Thingiverse

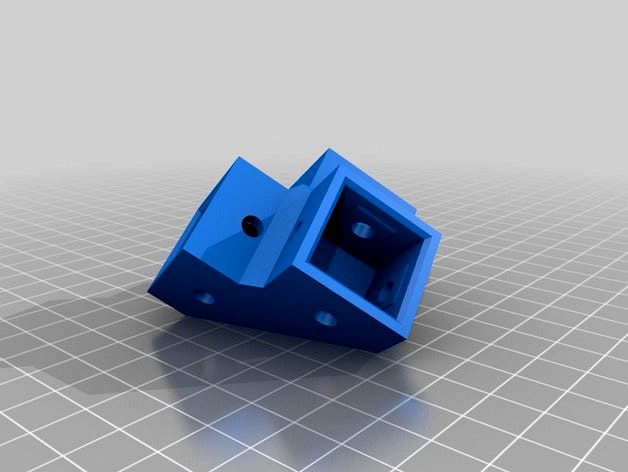

Corner Bracket 20x20 - (was) Untested - Now tested. by KiwiCat

by Thingiverse

Last crawled date: 4 years, 7 months ago

The idea is to use extruded square aluminium as a frame.

The inner dimension is 20.5. 20 was a little bit too tight.

The screw holes are 5mm you can not use all the holes because they are on the same line but if this is what you want , great.

I trimmed the corner. I rotate the print to the to the trimmed corner to keep the pattern consistent. It also makes that there is no seems that it would crack on(like my first attempt)

I need some suggestions.

**Corner_Bracket_3_cornerholes.stl

I was not happy with the amount of movement I was getting with the first bracket.

I made the fit a bit tighter. It is still easy to insert the tube but there is less movement. The dimensions are now precisely 20mm. Printing

*** As of today I can say it is tested. Printing stuff exactly the right size is a problem. Especially since we can work with infinite precision on a CAD program but after the molten plastic has been squirted into an accuracy of 100 microns, you still get a bit of shrinkage and change. So , the solution to the problem is hot water. No, Really. If the bracket does not fit 100% because of the slight shrinkage, just throw it in a bowl of hot water and then use it directly afterwards. The internet says it starts to go saggy at 60°C but that is only when don't want it to sag... if you are trying to force something onto a piece of metal then suddenly it needs to be boiling , go figure. Just use warm to 3/4 boiling water if the bracket does not fit perfectly.

The inner dimension is 20.5. 20 was a little bit too tight.

The screw holes are 5mm you can not use all the holes because they are on the same line but if this is what you want , great.

I trimmed the corner. I rotate the print to the to the trimmed corner to keep the pattern consistent. It also makes that there is no seems that it would crack on(like my first attempt)

I need some suggestions.

**Corner_Bracket_3_cornerholes.stl

I was not happy with the amount of movement I was getting with the first bracket.

I made the fit a bit tighter. It is still easy to insert the tube but there is less movement. The dimensions are now precisely 20mm. Printing

*** As of today I can say it is tested. Printing stuff exactly the right size is a problem. Especially since we can work with infinite precision on a CAD program but after the molten plastic has been squirted into an accuracy of 100 microns, you still get a bit of shrinkage and change. So , the solution to the problem is hot water. No, Really. If the bracket does not fit 100% because of the slight shrinkage, just throw it in a bowl of hot water and then use it directly afterwards. The internet says it starts to go saggy at 60°C but that is only when don't want it to sag... if you are trying to force something onto a piece of metal then suddenly it needs to be boiling , go figure. Just use warm to 3/4 boiling water if the bracket does not fit perfectly.