Thingiverse

Container Ship - MakeItFloat Challenge by TimeFramed

by Thingiverse

Last crawled date: 3 years ago

⚓ Container Ship ⚓ ‿‿‿‿‿‿‿‿‿‿‿‿

My entry into the "Science: Make It Float challenge"

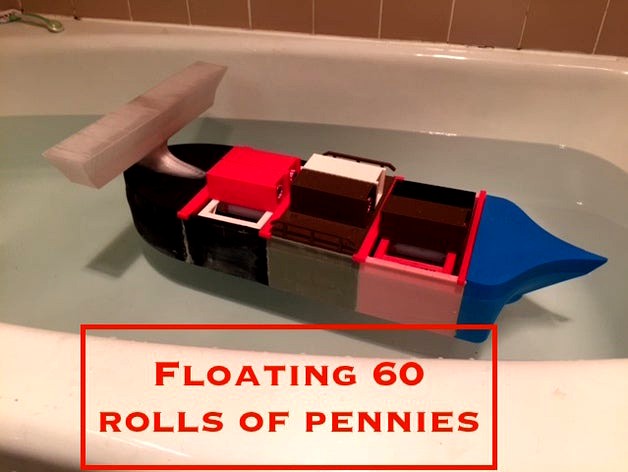

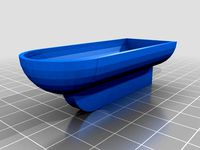

The current featured photo is a float-test of a three-hull-section container ship with SIXTY rolls of pennies (8.311kg); 16 in the front section, 16 in the center section, 15 in the rear section, and 7 in the stern (for pitch balance), and 6 containers "on deck". Had to move to the tub; the ship won't fit into the cooler I was using anymore...

In theory, this design can float an unlimited number of pennies, by simply adding more Container Hull sections, each of which can easily support the weight of 13-16 rolls of pennies.

Videos

60 rolls of pennies (8.311kg) floating in 3-hull container ship — final float test; That's all the penny rolls I have, and pretty much out of time. Lesson learned: lower the center of gravity.https://www.youtube.com/watch?v=ucUdUFSFkA0

Float test of 57 rolls of pennies (7.921kg)https://www.youtube.com/watch?v=lZGa6ZLCMuU

✅ Successful float test of 47 rolls of pennies (6.531kg)https://www.youtube.com/watch?v=nlUAm5jXbFs

An early float test (one-hull-section ship) with 4 containers in the hold, each with a roll of pennies inside.https://www.youtube.com/watch?v=wgOmfVg2kX4

Adding 3rd Container Hull section / Assembly

Part1 — https://www.youtube.com/watch?v=iOW4JNv2nHk

Part2 — https://www.youtube.com/watch?v=9WbwUSZzHJY

See the Instructions for a narrative of the iterative discoveries, and design modifications that resulted.

See Updates below to see changes since first published.

This is definitely a "work in progress". Things may still change based on the ongoing printing, testing, and experimentation.

I normally don't publish my things until after I successfully print one myself and verify everything prints and works as designed. However, for this challenge, you get to "come along for the ride", and follow the progress, setbacks, redesigns, and hopefully, the ultimate success of this project. A chronicle of the process can be found in the Narrative section under the Instructions tab.

Concept

The first thing that came to mind when I read the challenge goal — to optimize the amount of weight your boat can support using coins in your local currency — was a container ship, having the containers hold rolls of pennies.

An object floats based on Archimedes' principle:

Any object, wholly or partially immersed in a fluid, is buoyed up by a force equal to the weight of the fluid displaced by the object.

— Archimedes of Syracuse

Therefore, in order for a ship to float, it must displace a volume of water that weighs more that the ship and its cargo.

So, the first thing I did was weigh a roll of pennies to determine the size that a container would need to be in order to displace a volume of water having the same weight.

The idea behind that, is that if each container itself is at least (neutrally) buoyant, then a ship's hull that would surround the containers should have enough buoyancy to float the hull and the containers in it.

That conclusion is based on the fact that the hull would displace the volume of all the containers in its hold, plus the additional volume of the space around the containers (weighing only as much as the air in it), and the thickness of the hull itself. Since the hull will be made of plastic, and not solid, the volume of water equal to the volume of just the hull itself should be enough to float the hull. i.e., If I filled the hull with water it shouldn't sink.

This would be difficult to calculate ahead of time (although, using the slicer's "filament required", and approximating the weight of that much plastic would probably be close enough. Note: I proved this to be the case experimentally once the hull was printed.

Penny rolls ranged from 127g to 133g. I looked up the weight of water — 1g/1000mm³ (it varies with temperature, and of course salt content in the ocean, neither of which should be factors for this model...). From that, I determined a "container" size -- having dimensions to surround a roll of pennies, and enough volume that the container itself should float with a roll of pennies inside. If each container is buoyant, then by definition, the ship itself should be buoyant if the containers all fit inside the hull, since the ship's total water displacement would be even greater. It should, in fact, be greater by enough to add a layer or two of containers on the deck, and still be buoyant. I didn't try to pre-compute that; I figure that will be done by simple experimentation once the ship is loaded and floating by adding containers to the deck. Of course the weight of the water displaced by the hull must be greater than the weight of the ship, and it's cargo — by enough to raise the deck of the ship high enough above the water's surface to avoid flooding the hull.

The design I came up with is modular so that

It will fit in the print volume

In theory, it is infinitely scalable by using one Bow, one Stern, and any number of Hulls/Decks (I'm hoping to print as many hulls as time permits to test that theory...).

The bow and stern make it actually look somewhat like a ship (vs. a square barge), and add some buoyancy since they are empty, which should allow for on-deck containers.

Another design goal is to only use printed parts (other than the penny rolls), without the need for gluing, and to have no parts that require support material (which, for instance, influenced the shape of the stern away from being relatively flat to be somewhat pointed (it prints on end).

Note: In the end, the bow (second version) required support material; see Narration in the Instructions about that.

The hull part is sized to fit a dozen containers (4 wide × 3 high) based the dimensions described above.

I also incorporated a keel into the hull that can hold a roll of pennies to add weight at a the lowest point to aid in lowering the center of gravity, in an effort to increase lateral stability (to prevent the ship from rolling over).

In order for form a (reasonably) water-tight seal between the modules, there is a groove running the length of the joining edge of each piece. I employed a "gasket", printed with flexible filament, that is forced into the grooves, and the modules are then clipped together using 12 clips (ABS has enough "flex" to allow them to snap into place, while being rigid enough to hold tight).

Note: The flexible filament turned out to be too rigid to form a decent seal like a rubber gasket would. I wound up using a different solution — see the Narration section in the Instructions.

Updates

Jul 19

Added videos of 57- and 60-roll float tests of 3-hull-section ship.

Jul 18

Added video of 47-roll float test of 3-hull-section container ship.

Jul 17

Added 3rd Container Hull section

Jul 15

Added 2nd Container Hull section

Floated TWENTY SIX rolls of pennies (new photos)

Jul 14

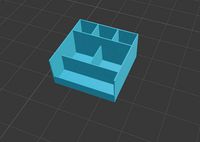

Added a "12 Container Replacement" consisting of a "grid" (print 2), and a "bar" (print 4).

Jul 13

Second float test (using plumber's putty between the hull seams) — success ✅ (new floating photo).

Deck Plate printed photos added.

New Bow printed, photos added.

Jul 11

Uploaded new, shorter, Bow, Bow_108.stl — it fits within required build volume limits. I left the original, Bow_68.stl for reference, and an option if your vertical print volume is not limited to 150mm.

Uploaded new Bridge halves, that are not as tall (as printed)/wide (as assembled)

Needed to reduce the print height to fit into the MakerBot's printable area (150mm).

Uploaded new Hull Joint Clip

Stronger (provides more pressure)

Does not interfere with the containers (is not wider than the "seam ridge".)

Uploaded new Joint Clip

It floats! (see pictures)

Of course, it leaks too...

Jul 9

Uploaded new (thinner gasket)

Jul 8

Bridge pictures

Jul 7

New (lighter) Container & Container Door)

new Penny Roll Holder (larger hole for roll, chamfered corners and slightly smaller outside dimension for easier fit into container)

new Container Door (looser fit, ridge on top for easier opening an look)

picture of completed container hull (one of hopefully 2 or more...)

Printing Progress:

☑ (1st revision) Bow

☑ New (2nd revision), shorter Bow

☑ 1st Hull

Containers (12) ☑ ☑ ☑ ☑ ☑ ☐ ☐ ☐ ☐ ☐ ☐ ☐

☑ Stern

☑ Gasket

☑ Hull Couplers (2)

☑ Hull Clips (12 per joint)

☑ Bow/Hull (12)

☑ Hull/Stern (12)

☑ Bridge

☑ Port Bridge

☑ Starboard Bridge

☑ Bridge Couplers (2)

☑ Stern Deck

☑ Crossbars

Bow Crossbar ☑

Container Hull Crossbars ☑ ☑ ☑

☑ Deck plate

☑ Re-designed container

☑ 2nd Hull

Containers (12) ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐

☑ 3rd Hull

Containers (12) ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐

☑☑ ☑ 24-container replacement penny roll holders (3)

To-do

☑ Redesign Bridge

☑ Redesign Bow

☑ Redesign container (see narration)

☑ Design "Clip" used to fasten the hull modules together

☑ Print second (container) Hull

☑ Test flotation

☑ New Container (success ✅)

☑ (original) Container only, with pennies (fail ⛔)

☑ Photos/video

☑&☒ Is ship balanced?

The new bow is lighter, and displaces less water than the original.

☑ The ship floats level when empty.

☒ When loaded with 26 rolls of pennies, the bow sinks further than the stern, since the stern has more buoyant force being applied to it due to the greater displacement than the bow.

Shifting 4 rolls from the front container section into the stern leveled the ship.

☑ Is it laterally stable, or susceptible to rolling? (I have a plan if it is unstable...)

☑ Determine how many containers can be added on-deck, and keep the deck above the waterline.

☑ Print more Hull sections (time permitting)

☑ 2nd Container Hull section

Containers ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐

☑ 3rd Container Hull section

Containers ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐

My entry into the "Science: Make It Float challenge"

The current featured photo is a float-test of a three-hull-section container ship with SIXTY rolls of pennies (8.311kg); 16 in the front section, 16 in the center section, 15 in the rear section, and 7 in the stern (for pitch balance), and 6 containers "on deck". Had to move to the tub; the ship won't fit into the cooler I was using anymore...

In theory, this design can float an unlimited number of pennies, by simply adding more Container Hull sections, each of which can easily support the weight of 13-16 rolls of pennies.

Videos

60 rolls of pennies (8.311kg) floating in 3-hull container ship — final float test; That's all the penny rolls I have, and pretty much out of time. Lesson learned: lower the center of gravity.https://www.youtube.com/watch?v=ucUdUFSFkA0

Float test of 57 rolls of pennies (7.921kg)https://www.youtube.com/watch?v=lZGa6ZLCMuU

✅ Successful float test of 47 rolls of pennies (6.531kg)https://www.youtube.com/watch?v=nlUAm5jXbFs

An early float test (one-hull-section ship) with 4 containers in the hold, each with a roll of pennies inside.https://www.youtube.com/watch?v=wgOmfVg2kX4

Adding 3rd Container Hull section / Assembly

Part1 — https://www.youtube.com/watch?v=iOW4JNv2nHk

Part2 — https://www.youtube.com/watch?v=9WbwUSZzHJY

See the Instructions for a narrative of the iterative discoveries, and design modifications that resulted.

See Updates below to see changes since first published.

This is definitely a "work in progress". Things may still change based on the ongoing printing, testing, and experimentation.

I normally don't publish my things until after I successfully print one myself and verify everything prints and works as designed. However, for this challenge, you get to "come along for the ride", and follow the progress, setbacks, redesigns, and hopefully, the ultimate success of this project. A chronicle of the process can be found in the Narrative section under the Instructions tab.

Concept

The first thing that came to mind when I read the challenge goal — to optimize the amount of weight your boat can support using coins in your local currency — was a container ship, having the containers hold rolls of pennies.

An object floats based on Archimedes' principle:

Any object, wholly or partially immersed in a fluid, is buoyed up by a force equal to the weight of the fluid displaced by the object.

— Archimedes of Syracuse

Therefore, in order for a ship to float, it must displace a volume of water that weighs more that the ship and its cargo.

So, the first thing I did was weigh a roll of pennies to determine the size that a container would need to be in order to displace a volume of water having the same weight.

The idea behind that, is that if each container itself is at least (neutrally) buoyant, then a ship's hull that would surround the containers should have enough buoyancy to float the hull and the containers in it.

That conclusion is based on the fact that the hull would displace the volume of all the containers in its hold, plus the additional volume of the space around the containers (weighing only as much as the air in it), and the thickness of the hull itself. Since the hull will be made of plastic, and not solid, the volume of water equal to the volume of just the hull itself should be enough to float the hull. i.e., If I filled the hull with water it shouldn't sink.

This would be difficult to calculate ahead of time (although, using the slicer's "filament required", and approximating the weight of that much plastic would probably be close enough. Note: I proved this to be the case experimentally once the hull was printed.

Penny rolls ranged from 127g to 133g. I looked up the weight of water — 1g/1000mm³ (it varies with temperature, and of course salt content in the ocean, neither of which should be factors for this model...). From that, I determined a "container" size -- having dimensions to surround a roll of pennies, and enough volume that the container itself should float with a roll of pennies inside. If each container is buoyant, then by definition, the ship itself should be buoyant if the containers all fit inside the hull, since the ship's total water displacement would be even greater. It should, in fact, be greater by enough to add a layer or two of containers on the deck, and still be buoyant. I didn't try to pre-compute that; I figure that will be done by simple experimentation once the ship is loaded and floating by adding containers to the deck. Of course the weight of the water displaced by the hull must be greater than the weight of the ship, and it's cargo — by enough to raise the deck of the ship high enough above the water's surface to avoid flooding the hull.

The design I came up with is modular so that

It will fit in the print volume

In theory, it is infinitely scalable by using one Bow, one Stern, and any number of Hulls/Decks (I'm hoping to print as many hulls as time permits to test that theory...).

The bow and stern make it actually look somewhat like a ship (vs. a square barge), and add some buoyancy since they are empty, which should allow for on-deck containers.

Another design goal is to only use printed parts (other than the penny rolls), without the need for gluing, and to have no parts that require support material (which, for instance, influenced the shape of the stern away from being relatively flat to be somewhat pointed (it prints on end).

Note: In the end, the bow (second version) required support material; see Narration in the Instructions about that.

The hull part is sized to fit a dozen containers (4 wide × 3 high) based the dimensions described above.

I also incorporated a keel into the hull that can hold a roll of pennies to add weight at a the lowest point to aid in lowering the center of gravity, in an effort to increase lateral stability (to prevent the ship from rolling over).

In order for form a (reasonably) water-tight seal between the modules, there is a groove running the length of the joining edge of each piece. I employed a "gasket", printed with flexible filament, that is forced into the grooves, and the modules are then clipped together using 12 clips (ABS has enough "flex" to allow them to snap into place, while being rigid enough to hold tight).

Note: The flexible filament turned out to be too rigid to form a decent seal like a rubber gasket would. I wound up using a different solution — see the Narration section in the Instructions.

Updates

Jul 19

Added videos of 57- and 60-roll float tests of 3-hull-section ship.

Jul 18

Added video of 47-roll float test of 3-hull-section container ship.

Jul 17

Added 3rd Container Hull section

Jul 15

Added 2nd Container Hull section

Floated TWENTY SIX rolls of pennies (new photos)

Jul 14

Added a "12 Container Replacement" consisting of a "grid" (print 2), and a "bar" (print 4).

Jul 13

Second float test (using plumber's putty between the hull seams) — success ✅ (new floating photo).

Deck Plate printed photos added.

New Bow printed, photos added.

Jul 11

Uploaded new, shorter, Bow, Bow_108.stl — it fits within required build volume limits. I left the original, Bow_68.stl for reference, and an option if your vertical print volume is not limited to 150mm.

Uploaded new Bridge halves, that are not as tall (as printed)/wide (as assembled)

Needed to reduce the print height to fit into the MakerBot's printable area (150mm).

Uploaded new Hull Joint Clip

Stronger (provides more pressure)

Does not interfere with the containers (is not wider than the "seam ridge".)

Uploaded new Joint Clip

It floats! (see pictures)

Of course, it leaks too...

Jul 9

Uploaded new (thinner gasket)

Jul 8

Bridge pictures

Jul 7

New (lighter) Container & Container Door)

new Penny Roll Holder (larger hole for roll, chamfered corners and slightly smaller outside dimension for easier fit into container)

new Container Door (looser fit, ridge on top for easier opening an look)

picture of completed container hull (one of hopefully 2 or more...)

Printing Progress:

☑ (1st revision) Bow

☑ New (2nd revision), shorter Bow

☑ 1st Hull

Containers (12) ☑ ☑ ☑ ☑ ☑ ☐ ☐ ☐ ☐ ☐ ☐ ☐

☑ Stern

☑ Gasket

☑ Hull Couplers (2)

☑ Hull Clips (12 per joint)

☑ Bow/Hull (12)

☑ Hull/Stern (12)

☑ Bridge

☑ Port Bridge

☑ Starboard Bridge

☑ Bridge Couplers (2)

☑ Stern Deck

☑ Crossbars

Bow Crossbar ☑

Container Hull Crossbars ☑ ☑ ☑

☑ Deck plate

☑ Re-designed container

☑ 2nd Hull

Containers (12) ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐

☑ 3rd Hull

Containers (12) ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐

☑☑ ☑ 24-container replacement penny roll holders (3)

To-do

☑ Redesign Bridge

☑ Redesign Bow

☑ Redesign container (see narration)

☑ Design "Clip" used to fasten the hull modules together

☑ Print second (container) Hull

☑ Test flotation

☑ New Container (success ✅)

☑ (original) Container only, with pennies (fail ⛔)

☑ Photos/video

☑&☒ Is ship balanced?

The new bow is lighter, and displaces less water than the original.

☑ The ship floats level when empty.

☒ When loaded with 26 rolls of pennies, the bow sinks further than the stern, since the stern has more buoyant force being applied to it due to the greater displacement than the bow.

Shifting 4 rolls from the front container section into the stern leveled the ship.

☑ Is it laterally stable, or susceptible to rolling? (I have a plan if it is unstable...)

☑ Determine how many containers can be added on-deck, and keep the deck above the waterline.

☑ Print more Hull sections (time permitting)

☑ 2nd Container Hull section

Containers ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐

☑ 3rd Container Hull section

Containers ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐

Similar models

3dwarehouse

free

hull

...hull

3dwarehouse

bow+stern=hull #bow #hull #stern

thingiverse

free

Sea-Ghost Stern-Open by rovingmind

...en" for the front section that matches this.

edit b, angled the bottom of the deck support - as requested for printing flat.

grabcad

free

Modular HDPE Pontoon Hull

...modular hdpe pontoon hull

grabcad

bow and stern pontoon sections for modular hdpe pontoon hulls

3dwarehouse

free

independence of the seas (full)

...nchors #boat #boats #bow #bronze #cargo #city #deck #floats #glass #gold #hull #metal #propellers #sea #ship #sky #stern #texture

3dwarehouse

free

Detailed ships hull with texture

...ains over 4000 faces and includes a template texture with deck, side and stern textures already mapped. #boat #hull #ship #vessel

3dwarehouse

free

Ship's bow

... bow

3dwarehouse

parabolic curves forms this ship's bow. hull cross section is a triangle. #boat #bow #hull #parabolic #ship

3dwarehouse

free

titanic ship wreck

...eck by deck in half then ruined the deck to make it look damaged hope you enjoy :) #1912 #bow #chevin #dead #ship #stern #titanic

thingiverse

free

A Typical Kayak (COMPLETE WITH PADDLES!) by SouthGeometric

...ake the density of the boat lower than the density of the water.

of course the usa sticker helps it float too! greatness rises!

thingiverse

free

Mariner Ship Hull (v1) by Myanc

...so if printed it does float.

when printing check your wall thickness (along with the usual settings).

re-scale to desirable size.

3dwarehouse

free

BARKENTINE JAMES TAYLOR

...barkentine james taylor

3dwarehouse

planked deck new deck house stern and bow rail

Makeitfloat

thingiverse

free

MakeItFloat yourself! by Horstage

...oat can support using coins in your local currency.

for more information seehttps://www.thingiverse.com/challenges/makeitfloat/

thingiverse

free

Concept Boat #MakeItFloat by danbdaj

...hingiverse

this is designed for 3d print without supports and rafts.

concept design inspired in some jet fighters.

makeitfloat

thingiverse

free

Boat2015#MakeItFloat by ben2015

...boat2015#makeitfloat by ben2015

thingiverse

boat with two positions standby and ready to float

thingiverse

free

Mr Q. Amphibian CarBoat. #MakeItFloat by MyMicrofactory

...mr q. amphibian carboat. #makeitfloat by mymicrofactory

thingiverse

work on progress. coming soon...

makeitfloat

thingiverse

free

Floating Koozie #MakeItFloat by JOSHUASCHWARTZ

...floating koozie #makeitfloat by joshuaschwartz

thingiverse

for those who like to have a drink in the pool.

thingiverse

free

Klein ship #MakeItFloat by obossio

...klein ship #makeitfloat by obossio

thingiverse

a nice little boat mixed with a klein bottle

thingiverse

free

Little boat #MakeItFloat by obossio

...little boat #makeitfloat by obossio

thingiverse

a nice boat that i design to mix it with the klein bottle

thingiverse

free

House Boat #MakeItFloat by cfrary

...house boat #makeitfloat by cfrary

thingiverse

a house boat that prints in two parts, the house and the floating platform.

thingiverse

free

MakeitFloat rubber duck by fmotta

...makeitfloat rubber duck by fmotta

thingiverse

i hacked the duck (see remix) and added an opening to make it boat-like.

thingiverse

free

quarter boat 1 #MakeItFloat by cfrary

...quarter boat 1 #makeitfloat by cfrary

thingiverse

a quarter transport boat, early model.

Timeframed

3d_export

$74

Tips About medical equipment loans You Can Use Today

...n-men and women and loans for dentists. the amount you can get by way of these loans might vary even they have got the base of .

thingiverse

free

Assembly "L" cube by TimeFramed

...be by timeframed

thingiverse

while constructing an enclosure for my prusa i3, i found i needed a variant of my assembly cube...

thingiverse

free

60mm Fan Grille by TimeFramed

...after accidentally touching the fan while it was running, and breaking one of the fins, i figured i should have a grille cover...

thingiverse

free

Balance packet box by TimeFramed

...d

thingiverse

i made it to carry my avisae balance packets.

i'm sure it would be useful for anything else of similar size.

thingiverse

free

Gyro cube gimbal by TimeFramed

... by a failed miniature print of my big thick gyro cube (see orange photo), i designed a gimbal based on the gyro cube components.

thingiverse

free

Balance™ packet container by TimeFramed

...sier to open/close than my original design, and the lid remains attached (no lose parts).

printed with makerseries petg filament.

thingiverse

free

Knob for Prusa i3 display (for MakerFarm) by TimeFramed

...for makerfarm) by timeframed

thingiverse

the lcd display has a turn-and-push shaft to control it; i wanted a nice knob for it...

thingiverse

free

Filament Guide by TimeFramed

.../b006kt1b80/ref=oh_details_o00_s00_i00?ie=utf8&psc=1 ), and then slide over a piece of standard 1/2" electrical conduit.

thingiverse

free

TimeFrame - A time portal to put on your desk. by cubic-print

...ttp://www.youtube.com/watch?v=llgywkkifci

get a kit from our webshop (shipment from germany):http://www.cubic-print.com/timeframe

thingiverse

free

Hiking pole basket by TimeFramed

...... as usual, i turned to my 3d printer.

for these, i used pctpe filament; a perfect material — flexible, but reasonably stiff.

Challenge

turbosquid

$120

Challenger 2 and challenger 2 TES

...e 3d model challenger 2 and challenger 2 tes for download as on turbosquid: 3d models for games, architecture, videos. (1430319)

3d_export

$59

dodge challenger srt8

...dodge challenger srt8

3dexport

dodge challenger srt8

3d_export

$20

dodge challenger 1970

...dodge challenger 1970

3dexport

dodge challenger 1970

3d_export

$15

Dodge Challenger Hellcat

...dodge challenger hellcat

3dexport

dodge challenger hellcat

turbosquid

$80

challenger-2

...rbosquid

royalty free 3d model challenger-2 for download as on turbosquid: 3d models for games, architecture, videos. (1498848)

3d_export

$5

dodge challenger car

...dodge challenger car

3dexport

3d model dodge challenger!

turbosquid

$99

Dodge Challenger

...

royalty free 3d model dodge challenger for download as blend on turbosquid: 3d models for games, architecture, videos. (1489358)

turbosquid

$49

Dodge Challenger

...

royalty free 3d model dodge challenger for download as blend on turbosquid: 3d models for games, architecture, videos. (1698375)

turbosquid

$10

dodge challenger

...

royalty free 3d model dodge challenger for download as blend on turbosquid: 3d models for games, architecture, videos. (1405948)

3d_export

free

dodge challenger srt8

...dodge challenger srt8

3dexport

dodge challenger srt8 free model

Ship

3d_export

$5

ship

...ship

3dexport

ship

3d_export

$5

Ship

...ship

3dexport

ship

archibase_planet

free

Ship

...ship

archibase planet

ship

ship n280909 - 3d model (*.gsm+*.3ds) for 3d visualization.

3d_export

$5

ship

...ship

3dexport

the ship is well suited for games.

3d_export

free

ship

...ship

3dexport

a lowpoly ship similar to the titanic...

archibase_planet

free

Ship

...ship

archibase planet

cruiser cruise ship

cruise ship n010807 - 3d model for interior 3d visualization.

archibase_planet

free

Ship

...ship

archibase planet

sailing vessel ship

ship n140110 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Ship

...ship

archibase planet

cutter launch ship

ship n010710 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

Ship

...ship

archibase planet

sailing vessel ship vehicle of the sea

ship n010708 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$15

ship destroyer

...ip,frigate ship,ship,corvette ship for download as ma and fbx on turbosquid: 3d models for games, architecture, videos. (1435217)

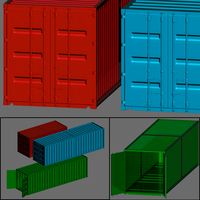

Container

3d_export

$5

container

...container

3dexport

3d model of a commercial container, cargo container, container

3d_ocean

$15

container

...container

3docean

container

create container in maya

archibase_planet

free

Container

...ontainer freight container transport container

container shipping n290612 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

3d_export

$5

container

...container

3dexport

container

archibase_planet

free

Container

...

archibase planet

container shipping container

container industry n250114 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

3d_ocean

$7

Container

...te industrial iso container ocean ocean transport container port ship shipment shipping transport truck vessel

detailed container

archibase_planet

free

Container

...errycan container jerry can jerrican fuel container

container gas n250815 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_ocean

$5

Containers

...containers

3docean

barrel black blue bottle container jerrycan

2 containers of hight quolity. renderer in mentalray

archibase_planet

free

Container

...container

archibase planet

container kitchen ware

container - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Container

...container

archibase planet

container dustbin

container n180209 - 3d model (*.gsm+*.3ds) for interior 3d visualization.