Thingiverse

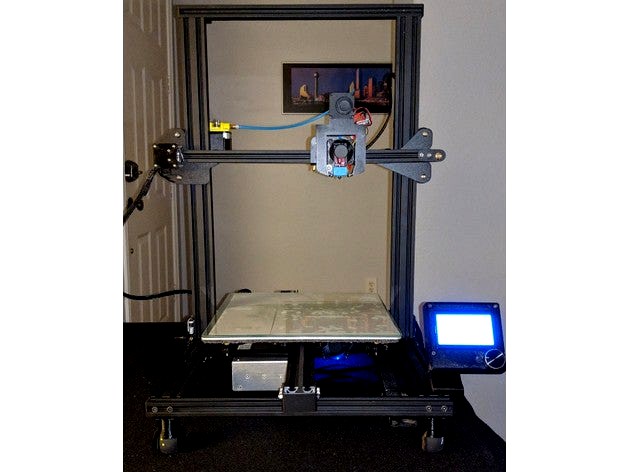

CR10 All-In-One by Jan_P

by Thingiverse

Last crawled date: 3 years ago

UPDATE 21. Sep 2018

I love how this is turning into a team effort.

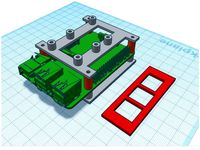

Janis Rocans was so kind as to share his update to the electronics cover that fit the newer boards for the 10S. He also included a picture and the actual Fusion file as well.

He also has a very interesting case/stand for a raspberry PI with 5 inch touch screen. Check it out here

UPDATE 16. Sep 2018

Many thanks to Scott Lahteine for remixing and sharing parts to support the 10S display. Check out his other models here.

Scott has some really interesting designs, and great updates to both the Creality and Prusa I3 printers.

NOTE It's been reported that my design may not fit newer CR10 control boards and displayes, but is reported to work with CR10 mini.

See comments for feedback.

To that end, I've added the Fusion360 design files, so that you can update and modify the design to fit your specific CR10 model.

Inspired by https://www.thingiverse.com/thing:2747280, I set out to make my own version of integrating the control box electronics and power supply.

This kit includes:

remodeled feet with integrated power connector and mount for squash ball for vibration dampening

mounting plate for power supply and mosfet with cooling fan

mounting plate for Melzi control board with integrated wire management and cooling fan

mount for navigator plugs from the stock wire harness

SD card slot moved to the front of the printer just below the control panel, and features a full size SD Card Reader, readily available from Amazon.

case and mount for the control display, and new display cable from Amazon

(update April 1, 2018)

Added STL for spool holder.

(update April 13, 2018)

Adding cover plate for the remaining area of the printer, which includes:

a cover plate with integrated mount for power supply

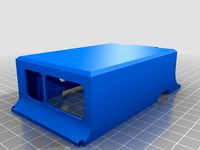

a cover plate for mounting an Raspberry PI

blank cover plate to cover the remaining area

Total cost of conversion is about $20 plus filament.

Original wires are used except for wires from the switch and power receptacle to the power supply. The ribbon cable to the display was also replaced. I re-purposed the original connectors from the ribbon cable, simply transferred them over to a new and longer ribbon cable.

You may need to lengthen the wires to the fans as well.

The stock wire harness that originally connected the control box to the printer is unchanged. The extra length of some of the wires are managed by the integrated wire management loops below the Melzi board.

The Melzi board is raised off the mounting plate allowing routing of wires underneath the Melzi board. Making a cleaner looking implementation, and free airflow over the stepper drivers.

I designed the cover plates to primary use M3 hardware for mounting the boards, and M5 for mounting the plates to the extrusion.

M3 x 8 for the mosfet

M3 x 12 for the control board

M3 x 10 for the raspberry PI (yes, I enlarged the M2.5 holes in Raspberry PI to M3)

M5 x 10 for mounting the cover plates to the extrusion

The end product is a nice, clean looking, and fully integrated printer. Gone is the umbilical cord, and the clunky control box.

This change could expose live mains voltage wires and terminals.

While the leg with integrated power connections have some shielding, it will not prevent users from reaching and touching wire terminals.

Should someone reach underneath the printer, it is conceivable that they could access live mains voltage terminals.

It is recommended to take additional safety measures.

I love how this is turning into a team effort.

Janis Rocans was so kind as to share his update to the electronics cover that fit the newer boards for the 10S. He also included a picture and the actual Fusion file as well.

He also has a very interesting case/stand for a raspberry PI with 5 inch touch screen. Check it out here

UPDATE 16. Sep 2018

Many thanks to Scott Lahteine for remixing and sharing parts to support the 10S display. Check out his other models here.

Scott has some really interesting designs, and great updates to both the Creality and Prusa I3 printers.

NOTE It's been reported that my design may not fit newer CR10 control boards and displayes, but is reported to work with CR10 mini.

See comments for feedback.

To that end, I've added the Fusion360 design files, so that you can update and modify the design to fit your specific CR10 model.

Inspired by https://www.thingiverse.com/thing:2747280, I set out to make my own version of integrating the control box electronics and power supply.

This kit includes:

remodeled feet with integrated power connector and mount for squash ball for vibration dampening

mounting plate for power supply and mosfet with cooling fan

mounting plate for Melzi control board with integrated wire management and cooling fan

mount for navigator plugs from the stock wire harness

SD card slot moved to the front of the printer just below the control panel, and features a full size SD Card Reader, readily available from Amazon.

case and mount for the control display, and new display cable from Amazon

(update April 1, 2018)

Added STL for spool holder.

(update April 13, 2018)

Adding cover plate for the remaining area of the printer, which includes:

a cover plate with integrated mount for power supply

a cover plate for mounting an Raspberry PI

blank cover plate to cover the remaining area

Total cost of conversion is about $20 plus filament.

Original wires are used except for wires from the switch and power receptacle to the power supply. The ribbon cable to the display was also replaced. I re-purposed the original connectors from the ribbon cable, simply transferred them over to a new and longer ribbon cable.

You may need to lengthen the wires to the fans as well.

The stock wire harness that originally connected the control box to the printer is unchanged. The extra length of some of the wires are managed by the integrated wire management loops below the Melzi board.

The Melzi board is raised off the mounting plate allowing routing of wires underneath the Melzi board. Making a cleaner looking implementation, and free airflow over the stepper drivers.

I designed the cover plates to primary use M3 hardware for mounting the boards, and M5 for mounting the plates to the extrusion.

M3 x 8 for the mosfet

M3 x 12 for the control board

M3 x 10 for the raspberry PI (yes, I enlarged the M2.5 holes in Raspberry PI to M3)

M5 x 10 for mounting the cover plates to the extrusion

The end product is a nice, clean looking, and fully integrated printer. Gone is the umbilical cord, and the clunky control box.

This change could expose live mains voltage wires and terminals.

While the leg with integrated power connections have some shielding, it will not prevent users from reaching and touching wire terminals.

Should someone reach underneath the printer, it is conceivable that they could access live mains voltage terminals.

It is recommended to take additional safety measures.

Similar models

thingiverse

free

Raspberry Pi CR10 V3 Mount by randomdude

...hingiverse

this is a raspberry pi 3 mount for attaching to the power supply of a creality cr-10 v3. attaches with two m3 bolts.

thingiverse

free

K8400 VERTEX Upgrade With Raspberry Pi and Fish Eye Camera by Bo_Ris

...u will need two m5x30mm screws.

update 2-feb-2017: added video streaming script. the description is on the bottom of this page.

thingiverse

free

CR-10 Raspberry Pi Integration by michaeldeberry

...haust fan to mount everything as they were the perfect length. to mount the new fan i used some m3x12mm screws that i had around.

thingiverse

free

Crealtiy CR-10 Raspberry Pi Tray With RAMPS to Replace Power Supply!

...reality case and uses m4 captive nuts. the sections and boards mount with m3 sized self threading screws. i use these.

thank you!

thingiverse

free

CR10V2 Pi Cam Mount by JarneMeylemans007

...erry pi camera mount for cr10 v2 3d printer

it mounts on the rods from the cr10 v2

its designed with a m3 hole for a nut and bold

thingiverse

free

Rapsberry Pi mount for Prusa i3 6mm Aluminium plate version by markbenson

...h a raspberry pi and octoprint and a suitable 5v power supply. i added an l78s05cv 2a 5v fixed regulator to the ramps 12v supply.

thingiverse

free

CR10S Mod Standalone Melzi Board V2.0 by kervehrt

... mounts to support creality board v2.0 which comes with stock cr10s. also adapted the slot for the dual cable to the display ...

thingiverse

free

NZXT H1 Power Supply 3.5 Inch Pi Display Cover by rashbalash

...h pi display cover by rashbalash

thingiverse

just my design of an nzxt h1 power supply cover for a 3.5 inch raspberry pi display

thingiverse

free

Raspberry Pi Cover for RPI DSI Touchscreen by prushik

... most of the wires. it also allows usb, ethernet, audio, and power to be connected.

it's not perfect, but good enough for me.

thingiverse

free

Case for Raspberry Pi with 4-Relay Board ks0212 by hdiessner

...s://astrohd.de

update: july, 5th 2018: added a tray for geeetech i3 / prusa to mount the case atop an i3 printer without screws.

Cr10

3d_export

$21

Hall tree and Clothing Rack CR10

... real object. 3. lights and cameras are included in the scenes renders using vray * renders are made in 3ds max 2018 using vray 5

thingiverse

free

Clips for Ender 3, CR10, CR10S

.... maybe others, but only been tested with these.

these clips makes a tight fit, so that the cable and bowden tube stays in place.

thingiverse

free

X-axis endstop offset for cr10 cr10s Ender 3

...x-axis endstop offset for cr10 cr10s ender 3

thingiverse

x-axis endstop offset for cr10 cr10s ender 3

thingiverse

free

Filament Sensor CR10

...or cr10

thingiverse

remix of the sensor with fixation in order to face directly the extruder and ptfe tube

cr10, cr10s ender3...

thingiverse

free

Fan V4 CR10/CR10S Ender3 Versione 4 by creativesolutions-lab

...fan v4 cr10/cr10s ender3 versione 4 by creativesolutions-lab

thingiverse

fan v4 cr10/cr10s versione 4

thingiverse

free

CR10 Feet by Leighton417

...cr10 feet by leighton417

thingiverse

this is a cr10 feet for people who have short table width.

thingiverse

free

Dremel Attachment for CR10, Ender 3, Cr10s by Conn22_43

...verse

a bracket to hold a dremel onto any ender 3, cr10 bracket. i printed it in petg, but it can be made in any rigid material.

thingiverse

free

CR10S-Plus Hotend by scorpio_man30ro

...cr10s-plus hotend by scorpio_man30ro

thingiverse

cr10s-plus hotend

thingiverse

free

Leveling knob CR10 by JMJacques

...leveling knob cr10 by jmjacques

thingiverse

leveling knob cr10

thingiverse

free

Soporte Superior sensor filamento CR10 v2 - CR10 v3 by Guimir

...3 by guimir

thingiverse

soporte sensor de filamento guia superiror tipo cr10 v3 para convertir la cr10 v2 en extrusión directa.

Jan

turbosquid

$40

jan

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Milano Bedding Jan

...диван , milano bedding , jan

milano bedding jan

design_connected

$29

Jan 350

...jan 350

designconnected

linteloo jan 350 computer generated 3d model. designed by navone, paola.

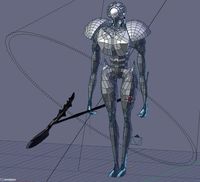

turbosquid

$9

Jan Robot

...rbosquid

royalty free 3d model jan robot for download as max on turbosquid: 3d models for games, architecture, videos. (1280124)

3d_export

$6

In-Jan 3D Model

...el

3dexport

in-jan logo ring pendent

in-jan 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl dekasin 108971 3dexport

3ddd

$1

Jan Showers - Sarah

...jan showers - sarah

3ddd

скамья

модель скамейки jan showers - sarah bench no 415

мультисаб-материал, fbx + obj + 3ds

3d_export

$100

Jan 3D Model

...people human character teeth sexy sex jeans t-shirt shirt suit pant underware dress realistic

jan 3d model mrpanda 77564 3dexport

3d_export

$45

Jan 3D Model

...export

asian woman girl nude female character beauty angel realistic lowpoly low poly textures 3d

jan 3d model bzq 11388 3dexport

turbosquid

$25

Art jan design

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$32

etcetera low chair by jan ekselius

...etcetera low chair by jan ekselius

3dexport

etcetera low chair by jan ekselius

P

turbosquid

$9

Z i p p o

...lty free 3d model z i p p o for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1607301)

3ddd

$1

Triple P!

...iple p!

3ddd

горшок , цветок , листья

triple p!

3ddd

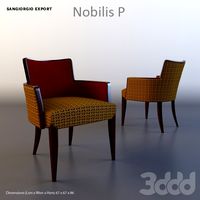

free

Nobilis P

... sangiorgio export

nobilis phttp://www.sangiorgioexport.com/nobilis.html#p

san giorgio export

design_connected

$16

Caravaggio P

...caravaggio p

designconnected

lightyears caravaggio p computer generated 3d model. designed by manz , cecilie .

design_connected

$16

Lady P

...lady p

designconnected

origlia lady p computer generated 3d model. designed by origlia, sviluppo.

design_connected

$16

Anfora P

...anfora p

designconnected

lzf anfora p computer generated 3d model. designed by herranz, miguel.

design_connected

$13

Tri-p

...tri-p

designconnected

foscarini tri-p computer generated 3d model. designed by diesel creative team.

turbosquid

$8

Z i p p o Lighter

... 3d model z i p p o lighter for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1617079)

3ddd

$1

Carlesso Pliet P

...carlesso pliet p

3ddd

carlesso , pliet p

carlesso pliet p

design_connected

$9

LC11-P

...lc11-p

designconnected

cassina lc11-p dining tables computer generated 3d model. designed by le corbusier.

One

turbosquid

$2

one plus one

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

One

...one

3ddd

стул

офисный стул one

3ddd

free

one

...

palazetti one ,http://palazzetti.ca/index.php/component/virtuemart/seating/armchairs-lounges/one-chair-detail?itemid=0

turbosquid

$35

One A

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

One

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Стул One

...стул one

3ddd

one , magis

кресло magis s.p.a , one

3ddd

$1

Стул One

...стул one

3ddd

one , magis

кресло one chair (4star), magis s.p.a.

3d_export

$20

xbox one

...xbox one

3dexport

xbox one

3ddd

$1

xbox one

... консоль , джойстик

xbox one + kinect + gamepad

3ddd

free

One

...nstantin grcic

артикул ct-284 (cosmorelax.ru)

размер l36xw41xh82.5, sh 77cm

цвет черный, красный

материал алюминий

вес 2,5 кг

All

turbosquid

$20

all

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

all

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$29

All-Two

...all-two

designconnected

bonaldo all-two computer generated 3d model. designed by bicego, sergio.

design_connected

$29

All-One

...all-one

designconnected

bonaldo all-one computer generated 3d model. designed by bicego, sergio.

design_connected

$16

Holly All

...holly all

designconnected

serralunga holly all computer generated 3d model. designed by starck, philippe.

3d_export

$15

all terrain

...all terrain

3dexport

turbosquid

$29

Holly All

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Fireplace (All)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Fireplace (All)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Fireplace (All)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.