Thingiverse

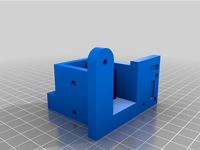

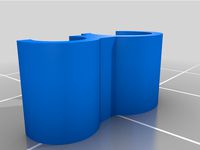

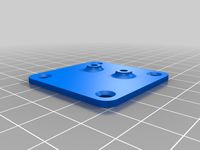

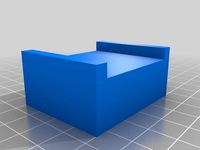

CR10 CoreXY Conversion by jvinraviv

by Thingiverse

Last crawled date: 2 years, 10 months ago

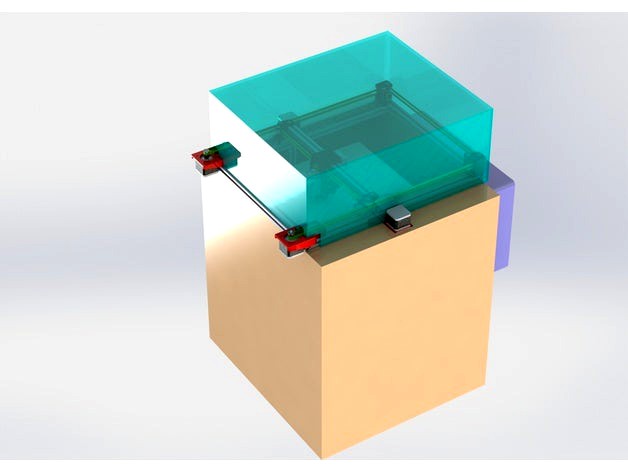

This is still a work in progress - Right now it's just CAD and a collection of printed and printer parts. Not a how to - this is just to document what I did

Currently at v0.3

This project is an answer to a question I had. If you have a CR-10 and you wanted to convert it to a CoreXY, how would you do that?

TL-DR -> It works! (and it's pretty fast too!)

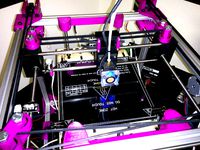

Overall this is working very well so far. I'm very happy with the resulting design and the print quality is really good. I still need to update some of the enclosure parameters but the mechanical design is fairly solid.

Some design wants:

1) Good printing Quality

2) Enclosure for ABS. Prefer working over 70°C

3) Move motors and electronics outside of enclosure

4) Use as much of my existing printer frame as I can

That being said, my printer was already highly modified. Here's a list of modifications that are going to be needed over the original CR10

1) Linear rails (MGN12: 4x450mm, 1x330mm)

2) Hemera Direct Drive Extruder with Volcano (modified Hemera to rotate motor)

3) BLTouch (v3.1)

4) Keenovo heated bed (mains powered, controlled via SSRI)

5) Klipper running on RPI 3B+

6) BigTreeTech SKR Mini E3 V2

7) 380x260x105mm Electronics Enclosure with fuse.

Resulting printer has a build volume of 250x300x400.

Solidworks source file included - I'll add a STEP assembly soon.

I really welcome input. Please let me know if you have any suggestions.

Currently at v0.3

This project is an answer to a question I had. If you have a CR-10 and you wanted to convert it to a CoreXY, how would you do that?

TL-DR -> It works! (and it's pretty fast too!)

Overall this is working very well so far. I'm very happy with the resulting design and the print quality is really good. I still need to update some of the enclosure parameters but the mechanical design is fairly solid.

Some design wants:

1) Good printing Quality

2) Enclosure for ABS. Prefer working over 70°C

3) Move motors and electronics outside of enclosure

4) Use as much of my existing printer frame as I can

That being said, my printer was already highly modified. Here's a list of modifications that are going to be needed over the original CR10

1) Linear rails (MGN12: 4x450mm, 1x330mm)

2) Hemera Direct Drive Extruder with Volcano (modified Hemera to rotate motor)

3) BLTouch (v3.1)

4) Keenovo heated bed (mains powered, controlled via SSRI)

5) Klipper running on RPI 3B+

6) BigTreeTech SKR Mini E3 V2

7) 380x260x105mm Electronics Enclosure with fuse.

Resulting printer has a build volume of 250x300x400.

Solidworks source file included - I'll add a STEP assembly soon.

I really welcome input. Please let me know if you have any suggestions.

Similar models

grabcad

free

3D Printer Enclosure

...ult and how it works. i hope you'll find it useful and will help you with your design.

the model fits the creality cr10 too.

thingiverse

free

Printer Enclosure with all print files by jjpowelly

...gineer/design things that way. and all my designs are built directly around these constraints.

thank you for visiting my page!

thingiverse

free

Mini CoreXY 3D Printer by Bobbyofna

...featured my build that aren't specific to this design are...

-- bondtech extruder

-- 0.9 deg x & y nema 17 stepper motors

thingiverse

free

Cooling Fan Spacer for A6 with lights by Kingmiwok

...39;t want to completely undo the loom and remove the fan from the printer, so that's how it had to be. still, well worth it.

thingiverse

free

Electronics enclosure

...electronics enclosure

thingiverse

a box that i plan to use for some of my electronics - still work in progress.

thingiverse

free

CR10s Pro Support Leg by Squidknacker

... probably good for the cr10 and ender 3 - or any printer.

this also free's up space underneath for tools etc etc if desired.

grabcad

free

Infinite Z Axis 3D Printer

...s could be very large prints from a small and cheap printer.

uploading files in case anyone wants to improve the concept/design.

thingiverse

free

Electronics platform for Prusa Mendel by jman

...de, or the right. i've uploaded the lhs version because that is the end with the x-axis motor. you obviously could have both!

thingiverse

free

CLIP TO BED CR10S by daysena

... easy put on and take off of bed. i hope that you enjoy!

my 3d printer is a cr10s and it's works good.

intern space = 7,5mm

thingiverse

free

CoreXY 3D Printer by HACKERPHIL

...rinter. still in progress. do not print it. the mounting for the stepper motor is only for uploading this project to thingiverse.

Jvinraviv

thingiverse

free

MGN12 to 2020 and 2040 alignment tool by jvinraviv

...giverse

alignment tools to make mounting mgn12 rails to 2020 and 2040 extrusion dead simple.

(just remember to print at least 2)

thingiverse

free

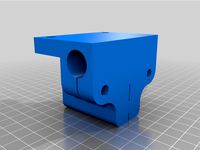

Creality Hemera Mount with BLTouch by jvinraviv

... to onshape part:https://cad.onshape.com/documents/2352fc472ae4643bed7a92a9/w/1d65b4d34fcf65c207b10ddb/e/8207dfc686111043660cf406

Corexy

thingiverse

free

CoreXY by Kaz_tech

...corexy by kaz_tech

thingiverse

this is the model of corexy platform. i separately put the parts on this place.

thingiverse

free

corexy plotter by tjwan

...corexy plotter by tjwan

thingiverse

parts for corexy mill inspired by http://der-frickler.net/technik/corexyportal

thingiverse

free

ScribbleJ CoreXY Beta by ScribbleJ

...j/corexy-v1https://github.com/scribblej/corexy-v1#corexy-beta

full gallery of development photos here: http://imgur.com/a/donun

thingiverse

free

CoreXY Emblem by emkajot

...by emkajot

thingiverse

an emblem for your corexy printer.

size: 100mm x 38mm x 2mm.

update: added a version with a proper mount.

thingiverse

free

SolidCore CoreXY Carriage by shanehooper

...olidcore 3d printer. this design could be used in other corexy 3d printers.

also see:https://3ddistributed.com/corexy-3d-printer/

thingiverse

free

CoreXY 3D Printer Model by ReginaFabricam

...bricam

thingiverse

this is an original design of a corexy printer.https://www.tinkercad.com/things/jggr9qk4s4p-3d-printer-corexy

thingiverse

free

coreXY Upper structure Left

...corexy upper structure left

thingiverse

my customized corexy 3d printer upper left parts

thingiverse

free

CoreXY by frankie

...ing machines, etc. the design is described in greater detail at http://www.corexy.com . a video is at http://vimeo.com/40914530 .

thingiverse

free

Endstop block for CoreXY carriage by svkeulen

...endstop block for corexy carriage by svkeulen

thingiverse

endstop for corexy carriage

thingiverse

free

X carriage for the CoreXY MGN12 by hackerbijay

...x carriage for the corexy mgn12 by hackerbijay

thingiverse

x carriage for the corexy frame

Cr10

3d_export

$21

Hall tree and Clothing Rack CR10

... real object. 3. lights and cameras are included in the scenes renders using vray * renders are made in 3ds max 2018 using vray 5

thingiverse

free

Clips for Ender 3, CR10, CR10S

.... maybe others, but only been tested with these.

these clips makes a tight fit, so that the cable and bowden tube stays in place.

thingiverse

free

X-axis endstop offset for cr10 cr10s Ender 3

...x-axis endstop offset for cr10 cr10s ender 3

thingiverse

x-axis endstop offset for cr10 cr10s ender 3

thingiverse

free

Filament Sensor CR10

...or cr10

thingiverse

remix of the sensor with fixation in order to face directly the extruder and ptfe tube

cr10, cr10s ender3...

thingiverse

free

Fan V4 CR10/CR10S Ender3 Versione 4 by creativesolutions-lab

...fan v4 cr10/cr10s ender3 versione 4 by creativesolutions-lab

thingiverse

fan v4 cr10/cr10s versione 4

thingiverse

free

CR10 Feet by Leighton417

...cr10 feet by leighton417

thingiverse

this is a cr10 feet for people who have short table width.

thingiverse

free

Dremel Attachment for CR10, Ender 3, Cr10s by Conn22_43

...verse

a bracket to hold a dremel onto any ender 3, cr10 bracket. i printed it in petg, but it can be made in any rigid material.

thingiverse

free

CR10S-Plus Hotend by scorpio_man30ro

...cr10s-plus hotend by scorpio_man30ro

thingiverse

cr10s-plus hotend

thingiverse

free

Leveling knob CR10 by JMJacques

...leveling knob cr10 by jmjacques

thingiverse

leveling knob cr10

thingiverse

free

Soporte Superior sensor filamento CR10 v2 - CR10 v3 by Guimir

...3 by guimir

thingiverse

soporte sensor de filamento guia superiror tipo cr10 v3 para convertir la cr10 v2 en extrusión directa.

Conversion

3ddd

$1

Conversation Seat

...шетка

the conversation seat made in englandhttp://www.squintlimited.com/products/the_conversation_seat/gold

+ max 2011

3d_export

$10

Converse 3D Model

...converse 3d model

3dexport

converse shoe pc unix mac

converse 3d model electropainter17075 38067 3dexport

turbosquid

$100

converse-shoe

...quid

royalty free 3d model converse-shoe for download as c4d on turbosquid: 3d models for games, architecture, videos. (1398427)

turbosquid

$10

Conversation Furniture

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$7

Converse Allstars

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$16

Conversation Club Chair

...conversation club chair

designconnected

donghia conversation club chair chairs computer generated 3d model. designed by n/a.

design_connected

$27

Hemicycle Conversation Chair

...rsation chair

designconnected

ligne roset hemicycle conversation chair computer generated 3d model. designed by nigro, philippe.

3d_export

$24

Converse keds 3D Model

...converse keds 3d model

3dexport

converse all star ked shoe clothes sports

converse keds 3d model vermi1ion 26201 3dexport

3ddd

$1

Converse All-Star Shoes

...converse all-star shoes

3ddd

кеды , обувь

converse all-star shoes

design_connected

$18

CONVERSE Jack Purcell Sneakers

...converse jack purcell sneakers

designconnected

converse jack purcell sneakers computer generated 3d model.