Thingiverse

Chess Piece Mandrel for Lathe (MT2 taper) by hbutler

by Thingiverse

Last crawled date: 3 years, 1 month ago

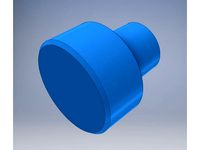

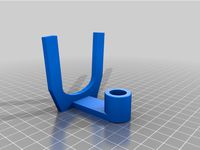

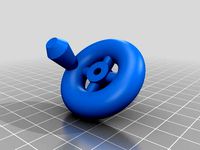

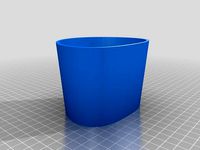

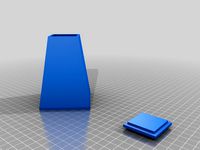

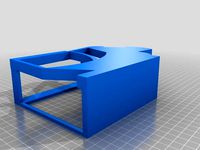

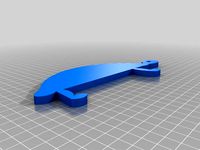

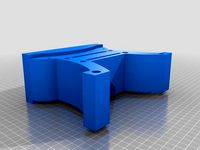

I'm printing the 4d Staunton Chess Set. I wanted to sand my chess pieces down smooth before painting, so I designed this expanding mandrel to go on my lathe. It fits inside the 3/4" recess in the bottom of the chess pieces and you tighten the nut on the back to make it expand and hold the piece tight. It is an #2 Morse Taper (MT2) and will fit any lathe or drill with an MT2 taper. You need four inches of 1/4"x20tpi threaded rod and a 1/4"x20tpi nut. Epoxy the inner mandrel piece onto the end of the threaded rod. Put the inner mandrel inside the outer mandrel and put the nut on the back. That's it!

One word of caution: Stick with sandpaper and don't use steel wool. I tried to buff with steel wool and it melted and deformed the top of one of my pawns. Look at the last picture for what it looks like. Also, keep your lathe at a low speed, maybe a few hundred RPM max. You probably won't be able to get your pieces on with zero runout and if you crank the lathe up to 3,000 rpm you'll end up with a spinning chess piece flying all over your shop.

One idea if you don't have a lathe: You could cut 1.5" off the back of the outer mandrel and hold the excess threaded rod in a drill chuck to spin the mandrel. It might not have a lot of holding torque, but I'd guess it would be enough for light sanding.

Designed in Autodesk Inventor. I've included the .ipt files as well if you want to have a go at modifying them.

One word of caution: Stick with sandpaper and don't use steel wool. I tried to buff with steel wool and it melted and deformed the top of one of my pawns. Look at the last picture for what it looks like. Also, keep your lathe at a low speed, maybe a few hundred RPM max. You probably won't be able to get your pieces on with zero runout and if you crank the lathe up to 3,000 rpm you'll end up with a spinning chess piece flying all over your shop.

One idea if you don't have a lathe: You could cut 1.5" off the back of the outer mandrel and hold the excess threaded rod in a drill chuck to spin the mandrel. It might not have a lot of holding torque, but I'd guess it would be enough for light sanding.

Designed in Autodesk Inventor. I've included the .ipt files as well if you want to have a go at modifying them.

Similar models

thingiverse

free

8mm threaded rod "nuts" by celebrity208

...gned and printed these hand wheels/thumb screws to thread onto an 8mm rod with an interference fit so they don't spin freely.

thingiverse

free

MT2 Morse Taper desktop holder for mini lathe

...mt2 morse taper desktop holder for mini lathe

thingiverse

mt2 morse taper desktop holder for mini lathe

thingiverse

free

Expander for copper plumbing by Doer

...o outside cones are pla. all parts are printed slow with 100% infill. you need to print two flexible tpu parts and two pla parts.

thingiverse

free

Morse taper tool holder by dramaturg

...eded a tool holder for my lathes morse taper tooling. this holds 4 mt2 tools nice and snug - or anything else that fits the bore.

thingiverse

free

stereoplug holder screw, nut - 1000% by marc_is_curious

...t: bayonet outer thread

c - screw: bayonet outer thread, inner m8x1 thread & negative of m8x1 nut - nut: bayonet outer thread

thingiverse

free

stereoplug holder screw, nut - 100% by marc_is_curious

...t: bayonet outer thread

c - screw: bayonet outer thread, inner m8x1 thread & negative of m8x1 nut - nut: bayonet outer thread

thingiverse

free

"Improved" Crytex by rickseiden

...le piece to the indicator ring. now the indicator ring can't spin around and get misaligned anymore.

no flat version, sorry.

thingiverse

free

3/8" threaded rod to 806 bearing adapter by tray_withdraw

... match perfectly with the inner diameter of the bearing. this goes on the end of the threaded rod and fits snugly in the bearing.

thingiverse

free

K8200/3DRAG Z axis support for trapezoidal rod TR8X2 by RDN_ROXAS

...signed in the part.

if you decide to use a tr8x2 threaded rod don't forget to set "steps per mm" to z:400.

enjoy ;)

thingiverse

free

TPU one-piece v-roller for 608 bearings by roliko

...h 3 perimeters and either zero or very few infill.

note: you won't get your bearing pressed in when using non-flex materials.

Mt2

thingiverse

free

MT2 WALL HOLDER

...mt2 wall holder

thingiverse

wall holder for mt2 tools. slightly tilted to improve ergonomy.

thingiverse

free

Plug MT2 by kinedryl

...plug mt2 by kinedryl

thingiverse

.

thingiverse

free

Threaded Container by MT2

...threaded container by mt2

thingiverse

originally posted on instagram.

thingiverse

free

Morse MT2 tool holder narrow

...morse mt2 tool holder narrow

thingiverse

make a wall holder for mt2 tools

thingiverse

free

Morse MT2 tool holder wide

...morse mt2 tool holder wide

thingiverse

yet another mt2 holder that is slightly wider

thingiverse

free

MT2 Morse Taper desktop holder for mini lathe

...mt2 morse taper desktop holder for mini lathe

thingiverse

mt2 morse taper desktop holder for mini lathe

thingiverse

free

6mm Sprinkler Nozzle by MT2

...kler nozzle by mt2

thingiverse

nozzle for large impact sprinklers. improved spray in my opinion. originally posted on instagram.

thingiverse

free

MT2 Morse Taper #2 by jimustanguitar

...e dimensions listed at http://littlemachineshop.com/reference/tapers.php

drawn in designspark mechanical - rsdoc source included.

thingiverse

free

Denford ORAC MT2 & ER11 Tool Holder by cilynx

...ock) and 2 er11 collets. it is deep enough to hold a mt2 jacob's chuck along with smaller things like live and dead centers.

thingiverse

free

MT2 Collet Wall Holders by Gazz292

...ww.thingiverse.com/thing:3588076

the screws i use to mount these to the wall are called 'flange head self tapping screws'

Mandrel

thingiverse

free

Mandrel Stand by whtbearfan

...2.5, 3.0 3.5, etc.). i made it stair stepped for ease of pulling the middle mandrels out. actually printed on a da vinci jr. 1.0

thingiverse

free

Finocyl Mandrel

...finocyl mandrel

thingiverse

for use as a mold to grain finocyl kernel core from rockets engine.

thingiverse

free

Ring Mandrel 14-24mm by wolfskrim

...ring mandrel 14-24mm by wolfskrim

thingiverse

it's a ring mandrel for making or polish ring

thingiverse

free

180° Pipe Bending Mandrel by arshan2998

...0° bend in rigid acrylic tubing with a maximum outer diameter of 15mm.

2.5mm holes so the mandrel can be screwed onto a worktop

thingiverse

free

Ring Mandrel by bruxsa

...ld take any size ring. requires live center to apply pressure. might modify this in future but at the moment this should suffice.

thingiverse

free

Mandrel Bearing Mount by Mr_Vigil

...mandrel bearing mount by mr_vigil

thingiverse

mount to t-bar

thingiverse

free

30cm Rifling Mandrel-9x19 by Untangle

...ieces were you can use 2 pieces of 1.75mm filament to make a strong rifling mandrel

see the installation picture for more details

thingiverse

free

Ring Mandrel/Sizer by stormsomething

...whole thing for taller printers.

the other has it split into a 5 to 8 piece and a 9 to 12 piece for printing on shorter printers.

thingiverse

free

Ring Mandrel Holder, remixed to make it taller by chriscbnss

... i got from patrick adair designs just right. if it is tight for your mandrel, scale it up just a couple of % or sand the inside.

thingiverse

free

Boxford mandrel sun gear CAD file. STEP and STL. by Steveo77

...boxford mandrel sun gear cad file. step and stl. by steveo77

thingiverse

boxford planet gear to fit gear end of mandrel.

Lathe

thingiverse

free

Mini Lathe - Egg Lathe by robertopaoli

...e to decorate things spherical.

speed variator pwm and double switch to reverse direction of rotation.

button for small advances.

thingiverse

free

lathe plug

...lathe plug

thingiverse

plug for back side of mighty turn lathe to stabilize 1.5" square stock

thingiverse

free

Wheel for lathe by Andrew1978

...wheel for lathe by andrew1978

thingiverse

wheel for lathe

thingiverse

free

Mini lathe by janblo

...mini lathe by janblo

thingiverse

wip mini lathe

thingiverse

free

Lathe Faceplate for 9x20 lathe by DasWookie

...ions:

dovetails are 12 degree and 25mm wide

mounting bolts are m6x1

centering rings are at 50, 100, and 150mm

center hole is 25mm

thingiverse

free

Lathe tool holder

...lathe tool holder

thingiverse

holder for small lathe tools

thingiverse

free

MINI-LATHE PROTECTION

...mini-lathe protection

thingiverse

protection and guide for mini-lathe

thingiverse

free

Homemade Lathe by comanderxv

...homemade lathe by comanderxv

thingiverse

this will be a lathe with parts of a cordless screwdriver.

thingiverse

free

Mini Lathe - Egg Lathe - New tailstock to 3 points. by robertopaoli

...lathe - egg lathe - new tailstock to 3 points. by robertopaoli

thingiverse

new tailstock to 3 points for mini lathe - egg lathe.

thingiverse

free

Lathe Parts by Muxlo

...lathe parts by muxlo

thingiverse

small cones for turning small objects in a lathe.

Chess

thingiverse

free

Chess

...chess

thingiverse

chess set modeled with 3d blender

thingiverse

free

#chess Chess Set by Vascilliator

...#chess chess set by vascilliator

thingiverse

chess set for the tinkercad contest

http://tinkercad.com/things/4oqpk3rwnsh

thingiverse

free

chess and super chess by kovadave

...chess and super chess by kovadave

thingiverse

i made

thingiverse

free

chess board for chess set alpha by alexanderstuarthathaway

...chess board for chess set alpha by alexanderstuarthathaway

thingiverse

chess board for chess set alpha

thingiverse

free

Chess by The_LAB

...chess by the_lab

thingiverse

chess

thingiverse

free

#Chess by hilekar

...erse

the chess set, designed through tinkercad. designed for chess players who want their own touch to the classical chess game.

thingiverse

free

Chess King

...iece i made for my new friend kareem who is a chess teacher. we both play chess avidly, i wanted him to have a cool chess piece.

thingiverse

free

Chess set

...chess set

thingiverse

chess set

thingiverse

free

chess pawn

...chess pawn

thingiverse

chess pawn

thingiverse

free

Chess board

...chess board

thingiverse

it is a chess board

Taper

thingiverse

free

Tapered fitting by abessetti

...tapered fitting by abessetti

thingiverse

tapered fitting

thingiverse

free

Arm taper by Davew1775

...arm taper by davew1775

thingiverse

lower arm taper

thingiverse

free

MAS Tapered column

...mas tapered column

thingiverse

modern architectural stone ltd tapered column 1/10 scale

thingiverse

free

Tapered Boxen by Stanistani

...tapered boxen by stanistani

thingiverse

two boxes... one slightly tapered, the other the same but slightly twisted.

thingiverse

free

Gauge Gleam Taper by benparvar

...gauge gleam taper by benparvar

thingiverse

gauge gleam taper

thingiverse

free

Tapered spiral by Miles3D

...tapered spiral by miles3d

thingiverse

a tapered spiral. you may need to scale the overall dimensions down before printing.

thingiverse

free

R8 Tapers

... male and female.

great for swap meets etc, take them and test fit the tool prior to purchase.

i have b&s #9, mt tapers also.

thingiverse

free

Tapered Headband by ARC7217

...tapered headband by arc7217

thingiverse

my wife wanted this headband thinner near her ears, so i added a taper.

thingiverse

free

Combtastic! Tapered by MacGyver

...d by macgyver

thingiverse

after making the flat bottomed version of this i realized it needed some tapering to be easier to use.

thingiverse

free

#9 BS Taper by paultyrer

...ingiverse

this is a taper checker / identifier for a brown sharpe #9 taper.

helps quickly identify tooling, sort, check fitment.

Piece

thingiverse

free

PIECE by kallik

...piece by kallik

thingiverse

piece

thingiverse

free

piece by kallik

...piece by kallik

thingiverse

piece

thingiverse

free

piece by kallik

...piece by kallik

thingiverse

piece

thingiverse

free

piece by nagato

...piece by nagato

thingiverse

piece

thingiverse

free

PIECE by nagato

...piece by nagato

thingiverse

piece

thingiverse

free

piece by nagato

...piece by nagato

thingiverse

piece

thingiverse

free

PIECE by nagato

...piece by nagato

thingiverse

piece

thingiverse

free

PIECE by nagato

...piece by nagato

thingiverse

piece

thingiverse

free

PIECE by nagato

...piece by nagato

thingiverse

piece

thingiverse

free

PIECE by nagato

...piece by nagato

thingiverse

piece