Thingiverse

Clothes dryer vent quick disconnect / dock by bummster

by Thingiverse

Last crawled date: 3 years, 3 months ago

I recently came into ownership of a K40 laser cutter. But how do I get the fumes out of the house? I didn't want to use a window contraption. It gets really cold in Chicago. Hey, why not use the dryer vent?!

There are plenty of other designs out there. Commercial and printable options use a series of clips or magnets for retention. I wasn't a fan of either of those. I wanted a more substantial retention method, yet clean. I didn't want to see bits of wire or frayed ends either.

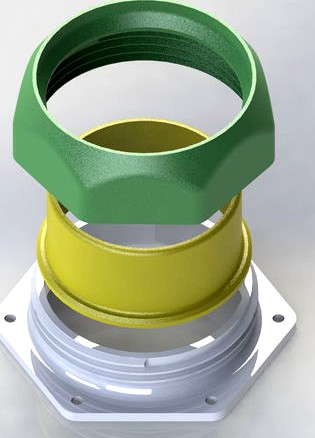

3 parts

A hexagonal wall flange that can slip around a 4" vent.

A heptagonal nut. Yes, a 7 sided nut. Why? Because they're cool.

A cylindrical hose insert that captures the nut.

The whole thing works sorta like a compression fitting. It's just the size of your hand...

Slide the hose insert into the heptagon. Then slide the 4" hose onto the outside of the hose insert. Stuff the wire and a coil or two into the relief of the heptagon to ensure the nut is captured and spins freely with no play. Sinch it all down with a hose clamp.

There's no need to cut the vent tube flat to the wall or anything. Though, you may need to trim it back. Apply some sort of gasket material to the flat side of the wall flange. I used neoprene strips cut to length. Attach the wall flange using your favorite sets of screws and anchors. I'm a fan of E-Z anchors.

The wall flange and hose insert should be printed in PETG due to temperatures. I also printed these 100% infill. You'll consume over 200g of filament on these two parts alone.

The heptagonal nut is fine in PLA. Seems plenty strong at 4 lines for the walls and 10% infill.

Do apply a very thin dose of white or dielectric grease to the threads. Be very sparing here. You're not trying to coat them, just give them a touch of slickness so the threads can spin freely. I've found that printed threading, even at a 6mm pitch, get kinda sticky

I printed a pair of these, and so far I'm quite pleased with their performance. And if you're wondering why these things aren't all circles, it's because I wanted them to stand out a bit. A conversation starter if you will. Before I sell the house, maybe I'll print a bunch in a more neutral color.

There are plenty of other designs out there. Commercial and printable options use a series of clips or magnets for retention. I wasn't a fan of either of those. I wanted a more substantial retention method, yet clean. I didn't want to see bits of wire or frayed ends either.

3 parts

A hexagonal wall flange that can slip around a 4" vent.

A heptagonal nut. Yes, a 7 sided nut. Why? Because they're cool.

A cylindrical hose insert that captures the nut.

The whole thing works sorta like a compression fitting. It's just the size of your hand...

Slide the hose insert into the heptagon. Then slide the 4" hose onto the outside of the hose insert. Stuff the wire and a coil or two into the relief of the heptagon to ensure the nut is captured and spins freely with no play. Sinch it all down with a hose clamp.

There's no need to cut the vent tube flat to the wall or anything. Though, you may need to trim it back. Apply some sort of gasket material to the flat side of the wall flange. I used neoprene strips cut to length. Attach the wall flange using your favorite sets of screws and anchors. I'm a fan of E-Z anchors.

The wall flange and hose insert should be printed in PETG due to temperatures. I also printed these 100% infill. You'll consume over 200g of filament on these two parts alone.

The heptagonal nut is fine in PLA. Seems plenty strong at 4 lines for the walls and 10% infill.

Do apply a very thin dose of white or dielectric grease to the threads. Be very sparing here. You're not trying to coat them, just give them a touch of slickness so the threads can spin freely. I've found that printed threading, even at a 6mm pitch, get kinda sticky

I printed a pair of these, and so far I'm quite pleased with their performance. And if you're wondering why these things aren't all circles, it's because I wanted them to stand out a bit. A conversation starter if you will. Before I sell the house, maybe I'll print a bunch in a more neutral color.

Similar models

thingiverse

free

8mm threaded rod "nuts" by celebrity208

...gned and printed these hand wheels/thumb screws to thread onto an 8mm rod with an interference fit so they don't spin freely.

thingiverse

free

Vacuum Hose Pivoting Adapter by ksuszka

...ched openscad file and modify the part diameter by yourself.

acknowledgments

i used the excellent thread library by dan kirshner.

thingiverse

free

Spool Winder Hub with M8 Nut by jimustanguitar

...ing, i wanted to make large batches of filament on a huge spool, and then re-spool the filament into smaller rolls with my drill.

thingiverse

free

flexible duct connection system by mightygrom

...se.com/thing:2877754

i am also using this 4" inline fan to move more air. https://amzn.to/2poew3j

it works... picture later.

thingiverse

free

Battery Vent Hose Flange by wwhaley

...lt wet cell batteries and they need to vented from a closed space. this is the thru the wall flange that fits 2" flex hose.

thingiverse

free

Anova mounting flange with nut by dkallback

...threads won't fit) and got a nice fit, both between the cooker / bushing and the bushing / nut. ymmv...

used a 74mm hole saw.

thingiverse

free

4040 Extrusion T Nut Holder by hansolouk

...es so made it as a two part. i used m6 nuts/bolts as that is what i had to hand

you can either use a nut in the flange or a bolt.

thingiverse

free

Dryer Hose Adapter

...ent in place.

this is for a 4" dryer hose. the flange has 5 holes for 6mm x 4mm magnetic discs to be glued/pressed in place.

thingiverse

free

Glowforge Air hose quick connect by HappyJackington

...pla .3mm layer height, and 2 walls, given that this one doesn't need to be secured nearly as tightly as the other connectors.

thingiverse

free

Glowforge 4" threaded exhaust hose adapter

...but good to my glowforge, you might have have to adjust your horizontal expansion a bit to get the perfect fit from your printer.

Bummster

thingiverse

free

Bridge 4 Glyph challenge ring for PK by bummster

...bridge 4 glyph challenge ring for pk by bummster

thingiverse

for my brother

thingiverse

free

Gladiator geartrack gearwall hook by bummster

...gladiator geartrack gearwall hook by bummster

thingiverse

a simple hook so i can hang up random garage trinkets on the wall.

thingiverse

free

Hobby Lobby Hunter GoPro mount by bummster

...ingiverse

gopro mount that bolts to the roll cage of a hobby lobby hunter.

required hardware:

2x m3 x 10mm bolt

2x m3 nylock nut

thingiverse

free

Overlord Pro - magnet holders by bummster

...gnets can then be used to hold a door closed or hold up frequently used tools. uses a common computer screw to keep it in place.

thingiverse

free

Overlord Pro - microswitch z probe mount by bummster

...ave a note if it works alright for you though.

the switch this is made for is a typical omron 5a 250v ss-5gl2t with a roller arm.

thingiverse

free

M20x1.5 male to 8mm ID barb by bummster

...e with my k40 didn't have the fitting i needed. this will fit a dymax 2000. i scavenged a 21mm od o-ring from somewhere else.

thingiverse

free

Overlord Pro - Belt and pulley cover by bummster

...ng the belt tensioners when at the extremes of the build volume.

friction fit. shouldn't move much at all once its in there.

thingiverse

free

Pokemon Go Plus - Great ball case by bummster

...keball version here: https://www.thingiverse.com/thing:3013470

ultra ball version here: https://www.thingiverse.com/thing:3027704

thingiverse

free

Paracord spool (100ft capacity) by bummster

...ere. the other end escapes the spool through the notch. pass the escaped end through the loop the other end made and pull taught.

thingiverse

free

Overlord Pro - Optical end stop bracket by bummster

...e: these endstops do require a 5v vsc, so you'll need to do some ninja wiring to get it to work on the stock microcontroller.

Disconnect

3d_export

$30

Disconnect switches remote control cabinet 3D Model

...cabinet substation rotary cam switch lamp metal hose

disconnect switches remote control cabinet 3d model rostislav 85722 3dexport

turbosquid

$2

DISCONNECT CUT OFF POWER KILL SWITCH

..., max, ige, lwo, obj, fbx, 3dm, dwg, blend, dae, skp, and stl on turbosquid: 3d models for games, architecture, videos. (1487509)

3d_export

$6

my nest sofa

...our partner. a “nest” to enjoy at home and disconnect from the world. ideal for reading, writing, working with...

3d_export

$10

focus 3 square led

...and also its support is adjustable. the connection and disconnecton of the light is made by changing the material...

3d_export

$55

3D KA 52 Black Shark

...games. textures 2k and 4k all moving parts are disconnectd and can be animated. blurred motion texture of screws....

3d_export

$6

blowing dust collector

...material reaches the corresponding position, the clutch will be disconnectd and wait for the material to arrive at the...

3dfindit

free

Knife Disconnects

...knife disconnects

3dfind.it

catalog: te connectivity

3dfindit

free

Quick Disconnects

...quick disconnects

3dfind.it

catalog: te connectivity

3dfindit

free

Quick Disconnects

...quick disconnects

3dfind.it

catalog: te connectivity

thingiverse

free

Quick Disconnect Collar by dvandaal

...quick disconnect collar by dvandaal

thingiverse

small collar to sit around a quick disconnect.

Dryer

archibase_planet

free

Dryer

...dryer

archibase planet

dryer hand dryer

dryer hand dryer airblade n210114 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Dryer

...yer

archibase planet

dryer washer dryer drying machine tumble dryer

dryer - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Dryer

...dryer

archibase planet

dryer hand dryer

dryer n221113 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

archibase_planet

free

Dryer

...dryer

archibase planet

drying apparatus dryer

hand dryer - 3d model for interior 3d visualization.

archibase_planet

free

Dryer

...dryer

archibase planet

dryer kitchen ware

dryer - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Dryer

...dryer

archibase planet

dryer heater radiator

dryer 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Dryer

...dryer

archibase planet

dryer radiator heater

dryer 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Dryer

...dryer

archibase planet

dryer radiator heater

dryer towel rail n121213 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Dryer

...rchibase planet

dryer radiator heater towel rail

dryer towel rail n241213 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Dryer

...r towel rail radiator heater

dryer towel rail villeroy & boch n260514 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Vent

archibase_planet

free

Vent

...vent

archibase planet

aeration venting home equipment

diffuser vent - 3d model for interior 3d visualization.

archibase_planet

free

Vent

...vent

archibase planet

cooker hood cooking hood

vent - 3d model for interior 3d visualization.

archibase_planet

free

Vent

...vent

archibase planet

cooker hood cooking hood

vent atlantica - 3d model for interior 3d visualization.

archibase_planet

free

Vent

...vent

archibase planet

cooker hood cooking hood

vent half frame - 3d model for interior 3d visualization.

archibase_planet

free

Vent

...vent

archibase planet

cooker hood cooking hood

vent - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Vent

...vent

archibase planet

cooker hood cooking hood kitchen equipment

vent - 3d model for interior 3d visualization.

archibase_planet

free

Vent

...vent

archibase planet

damper diffuser air gate

vent grate n100807 - 3d model for interior 3d visualization.

archibase_planet

free

Vent

...vent

archibase planet

cooker hood cooking hood

vent - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$10

Vent

...nt

turbosquid

royalty free 3d model vent for download as fbx on turbosquid: 3d models for games, architecture, videos. (1143454)

turbosquid

$2

Vent

...nt

turbosquid

royalty free 3d model vent for download as obj on turbosquid: 3d models for games, architecture, videos. (1323956)

Dock

design_connected

$20

Docks

...docks

designconnected

gandia blasco docks computer generated 3d model. designed by romero vallejo.

turbosquid

$5

Dock

...squid

royalty free 3d model dock for download as 3ds and fbx on turbosquid: 3d models for games, architecture, videos. (1159328)

turbosquid

$20

Dock

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Dock

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Dock

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

dock

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$65

dock

...dock

3dexport

simple rendering of the scene file

design_connected

$16

Dry-Dock

...dry-dock

designconnected

restoration hardware dry-dock computer generated 3d model.

3d_ocean

$6

The Boat Dock

...s you see are separate, so you can remove the tyres and ladder and extend out the main section of the dock to make a long section

3ddd

$1

Bjorn Meier docks

... docks , модульный

bjorn meier docks

vray+corona

Quick

3ddd

$1

Quick-Step / Quadra

...quick-step / quadra

3ddd

quick step

ламинат quick-step, серия quadra. сайт источник -http://www.quick-step.com

3ddd

$1

Quick-Step / Lagune

...quick-step / lagune

3ddd

quick step

ламинат quick-step, серия lagune. сайт источник -http://www.quick-step.com

3ddd

$1

Quick-Step / Classic

...quick-step / classic

3ddd

quick step

ламинат quick-step, серия classic. сайт источник -http://www.quick-step.com

3ddd

$1

Quick-Step / Arte

...quick-step / arte

3ddd

quick step

ламинат quick-step, серия arte. сайт источник -http://www.quick-step.com

3ddd

$1

Quick-Step / Vogue

...quick-step / vogue

3ddd

quick step

ламинат quick-step, серия vogue. сайт источник -http://www.quick-step.com

3ddd

$1

Quick-Step / Rustic

...quick-step / rustic

3ddd

quick step

ламинат quick-step, серия rustic. сайт источник -http://www.quick-step.com

3ddd

$1

Quick-Step / Eligna

...quick-step / eligna

3ddd

quick step

ламинат quick-step, серия eligna. сайт источник -http://www.quick-step.com

turbosquid

$3

Quick Ball

...lty free 3d model quick ball for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1521597)

3ddd

free

Quick-Step / Elite

... ламинат

ламинат quick-step, серия elite. сайт источник -http://www.quick-step.com

turbosquid

$10

Quick Chrome

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Clothes

3d_export

$10

Clothes

...clothes

3dexport

clothes

archibase_planet

free

Clothing

...clothing archibase planet samurai clothing clothes glothing clothing japan samurai n190311 - 3d model (*.3ds)...

3ddd

$1

bed cloth

...bed cloth

3ddd

bed cloth , постель

cloth

3ddd

$1

Clothes Basket

... clothes , linens

clothes basket in formats 3dsmax - fbx - obj

3ddd

$1

Bed Clothing

...bed clothing

3ddd

bed clothing , постельное белье

bed clothing

3ddd

$1

bed cloth bed cloth and Pillow

...bed cloth bed cloth and pillow

3ddd

постельное белье

bed cloth and pillow

turbosquid

$7

Clothes

...turbosquid

royalty free 3d model clothes for download as fbx on turbosquid: 3d models for games, architecture, videos. (1396655)

turbosquid

$5

clothes

...turbosquid

royalty free 3d model clothes for download as 3ds on turbosquid: 3d models for games, architecture, videos. (1469434)

turbosquid

$2

Cloth

...h

turbosquid

royalty free 3d model cloth for download as max on turbosquid: 3d models for games, architecture, videos. (1192139)

turbosquid

free

Cloth

...h

turbosquid

royalty free 3d model cloth for download as max on turbosquid: 3d models for games, architecture, videos. (1192255)