Thingiverse

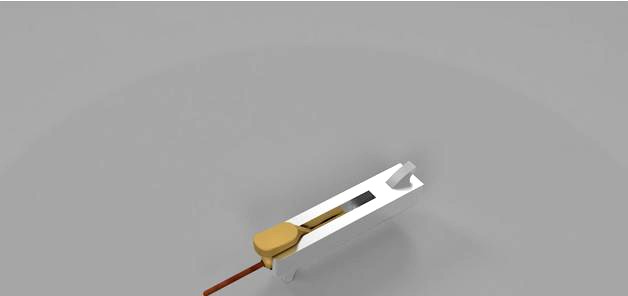

Covid-19 self-retracting safety probe w/replaceable tip - *** updated *** by cgfan

by Thingiverse

Last crawled date: 4 years ago

updated 4/02/20 - Design updated with a rear finger guard/stop, added additional internal bushings (for 4 total), updated geometry to reduce need for support & removed upper elastic band hook. (In this update the elastic band is looped above and behind the thumb slide.) updated 3/31/20 - Design updated with dual internal bushings to help guide the shuttle, keeping the probe centered through its travel updated 3/30/20 - Design updated with improved retention of elastic band, a more profiled and thicker thumb slide and a more pronounced locking detent original design 3/28/20

A simple and pocketable safety probe to provide a safe, touch-free means to operate mechanical buttons whether at the ATM, elevator, POS terminal, etc.

It possesses a few key features:

a simple and universally replaceable probe which utilizes a standard toothpick

has a self-retracting mechanism utilizing readily available and off-the-shelf 3/8 in (9.5 mm) diameter elastic bands (commonly used a a hair band)

a simple locking mechanism allows it to stay extended during use. Alternatively one can use it in its "elastic range" for immediate retraction. (It locks in place only at maximum extension.)

when retracted, the probe is safely kept inside the body of the tool. If a deeper retraction is desired, one can simply clip the length of the toothpick before first use.

designed to be direct printed in its pre-assembled state, provided care is taken with part orientation and support.

Video demonstration here: https://www.youtube.com/watch?v=NvYNFBGi4hs

MISC NOTES

Note that this was designed to support direct printing in its pre-assembled state. In order to do that great care must be taken in the nature of the support and part orientation.

Please see the photo for details. You will see that it was printed with a generous raft, as the part is printed standing up on its very small base. Set support to "touching baseplate" and enable "tree support". This allows the support to snake into a couple of nooks and crannies in order to allow for proper support.

Studying the STL in your slicer is highly recommended before attempting to slice and print this design.

If sliced properly, cleanup is rather simple.

FREEING THE SLIDING MECHANISM

Once all support is removed it may require a bit of force to free the sliding mechanism. To free, simply invert over a solid table with the receiver hole for the toothpick downwards on the table. As printed this receiver hole stands proud of the rest of the case body.

With a firm blow from a non-marring hammer, sharply tap the case. This should shock the slider to break free from the case.

Now extend the slider all the way and place a couple of drops of a dry lube through the larger hole on top. I use a wax lube made for bicycles. Then run the slider up and down with your thumb to wear down any interfering rough surface.

ASSEMBLY

Insert toothpick with the sliding shuttle fully extended and locked. If the fit is too loose, use the woodworker's trick of soaking the toothpick in water to raise the grain. It will remain raised even after the toothpick dries.

When done stretch a 3/8 " (9.5 mm) elastic band between the bottom hook and around and behind the thumb slide for smooth operation, locking and self-retraction.

A simple and pocketable safety probe to provide a safe, touch-free means to operate mechanical buttons whether at the ATM, elevator, POS terminal, etc.

It possesses a few key features:

a simple and universally replaceable probe which utilizes a standard toothpick

has a self-retracting mechanism utilizing readily available and off-the-shelf 3/8 in (9.5 mm) diameter elastic bands (commonly used a a hair band)

a simple locking mechanism allows it to stay extended during use. Alternatively one can use it in its "elastic range" for immediate retraction. (It locks in place only at maximum extension.)

when retracted, the probe is safely kept inside the body of the tool. If a deeper retraction is desired, one can simply clip the length of the toothpick before first use.

designed to be direct printed in its pre-assembled state, provided care is taken with part orientation and support.

Video demonstration here: https://www.youtube.com/watch?v=NvYNFBGi4hs

MISC NOTES

Note that this was designed to support direct printing in its pre-assembled state. In order to do that great care must be taken in the nature of the support and part orientation.

Please see the photo for details. You will see that it was printed with a generous raft, as the part is printed standing up on its very small base. Set support to "touching baseplate" and enable "tree support". This allows the support to snake into a couple of nooks and crannies in order to allow for proper support.

Studying the STL in your slicer is highly recommended before attempting to slice and print this design.

If sliced properly, cleanup is rather simple.

FREEING THE SLIDING MECHANISM

Once all support is removed it may require a bit of force to free the sliding mechanism. To free, simply invert over a solid table with the receiver hole for the toothpick downwards on the table. As printed this receiver hole stands proud of the rest of the case body.

With a firm blow from a non-marring hammer, sharply tap the case. This should shock the slider to break free from the case.

Now extend the slider all the way and place a couple of drops of a dry lube through the larger hole on top. I use a wax lube made for bicycles. Then run the slider up and down with your thumb to wear down any interfering rough surface.

ASSEMBLY

Insert toothpick with the sliding shuttle fully extended and locked. If the fit is too loose, use the woodworker's trick of soaking the toothpick in water to raise the grain. It will remain raised even after the toothpick dries.

When done stretch a 3/8 " (9.5 mm) elastic band between the bottom hook and around and behind the thumb slide for smooth operation, locking and self-retraction.

Similar models

thingiverse

free

Elastic Band Slide by BigBertGU

...e not tried it with actual elastic bands but i did use it with some 6mm x 0.84mm ninjaflex bands that i made and it worked great.

thingiverse

free

Dual Action- Out the Front Automatic Both Ways Extender by MrJohn

...on to retract the object.

i've included a plate with all the files and each one as singles. also, the google sketchup! file.

thingiverse

free

Sliding Double-Deck bins for the small storage system

...h both 0.2 and 0.3 layer height.

i am most happy with 0.3 - not is it only faster, but i feel the locking mechanism works better.

grabcad

free

Mechanical Hopper

...contraption is designed to use elastic bands to jump, flip a full 360 degrees and land back on its base. updated version to come.

thingiverse

free

ShapeOko Slider Penholder "Sliding" by nischi

...shapeoko slider penholder "sliding" by nischi

thingiverse

shapeoko slider penholder

with sliding mechanism

grabcad

free

Mechanical model 3d puzzle Bulldozer

...using an elastic band, has rotary front wheels and front shock absorber.

it is used without glue on toothpicks and axes of 3 mm.

grabcad

free

Slider Crank Mechanism

...slider crank mechanism

grabcad

this is a simple slider crank mechanism.

use "digital mockup" to see how it works.

grabcad

free

Elastic Band Ammo

...stic and shoot down targets.

no more folding paper required...

just print this, slide over the elastic, pull back, aim and shoot.

grabcad

free

Slider-crank mechanism

...signed it using only its video and performed an analysis with the solidworks motion plugin.

original mechanism below description

thingiverse

free

Elastic Band (6 mm x 0.84 mm) by BigBertGU

...h face masks and face shields for the covid-19 support efforts. this model will create just under 7 meters of 6mm x 0.84mm band.

Cgfan

thingiverse

free

Replacement cap for Opus hummingbird feeder by cgfan

...replacement cap for opus hummingbird feeder by cgfan

thingiverse

a replacement cap for the opus hummingbird feeder.

thingiverse

free

* UPDATED * - Drop-in decorative (musical Neumes motif) plate for 10" Bannetons by cgfan

...39 - https://www.thingiverse.com/thing:4829439

please refer to that version for the full description, details and latest updates.

thingiverse

free

Contact tuner adapter for thicker guitar headstocks/instruments by cgfan

...addario contact tuner, and another one for a chinese clone. simply replace the factory sliding tab with this 3d printed version.

thingiverse

free

"The Fork" by Nissin Cup Noodle by cgfan

...promotional video: https://www.youtube.com/watch?v=4b0ck9xyxty

edits: 8/27/2020 - cleaned up geometry of handle and clip features

thingiverse

free

Replacement bushing - GSI Outdoors JAVAMILL manual grinder by cgfan

...ercome the factory part's limitations. the fit is very snug, at least when printed on my monoprice mini select 3d with petg.

thingiverse

free

Vertical handle for E61 grouphead flow control valve by cgfan

...did not check for fit on the profitec version, though they are so similar i wouldn't be at all surrise if it also fits those.

thingiverse

free

Bread lame (after Wire Monkey's Arc Lame) by cgfan

... being careful not to injure yourself on the sharp end of the blade.

video link here: https://photos.app.goo.gl/ovc9hvhzzadz227l6

thingiverse

free

Stand for Iwatani torch & butane canister (updated: 9/7/2020) by cgfan

...eliminates that with the simulaneous storage of both the butane canister and the detached torch by providing it a separate stand.

thingiverse

free

* UPDATED * - Drop-in decorative (musical Neumes motif) plate for 10" Bannetons by cgfan

...anneton (traditional cane proofing basket).

neumes are an early form of music notation most often associated with medieval chant.

thingiverse

free

Ver. 2 - "Leave-in-place" Bean funnel & Plug for Zassenhaus Box Coffee Mill by cgfan

...en with the elevated backstop, the funnel (and lid) clears the zassenhaus' handle so can be left in during active grinding...

Probe

turbosquid

$25

Probe

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

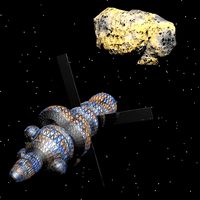

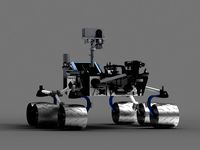

Mars probe space space exploration lunar probe

...be space space exploration lunar probe for download as max on turbosquid: 3d models for games, architecture, videos. (1630876)

turbosquid

$35

Space Probe

...osquid

royalty free 3d model space probe for download as c4d on turbosquid: 3d models for games, architecture, videos. (1571168)

turbosquid

$15

Space Probe

...osquid

royalty free 3d model space probe for download as obj on turbosquid: 3d models for games, architecture, videos. (1314864)

turbosquid

$25

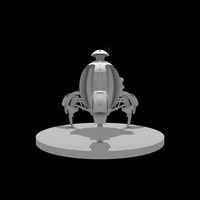

Robot Probe

...y free 3d model robot probe for download as fbx, obj, and dae on turbosquid: 3d models for games, architecture, videos. (1537490)

turbosquid

$1

Dental Probe

...e 3d model dental probe for download as ma, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1312400)

turbosquid

$60

Police Probe

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$9

Space probe

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Cassini Probe

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$70

parker solar probe

...3d model parker solar probe for download as jpg, max, and fbx on turbosquid: 3d models for games, architecture, videos. (1372573)

Covid

turbosquid

$6

covid

...d

turbosquid

royalty free 3d model covid for download as max on turbosquid: 3d models for games, architecture, videos. (1667862)

3d_export

$50

covid-19

...covid-19

3dexport

3d obj model. covid-19

3d_export

$11

covid-19

...covid-19

3dexport

this is 3d model about covid-19 virus

3d_export

$10

covid 3d mask

...covid 3d mask

3dexport

3d covid mask for 3d avatars to implement in covid information projects

3d_export

$5

covid-19 korona

...covid-19 korona

3dexport

covid-19

3d_export

$8

coronavirus covid-19

...coronavirus covid-19

3dexport

coronavirus covid-19

3d_export

$5

covid mask black

...covid mask black

3dexport

black covid mask

3d_export

$5

coronavirus covid-19

...coronavirus covid-19

3dexport

coronavirus covid-19

turbosquid

$29

Covid Collection

...quid

royalty free 3d model covid collection for download as on turbosquid: 3d models for games, architecture, videos. (1682309)

3d_export

$5

mask covid-19

...mask covid-19

3dexport

covid-19 virus protection mask

Retracting

turbosquid

$49

Retractable Hiking Pole

...lty free 3d model retractable hiking pole for download as max on turbosquid: 3d models for games, architecture, videos. (1639636)

turbosquid

$16

Retractable cable lock

...able cable lock for download as blend, fbx, stl, obj, and dae on turbosquid: 3d models for games, architecture, videos. (1629661)

3d_ocean

$12

Retractable pull low poly

...ble pull low poly

3docean

3d 3ds max furniture modern rounded forms sofa vintage nubuk leather

retractable pull low poly animated

3d_ocean

$3

Retractable Ballpoint-Pen

...ek black-and-clear design make it perfect for any situation. it is not rigged, as it is two separate pieces, the casing and th...

turbosquid

$20

RETRACTABLE BLEACHERS 3D model

...el retractable bleachers 3d model for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1259004)

3d_export

$10

retractable clothesline

...gically named.<br>other formats<br>=================<br>- collada (.dae)<br>- autodesk fbx<br>- obj

turbosquid

$29

UFO 11 Retracting Landing gear

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

free

retractable barrier

...: 1510<br>texture: jpg<br>materials: yes<br>for any questions, please contact us and we'll respond quickly.

3ddd

$1

шасси для рамы DJI S800

...шасси для рамы dji s800 dji s800 retractable landing skidhttp://www.rcteam.ru/dji/s800-retractinglanding-gear.html ...

3d_export

$5

glove with blade

...glove with blade

3dexport

cyclse render, clawed glove with<br>retractable blade.

Safety

3d_export

$20

safety helmet

...safety helmet

3dexport

safety helmet

3ddd

$1

Safety Locker

...safety locker

3ddd

сейф

this contains godrej rhino safety locker model

3d_export

$5

safety pin

...safety pin

3dexport

3d_export

$20

safety goggles glasses

...safety goggles glasses

3dexport

safety goggles glasses

turbosquid

free

SAFETY PIN

... pin

turbosquid

free 3d model safety pin for download as c4d on turbosquid: 3d models for games, architecture, videos. (1243440)

turbosquid

$2

Safety cone

...osquid

royalty free 3d model safety cone for download as fbx on turbosquid: 3d models for games, architecture, videos. (1466201)

turbosquid

$1

Safety signs

...uid

royalty free 3d model safety signs for download as blend on turbosquid: 3d models for games, architecture, videos. (1234048)

turbosquid

$35

Safety Razor

... free 3d model safety razor for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1298467)

turbosquid

$19

Safety Rack

...y free 3d model safety rack for download as max, 3ds, and obj on turbosquid: 3d models for games, architecture, videos. (1547678)

turbosquid

$10

Safety Pin

...lty free 3d model safety pin for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1626486)

Self

3ddd

$1

Self

... банкетка

каталог minotti 2010модель selfдизайнер rodolfo dordoniш\д\в 60\120\42

3ddd

$1

Minotti Self

...minotti self

3ddd

minotti

банкетка minotti self

3ddd

$1

Minotti Self

...minotti self

3ddd

minotti , self

текстуры и материалы прилагаются.

3ddd

$1

Self cleaning ashtrays

...self cleaning ashtrays

3ddd

пепельница

self cleaning ashtrays

turbosquid

$15

Book self

...

royalty free 3d model book self for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1502520)

3d_export

free

self-tapping screw

...self-tapping screw

3dexport

self-tapping screw 55 мм

turbosquid

$12

Book Self

...lty free 3d model book self for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1473695)

turbosquid

$4

Self with Desk

...d model self with desk for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1511139)

turbosquid

$2

Book Self

...ree 3d model book self for download as max, fbx, 3ds, and obj on turbosquid: 3d models for games, architecture, videos. (1544366)

turbosquid

$2

Book self

...ree 3d model book self for download as 3ds, max, fbx, and dwg on turbosquid: 3d models for games, architecture, videos. (1300384)

Tip

archibase_planet

free

Felt-tips

...felt-tips

archibase planet

felt-tips felt-tips soft-tip pen

felt-tips - 3d model (*.gsm+*.3ds) for interior 3d visualization.

design_connected

$16

Tip Ton

...tip ton

designconnected

vitra tip ton computer generated 3d model. designed by osgerby , jay.

design_connected

$16

Tip toe

...tip toe

designconnected

bonaldo tip toe chairs computer generated 3d model. designed by mauro lipparini.

turbosquid

$30

Tip of toes

...osquid

royalty free 3d model tip of toes for download as ige on turbosquid: 3d models for games, architecture, videos. (1338675)

turbosquid

$7

Tip Ton

...turbosquid

royalty free 3d model tip ton for download as max on turbosquid: 3d models for games, architecture, videos. (1647484)

turbosquid

$5

jar to tip

...bosquid

royalty free 3d model jar to tip for download as max on turbosquid: 3d models for games, architecture, videos. (1335825)

turbosquid

$5

Tip of the Tongue

...alty free 3d model tip of the tongue for download as and obj on turbosquid: 3d models for games, architecture, videos. (1658556)

turbosquid

$2

Tip for stick

...id

royalty free 3d model tip for stick for download as blend on turbosquid: 3d models for games, architecture, videos. (1491971)

3ddd

$1

Bonaldo / Tip Toe

...bonaldo / tip toe

3ddd

bonaldo

bonaldo tip toe

3ddd

$1

VITRA TIP TON

...a , tip ton

vitra tip ton

rocking chair

meshsmooth with iterations = 3

as render values

19

3d_export

$15

rocks 19

...rocks 19

3dexport

rocks 3d model 19

3d_export

$50

covid-19

...covid-19

3dexport

3d obj model. covid-19

3ddd

$1

PLANTS 19

...plants 19

3ddd

цветок , горшок

plants 19.. enjoy

3d_export

$11

covid-19

...covid-19

3dexport

this is 3d model about covid-19 virus

turbosquid

$25

COVID-19 coronavirus-19 virus microorganism

...virus-19 virus microorganism for download as ma, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1598091)

3ddd

$1

Curtains 19

...curtains 19

3ddd

ламбрекен

curtains 19

other models:http://3ddd.ru/users/brast/models

3d_export

$5

covid-19 korona

...covid-19 korona

3dexport

covid-19

3d_export

$6

tap-19

...tap-19

3dexport

3d_export

$8

coronavirus covid-19

...coronavirus covid-19

3dexport

coronavirus covid-19

3d_export

$5

coronavirus covid-19

...coronavirus covid-19

3dexport

coronavirus covid-19

Updated

turbosquid

$5

orthographic room (updated)

...ee 3d model orthographic room (updated) for download as blend on turbosquid: 3d models for games, architecture, videos. (1375451)

turbosquid

$95

Romantic Bedroom - Updated

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$39

Sofa. Updated release

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Procedurally updating cartoon crystal

...l procedurally updating cartoon crystal for download as blend on turbosquid: 3d models for games, architecture, videos. (1525853)

3d_export

$5

10 Surfboard s UPDATE

...10 surfboard s update

3dexport

3d_export

$10

chair updated rocking

...chair updated rocking

3dexport

armchair renewed plywood 18 mm. for cnc machines. layout in the stp archive.

turbosquid

free

Marble Table Updated

...el marble table for download as 3ds, obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1201300)

turbosquid

$35

Mauser 1930the model is updated with the kits

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$145

Contemporary Bedroom Collection Vol 1 - Updated

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$16

B&B Mart Armchair MPRN (Updated)

...art armchair mprn (updated) for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1284355)

Replaceable

3d_export

$12

replaceable bristle

...replaceable bristle

3dexport

this is 3d printable replaceable bristle toothbrush.

3d_export

$34

Knee Replacement

...h meets the lower leg. ... during a total knee replacement, the end of the femur bone is removed and replaced with a metal shell.

3d_export

$44

Hip Replacement

...omponents. the damaged femoral head is removed and replaced with a metal stem that is placed into the hollow center of the femur.

turbosquid

$59

Hip replacement

...el hip replacement for download as ma, c4d, lwo, lxo, and obj on turbosquid: 3d models for games, architecture, videos. (1520195)

turbosquid

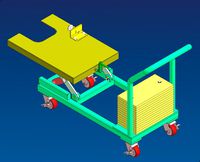

$10

Module replacment station

...alty free 3d model module replacment station for download as on turbosquid: 3d models for games, architecture, videos. (1271271)

3d_export

$8

tool replacement gearbox

...tool replacement gearbox

3dexport

eccentric lifting mechanism, you can process according to available drawings.

turbosquid

$7

Globe Oil Atomizer Replacement Housing

... oil atomizer replacement housing for download as ige and stl on turbosquid: 3d models for games, architecture, videos. (1253839)

turbosquid

free

SLICE Ceramic Scapel (Replaceable Blade)

... (replaceable blade) for download as obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1363525)

3d_export

$19

Knee Replacement Implant

...ntimeter<br>__________________________<br>poly count :<br>polygon count - 217440<br>vertex count - 108776

turbosquid

$19

(Project) Bad odor filtering sytem with support rail and pulley that assure a comfortable gel filter element replacement.

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

W

3ddd

$1

chair W

...chair w

3ddd

chair w

3ddd

$1

кресло w

...кресло w

3ddd

капитоне

кресло w

3ddd

$1

KUTEK (W) W-ZW-5

...kutek (w) w-zw-5

3ddd

kutek

3d модель люстри (w) w-zw-5 фабрики kutek. в архиве: max2012, obj, fbx, mat.(два варианта металла)

3ddd

$1

KUTEK (W) W-ZW-3

...kutek (w) w-zw-3

3ddd

kutek

3d модель люстри (w) w-zw-3 фабрики kutek. в архиве: max2012, obj, fbx, mat. (два варианта металла)

3ddd

$1

KUTEK (W) W-ZW-1

...kutek (w) w-zw-1

3ddd

kutek

3d модель люстри (w) w-zw-1 фабрики kutek. в архиве: max2012, obj, fbx, mat (два варианта металла).

3ddd

free

aneken W&W

...aneken w&w

3ddd

2 женских манекена, ценники и фолио. материалы и текстуры прилагаются.

design_connected

$9

KTribe W

...ktribe w

designconnected

ktribe w computer generated 3d model. designed by starck, philippe.

design_connected

$16

Troy W

...troy w

designconnected

magis troy w computer generated 3d model. designed by wanders, marcel.

turbosquid

$9

Menu - Benjamin Hubert - W W Carafe

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$9

Menu - Benjamin Hubert - W W Carafe

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.