Thingiverse

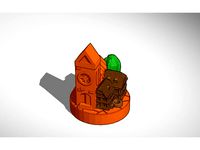

clip glass prusa MK2 by Dakanzla

by Thingiverse

Last crawled date: 3 years ago

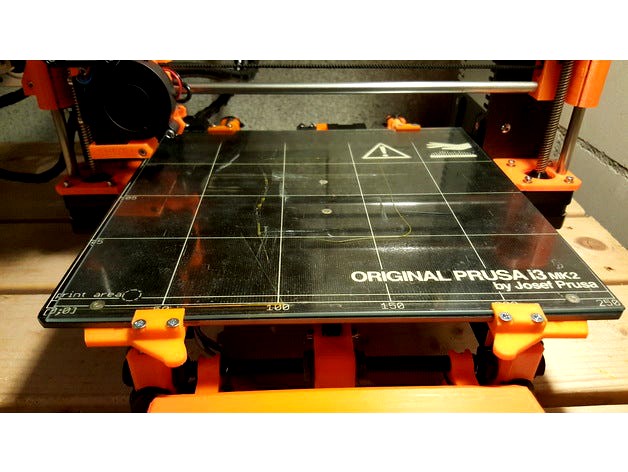

I love my prusa mk2 and I wanted to print on glass with it, so I checked out techtiptricks video on youtube about that: https://www.youtube.com/watch?v=VQNCvE2OLhA

The gcode to do this is available on prusamk2.com: http://www.prusamk2.com/printing-on-glass-with-youre-prusa-i3-mk2-ohhh-so-smooth/

Unfortunately all my clips to hold the glass didn't work verry well and were often been pulled away by the extruder, like in techtipricks video. So I created my own clips that can be integrated into the heatbed and don't desturbe the extruder.

Heres the manual how you install them on your prusa mk2 (compare the pictures):

unscrew all the 6 screws (2 front, 2 back, 2 middle) that hold the heatbed to the printer

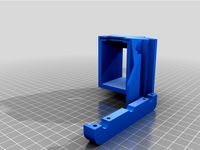

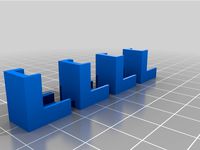

put the 4 hex-nut-pieces into the four bottom-clip-parts (FL,FR,BL,BR). Make sure that they are under the bottom-clip-parts!

clean the top-clip parts and put some M3x16 screws through them. let them stand out a little bit like shown on the pictures

combine all the bottom-clip-parts and the top-clip-parts exept the BL-part by screwing them together. let some space between both parts.

put on the clips together with the already entered hex-nut-parts under the hex-nuts of the heatbed. Make sure the hex-nut-parts are NOT on top (compare pictures). the clips are labled: FL (front left), FR (front right), BL (back left), BR (back right).

tighten all the screws to the heatbed again. ATTENTION: Make sure the white cable from under the heatbed doesn't get jammed by the BL-clip (should go right around it)!

now put the top-clip-part and the BL-clip together with the screws.

put the glass on the heatbed and close all clips. Then tighten all screws until the clips hold the glass tight an can be removed easely. Make shure the screws dont poke out from the top-clip parts, especially not on the FL- and the FR-parts! If they poke out to much, they can get in contact with the extruder.

GCODE: This is the gcode I use on my printer for the starting procedure. Make sure you adapt it for yours:

G1 Z2.0 : Enter the thickness of your glass in this line of code (in this example 2.0 millimeters)

You got 2 minutes to insert the glass (beep after the first minute)

G21 ; set units to millimeters

G90 ; use absolute positioning

M82 ; absolute extrusion mode

M104 S{material_print_temperature} ; set extruder temp

M140 S{material_bed_temperature} ; set bed temp

M190 S{material_bed_temperature} ; wait for bed temp

M109 S{material_print_temperature} ; wait for extruder temp

G92 E0.0 ; reset extruder distance position

G80 ; mesh bed leveling

G1 Y-3.0 F1000.0 ; go outside printing area

G1 F600 Z+30

G4 P30000 ; pause for 1 minute

M300 S1567 P240 ; Play a Beep

M117 One minute remaining ; One minute remaining warning

G4 P30000 ; pause 1 more minute

G1 Z2.0 ; consider glass thickness Measure your glass thickness first

G92 Z0 ; Set absolute positioning for remaining print

G1 X60.0 E9.0 F1000.0 ; intro line

G1 X100.0 E12.5 F1000.0 ; intro line

G92 E0.0 ; reset extruder distance position

Thats it :-) Now you got a mk2 with mounted clips that are not influenced by the extruder and can be removed easely to take out the glass. Have fun! :-)

The gcode to do this is available on prusamk2.com: http://www.prusamk2.com/printing-on-glass-with-youre-prusa-i3-mk2-ohhh-so-smooth/

Unfortunately all my clips to hold the glass didn't work verry well and were often been pulled away by the extruder, like in techtipricks video. So I created my own clips that can be integrated into the heatbed and don't desturbe the extruder.

Heres the manual how you install them on your prusa mk2 (compare the pictures):

unscrew all the 6 screws (2 front, 2 back, 2 middle) that hold the heatbed to the printer

put the 4 hex-nut-pieces into the four bottom-clip-parts (FL,FR,BL,BR). Make sure that they are under the bottom-clip-parts!

clean the top-clip parts and put some M3x16 screws through them. let them stand out a little bit like shown on the pictures

combine all the bottom-clip-parts and the top-clip-parts exept the BL-part by screwing them together. let some space between both parts.

put on the clips together with the already entered hex-nut-parts under the hex-nuts of the heatbed. Make sure the hex-nut-parts are NOT on top (compare pictures). the clips are labled: FL (front left), FR (front right), BL (back left), BR (back right).

tighten all the screws to the heatbed again. ATTENTION: Make sure the white cable from under the heatbed doesn't get jammed by the BL-clip (should go right around it)!

now put the top-clip-part and the BL-clip together with the screws.

put the glass on the heatbed and close all clips. Then tighten all screws until the clips hold the glass tight an can be removed easely. Make shure the screws dont poke out from the top-clip parts, especially not on the FL- and the FR-parts! If they poke out to much, they can get in contact with the extruder.

GCODE: This is the gcode I use on my printer for the starting procedure. Make sure you adapt it for yours:

G1 Z2.0 : Enter the thickness of your glass in this line of code (in this example 2.0 millimeters)

You got 2 minutes to insert the glass (beep after the first minute)

G21 ; set units to millimeters

G90 ; use absolute positioning

M82 ; absolute extrusion mode

M104 S{material_print_temperature} ; set extruder temp

M140 S{material_bed_temperature} ; set bed temp

M190 S{material_bed_temperature} ; wait for bed temp

M109 S{material_print_temperature} ; wait for extruder temp

G92 E0.0 ; reset extruder distance position

G80 ; mesh bed leveling

G1 Y-3.0 F1000.0 ; go outside printing area

G1 F600 Z+30

G4 P30000 ; pause for 1 minute

M300 S1567 P240 ; Play a Beep

M117 One minute remaining ; One minute remaining warning

G4 P30000 ; pause 1 more minute

G1 Z2.0 ; consider glass thickness Measure your glass thickness first

G92 Z0 ; Set absolute positioning for remaining print

G1 X60.0 E9.0 F1000.0 ; intro line

G1 X100.0 E12.5 F1000.0 ; intro line

G92 E0.0 ; reset extruder distance position

Thats it :-) Now you got a mk2 with mounted clips that are not influenced by the extruder and can be removed easely to take out the glass. Have fun! :-)

Similar models

thingiverse

free

SVO2 Purge Bucket and GCODE by RedSquirrelHobbies

... positioning on

g1 z-1 f1000 ; lower nozzle by 1mm

g90 ; absolute positioning on

m400 ; wait for finish

thingiverse

free

Prusa Mini / Mini+ Dragon Hotend Mount by Spodesta

...it uses the standard x carriage

print both on abs, pc, nylon, asa or other temp resistant filament, personally i will use cf-abs.

thingiverse

free

Geeetech A10t Purge Bucket with removable bucket by 123TaDa

...ipe

g0 x0 f2000 ; return

m211 s1 ; turn on soft stops once more

g1 e-0.5 ; try to prevent pips

g92 e0

; start extruder script end

thingiverse

free

Custom start Gcode by monopriceman

... a priming/wiping line to the rear)

g0 z3

g0 y0

g0 z0

g1 x-1;(move a little closer to the print area)

g1 e15 f250;(small retract)

thingiverse

free

Dual material Y joiner remix by hackwell

...ustom gcode

g92 e0 t1

g91

g1 t1 e-140 f3500; unload filament

g90

g92 e0 t1

g0 x{prime_tower_position_x} y{prime_tower_position_y}

thingiverse

free

Purge Bucket for A10M (cleaned up) by carterlewellyn

... e0 ;reset extruder positioning

g1 e-2 f5000 ;retract filament to resting spot

g92 e0 ;reset extruder positioning

i hope it helps

thingiverse

free

Palette+ Teflon Tube Clip for Prusa i3 MK2 by rorech

...ech

thingiverse

this is a tube holder for the palette+ at the prusa i3 mk2. it will just snap in on top of the prusa extruder.

thingiverse

free

A10M A20M Purge extension (Aibecy hotend) by deakbannok

...91 ; switch from absolute positioning to relative positioning

g1 z-0.4 f800 ;

g90 ; return to absolute

g1 e6.5 f3600.0 ;

g92 e0 ;

thingiverse

free

E3(Pro) Glass Build Plate Corner Caps by kai_to_makes

... ;move to side a little

g1 x10.4 y20 z0.28 f1500.0 e30 ;draw the second line

g92 e0 ;reset extruder

g1 z2.0 f3000 ;move z axis up

thingiverse

free

Mini dual Y adapter for E3D V6 style hotend with bowden extruders by gimle

...r

slic3r custom tool change gcode:

t[previous_extruder]

g92 e0

g1 e-110 f4200

g92 e0

t[next_extruder]

g92 e0

g1 e110 f4200

g92 e0

Dakanzla

thingiverse

free

jail by Dakanzla

...verse

overview: https://www.thingiverse.com/thing:2893324

open design in tinkercad: https://www.tinkercad.com/things/5fezh5g6gb0

thingiverse

free

start by Dakanzla

...verse

overview: https://www.thingiverse.com/thing:2893324

open design in tinkercad: https://www.tinkercad.com/things/4xtoe11fm8i

thingiverse

free

gold by Dakanzla

...iew: https://www.thingiverse.com/thing:3072272

print 2 ore

open design in tinkercad: https://www.tinkercad.com/things/3srax43ofkx

thingiverse

free

hotel by Dakanzla

...thingiverse.com/thing:2893324

print 12 hotels for the game

open design in tinkercad: https://www.tinkercad.com/things/jbvibq1evpl

thingiverse

free

house by Dakanzla

...thingiverse.com/thing:2893324

print 32 houses for the game

open design in tinkercad: https://www.tinkercad.com/things/9spnu3bb0m4

thingiverse

free

settlement by Dakanzla

...erse.com/thing:2525047

print 5 settlements for each player

open design in tinkercad: https://www.tinkercad.com/things/anztrd1nr0x

thingiverse

free

crossing by Dakanzla

...verse.com/thing:2525047

print 10 crossings for each player

open design in tinkercad: https://www.tinkercad.com/things/izzkptm0xlw

thingiverse

free

road by Dakanzla

...ingiverse.com/thing:2525047

print 15 roads for each player

open design in tinkercad: https://www.tinkercad.com/things/bzisnjkafex

thingiverse

free

city by Dakanzla

...ingiverse.com/thing:2525047

print 4 cities for each player

open design in tinkercad: https://www.tinkercad.com/things/ectp1wisgli

thingiverse

free

chance by Dakanzla

...iverse.com/thing:2893324

print 3 chance-parts for the game

open design in tinkercad: https://www.tinkercad.com/things/hgyi19uivzr

Mk2

turbosquid

$4

Mk2

...

royalty free 3d model mk2 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1305687)

turbosquid

$9

Mk2 Grenade

...osquid

royalty free 3d model mk2 grenade for download as fbx on turbosquid: 3d models for games, architecture, videos. (1175401)

turbosquid

$4

Mk2 Grenade

...quid

royalty free 3d model mk2 grenade for download as blend on turbosquid: 3d models for games, architecture, videos. (1228888)

turbosquid

$2

GRENADE MK2

...osquid

royalty free 3d model grenade mk2 for download as fbx on turbosquid: 3d models for games, architecture, videos. (1202615)

turbosquid

$2

Grenade Mk2

...osquid

royalty free 3d model grenade mk2 for download as max on turbosquid: 3d models for games, architecture, videos. (1658201)

turbosquid

$2

mk2 Grenade

...osquid

royalty free 3d model mk2 grenade for download as fbx on turbosquid: 3d models for games, architecture, videos. (1329079)

turbosquid

$75

Lanchester Mk2

...alty free 3d model lanchester mk2 for download as 3ds and max on turbosquid: 3d models for games, architecture, videos. (1497085)

turbosquid

$10

Grenade MK2

...royalty free 3d model grenade mk2 for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1146970)

turbosquid

$10

MK2 helmet

...

royalty free 3d model mk2 helmet for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1371428)

turbosquid

free

MK2 Grenade

...

free 3d model mk2 grenade for download as png, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1225336)

Prusa

turbosquid

$2

Frame Filament Guide Clip-On for Prusa Mk3

...rame filament guide clip-on for prusa mk3 for download as stl on turbosquid: 3d models for games, architecture, videos. (1634730)

3d_export

free

prusa i3 mk3s laser mount for opt lasers

...to learn more about the blue laser technology that conceived the cutting and engraving laser heads from opt lasers, please visit:

turbosquid

free

Prusa small printer adapter holder

...er for download as ipt, skp, dwg, dxf, fbx, ige, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1642936)

3d_export

$30

geisha by jonathan adler

...** i did a 3d printing test in the prusa software, you can find it among the attached images.<br>exchange:<br>.blend...

thingiverse

free

Prusa without Prusa (rc2) by madless

...prusa without prusa (rc2) by madless

thingiverse

just the main part of prusa rc2 faceshield, without writing.

enjoy :)

thingiverse

free

Prusa by acejbc

...prusa by acejbc

thingiverse

prusa knob info

m3 8mm screw

thingiverse

free

Prusa house

...prusa house

thingiverse

how prusa house could look like...

thingiverse

free

Prusa Mk2 "Fake Prusa" LCD cover by anraf1001

...r by anraf1001

thingiverse

version of prusa's lcd cover with "fake prusa" instead of "original prusa"

thingiverse

free

Prusa stabilizator by gutiueugen

...prusa stabilizator by gutiueugen

thingiverse

prusa stabilizator

thingiverse

free

Keychain Prusa by rbarbalho

...keychain prusa by rbarbalho

thingiverse

keychain with text prusa.

Clip

archibase_planet

free

Clip

...clip

archibase planet

paper-clip clip office equipment

clip band - 3d model for interior 3d visualization.

3d_export

$5

screw clip

...screw clip

3dexport

screw clip

3d_ocean

$4

Butterfly clip

... a butterfly clip, it comes with a ready to render set for out of the box rendering. obj version and max alones version included.

turbosquid

$2

clip

...

royalty free 3d model clip for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1358622)

turbosquid

$5

Clip

...lty free 3d model clip for download as c4d, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1521355)

turbosquid

$19

Clip

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$4

Clips

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

clip

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

clips

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

clip

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Glass

archibase_planet

free

Glasses

...glasses

archibase planet

glass wine-glass liqueur-glass

glasses- 3d model for interior 3d visualization.

archibase_planet

free

Glass

...archibase planet

glass cocktail glass tall wine glass martini glass

glass - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Glass

...glass

archibase planet

glass wine-glass glass-ware

glass n030209 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Glass

...glass

archibase planet

glass-ware glass glass ware

glass n141109 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_ocean

$2

Glass

...liquid container low-poly glass nice glass obj r15 water glass

3d model of a beautiful glass. created the model in cinema 4d r15.

archibase_planet

free

Glass

...glass

archibase planet

glass tall wine glass wine-glass

glass n300514 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Glass

...glass

archibase planet

glass wine-glass tall wine glass

glass n091210 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Glass

...glass

archibase planet

glass tall wine glass glass-ware

glass n081011 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_ocean

$9

glasses

...glasses

3docean

glasses

max glasses v-ray

archibase_planet

free

Glass

...glass

archibase planet

glass-ware glass

glass - 3d model (*.gsm+*.3ds) for interior 3d visualization.