Thingiverse

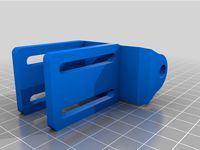

CR-10 Dual Z with top mounted stepper by StvPtrsn

by Thingiverse

Last crawled date: 3 years, 1 month ago

Last Fall I purchased and installed the dual Z upgrade for my regular CR-10. For weeks I fought bed leveling with the steppers going out of alignment for whatever reason. Drawing inspiration from Caster's Youtube video (thing 2569379) I set out to design my own belt driven dual Z setup. I completed it and published it as thing 2628377. Having used it for the past 4+ months I have to say this is the best modification I've done to my CR-10. Where I used to re-level the bed after almost every print, now I only do it when I change build surfaces.

One of the problems with the previous design was that it over constrained the left side lead screw. I spent a lot of time with a set of calipers and a straight edge making sure the z stepper and the upper bearing mounts were lined up perfectly with the lead screw nut so this wouldn't actually cause print problems.

My new design is an attempt to resolve that problem. With this setup the Z stepper is relocated to the top of the frame and the lead screws are allowed to float at the bottom. As before I do not like driving set screws into the threads of the lead screws so I spent the effort designing alternative ways to attach the pulleys :)

I secured the wiring extension with 1" lengths cut from the extrusion inserts that came with the printer. If you split them down the back side they will wrap around the wiring and allow you to secure it in the frame slots. There is plenty of room to run this down the right extrusion and the X carriage bracket clears it without problem.

Parts list (for CR-10S):

BIQU GT2 Synchronous Wheel 60 Teeth 8mm Bore Aluminum Timing Pulley for 3D Printer 6mm Width Belt (Pack of 2pcs)

Link: http://a.co/eORAb49

BIQU GT2 5mm Bore Aluminum Toothless Timing Belt Idler Pulley for 3D Printer 6mm Width Timing Belt (Pack of 5pcs)

Link: http://a.co/2LMLfJs

BEMONOC Pack of 2pcs GT2 Driver Belt 900-2GT-6 Timing Belt in Closed Loop Rubber L=900mm W=6mm 450 Teeth

Link: http://a.co/1px2mDt

Qunqi 5PCS Aluminum GT2 Timing Belt Pulley 20 Teeth Bore 5mm Width 6mm and Wrench for RepRap 3D Printer Prusa i3

Link: http://a.co/hLGLZjm

20-Pack 608 ZZ Ball Bearings , 608zz Metal Double Shielded Miniature Deep Groove Skateboard Ball Bearings (8mm x 22mm x 7mm)

Link: http://a.co/6dibLpCAny 608 bearing should work since we are not putting a heavy axial load on these. The ones linked above specify "deep groove", I'm not sure if all 608s have the same groove or not. The bearings I used I bought for fidget spinners and did not specify they were deep groove.

You'll also need some way to extend the stepper wiring. I have a CR-10 harness extension kit so I just used the Z wire out of that.

*in addition to these parts a standard CR-10 will require a second lead screw and right side bracket. Since I bought the dual Z upgrade I have not needed to model the right side bracket.

Hardware:

(2) M5x20 screws for the stepper mount idlers. Just thread them into the plastic.

(2) M5 washers for under the stepper idlers to keep them from rubbing on the mount

(4) M5x8 screws with t-nuts to attach the stepper mount to the frame

(4) M4x20 screws with t-nuts for mounting the bearing brackets to the frame

(4) M4x6 button head cap screws with the head filed down to about 6.5mm diameter (chuck it up in a drill and run it over a file) These are only if you are using the 60T pulley adapters provided. Alternatively just use the set screws.

(4) M3 locknuts for Below_Bearing_Clamp_x2 and 8mm_60T_GT2_Clamp_x2

(4) M3x10 for Z_Bearing_Mount_x2. They screw into the sides to lock the bearing in place.

(4) M3x10 to attach the stepper motor

(4) M3 washers for the stepper motor screws

(2) M3x12 for Below_Bearing_Clamp_x2

(2) M3x20 for 8mm_60T_GT2_Clamp_x2

Firmware changes are required. You can do this at least two ways.

Edit Marlin 1.1.8 line 532

define DEFAULT_AXIS_STEPS_PER_UNIT { 80, 80, 400, 101 }

Change the 400 to 1200

or

From a terminal send commands:

M92 Z1200 to set the Z steps/mm then M500 to save the setting

Note: You will likely lose some Z height with this modification depending on how your x carriage wiring is set up.

Please let me know if you build this. I'd like to hear how it works out.

One of the problems with the previous design was that it over constrained the left side lead screw. I spent a lot of time with a set of calipers and a straight edge making sure the z stepper and the upper bearing mounts were lined up perfectly with the lead screw nut so this wouldn't actually cause print problems.

My new design is an attempt to resolve that problem. With this setup the Z stepper is relocated to the top of the frame and the lead screws are allowed to float at the bottom. As before I do not like driving set screws into the threads of the lead screws so I spent the effort designing alternative ways to attach the pulleys :)

I secured the wiring extension with 1" lengths cut from the extrusion inserts that came with the printer. If you split them down the back side they will wrap around the wiring and allow you to secure it in the frame slots. There is plenty of room to run this down the right extrusion and the X carriage bracket clears it without problem.

Parts list (for CR-10S):

BIQU GT2 Synchronous Wheel 60 Teeth 8mm Bore Aluminum Timing Pulley for 3D Printer 6mm Width Belt (Pack of 2pcs)

Link: http://a.co/eORAb49

BIQU GT2 5mm Bore Aluminum Toothless Timing Belt Idler Pulley for 3D Printer 6mm Width Timing Belt (Pack of 5pcs)

Link: http://a.co/2LMLfJs

BEMONOC Pack of 2pcs GT2 Driver Belt 900-2GT-6 Timing Belt in Closed Loop Rubber L=900mm W=6mm 450 Teeth

Link: http://a.co/1px2mDt

Qunqi 5PCS Aluminum GT2 Timing Belt Pulley 20 Teeth Bore 5mm Width 6mm and Wrench for RepRap 3D Printer Prusa i3

Link: http://a.co/hLGLZjm

20-Pack 608 ZZ Ball Bearings , 608zz Metal Double Shielded Miniature Deep Groove Skateboard Ball Bearings (8mm x 22mm x 7mm)

Link: http://a.co/6dibLpCAny 608 bearing should work since we are not putting a heavy axial load on these. The ones linked above specify "deep groove", I'm not sure if all 608s have the same groove or not. The bearings I used I bought for fidget spinners and did not specify they were deep groove.

You'll also need some way to extend the stepper wiring. I have a CR-10 harness extension kit so I just used the Z wire out of that.

*in addition to these parts a standard CR-10 will require a second lead screw and right side bracket. Since I bought the dual Z upgrade I have not needed to model the right side bracket.

Hardware:

(2) M5x20 screws for the stepper mount idlers. Just thread them into the plastic.

(2) M5 washers for under the stepper idlers to keep them from rubbing on the mount

(4) M5x8 screws with t-nuts to attach the stepper mount to the frame

(4) M4x20 screws with t-nuts for mounting the bearing brackets to the frame

(4) M4x6 button head cap screws with the head filed down to about 6.5mm diameter (chuck it up in a drill and run it over a file) These are only if you are using the 60T pulley adapters provided. Alternatively just use the set screws.

(4) M3 locknuts for Below_Bearing_Clamp_x2 and 8mm_60T_GT2_Clamp_x2

(4) M3x10 for Z_Bearing_Mount_x2. They screw into the sides to lock the bearing in place.

(4) M3x10 to attach the stepper motor

(4) M3 washers for the stepper motor screws

(2) M3x12 for Below_Bearing_Clamp_x2

(2) M3x20 for 8mm_60T_GT2_Clamp_x2

Firmware changes are required. You can do this at least two ways.

Edit Marlin 1.1.8 line 532

define DEFAULT_AXIS_STEPS_PER_UNIT { 80, 80, 400, 101 }

Change the 400 to 1200

or

From a terminal send commands:

M92 Z1200 to set the Z steps/mm then M500 to save the setting

Note: You will likely lose some Z height with this modification depending on how your x carriage wiring is set up.

Please let me know if you build this. I'd like to hear how it works out.

Similar models

thingiverse

free

CR-10 Dual Z Pulley Setup by StvPtrsn

...uxcell a16031400ux0530 3d printer 2gt-6 ring closure timing belt closed 852mm circumference, hss

uxcell

link: http://a.co/bhjz4wh

thingiverse

free

GT2 idler for 608 bearing M3 NEMA 17 stepper

...

idler for 6mm gt2 belt, designed to mount onto a nema 17 stepper motor and leave room for a 16 tooth pulley

step files included

thingiverse

free

Idler pulley for 6mm GT2 timing belt with one 624ZZ ball bearing by hlavaatch

...iverse

idler pulley for a 6mm gt2 timing belt.

comes with two spacers for 10mm wide mount slot to keep the pulley in the middle.

thingiverse

free

CR-10s Pro Z Belt Tensioner

...for the belt sync or an actual idler of similar size. on tinkercad: z belt tensioner updated with yet...

thingiverse

free

TRONXY X5S - Z motor sync by WT1704

...e platform on the stepper and 3 * m5 screws and nuts for the pulley

1 * m3 screw and nut to hold the tension stick with the block

thingiverse

free

Belt driven Z pulley mount w/ GT2 6mm belt 5mm bore 20t idler by Evilkoal

...e idler mount to fit the idlers i have.

gt2 20t 6mm belt, 5mm bore idler.

printed with 50% "archimedian chords" infill.

thingiverse

free

GT2 2mm Idler Pully by Timelord83

...gt2 2mm idler pully by timelord83

thingiverse

40 tooth idler 608 pulley for gt2 2mm x 6mm wide gt2 belts

grabcad

free

GT2-6mm Pulleys and Idlers

...gt2-6mm pulleys and idlers

grabcad

some of the most used pulleys and idlers for gt2-6mm timing belts.

created with freecad 0.18

thingiverse

free

Internal NEMA17 Timing Belt reduction by gouldpa

...

2xhttps://3dprintingperth.com/collections/stepper-motors/products/20-teeth-6mm-width-3mm-inner-18mm-outer-gt2-idler-pulley-wheel

thingiverse

free

Idler 6mm GT2 6mm timing belt by Vandalisimo

....alicdn.com/kf/htb1mtv5ipxxxxalxfxxq6xxfxxx2/hot-10pcs-lot-624zz-ball-bearing-4-13-5-mm-chrome-steel-bearing-deep-groove-ball.jpg

Stvptrsn

thingiverse

free

Bin Dividers for Harbor Freight 40 Bin Organizer by StvPtrsn

... let me know if you make this and find it useful.

update: i ended up needing 4 and 5 compartment bin inserts so i uploaded them.

thingiverse

free

MMU2 Amazon "Festo" Holder by StvPtrsn

...r in or it will not snap onto the spool holder stand. step file included. original fusion360 file included in the source thing.

thingiverse

free

OpenRC F1 2017 Update - 1pc Chassis, Dual Ext Lid by StvPtrsn

...e 300x300mm cr-10 build plate.

second i spliced the 2017 updated lid onto the dual extrusion original lid to accommodate the fin.

thingiverse

free

CR-10 30mm Spool Holder by StvPtrsn

...rger than stock diameter nut. it fits nicely behind the spool holder bracket so it doesn't need to be held while tightening.

thingiverse

free

Prusa MK3 Spool Holder for 30mm Spools by StvPtrsn

... maximum 95mm width.

update:

uploaded step files and added a shorter version of the mount for narrower spools (up to 70mm width).

thingiverse

free

Sterilite 20qt Filament Storage System by StvPtrsn

...uwpnbb

1x new and improved eva-dry e-333 renewable mini dehumidifier

by eva-dry

link: http://a.co/fqjpxtf

4x lengths of ptfe tube

thingiverse

free

Bin Dividers for Akro-Mils Small Parts Organizers by StvPtrsn

...and/or remix.

if you have a specific divider configuration request leave it in the comments. it doesn't take long to create.

thingiverse

free

CR-10 Dual Z Pulley Setup by StvPtrsn

...uxcell a16031400ux0530 3d printer 2gt-6 ring closure timing belt closed 852mm circumference, hss

uxcell

link: http://a.co/bhjz4wh

thingiverse

free

Folgertech FT-5 R2 Assembly Aids by StvPtrsn

...ossbars made it much easier than using the spool holder as a spacer. the stl should be both parts in one so just print one pair.

thingiverse

free

Hypercube Evolution, My Parts and Remixes - No inserts by StvPtrsn

...d models. they are not exact duplicates (though the y carriage is close to exact), i made changes where i thought it made sense.

Cr

turbosquid

$15

Creazioni CR-673 CR-4461

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Ravak CR 055.00

...ravak cr 055.00

3ddd

ravak , смеситель

ravak cr 055.00

turbosquid

$100

CR-002

...

turbosquid

royalty free 3d model cr-002 for download as stl on turbosquid: 3d models for games, architecture, videos. (1686037)

3ddd

$1

Ravak CR 012.00

...ravak cr 012.00

3ddd

ravak , смеситель

смеситель ravak cr 012.00

3ddd

free

Консоль CR Currin

...ь , cr currin

консоль cr currin

ширина - 1675 мм

глубина - 510 мм

общая высота - 810 мм

3ddd

$1

CR 39444

...0

диаметр: 100

тип патрона: gu5,3 gu10

количество ламп: 1

мощность: 35w

цвет: золото хрусталь

материал: металл хрусталь exclusive

3d_ocean

$89

Honda CR-Z

...www.youtube.com/watch?v=rrbb4d4lypk ` he honda cr-z‘s exterior styling is formed around a “one-motion wedge” concept with a lo...

3ddd

$1

Creazoni / STEFY CR-8901

...creazoni / stefy cr-8901

3ddd

creazoni

creazioni stefy cr-8901

turbosquid

$60

Chain-CR-001

...squid

royalty free 3d model chain-cr-001 for download as stl on turbosquid: 3d models for games, architecture, videos. (1680536)

turbosquid

$99

Honda CR-Z

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Stepper

turbosquid

$85

Stepper

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$22

Mini Stepper

...gymnastic indoor legs machine mini silver sport stepper trainer workout

3d model of silver and black mini stepper with a counter.

turbosquid

$3

stepper deluxe

...osquid

royalty free 3d model stepper deluxe for download as on turbosquid: 3d models for games, architecture, videos. (1284335)

turbosquid

$49

Stepper Motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Fitness Stepper

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

stepper motor driver

...stepper motor driver for download as , fbx, dae, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1688860)

turbosquid

$1

Stepper motor driver

... model stepper motor driver for download as obj, stl, and ige on turbosquid: 3d models for games, architecture, videos. (1577811)

3d_export

$5

Stepper motor Nema17 17HS4401

...stepper motor nema17 17hs4401

3dexport

turbosquid

$1

Nema 17 Stepper motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Nema 17 Stepper Motor 59Nm

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Dual

turbosquid

free

Dual Pistols

...ls

turbosquid

free 3d model dual pistols for download as fbx on turbosquid: 3d models for games, architecture, videos. (1320360)

turbosquid

$2

Dual Axe

...urbosquid

royalty free 3d model dual axe for download as fbx on turbosquid: 3d models for games, architecture, videos. (1332372)

turbosquid

$10

Dual Lesaths

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

плитка Dual Bianco (Испания)

...й плитки venis dual (испания). технические качества: устойчивость к стирания, отличная геометрия, отсутствие проблем при укладке.

turbosquid

$35

Dual Mesh Fonts

...ree 3d model dual mesh fonts for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1352989)

turbosquid

$29

Dual Flask with Bungs

...del dual flask with bungs for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1210512)

turbosquid

$19

Dual Socket Plug

...3d model dual socket plug for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1303912)

turbosquid

$13

Dual Adjustable Pulley

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Amoi N809 Dual

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Dual Turret Tank

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Z

3d_export

$5

nissan z

...nissan z

3dexport

nissan z

3ddd

$1

Vase Z

...vase z

3ddd

vase z

3ddd

$1

полотенцесушить Z

...полотенцесушить z

3ddd

полотенцесушитель

полотенцесушить z

design_connected

free

Z-Chair

...z-chair

designconnected

free 3d model of z-chair designed by karman, aleksei.

design_connected

$11

Z Lamp

...z lamp

designconnected

phillips z lamp computer generated 3d model. designed by kalff, louis.

3d_export

$5

Dragon balls z

...dragon balls z

3dexport

dragon ball z

turbosquid

$20

Fighter Z

...

turbosquid

royalty free 3d model fighter z for download as on turbosquid: 3d models for games, architecture, videos. (1292563)

turbosquid

$9

Pen Z

...pen z

turbosquid

free 3d model pen z for download as obj on turbosquid: 3d models for games, architecture, videos. (1686775)

turbosquid

free

z chair

...z chair

turbosquid

free 3d model z chair for download as max on turbosquid: 3d models for games, architecture, videos. (1410230)

turbosquid

$5

Letter Z

...urbosquid

royalty free 3d model letter z for download as max on turbosquid: 3d models for games, architecture, videos. (1408540)

10

turbosquid

$25

10

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

a-10

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

EX 10

...ex 10

3ddd

samsung , фотоаппарат

ex 10

3ddd

$1

Bed 10

...bed 10

3ddd

постельное белье

bed 10

evermotion

$25

Scene 10 Archinteriors vol. 10

...dering design interior

take a look at textured and shadered visualization scene ready to be rendered.. evermotion 3d models shop.

3ddd

$1

Curtains 10

...curtains 10

3ddd

curtains 10

3ds max 2011,fbx + textures

polys: 100355

3ddd

free

PLANTS 10

...plants 10

3ddd

цветок , горшок

plants 10,, with 3 different color planter boxes

turbosquid

$24

Chandelier MD 89310-10+10 Osgona

... chandelier md 89310-10+10 osgona for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1218762)

design_connected

$29

Nuvola 10

...nuvola 10

designconnected

gervasoni nuvola 10 computer generated 3d model. designed by navone, paola.

design_connected

$22

Kilt 10

...kilt 10

designconnected

zanotta kilt 10 computer generated 3d model. designed by progetti, emaf.

Top

archibase_planet

free

Top

...top

archibase planet

top

top - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

free

Range Top V36C top

...range top v36c top

3ddd

гриль

проф. гриль range top v36c top

archibase_planet

free

Top

...top

archibase planet

dresser kitchen furniture

top - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Top

...top

archibase planet

bracket bar furniture

bar top - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$5

Top

...lty free 3d model top for download as ma, max, blend, and obj on turbosquid: 3d models for games, architecture, videos. (1579951)

turbosquid

$39

Top

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Top

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$15

top knifle

...top knifle

3dexport

top knifle

design_connected

$11

Drop Top

...drop top

designconnected

plumen drop top computer generated 3d model.

3d_export

$245

top of the material

...top of the material

3dexport

top of the material,commercial ceiling ceiling material, metal material

Mounted

3d_export

free

mounting bracket

...mounting plate is the portion of a hinge that attaches to the wood. mounting plates can be used indoors, cabinetry and furniture.

turbosquid

$2

MOUNTING

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mounts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mount Fuji

...fuji

turbosquid

free 3d model mount fuji for download as obj on turbosquid: 3d models for games, architecture, videos. (1579977)

3d_export

$5

Headphone mount LR

...headphone mount lr

3dexport

headphone mount l+r

turbosquid

$39

Mount rainier

...quid

royalty free 3d model mount rainier for download as fbx on turbosquid: 3d models for games, architecture, videos. (1492586)

turbosquid

$5

pipe mounting

...quid

royalty free 3d model pipe mounting for download as obj on turbosquid: 3d models for games, architecture, videos. (1293744)

turbosquid

$3

Mounting Tires

...uid

royalty free 3d model mounting tires for download as fbx on turbosquid: 3d models for games, architecture, videos. (1708511)

3d_export

$5

Magnetic GoPro Mount

...pro mount

3dexport

cool magnetic mount for gopro. allows you to mount the camera on flat metal surfaces and get exclusive shots.

turbosquid

$5

Stone Mount

...ty free 3d model stone mount for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1370306)