GrabCAD

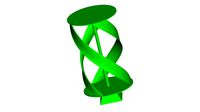

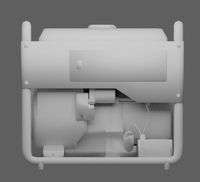

Cryo Aeolipile Turbine Generator

by GrabCAD

Last crawled date: 1 year, 7 months ago

***Liability disclaimer*** This device has not been tested, it is a potentially dangerous experiment as it deals with high rotational velocity, liquid nitrogen, and electricity in the event the stator is built. User/maker assumes all liability and responsibility when building this experiment. License: creative commons, attribution, Share Alike

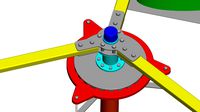

This is my design based on the Heron steam engine from the 1st century AD, commonly known as an aeolipile. I designed this to gauge the potential feasibility for this device or a similar one that is powered from the boiling of room temp gas to be used for extending the range of electric vehicles, and flight time of electric aircraft, or even potentially, be the main power source in one of those systems. Using merely the transitioning of the liquid to gas state could provide the possibility of a cheap, renewable, sustainable, and clean method of energy production. Instead of using boiling water it uses liquid nitrogen or other atmospheric gases that are put in a liquid state and boil at room temp. It seems highly energetic, (and potentially dangerous) based on these reference videos of people putting liquid nitrogen in an aeolipile, https://www.youtube.com/watch?v=ok7V5j3DyQo&t=18s , https://www.youtube.com/shorts/1VR1JYuqDNE . I have not tested the device yet, but do plan on it in the future, I will update when I have performed testing, hopefully others will test as well! It should be noted that it would be wise that the rotor be made of steel that is rated for cryogenic temps, as I think this would be the safest option for the rotor's material which will contain the LN2 or other cryo material. Also the nozzle diameters and length could be altered to control the speed of rotation as well as flaps for drag to reduce rpm. I need to come up with a stator coil configuration that is optimal as well. Note bearing size for this model is OD 50mm, ID 30mm. The top and bottom rotor need to be threaded as well.

Some concept ideas to improve the device and make it potentially super conduct, but have not figured out how to implement in the design mechanically yet. It may be possible to make it super conduct if the stator is made out of a high temp superconducting wire such as, a wire made with Yttrium barium copper oxide (YBCO), or using carbon nano-tube wire with liquid helium in the chamber, but this would require the YBCO or CNT based stator to be in a fixed postion inside the spinning rotor which holds your liquid gas.

This is my design based on the Heron steam engine from the 1st century AD, commonly known as an aeolipile. I designed this to gauge the potential feasibility for this device or a similar one that is powered from the boiling of room temp gas to be used for extending the range of electric vehicles, and flight time of electric aircraft, or even potentially, be the main power source in one of those systems. Using merely the transitioning of the liquid to gas state could provide the possibility of a cheap, renewable, sustainable, and clean method of energy production. Instead of using boiling water it uses liquid nitrogen or other atmospheric gases that are put in a liquid state and boil at room temp. It seems highly energetic, (and potentially dangerous) based on these reference videos of people putting liquid nitrogen in an aeolipile, https://www.youtube.com/watch?v=ok7V5j3DyQo&t=18s , https://www.youtube.com/shorts/1VR1JYuqDNE . I have not tested the device yet, but do plan on it in the future, I will update when I have performed testing, hopefully others will test as well! It should be noted that it would be wise that the rotor be made of steel that is rated for cryogenic temps, as I think this would be the safest option for the rotor's material which will contain the LN2 or other cryo material. Also the nozzle diameters and length could be altered to control the speed of rotation as well as flaps for drag to reduce rpm. I need to come up with a stator coil configuration that is optimal as well. Note bearing size for this model is OD 50mm, ID 30mm. The top and bottom rotor need to be threaded as well.

Some concept ideas to improve the device and make it potentially super conduct, but have not figured out how to implement in the design mechanically yet. It may be possible to make it super conduct if the stator is made out of a high temp superconducting wire such as, a wire made with Yttrium barium copper oxide (YBCO), or using carbon nano-tube wire with liquid helium in the chamber, but this would require the YBCO or CNT based stator to be in a fixed postion inside the spinning rotor which holds your liquid gas.

Similar models

grabcad

free

Cryo Aeolipile Turbine Generator *updated with .stp file available*

...gauge the potential feasibility for this device or a similar one that is powered from the boiling of room...

grabcad

free

Cryo Aeolipile Tesla Turbojet **creative commons-attribution-share alike**

...unner motor 3d model was used from this creator linked here : https://grabcad.com/library/mad-components-m50c35-brushless-motor-1

grabcad

free

Cryo Aeolipile Tesla Turbojet **Updated!!**

...unner motor 3d model was used from this creator linked here : https://grabcad.com/library/mad-components-m50c35-brushless-motor-1

grabcad

free

NITROGEN PRESSURE REGULATOR SUNLIGHT

...as from a pressurized tank. it is typically used to regulate the pressure of nitrogen gas in a system, such as an air compressor.

3dwarehouse

free

Cryo Therapy

... closely after real cryo therapy (nitrogen) machine for a local gym. i hope you enjoy and find this useful. (www.danweirauch.com)

grabcad

free

INERT GAS SYSTEM

...warming potential.

ig01 - 100% argon

ig100 - 100% nitrogen

ig55 - 50% argon+ 50% nitrogen

ig541- 52% nitrogen+ 40% argon+ 8% co2

grabcad

free

Full scale Engine Liquid Nitrogen Powered Car

...otice them.

information on the liquid nitrogen car project:

gofundme: gofundme.com/f/environmentally-friendly-liquid-nitrogen-car

grabcad

free

Simplified Electric Motor

...simplified electric motor

grabcad

simplified electric motor containing a stator, rotor and shield.

grabcad

free

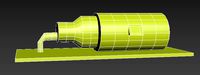

Gas Turbine Engine

...gas turbine engine

grabcad

a model of a gas turbine including a fan, rotor and stator blades and a shaft

cg_trader

$59

Electric Motor Rotor Stator

...electric motor rotor stator

cg trader

high quality polygonal model

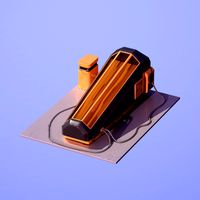

Aeolipile

thingiverse

free

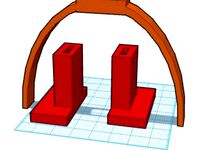

soda can aeolipile stand by ari11235

.... edit it online https://tinkercad.com/things/7kwkcndiyr1

more info about the aeolipile: http://en.wikipedia.org/wiki/aeolipile

grabcad

free

aeolipile

...he central water container is heated. torque is produced by steam jets exiting the turbine, much like a tip jet or rocket engine.

grabcad

free

Cryo Aeolipile Tesla Turbojet **Updated!!**

...unner motor 3d model was used from this creator linked here : https://grabcad.com/library/mad-components-m50c35-brushless-motor-1

grabcad

free

Cryo Aeolipile Tesla Turbojet **creative commons-attribution-share alike**

...unner motor 3d model was used from this creator linked here : https://grabcad.com/library/mad-components-m50c35-brushless-motor-1

grabcad

free

Cryo Aeolipile Turbine Generator *updated with .stp file available*

... postion inside the spinning rotor which holds your liquid gas. something like this could ease the reliance on demand for li-ion.

3dwarehouse

free

Aeolipile Engine by John

...otate). almost works without any joints except plain hinges. sketchyphysics 3 #aeolipile #egyptian #engine #sketchyphysics #steam

3dwarehouse

free

Aeolipile

... perpendiculaires à l’axe laissent sortir la vapeur qui, par propulsion, fait tourner la sphère #chaudiére #eau #rotation #vapeur

3dwarehouse

free

Roman Aeolipile Airship

...ze #airship #roman #aircraft #ancient_times credits: isaac r. conner f. hakan özerdem john t.arkadiusz chris m. yeazel changjiang

Cryo

turbosquid

$50

Cryo Pod

...bosquid

royalty free 3d model cryo pod for download as blend on turbosquid: 3d models for games, architecture, videos. (1467032)

3d_ocean

$5

Cryo Tube

...cifi design. this model is low poly triangles, and ready for most game engines. textures is created using photoshop, and has a...

turbosquid

$20

sci-fi cryo pod

...ree 3d model sci-fi cryo pod for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1234174)

turbosquid

$79

Cryo Tank Madina 900

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

SCI-FI CRYO-TUBE.lwo

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$14

Sci Fi Chamber Cryo #5

...odel sci fi chamber cryo #5 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1505349)

turbosquid

$14

Sci Fi Chamber Cryo #4

...odel sci fi chamber cryo #4 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1505346)

turbosquid

$14

Sci Fi Chamber Cryo #2

...odel sci fi chamber cryo #2 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1505250)

3d_export

$8

Sci Fi Cryo Pod 3D Model

... freezing frozen suspention

sci fi cryo pod 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl gajatix 108691 3dexport

3d_export

$15

cryo hilichurl - genshin impact

...hilichurl - genshin impact

3dexport

render by vray 5 format includes .max .3ds .obj .fbx .mtl .stl polys : 40.918 verts : 24.515

Turbine

3d_export

$5

turbine

...turbine

3dexport

it is a turbine to use it in some spaceship

3d_export

$5

turbine

...turbine

3dexport

turbine, with animation included, more texture of it

3d_ocean

$4

Wind Turbine

...n

and render setup turbine wind

wind turbine, modeled with cinema4d r13 , render setup and textured, custom logo for wind turbine

turbosquid

$1

Turbine

...turbosquid

royalty free 3d model turbine for download as ige on turbosquid: 3d models for games, architecture, videos. (1385242)

3d_export

$40

wind turbine

...wind turbine

3dexport

wind turbine

3d_export

$40

wind turbine

...wind turbine

3dexport

wind turbine

3d_export

$40

wind turbine

...wind turbine

3dexport

wind turbine

3d_export

$40

wind turbine

...wind turbine

3dexport

wind turbine

3d_export

$40

wind turbine

...wind turbine

3dexport

wind turbine

3d_export

$40

wind turbine

...wind turbine

3dexport

wind turbine

Generator

3d_export

$17

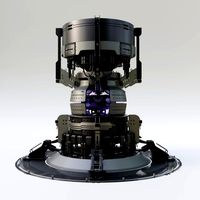

Generator

...generator

3dexport

generator

archibase_planet

free

Generator

...base planet

generator electric generator

generator electric n300715 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

design_connected

$20

Generation

...generation

designconnected

knoll generation computer generated 3d model. designed by formway design.

3d_export

$8

generator

...generator

3dexport

generator - obj, 3ds, fbx.

3d_export

$7

generator

...generator

3dexport

generator extures 4k resolution, basecolor -normal -metallic -ao-roughness-height tris:3084

turbosquid

free

generator

...rator

turbosquid

free 3d model generator for download as max on turbosquid: 3d models for games, architecture, videos. (1492909)

3ddd

$1

general

...general

3ddd

генерал

turbosquid

$99

generator

...urbosquid

royalty free 3d model generator for download as ma on turbosquid: 3d models for games, architecture, videos. (1514125)

turbosquid

$20

Generator

...rbosquid

royalty free 3d model generator for download as max on turbosquid: 3d models for games, architecture, videos. (1244841)

turbosquid

$2

Generator

...rbosquid

royalty free 3d model generator for download as fbx on turbosquid: 3d models for games, architecture, videos. (1245541)