the previous version

When you assemble the M5 version, cut a short length of PTFE bowden tube a little shorter than the center post itself as seen in the first picture. This fits between the festo fittings and keeps the filament lined up. This step is not necessary with the P4-M10 version.

Hardware Used:

For the M5 inner plate:

M5-4 push-in fittings (2x per post on each gland) https://www.amazon.com/gp/product/B00RN3KKWA/

for both M5 and M10 variants:

M5-0.8 heat-set inserts (6x per pair for singles, add 2 for each additional filament post) https://www.amazon.com/gp/product/B0754MY5H8/

M10 variant will use 2 fewer of these as they are only needed for the corners

M5-0.8 screws of sufficient length (4x per pair, I used M5x10mm)

Assembly:

Four M5-0.8 heat-set inserts go into the corner pieces for the "outside" pieces.

Two M5-0.8 heat-set inserts go into each filament post, from each end of the M5 inner post. Not needed or possible on the M10 version

Use the drill template piece to drill holes. I used a 5mm twist drill for the corner screw holes, and a 5/8" forstner bit for the center hole. The holes drilled don't need to be the exact size as long as the plate still covers them.

Once the inserts have cooled a bit, insert a short piece of PTFE into each filament post, then thread an M5-4 push-in fitting into each end. The PTFE tube should be short enough to account for how far the fittings thread in so that they do not compress it, as this will cause filament to bind up inside the post instead of sliding through freely.

added M10 threaded inner plate variant, for use with PC4-M10 fittings; updated instructions and hardware list

added a couple of stls featuring the M10 inner variant

Storage box filament gland with two holes. This version has a customizable number of filament openings. This version also fixes two problems I had with the earlier version:

It's now much easier and faster to print, requiring no supports whatsoever

Filament moves through it much more easily than the previous version

When you assemble the M5 version, cut a short length of PTFE bowden tube a little shorter than the center post itself as seen in the first picture. This fits between the festo fittings and keeps the filament lined up. This step is not necessary with the P4-M10 version.

Hardware Used:

For the M5 inner plate:

M5-4 push-in fittings (2x per post on each gland) https://www.amazon.com/gp/product/B00RN3KKWA/

for both M5 and M10 variants:

M5-0.8 heat-set inserts (6x per pair for singles, add 2 for each additional filament post) https://www.amazon.com/gp/product/B0754MY5H8/

M10 variant will use 2 fewer of these as they are only needed for the corners

M5-0.8 screws of sufficient length (4x per pair, I used M5x10mm)

Assembly:

Four M5-0.8 heat-set inserts go into the corner pieces for the "outside" pieces.

Two M5-0.8 heat-set inserts go into each filament post, from each end of the M5 inner post. Not needed or possible on the M10 version

Use the drill template piece to drill holes. I used a 5mm twist drill for the corner screw holes, and a 5/8" forstner bit for the center hole. The holes drilled don't need to be the exact size as long as the plate still covers them.

Once the inserts have cooled a bit, insert a short piece of PTFE into each filament post, then thread an M5-4 push-in fitting into each end. The PTFE tube should be short enough to account for how far the fittings thread in so that they do not compress it, as this will cause filament to bind up inside the post instead of sliding through freely.

Similar models

thingiverse

free

Customizable Filament Gland by Commod0re

...sed m5x10mm)

update 2018-03-29: added a version with just one filament opening

update 2018-07-11: uploaded a revised version here

thingiverse

free

M6 Extruder PTFE Tube Insert by PhilKloppers

...in the open area of my extruder.

the bolt piece was created using a customized version of http://www.thingiverse.com/thing:193647

thingiverse

free

Drybox Filament Pass-Through

...

any comments and suggestions for improvements appreciated ;-)

feel free to remix, fusion 360 files are included in the download.

thingiverse

free

Enclosure filament guide PTFE by climber4fun

...at you can insert the 4mm od ptfe tube to avoid friktion.

enclosure: < 20mm

hole to drill: 13mm

pfte tube: 4mm od

fitting: m10

thingiverse

free

Small improvements

...tting was loose

after printing the hole for filament between ptfe tube and fitting was too small

no option for securing the cable

thingiverse

free

Filament Guide for Ender 2 by Poliflex

...or ender 2 by poliflex

thingiverse

clip-on - no drilling to any metal parts required. insert a short piece of ptfe hose (od 4mm)

thingiverse

free

Filament Filter (LACK) by cody3D

...to screw filament filter cover over the filament filter base

use a cotten ball or whatever you want as the filter inside the base

thingiverse

free

IKEA Stuva filament guide with PTFE tube by Garantiefall

...ptfe tube.

the screwholes are 32mm apart (center to center), so you can mount it on your stuva without drilling additional holes.

thingiverse

free

C-Beam Belt Clamp by makerparts

...mhttps://makerparts.ca/products/brass-threaded-inserts?variant=19933782468

uses two m5 nylock nuts

4 x 15mm m5 low profile screws

thingiverse

free

Sunlu FilaDryer PTFE Connector by fatmanl

...10 ptfe tube connector on the top hole.

the thread is tight, it is better to use wrench for thread tapping before installation.

Commod0Re

thingiverse

free

Stackable Battery Holders - Flush Labels for Multi Extrusion by Commod0re

...ly printed in place using multiple extruders. these are intended to be printed as a component part with the original cover parts.

thingiverse

free

Customizable Filament Gland by Commod0re

...sed m5x10mm)

update 2018-03-29: added a version with just one filament opening

update 2018-07-11: uploaded a revised version here

thingiverse

free

Experimental Interlocking Shoerack by Commod0re

...inting even longer...

the clips, at least, print ultra fast. each hexagon needs 18 clips, and that takes 24 minutes for my mk2.5.

thingiverse

free

Filament Straightener for ESteps Calibration (1.75mm) by Commod0re

...egative sign.

now you can proceed with calculations or guess-and-check to dial in until your esteps are as accurate as you like!

Gland

3d_export

$29

Thyroid Gland 3D Model

...thyroid gland 3d model

3dexport

thyroid gland human anatomy body parts organ

thyroid gland 3d model ghaida85s 89874 3dexport

turbosquid

$190

Adrenal gland gross microscopic

...d model adrenal gland gross microscopic for download as blend on turbosquid: 3d models for games, architecture, videos. (1393637)

3d_export

$50

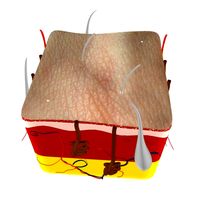

Skin 3D Model

...model 3dexport skin section hairs hair roots sebaceous gland gland perspiratory receptors nerve blood vessel follicle follicles cutaneous sweat...

3d_export

$14

Penis 3D Model

...penis 3d model 3dexport male penis body genital gland testes testicle ureter low penis 3d model mohammadmax 67962...

3d_export

$12

Human Skin 3D Model

...cutaneous receptors hair medical fur lab science section sweat gland teaching membrane dermal skin fibers sensory human skin 3d...

3d_export

$39

Male Testis 3D Model

...maya people lwo human anatomy testis penis testicles generative gland male testis 3d model download .c4d .max .obj .fbx...

3d_export

$49

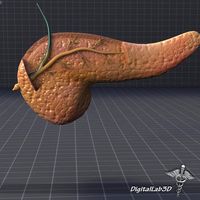

Pancreas External 3D Model

...medical 3ds max maya internal organs torso endocrine system gland organ pancreas external 3d model download .c4d .max .obj...

cg_studio

$39

Male Testis3d model

...maya people lwo human anatomy testis penis testicles generative gland .xsi .obj .max .ma .lxo .lwo .fbx .c4d .3ds...

3d_export

$79

Pancreas Anatomy 3D Model

...medical 3ds max maya internal organs torso endocrine system gland organ characters cancer pancreas anatomy 3d model download .c4d...

cg_studio

$79

Pancreas Anatomy3d model

...medical 3ds max maya internal organs torso endocrine system gland organ characters cancer .fbx .c4d .3ds .xsi .x .obj...

Customizable

3d_export

$10

customizable sd port

...customizable sd port

3dexport

customizable sd port

turbosquid

$99

Customizable character

...alty free 3d model customizable character for download as max on turbosquid: 3d models for games, architecture, videos. (1152525)

turbosquid

$1

Customizable Mug

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Customizable Spider Mech

... free 3d model customizable spider mech for download as blend on turbosquid: 3d models for games, architecture, videos. (1462055)

turbosquid

$20

Customizable Egyptian Pillar

...zable egyptian pillar for download as ma, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1307376)

turbosquid

$75

Fully Customizable Hospital

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Customizable Caste Pieces

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Customizable Tea Cup

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Water Bottle(Customizeable)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$49

Book customizable 3D Model

...3dexport

book booshelf novel teach library learn read pages cover fairy tales

book customizable 3d model guitargoa 74240 3dexport

V2

3d_export

free

Lamp v2

...lamp v2

3dexport

lamp v2 with solar panel

3d_export

$5

hammerhead v2

...hammerhead v2

3dexport

razer hammerhead v2 headphones, modeled in cinema 4d, render in corona

3d_export

$5

manometer v2

...manometer v2

3dexport

3d_export

$5

potato v2

...potato v2

3dexport

turbosquid

$52

Lifebuoys v2

...squid

royalty free 3d model lifebuoys v2 for download as fbx on turbosquid: 3d models for games, architecture, videos. (1560870)

turbosquid

$2

Mask v2

...turbosquid

royalty free 3d model mask v2 for download as stl on turbosquid: 3d models for games, architecture, videos. (1527741)

turbosquid

free

Flashlight V2

...d

free 3d model flashlight v2 for download as , obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1663559)

turbosquid

$29

Thanos v2

...

royalty free 3d model thanos v2 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1651077)

turbosquid

$29

Titan v2

...d

royalty free 3d model titan v2 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1540228)

turbosquid

$29

Frieza v2

...

royalty free 3d model frieza v2 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1701238)

Filament

3ddd

$1

Filament Cage

...filament cage

3ddd

лофт , filament cage

модель бра, делалась по фото!

turbosquid

$3

FILAMENT COUNTER

...d

royalty free 3d model filament counter for download as stl on turbosquid: 3d models for games, architecture, videos. (1563049)

3d_export

$5

Filament lamp 3D Model

...filament lamp 3d model

3dexport

filament lamp 3d model kevin 54161 3dexport

3d_export

$5

Filament bulb candle 3D Model

...filament bulb candle 3d model

3dexport

filament bulb-candle

filament bulb candle 3d model kevin 54163 3dexport

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3ddd

$1

Factory filament metal shade

...factory filament metal shade

3ddd

restoration hardware

restoration hardware. 20th c. factory filament metal shade.

1

turbosquid

$69

armchairs(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

ring 1+1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

RING 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

house 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Table 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$59

Formula 1(1)

...lty free 3d model formula 1 for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1567088)

design_connected

$11

No 1

...no 1

designconnected

sibast no 1 computer generated 3d model. designed by sibast, helge.

turbosquid

$2

desert house(1)(1)

...3d model desert house(1)(1) for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1055095)