GrabCAD

Connect the Ship Challenge - Internal Mechanical Solution & Automated Attachment/Removal Options

by GrabCAD

Last crawled date: 1 year, 11 months ago

The goal of this submission is to provide a very basic and very brief concept of two similar potential new corner locks for stackable shipping containers as well as provide a general idea for two automated designs to attach/remove corner locks (whether this design or use of others) from shipping containers as they leave or head to the ship. (Continued below)

Additional refinement of the current models including for manufacturability, cost, additional details, and stress as shown would be required moving forward and as this is meant to only show a basic mechanical solution idea as well as usage of the space standardized container corners allow.

Thanks for the opportunity and for your consideration.

-ChrisB

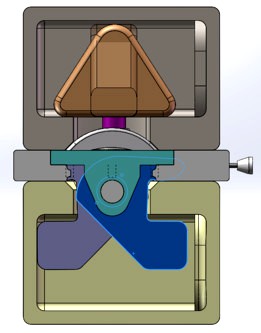

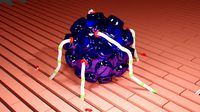

Corner Lock Design1 - '3-Fingers':

Uses mechanical cam system to auto lock the upper container to container below. As the upper container is lowered springs keep the cam plate pointed downward, ready to insert into container below. Position and shape of this plate allows it to easily fit in hole of the container below. As the upper container is lowered the cam plate hits top of lower container and starts to pivot the lock into place inside the lower container corner (ref attached screen shots). The unique cam system allows the potential to provide two walls of contact inside the lower container at once from this rotating arm in lieu of current designs on the market that only attach to a small portion of the uppermost surface of the inside of the lower container corner.

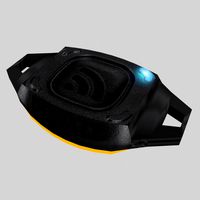

Corner Lock Design2 - 'OneSided':

Similar to Design1 above but only uses the mechanical cam plate on one side to hold container (as four points on container should only need for one side per hole).

Automate Insertion/Removal of Corner Locks - Option 1-Staging Table:

An automated staging table would sit between the ship and trucks(or other) delivering containers. This could be setup to work with a chosen corner lock design and be made to service all standard size containers of varying lengths. The crane moving a container would briefly set the container down on the table where automated process would add/remove the corner locks within

seconds and then lift back up to continue its journey whether that be to the ship or to an awaiting truck.

Automate Insertion/Removal of Corner Locks - Option 2-Staging Stand:

A truck delivering a shipping container would pull under a crane being used to load/unload an awaiting cargo ship. This same area would have several post to the left and right of the truck. The crane would lift the shipping container just enough off the truck to clear it, allowing the truck to continue on its way. This would also put the container in position of the surrounding post that hold automated equipment to attached the corner locks. The post would be spaced and numbered as necessary to accommodate the different standardized lengths of shipping containers and software would ensure the correct locations are turned on to locate and attach corner locks to the container within seconds. Software and the mechanical design of these automated post would mean the truck delivering the container did not have to stop in an exact location eliminating a potential roadblock of this idea. The automated system could self align and insert locks within seconds, allowing the crane to quickly continue on its way without adding any additional movements to the loading process.

Original SW2015 Models and a STP file attached.

Blue Container model by GC user Michael Herbert

Grey Container corners by 3DCC user Justin Nitz

Green Flatbed Trailer model by GC user Erjan Rohaan

Additional refinement of the current models including for manufacturability, cost, additional details, and stress as shown would be required moving forward and as this is meant to only show a basic mechanical solution idea as well as usage of the space standardized container corners allow.

Thanks for the opportunity and for your consideration.

-ChrisB

Corner Lock Design1 - '3-Fingers':

Uses mechanical cam system to auto lock the upper container to container below. As the upper container is lowered springs keep the cam plate pointed downward, ready to insert into container below. Position and shape of this plate allows it to easily fit in hole of the container below. As the upper container is lowered the cam plate hits top of lower container and starts to pivot the lock into place inside the lower container corner (ref attached screen shots). The unique cam system allows the potential to provide two walls of contact inside the lower container at once from this rotating arm in lieu of current designs on the market that only attach to a small portion of the uppermost surface of the inside of the lower container corner.

Corner Lock Design2 - 'OneSided':

Similar to Design1 above but only uses the mechanical cam plate on one side to hold container (as four points on container should only need for one side per hole).

Automate Insertion/Removal of Corner Locks - Option 1-Staging Table:

An automated staging table would sit between the ship and trucks(or other) delivering containers. This could be setup to work with a chosen corner lock design and be made to service all standard size containers of varying lengths. The crane moving a container would briefly set the container down on the table where automated process would add/remove the corner locks within

seconds and then lift back up to continue its journey whether that be to the ship or to an awaiting truck.

Automate Insertion/Removal of Corner Locks - Option 2-Staging Stand:

A truck delivering a shipping container would pull under a crane being used to load/unload an awaiting cargo ship. This same area would have several post to the left and right of the truck. The crane would lift the shipping container just enough off the truck to clear it, allowing the truck to continue on its way. This would also put the container in position of the surrounding post that hold automated equipment to attached the corner locks. The post would be spaced and numbered as necessary to accommodate the different standardized lengths of shipping containers and software would ensure the correct locations are turned on to locate and attach corner locks to the container within seconds. Software and the mechanical design of these automated post would mean the truck delivering the container did not have to stop in an exact location eliminating a potential roadblock of this idea. The automated system could self align and insert locks within seconds, allowing the crane to quickly continue on its way without adding any additional movements to the loading process.

Original SW2015 Models and a STP file attached.

Blue Container model by GC user Michael Herbert

Grey Container corners by 3DCC user Justin Nitz

Green Flatbed Trailer model by GC user Erjan Rohaan

Similar models

grabcad

free

low_tec_twist_lock

...can be pushed in. since it releases itself after lifting up the container, there's no need for any removal of the twist lock.

grabcad

free

E.M.L. Concept

...ed with wires

- the wires are inserted into container corner post

this system is activated and deactivated by means of current.

grabcad

free

Twitlock with automatic locking/unlocking

...g\unlocking there is no accident possible

twistlock weight is ~9 kg

maximum vertical load - 500 kn

maximum racking load - 300kn

cg_trader

$13

Container Tower Crane

...ransport a single container at once, but some newer cranes have the capability to pick up two to four 20-foot containers at once.

grabcad

free

Automatic Twist Lock

...s is a straightforward but complex design and i'm not even sure if it's practical, but i just wanted to put it out there.

grabcad

free

Weight-Enabled-Lock

...ner has been removed.

the weight of the upper container will be used to lock itself in position and lose itself during unloading

cg_trader

$21

Container Head Crane

...strial container box ship crane trailer storage cargo container 40ft logistic truck cardboard box lift machine industrial machine

cg_trader

$17

Container Crane

...avy shipping platform port lift dock loader tool excavator airplane large truck transport cargo container 40ft sea elevator other

grabcad

free

Robinson Auto Twist Lock

...r great advantage of the design is that trough 4 screws it allows an easy access to all interior components for easy maintenance.

cg_trader

$13

Container Crane Head

...container cranes are generally classified by their lifting capacity and the size of the container ships they can load and unload.

Automated

turbosquid

$19

Automation for gates

... model automation for gates for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1600153)

turbosquid

$5

Automated Teller Machine

...tomated teller machine for download as c4d, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1677841)

turbosquid

$30

AUTOMATED GUARD STATION

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$19

Drink Automate New

...w office old red retro rust soda store vending vintage

old rusty drink machine, and new shiny. xsi and lvo exported from blender.

evermotion

$10

home automation system 32 am95

...ion system with all textures, shaders and materials.

it is ready to use, just put it into your scene.. evermotion 3d models shop.

evermotion

$10

home automation system 35 am95

...ion system with all textures, shaders and materials.

it is ready to use, just put it into your scene.. evermotion 3d models shop.

evermotion

$10

home automation system 38 am95

...ion system with all textures, shaders and materials.

it is ready to use, just put it into your scene.. evermotion 3d models shop.

evermotion

$10

home automation system 24 am95

...ion system with all textures, shaders and materials.

it is ready to use, just put it into your scene.. evermotion 3d models shop.

evermotion

$10

home automation system 30 am95

...ion system with all textures, shaders and materials.

it is ready to use, just put it into your scene.. evermotion 3d models shop.

evermotion

$10

home automation system 27 am95

...ion system with all textures, shaders and materials.

it is ready to use, just put it into your scene.. evermotion 3d models shop.

Challenge

turbosquid

$120

Challenger 2 and challenger 2 TES

...e 3d model challenger 2 and challenger 2 tes for download as on turbosquid: 3d models for games, architecture, videos. (1430319)

3d_export

$59

dodge challenger srt8

...dodge challenger srt8

3dexport

dodge challenger srt8

3d_export

$20

dodge challenger 1970

...dodge challenger 1970

3dexport

dodge challenger 1970

3d_export

$15

Dodge Challenger Hellcat

...dodge challenger hellcat

3dexport

dodge challenger hellcat

turbosquid

$80

challenger-2

...rbosquid

royalty free 3d model challenger-2 for download as on turbosquid: 3d models for games, architecture, videos. (1498848)

3d_export

$5

dodge challenger car

...dodge challenger car

3dexport

3d model dodge challenger!

turbosquid

$99

Dodge Challenger

...

royalty free 3d model dodge challenger for download as blend on turbosquid: 3d models for games, architecture, videos. (1489358)

turbosquid

$49

Dodge Challenger

...

royalty free 3d model dodge challenger for download as blend on turbosquid: 3d models for games, architecture, videos. (1698375)

turbosquid

$10

dodge challenger

...

royalty free 3d model dodge challenger for download as blend on turbosquid: 3d models for games, architecture, videos. (1405948)

3d_export

free

dodge challenger srt8

...dodge challenger srt8

3dexport

dodge challenger srt8 free model

Internal

3ddd

$1

Quorum International

... international

3ddd

florence , quorum international

люстра quorum international florence

3d_export

$5

internal door

...internal door

3dexport

internal door

turbosquid

$40

international

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Lamp International

...ernational

3ddd

lamp international

в файле содержится два светильника от lamp international - люстра арт. 2034/f9 и бра арт. 2026

3ddd

$1

VACCARI INTERNATIONAL

... овальное

производитель vaccari international

серия verona

длина 90, глубина 4,5, высота 70

3ddd

$1

Торшер / Lamp International

...торшер / lamp international

3ddd

lamp international

фабрика lamp international (италия).коллекция siena, арт.3452.

turbosquid

$99

International Soldier

...yalty free 3d model international soldier for download as max on turbosquid: 3d models for games, architecture, videos. (1556764)

turbosquid

$5

Internal door

...id

royalty free 3d model internal door for download as blend on turbosquid: 3d models for games, architecture, videos. (1691264)

3ddd

$1

International Italia 8100

...international italia 8100

3ddd

international italia

люстра lamp international italia 8100 с текстурами и материалами v-ray

turbosquid

$79

International Loadstar

...model international loadstar for download as ma, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1678922)

Ship

3d_export

$5

ship

...ship

3dexport

ship

3d_export

$5

Ship

...ship

3dexport

ship

archibase_planet

free

Ship

...ship

archibase planet

ship

ship n280909 - 3d model (*.gsm+*.3ds) for 3d visualization.

3d_export

$5

ship

...ship

3dexport

the ship is well suited for games.

3d_export

free

ship

...ship

3dexport

a lowpoly ship similar to the titanic...

archibase_planet

free

Ship

...ship

archibase planet

cruiser cruise ship

cruise ship n010807 - 3d model for interior 3d visualization.

archibase_planet

free

Ship

...ship

archibase planet

sailing vessel ship

ship n140110 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Ship

...ship

archibase planet

cutter launch ship

ship n010710 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

Ship

...ship

archibase planet

sailing vessel ship vehicle of the sea

ship n010708 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$15

ship destroyer

...ip,frigate ship,ship,corvette ship for download as ma and fbx on turbosquid: 3d models for games, architecture, videos. (1435217)

Mechanical

3d_export

$50

Mechanism

...mechanism

3dexport

mechanism -------- animation is present only in the blender file.

3d_export

$5

mechanics

...mechanics

3dexport

turbosquid

$50

mechanic

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Mechanical Wasp

...mechanical wasp

3ddd

робот

mechanical wasp

3d_export

$20

Mechanical tail

...mechanical tail

3dexport

mechanical tail<br>four-part movement

3d_export

$5

mechanical ballista

...mechanical ballista

3dexport

a mechanical ballista useful for medieval or fantasy games does not contain animations

turbosquid

$59

Mechanical Part

...id

royalty free 3d model mechanical part for download as c4d on turbosquid: 3d models for games, architecture, videos. (1410833)

turbosquid

$50

Mechanical Spider

...royalty free 3d model mechanical spider for download as blend on turbosquid: 3d models for games, architecture, videos. (1599864)

turbosquid

$45

Mechanical Pencil

...royalty free 3d model mechanical pencil for download as blend on turbosquid: 3d models for games, architecture, videos. (1503379)

turbosquid

$35

Mechanical fish

...id

royalty free 3d model mechanical fish for download as max on turbosquid: 3d models for games, architecture, videos. (1152530)

Connect

turbosquid

$12

connection

...bosquid

royalty free 3d model connection for download as max on turbosquid: 3d models for games, architecture, videos. (1479836)

3d_export

$5

CONNECTED PUMP

...connected pump

3dexport

connected pump<br>.blend

design_connected

$11

Connect Ottomans

...connect ottomans

designconnected

muuto connect ottomans computer generated 3d model. designed by anderssen & voll.

design_connected

$11

Connection Rectangular

...angular

designconnected

gallotti & radice connection rectangular computer generated 3d model. designed by castagna, massimo.

3d_export

$5

rope connection ring

...rope connection ring

3dexport

rope connection ring

3ddd

free

nurus - connect

... диваны, моделились под проект гостиницы новотель.

более подробная инфа тут:http://www.nurus.com.tr/en/product/connect

turbosquid

$11

pipe connective

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Connected Mirror

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

connecting road

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$29

Tool Connect

...ol connect for download as 3ds, max, obj, fbx, blend, and stl on turbosquid: 3d models for games, architecture, videos. (1342648)

Solution

3ddd

$1

Grammer / Solution

... кресло

офисное кресло solution фирмы grammer office. подробнее на www.grammer-office.com

3d_export

$48

TV Solution 3D Model

...solution 3d model

3dexport

tv solution interior dvd decor gypsum cornices spotlights

tv solution 3d model mr.kiwan 19449 3dexport

3d_export

$86

architectural solution 352a1

...architectural solution 352a1

3dexport

3dsmax 2017 3dsmax 2020 fbx obj map

3ddd

$1

Светильник польского производителя Aquaform Lighting Solution

...ution

3ddd

aquaform

светильник польского производителя aquaform lighting solution

модели:

tuba 111x1 distance

tuba 111x2 distance

3d_export

$20

lift internet solutions 3

...ly model of an industrial elevator. - materials are configured in 3ds max and corona render. - formats: fbx, obj, step, max 2020.

3ddd

$1

Светильник польского производителя Aquaform Lighting Solution

...

светильник польского производителя aquaform lighting solution

серия: tuba 111

модели:

tuba 111 on

tuba 111 on 23

tuba 111 on 34

3ddd

$1

Одинарный спот польского производителя Aquaform Lighting Solution

... aquaform

одинарный спот польского производителя aquaform lighting solution

модель: zuma 90

turbosquid

$25

Triple Hair Core Set Shampoo Serum Solution

... shampoo solution serum set for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1638904)

3ddd

$1

Поворотный светильник польского производителя Aquaform Lighting Solution

...воротный светильник польского производителя aquaform lighting solutionhttp://www.aquaformlighting.com/

модель: rotto

3ddd

$1

PotteryBarn ROLLING CABINET MEDIA SOLUTION

... телевизор , роллинг

279.4cm wide x 111.8cm high x 12.06cm deep

fits most 152.4cm tvs.

Removal

turbosquid

$15

Staple Remover

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Staple Remover

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Staple Remover

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$25

Staple Remover 3D Model

...remover office supplies pull desk paper remove workplace school work desktop vray

staple remover 3d model plutonius 7699 3dexport

turbosquid

$28

Removable Wall Hatch

... 3d model removable wall hatch for download as , fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1670326)

3d_export

$15

Staple Remover 3D Model

... desktop paper accessories household tool desk workplace instrument equipment pull

staple remover 3d model firdz3d 90012 3dexport

3ddd

free

Missed Maps Remover

...

3ddd

missed maps remover

скрипт находит потерянные карты в файле и позволяет удалить их или открыть в окне редактора материалов.

turbosquid

$29

Eye remover

...bosquid

royalty free 3d model eyeremover for download as 3dm on turbosquid: 3d models for games, architecture, videos. (1695439)

3ddd

$1

Remove Note Track

...аем скрипт чтобы удалить нулевые треки,которые грузят систему при сохранении и файл начинает сохраняться снова нормально и быстро

3d_export

$6

Gas dust removal bag filter

...gas dust removal bag filter

3dexport

gas dust removal, bag filter

Attachment

turbosquid

$20

M4A1 + Attachements

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Attached House

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Attache case

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

cg_studio

$75

Attached House3d model

...d model

cgstudio

.3ds .fbx .max .obj - attached house 3d model, royalty free license available, instant download after purchase.

turbosquid

$2

M416 AR with attachments

... model m416 ar with attachments for download as blend and fbx on turbosquid: 3d models for games, architecture, videos. (1614294)

turbosquid

$10

M16A2 with M203 Attachment

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Modern 1911 with Attachments

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

bench attached to greenery

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$8

Mercedes Sprinter sun visor attachment

...mercedes sprinter sun visor attachment

3dexport

mercedes sprinter sun visor attachment

turbosquid

$14

Residential building with attached shop

...l residential building with attached shop for download as max on turbosquid: 3d models for games, architecture, videos. (1482935)

Options

3ddd

$1

Фритюр SG14S with Options

...фритюр sg14s with options

3ddd

фритюр

проф. фритюр sg14s with options

3d_ocean

$15

trophy options

...e material property props trophy winner

-trophy options -low polys -obj, fbx,blender, 3ds. -zip : 5.7 mb - include gold material.

turbosquid

$2

keyboard 3 options

...oyalty free 3d model keyboard 3 options for download as blend on turbosquid: 3d models for games, architecture, videos. (1711408)

design_connected

$18

Swivel Chairs with Footrest Option

...swivel chairs with footrest option

designconnected

swivel chairs with footrest option computer generated 3d model.

design_connected

$16

Swivel Armchairs with Footrest Option

...swivel armchairs with footrest option

designconnected

swivel armchairs with footrest option computer generated 3d model.

3d_export

$19

1955 sideboard 3 options

...1955 sideboard 3 options

3dexport

turbosquid

$29

Office Chair with Multi Options

... 3d model office chair with multi options for download as max on turbosquid: 3d models for games, architecture, videos. (1380794)

turbosquid

$25

claddagh ring two options

...y free 3d model claddagh ring two options for download as 3dm on turbosquid: 3d models for games, architecture, videos. (1673087)

turbosquid

$20

PADDY PLANE OPTION 12

...yalty free 3d model paddy plane option 12 for download as max on turbosquid: 3d models for games, architecture, videos. (1696286)

turbosquid

$18

pendant sun three options

...free 3d model pendant sun three options for download as 3dm on turbosquid: 3d models for games, architecture, videos. (1555386)