Thingiverse

Children folding kayak "Yukaghir" by DarthCorvus

by Thingiverse

Last crawled date: 3 years ago

It's my first printable venicle project and there are two things because I did it:

1) There are almost no any folding kayaks for children.

2) I need a simpe project to start mayking kayaks with.

This kayak was designed for paddling learning on still water. It's enough fast for a little journey.

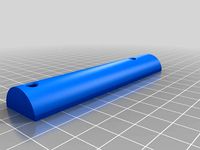

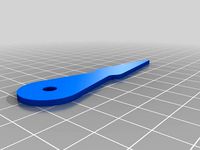

The type of construction is the same as Triton Ladoga 1, 70% scaled. All parts was re-designet to be 3d printable. The original Ladoga1 uses 20mm and 25mm aluminium alloy tubes and fiberglass-filled plastic connectors. Because non-composit ABS is not so strong so fiberglass-filled ABS, i use PVC tubes in my design, without scaling their diametres. So, because i did not scale tubes diameter, i can use 2 times less strong materials to make the same rigid and durability boat. The second thing I change is the lenght of stern. It is 140 mm longer to make kayak faster and more stable.

The main parameters:

Length - 3500 mm

Width - 450 mm

Sitting place width - 260 mm

Nominal load - 20-30 kg

Maximum load - 50 kg

Frames places (from nose, 1,2,3,5,6, in mm) - 620, 1180, 1740, 2310, 2900

(The 4-th frame is an additional one, needed for sitting place mounting and it's place can be some different)

Weight of assembled framework - 4.5 kg

Total weight - 7 kg

3d printer platform for making - 200x200 mm or more.

That's all screw:

M4 bolts:

45mm - 5pcs

35mm - 3pcs

30mm - 4pcs

25mm - 2 pcs

M4 nuts, self-fixing - 6pcs

M4 nuts - 7pcs

4mm washers - 12psc.

Also you need in PVC tubes. I use 25mm OD 22mm ID - 5x2m and 20mm OD 17.5mm ID - 12x2m. If you can find 3m length tubes it will make less garbage. And, what is more, you need about 200 ml of good plastic glue. I used "Moment crystal".

For "skin" I used PVC coated synthetic fabric 0.65 kg per m2, black for hool and yellow for deck and sponsors. Them are different only for colour.

Hool material spreads along the body and cutts to form sterns. The material must be tightened along the frame, so it's good idea to assemble the frame on any tape to be 2-3 cm shorter, then it will be, when doing this operation.

It's easier to glue the fabric first, and then sew them by strong thread.

For sterns watertight and more durable i glued 10 cm wide band of that black fabric along the keel and sterns.

I cut off the hool fabric on it's place, about 3 cm from the upper stringers. Do not tight the hool and deck fabric across the frame, the air sponsors will do it.

The deck material must be tightened along the frame, too. First of all i glued it, and then i did cockpit hole and sew perimeter to hool. Zippos are needed for assembling and simplifing packing goods.

Air sponsors are 280 cm long, and about 10 cm in diameter. Do not necessarily make them accurate, but airtight.

In assembling kayak, air sponsor goes from upper stringer, first frame to lower stringer 3-5 frames and then to upper stringer, 6 frame.

The seat made from 5mm plywood, 24x28 cm, but you can use any.

Backrest is standart one from kayak (see photo).

This kayak is really fast one, goes up to 5 kmh with my son, so I am planning some little weekend journeys now.

Warnings:

do not heat PVC tubes over 100°C. It will produce VERY TOXIC gases. 80-90°C is enough for forming.

do not use if there are more then 150 mm high water waves or more then 5 meters per second wind.

always use live vest.

there must be a second boat close to young paddler while learning.

UPD 7/3/2017 - paddle added http://www.thingiverse.com/thing:2160535

UPD 26/6/2017 - skin photos and text

1) There are almost no any folding kayaks for children.

2) I need a simpe project to start mayking kayaks with.

This kayak was designed for paddling learning on still water. It's enough fast for a little journey.

The type of construction is the same as Triton Ladoga 1, 70% scaled. All parts was re-designet to be 3d printable. The original Ladoga1 uses 20mm and 25mm aluminium alloy tubes and fiberglass-filled plastic connectors. Because non-composit ABS is not so strong so fiberglass-filled ABS, i use PVC tubes in my design, without scaling their diametres. So, because i did not scale tubes diameter, i can use 2 times less strong materials to make the same rigid and durability boat. The second thing I change is the lenght of stern. It is 140 mm longer to make kayak faster and more stable.

The main parameters:

Length - 3500 mm

Width - 450 mm

Sitting place width - 260 mm

Nominal load - 20-30 kg

Maximum load - 50 kg

Frames places (from nose, 1,2,3,5,6, in mm) - 620, 1180, 1740, 2310, 2900

(The 4-th frame is an additional one, needed for sitting place mounting and it's place can be some different)

Weight of assembled framework - 4.5 kg

Total weight - 7 kg

3d printer platform for making - 200x200 mm or more.

That's all screw:

M4 bolts:

45mm - 5pcs

35mm - 3pcs

30mm - 4pcs

25mm - 2 pcs

M4 nuts, self-fixing - 6pcs

M4 nuts - 7pcs

4mm washers - 12psc.

Also you need in PVC tubes. I use 25mm OD 22mm ID - 5x2m and 20mm OD 17.5mm ID - 12x2m. If you can find 3m length tubes it will make less garbage. And, what is more, you need about 200 ml of good plastic glue. I used "Moment crystal".

For "skin" I used PVC coated synthetic fabric 0.65 kg per m2, black for hool and yellow for deck and sponsors. Them are different only for colour.

Hool material spreads along the body and cutts to form sterns. The material must be tightened along the frame, so it's good idea to assemble the frame on any tape to be 2-3 cm shorter, then it will be, when doing this operation.

It's easier to glue the fabric first, and then sew them by strong thread.

For sterns watertight and more durable i glued 10 cm wide band of that black fabric along the keel and sterns.

I cut off the hool fabric on it's place, about 3 cm from the upper stringers. Do not tight the hool and deck fabric across the frame, the air sponsors will do it.

The deck material must be tightened along the frame, too. First of all i glued it, and then i did cockpit hole and sew perimeter to hool. Zippos are needed for assembling and simplifing packing goods.

Air sponsors are 280 cm long, and about 10 cm in diameter. Do not necessarily make them accurate, but airtight.

In assembling kayak, air sponsor goes from upper stringer, first frame to lower stringer 3-5 frames and then to upper stringer, 6 frame.

The seat made from 5mm plywood, 24x28 cm, but you can use any.

Backrest is standart one from kayak (see photo).

This kayak is really fast one, goes up to 5 kmh with my son, so I am planning some little weekend journeys now.

Warnings:

do not heat PVC tubes over 100°C. It will produce VERY TOXIC gases. 80-90°C is enough for forming.

do not use if there are more then 150 mm high water waves or more then 5 meters per second wind.

always use live vest.

there must be a second boat close to young paddler while learning.

UPD 7/3/2017 - paddle added http://www.thingiverse.com/thing:2160535

UPD 26/6/2017 - skin photos and text

Similar models

thingiverse

free

PVC Tube Stopper for filament holder by piffio

...or my wanaho d4s and a simple 20 mm pvc tube.

it fits nicely in the tube with enough grip to stay in place and be easily removed.

thingiverse

free

F-Nut Trap for MPCNC (25 mm OD, M4) by matonym

....tubing 25mm x 1.5) and it uses m4 nuts instead of the #6-32, since inch is such a funny standard... :-)

rhino sources included

thingiverse

free

Third Hand by crysis_ps

.../nuts.

upd:

just splited the files

there are two options of stand detal:

v1 and variant2 for using alum tubes as "legs"

thingiverse

free

1" PVC Clincher by MT2

... many different things you can do. mount this on a wall and snap 1" pvc into it. relish your pvc tubing hack to do whatever.

thingiverse

free

Airsoft .►. Impact Sound Grenade 40mm PVC By Goticwar by Goticwar

...crew the "against weight" with 2 m5 nuts at both ends

-you can donate to support me if you wish. it will help me a lot.

thingiverse

free

PVC Lid and Cover for Storage Rack by fernandogarzaw

...this is what i came with. didn't find anything similar on thingiverse so i decided to post it. i...

thingiverse

free

Airsoft .►. Impact Sound Grenade By Goticwar by Goticwar

...crew the "against weight" with 2 m5 nuts at both ends

-you can donate to support me if you wish. it will help me a lot.

thingiverse

free

TUSH - US 1/2" PVC Framed Filament Spool Holder by RonnieG303

... pvc connector sizes, have been well proven in several of my other pvc based projects. only a few details are added for this one.

cg_trader

$10

Fruit Picker | 3D

...with 20mm outside diameter and other with 25mm outside diameter, the inner tube is used to pull the trigger, closing the fingers.

thingiverse

free

railblaza kayak light pole adapter for 3/4" ID PVC EMT pipe by styk

...on light with strobe, model # sl92001on a length of 3/4" pipe (aluminum, pvc or abs).

for the top adapter see thing: 3048389

Darthcorvus

thingiverse

free

Merkaba by DarthCorvus

...merkaba by darthcorvus

thingiverse

mercaba figure (sacred geometry)

thingiverse

free

Bath filter by DarthCorvus

...bath filter by darthcorvus

thingiverse

a bath filter, no support or raft needed.

thingiverse

free

Toy clock arrows by DarthCorvus

...toy clock arrows by darthcorvus

thingiverse

arrows for diy toy clock

thingiverse

free

hooks set for bathroom by DarthCorvus

...hooks set for bathroom by darthcorvus

thingiverse

glueble hooks set for bathroom.

thingiverse

free

A screw for Planes toy by DarthCorvus

...a screw for planes toy by darthcorvus

thingiverse

a screw for planes toy. reverse engineering.

thingiverse

free

Table handle by DarthCorvus

...table handle by darthcorvus

thingiverse

а standart (95 mm between holes) handle. need some glue or acetone, but no support.

thingiverse

free

Moai lego duplo brick by DarthCorvus

...moai lego duplo brick by darthcorvus

thingiverse

a moai for your duplo

thingiverse

free

whiteboard marker wall mounting by DarthCorvus

...whiteboard marker wall mounting by darthcorvus

thingiverse

d = 18.2 mm

thingiverse

free

A nagel for Ikea hummer-toy. by DarthCorvus

...a nagel for ikea hummer-toy. by darthcorvus

thingiverse

a nagel for ikea toy. reverse engineering.

thingiverse

free

Whiteboard holder by DarthCorvus

...on them when installing and need to replace it. as you can see, a printed one has not a technologic hole, so it must be stronger.

Kayak

turbosquid

$8

kayak

...k

turbosquid

royalty free 3d model kayak for download as obj on turbosquid: 3d models for games, architecture, videos. (1381194)

3d_export

$10

Kayak

...kayak

3dexport

modelled in solidworks 2019.

turbosquid

$6

Kayak 10

...alty free 3d model kayak 10 for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1712455)

turbosquid

$6

Kayak 09

...alty free 3d model kayak 09 for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1712454)

turbosquid

$6

Kayak 08

...alty free 3d model kayak 08 for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1712453)

turbosquid

$6

Kayak 06

...alty free 3d model kayak 06 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1712451)

turbosquid

$6

Kayak 05

...alty free 3d model kayak 05 for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1712450)

turbosquid

$6

Kayak 04

...alty free 3d model kayak 04 for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1712449)

turbosquid

$6

Kayak 02

...alty free 3d model kayak 02 for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1712447)

turbosquid

$6

Kayak 01

...alty free 3d model kayak 01 for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1712446)

Children

3d_export

$15

children room

...children room

3dexport

children room

3d_export

free

childrens

...childrens

3dexport

3d_export

$10

childrens bedroom

...childrens bedroom

3dexport

childrens bedroom 3dmax vray

3d_export

$10

childrens bedroom

...childrens bedroom

3dexport

childrens bedroom 3dmax vray

3d_export

$10

childrens bedroom

...childrens bedroom

3dexport

childrens bedroom 3dmax vray

3d_export

$10

childrens bedroom

...childrens bedroom

3dexport

childrens bedroom 3dmax vray

3d_export

$10

childrens bedroom

...childrens bedroom

3dexport

childrens bedroom 3dmax vray

3d_export

$10

childrens bedroom

...childrens bedroom

3dexport

childrens bedroom 3dmax vray

3d_export

$10

childrens bedroom

...childrens bedroom

3dexport

childrens bedroom 3dmax vray

3d_export

$10

childrens bedroom

...childrens bedroom

3dexport

childrens bedroom 3dmax vray

Folding

design_connected

$16

Fold

...fold

designconnected

poliform fold computer generated 3d model. designed by torres, rodrigo.

design_connected

$7

Folded

...folded

designconnected

baleri italia folded computer generated 3d model. designed by levy, arik.

3ddd

$1

folding sofa

...3ddd

sofa , folding , sofa bed

folding sofa bed

3d_ocean

$4

Chair folding

...chair folding

3docean

camp chair folding hammock light stool wood

folding chair light wood

3ddd

free

Nando FOLD

... fold , стеллаж

http://www.nendo.jp/en/works/fold-2/?egenre

turbosquid

$9

FOLD

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

Folding Chair

...folding chair

3ddd

раскладной

folding chairhttp://www.journal-du-design.fr/design/folding-chair-par-leo-salom-23471/

3ddd

free

FOLDING TABLE

...folding table

3ddd

обеденный

folding table designed by endrit hajno

3d_export

$10

Folding trailer

...folding trailer

3dexport

this is a 3d model of folding trailer for shipping and handling objects

3ddd

$1

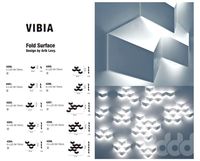

vibia fold surface

...vibia fold surface

3ddd

vibia fold surface , vibia

vibia fold surface