GrabCAD

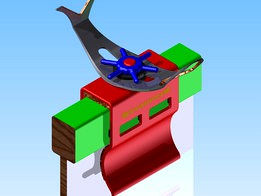

"Click and fish" rodholder

by GrabCAD

Last crawled date: 1 year, 10 months ago

This is my second entry for the Trapper rodholder challenge.

Easier to manufacture, less weight, better design, less moving parts, faster adjustment, lower cost.

Place the rodholder on the edge of the canoe, push down, take your fishing rod, throw out your line, place rod into the holder, adjust to the desired position, catch fish.

*******List of materials*******

* Rubber

* Corck

* Stainless steel

* Spring steel

* Aluminum

*******Parts*******

Base:

The base is made of spring steel that is formed with punched out sheet metal. It is self-clamping and doesn’t need any screws to be attached to the edge of the canoe. Just push it onto the edge.

On top of the base there will be a cylinder with thread welded or screwed on (for the thread read further).

The choice of spring steel enables us to use a less thick material for the base because of its resilient property.

To make it the user easier to detach the holder of the canoe, there is a lip on both sides that will allow your fingers to get a better grip on the holder.

Holder:

The holder itself is made of stainless steel (polished for a nice appearance) and is also formed with punched out sheet metal. To prevent damaging of the fishing rod it is needed that the contact area of the holder with the rod has some corck on it.

The design of the holder has the contour of a fish, this design allows to save material and reduce the weight. However it is still strong enough to handle a big fat fish on the hook.

Locknut:

The locknut can be fabricated out of aluminum. Doesn’t rust, strong, easy to machine, lightweight.

For the thread I used the system that we see on the caps of plastic bottles. This causes that it is easier to fit the locknut on the base and that there are only a few rotations needed.

To make it easier to loosen/tighten the locknut there are 6 little bars attached to it, this also makes it look a bit like the steering wheel of a ship.

Rings:

Those will perform the best when they are fabricated out of recycled rubber instead of corck.

Used for clamping the holder in the desired position.

Pads:

The other pads can be fabricated out of recycled rubber or corck.

*******Painting?*******

If any (metal) part has to be painted, the best choice will be powder coating.

Advantages of powder coating:

• No solvents, near zero Volatile Organic Compounds (VOC)

• Possibility of (much) thicker coatings without running or sagging

• Recycling of the overspray (maximum material usage efficiency of 98%)

• Less hazardous waste than conventional liquid coatings

• Less operating costs

• Operator friendly

• Robust

• Easy clean-up and maintenance

• High volume production rates

• One layer

• Time saving

Easier to manufacture, less weight, better design, less moving parts, faster adjustment, lower cost.

Place the rodholder on the edge of the canoe, push down, take your fishing rod, throw out your line, place rod into the holder, adjust to the desired position, catch fish.

*******List of materials*******

* Rubber

* Corck

* Stainless steel

* Spring steel

* Aluminum

*******Parts*******

Base:

The base is made of spring steel that is formed with punched out sheet metal. It is self-clamping and doesn’t need any screws to be attached to the edge of the canoe. Just push it onto the edge.

On top of the base there will be a cylinder with thread welded or screwed on (for the thread read further).

The choice of spring steel enables us to use a less thick material for the base because of its resilient property.

To make it the user easier to detach the holder of the canoe, there is a lip on both sides that will allow your fingers to get a better grip on the holder.

Holder:

The holder itself is made of stainless steel (polished for a nice appearance) and is also formed with punched out sheet metal. To prevent damaging of the fishing rod it is needed that the contact area of the holder with the rod has some corck on it.

The design of the holder has the contour of a fish, this design allows to save material and reduce the weight. However it is still strong enough to handle a big fat fish on the hook.

Locknut:

The locknut can be fabricated out of aluminum. Doesn’t rust, strong, easy to machine, lightweight.

For the thread I used the system that we see on the caps of plastic bottles. This causes that it is easier to fit the locknut on the base and that there are only a few rotations needed.

To make it easier to loosen/tighten the locknut there are 6 little bars attached to it, this also makes it look a bit like the steering wheel of a ship.

Rings:

Those will perform the best when they are fabricated out of recycled rubber instead of corck.

Used for clamping the holder in the desired position.

Pads:

The other pads can be fabricated out of recycled rubber or corck.

*******Painting?*******

If any (metal) part has to be painted, the best choice will be powder coating.

Advantages of powder coating:

• No solvents, near zero Volatile Organic Compounds (VOC)

• Possibility of (much) thicker coatings without running or sagging

• Recycling of the overspray (maximum material usage efficiency of 98%)

• Less hazardous waste than conventional liquid coatings

• Less operating costs

• Operator friendly

• Robust

• Easy clean-up and maintenance

• High volume production rates

• One layer

• Time saving

Similar models

grabcad

free

Trapper Challenge

...e. the main body of the rod holder could be die cut directly from the recycled tires or die cut from crumb-rubber/urethane sheet.

grabcad

free

Clip rodholder

...kable in position.

materials:

clothespin: wood

sheet metal and pins: stainless steel

springs: steel

commercial knob din: aluminum

grabcad

free

Spring fishingrod holder

...

credits for the rod and reel goes to:

https://grabcad.com/library/fishing-spinning-rod

https://grabcad.com/library/fishing-reel

grabcad

free

Canoe Rodholder Challenge- Adjustable rod holder

...o make pressure at the canoe.

used the fishing rod model https://grabcad.com/library/fishing-spinning-rod by andrey jasiukaitis

grabcad

free

Rod Holder, OCC

...t;br />this has been very enjoyable challenge but after generating this 3rd concept i will now get back to raising 2greatkids!

grabcad

free

Rodholder

...ly to become a product that is robust, good looking and that will do the job regardless the weather is what the brand stands for.

grabcad

free

Quicklock Rodholder

...se of the fishing rod. any manufactured from recycled plastic!

written with google translate, sorry about my horrible english...

grabcad

free

Rodholder Challenge Entry - Wood Composite

...ikes boring.

- dimensions: 124mm wide at low end of base plate

290mm from highest point to top of gunwale

cg_trader

free

Fishing Rod holder

...sign for the "canoe rodholder challenge". step and iges with detailed pictures and my explanation will be up tomorrow.

grabcad

free

Trapper Sheetmetal Rodholder

...own design.

the essence of this design is the technical principle, not the looks. but i guess most of you had already noticed! ;)

Rodholder

turbosquid

$10

RodHolder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

thingiverse

free

rodholder by coluber

...rodholder by coluber

thingiverse

print two of these, add 6 screws and you can store four of your rods in the ceiling

thingiverse

free

RodHolder by Arnic

... of too many clothes. it is made for a round or oblong rod 14.2 mm wide.

modelled from scratch in 3d with the foundry's modo.

thingiverse

free

Anet A4 modified rodholder by 3DGedoens

...anet a4 modified rodholder by 3dgedoens

thingiverse

added distance ring for gt2 pulley

thingiverse

free

![Shower Rodholder [reinforced] by NeoLogy](/t/8621287.jpg)

Shower Rodholder [reinforced] by NeoLogy

...eciated.

if you loved my design or this thing really helped you, feel free to tip me, so i can evolve in my new "hobby"

thingiverse

free

IKEA Billy spoolholder by Marcel_Thingyverse

...of 76cm. use 8x m5x20mm screws/bolts for the two rodholder. i printed mine without top/bottom layers and honeycomb...

thingiverse

free

Cupholder for Boat Fishing Rod Holder by Darkstar076

...swivel is designed to fit 15 - 30 degree rodholder. since this was designed for a friend and not...

thingiverse

free

Z-Level for Vulcanus V1 by killi

...build my own easy-to-level-z-parts. you have to print my z-rodholder to screw the endstop in and my z-axis lm8uu...

thingiverse

free

Alternative Z Top Rod Holders for RepRap Wilson by unknown_lamer

...hack -- it just cuts a rectangle out from z-top-rodholder-origin.stl (just the wilson z top rod holders but moved...

thingiverse

free

3D Printer 3030 Extrusion all Parts by GaryK47

...z-wobble (remix) is smaller fromhttp://www.thingiverse.com/thing:2067676 my x-axis mounthttp://www.thingiverse.com/thing:2138921 y-axis rodholder motormount,.. fromhttp://www.thingiverse.com/thing:1692666 extrusion profil cover from:http://www.thingiverse.com/thing:1478147 slicer settings width...

Fish

archibase_planet

free

Fish

...fish

archibase planet

fish aquarium fish toy fish

fish n250113 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Fish

...fish

archibase planet

fish aquarium fish toy fish

fish n310113 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Fish

...fish

archibase planet

fish aquarium fish

fish - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Fish

...fish

archibase planet

fish aquarium fish

fish - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$200

Fish Red | Fish 3D | Fish devil | Fish fat

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

free

fish

...fish

3dexport

fish

3ddd

$1

fish

...fish

3ddd

рыба

fish

archibase_planet

free

Fish

...fish

archibase planet

fish sculpture statue

fish - 3d model for interior 3d visualization.

archibase_planet

free

Fish

...fish

archibase planet

fish picturesque element

fish - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Fish

...fish

archibase planet

fish picturesque element

fish - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Click

turbosquid

$25

Click pen

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

Click pen

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

Click pen

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

smartpot Click and grow

...ick and grow

3ddd

smartpot , click and grow

300x140 h=290

2 led lamps

place for 3 plants

3ddd

free

Vitra Click SRG

... складной

детальная модель складного стола vitra click.

в архиве столь сложенный и стол раскрытый.

3ddd

$1

Arreda Click Chair

...arreda click chair

3ddd

arreda

modern chair, suitable for modern interior scenes.

turbosquid

$5

3D Font Click Clack

...odel 3d font click clack for download as fbx and unitypackage on turbosquid: 3d models for games, architecture, videos. (1436031)

3d_export

$5

clicking pen mechanism

...other version of this mechanism. i make it fast for you with at least a price. there are .2 mm gap between to moveable components

turbosquid

$18

Click Clack lounge chair Resol

...e 3d model click clack lounge chair resol for download as max on turbosquid: 3d models for games, architecture, videos. (1579183)

3d_ocean

$6

One Click Grass Generator Script

...-fast way. a script to help users to create grass with the help of single-click. users can create n-number of grasses as it is...