Thingiverse

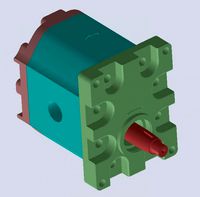

Centrifugal Pump by Ulf_vom_Mond

by Thingiverse

Last crawled date: 3 years, 4 months ago

Summary

Please read the description carefully. Not because it is relevant or helpful, but because i think its funny and interesting.

There already exist a lot of centrifugal pump designs on Thingiverse, so just go ahead and download this one: https://www.thingiverse.com/thing:4839

Still here? Ok, so i designed another one because the existing models didn't satisfy me. I also made another design myself previously, but i was still not happy.

The reason is that i dont know how all the pumps are designed.

Why do some pumps have straight blades, some two dimensional curved blades and some even three dimensional curved blades?

Why are some pumps thick and have a small diameter while others are thin with a large diameter?

Why do some pumps rotate forward and some backward? (Towards outer/inner edge of the blades)

How is the shape of the curved blades determined? Are they just drawn how they look good? How do i know the blades dont only look good for me, but for the water?

How much blades should the impeller have?

How i answered these questions can be found in How to design a centrifugal pump

The next thing bothering me was how to compare the different pump designs. Every design just named centrifugal pump (like mine) doesnt help much.

After some research i found two numbers to rate pumps:

The head they produce. Its just the height the pump can push water upwards.

The flowrate, thats the amount of water they can move per amount of time.

My experiments have established the following experience:

The first thing i found out is that the head of my pump is definitely larger than the border of my sink. The second thing i found out is that if i raised the end of the tube above 1.4 m above my pump, water still flows and shortly after that the cap comes off the pump case. On another attempt i got to 2 m head (which equals 0.2 bars of pressure) until the flow stopped without the pump breaking.

The flowrate wasn't as wet to measure and resulted in 7.5 litres per minute at a head of 0 m.

Another effect occured when operating the pump which may be taken into account: It was strong enough to drive my parents crazy. (Not yet, but it will when they wake up the next morning)

EDIT: yes it did!!!

Maybe the pump could be even better if it was tight. More about that in Print settings and Post-Printing.

The first piece of useful information: All tests were conducted with a little 12 V DC motor which consumes 0.6 W on idle.

Print Settings

Printer brand:

Creality

Printer:

CR-10

Rafts:

No

Supports:

Yes

Resolution:

0,2 mm

Infill:

15 %

Filament_brand:

Conrad Electronics

Filament_color:

black

Filament_material:

PLA

Notes:

Supports are only needed under the outlet of the case part. I think the material doesnt matter, just be careful about the water temperature. You may want to increase flow rate, shell line count and top/bottom layer count in order to make the pump more tight.

Post-Printing and Assembly

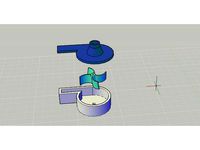

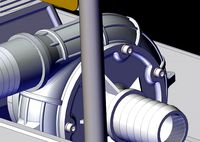

The pump case has a 6.7 mm hole at the bottom. Most little DC motors have a little edge which fits there perfectly. The impeller itself supports a 2 mm motor shaft, however, you have to file one side of the shaft flat to make it fit. It has to be filed until it measures 1.7 mm from the flat side to the opposing point of the round side. This is to ensure that the shaft isnt slipping in the impeller and it works pretty good. See this image for reference:

When your motor shaft fits, just put the parts together in the most obvious way. If you do something wrong there, i cant help you, too.

Then you should seal everything up water tight.

You can either do this the proper way and use silicone, which is made for this purpose and definitely water proof.

Or you can do it like me and use a hotglue. With a hotglue i dont mean a drop or a little or some hotglue, i mean something like a lot or much or a whole stick of hotglue. Your hotglue gun shouldnt make pfft it should make BLAAAAAARGHHHH while applying the glue. If you arent sure whether you used not enough or to less hotglue, you should add more.

These images tell you more about a hotglue:

(Yes, the tube adapter broke of in the second image. Be careful when removing the tube)

The tube adapters are designed for aquarium tubes with 12 mm inner diameter and 16 mm outer diameter. If the tubes dont fit, heat them up in a bowl of boiling water to make them soft and then push them over the adapters.

How to design a centrifugal pump

I used Fusion 360. You can access the design here: https://a360.co/3ixGKq7

About my used tolerances:

Everything that should fit tight together has a gap of 0.15 mm like the cap and the case.

The spinny thingy and the not so spinny thingy have a gap of radially 0.5 mm and axially 0.8 mm.

This part is really important to me as it was hard to find any solid information on the internet.

The things i found and used while designing are the following:

Centrifugal pump impeller vane profile

This article describes a conventional impeller blade design method in the Section 5.3 CONSTRUCTION OF VANE PROFILE. Thats the method i used and its called circular arc method.

A Review of Different Blade Design Methods for Radial Flow Centrifugal Pump

Here, further blade design methods are discussed which also may be helpful.

The Theory and Design of a Centrifugal Pump

Thats a bachelor thesis from 1911 which handles all the theory, but misses any practical advice on "how to do this" or "how to do that" but its quite interesting to read. Simply the fact that it was written on a typewriter made me curious.

Pump Handbook by Igor J. Karassik

This document probably contains every piece of information for every pump type on nearly 1800 pages (Why is this allowed to be called a handbook? I am happy that its digital because i could never even lift it). Its really interesting and has a lot of useful, detailed information. If you dont find your seeked knowledge there, it doesnt exist yet.

DESIGN AND ANALYSIS OF CENTRIFUGAL PUMP IMPELLER USING ANSYS FLUENT

Ajith MS made a good job simulating and comparing the different impeller blade design methods here. Its a nice addition if the 1800 pages werent enough for you.

Investigation of a centrifugal pump impeller vane profile using CFD

Another paper which researches the fluid dynamics of different impellers with simulation.

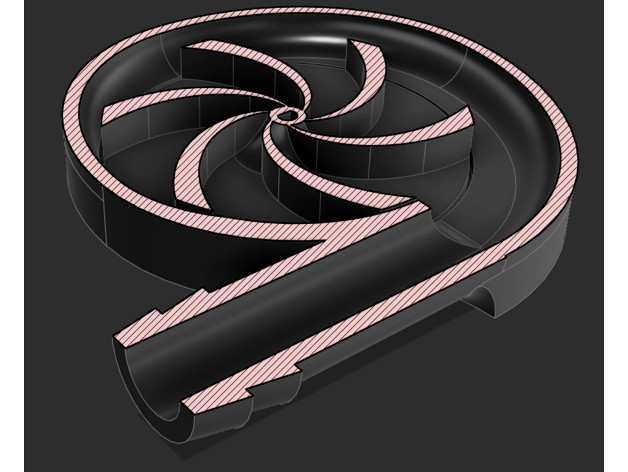

After reading a lot about pumps, this is how my sketch looks in Fusion 360:

I also included the impeller profile as a .svg and a .dxf file if you want to have a closer look.

Different pump sizes

If you need a different height, diameter, motor shaft, tube size or something else feel free to ask and i will upload your requested size. Thats not hard for me, so dont hesitate.

Please read the description carefully. Not because it is relevant or helpful, but because i think its funny and interesting.

There already exist a lot of centrifugal pump designs on Thingiverse, so just go ahead and download this one: https://www.thingiverse.com/thing:4839

Still here? Ok, so i designed another one because the existing models didn't satisfy me. I also made another design myself previously, but i was still not happy.

The reason is that i dont know how all the pumps are designed.

Why do some pumps have straight blades, some two dimensional curved blades and some even three dimensional curved blades?

Why are some pumps thick and have a small diameter while others are thin with a large diameter?

Why do some pumps rotate forward and some backward? (Towards outer/inner edge of the blades)

How is the shape of the curved blades determined? Are they just drawn how they look good? How do i know the blades dont only look good for me, but for the water?

How much blades should the impeller have?

How i answered these questions can be found in How to design a centrifugal pump

The next thing bothering me was how to compare the different pump designs. Every design just named centrifugal pump (like mine) doesnt help much.

After some research i found two numbers to rate pumps:

The head they produce. Its just the height the pump can push water upwards.

The flowrate, thats the amount of water they can move per amount of time.

My experiments have established the following experience:

The first thing i found out is that the head of my pump is definitely larger than the border of my sink. The second thing i found out is that if i raised the end of the tube above 1.4 m above my pump, water still flows and shortly after that the cap comes off the pump case. On another attempt i got to 2 m head (which equals 0.2 bars of pressure) until the flow stopped without the pump breaking.

The flowrate wasn't as wet to measure and resulted in 7.5 litres per minute at a head of 0 m.

Another effect occured when operating the pump which may be taken into account: It was strong enough to drive my parents crazy. (Not yet, but it will when they wake up the next morning)

EDIT: yes it did!!!

Maybe the pump could be even better if it was tight. More about that in Print settings and Post-Printing.

The first piece of useful information: All tests were conducted with a little 12 V DC motor which consumes 0.6 W on idle.

Print Settings

Printer brand:

Creality

Printer:

CR-10

Rafts:

No

Supports:

Yes

Resolution:

0,2 mm

Infill:

15 %

Filament_brand:

Conrad Electronics

Filament_color:

black

Filament_material:

PLA

Notes:

Supports are only needed under the outlet of the case part. I think the material doesnt matter, just be careful about the water temperature. You may want to increase flow rate, shell line count and top/bottom layer count in order to make the pump more tight.

Post-Printing and Assembly

The pump case has a 6.7 mm hole at the bottom. Most little DC motors have a little edge which fits there perfectly. The impeller itself supports a 2 mm motor shaft, however, you have to file one side of the shaft flat to make it fit. It has to be filed until it measures 1.7 mm from the flat side to the opposing point of the round side. This is to ensure that the shaft isnt slipping in the impeller and it works pretty good. See this image for reference:

When your motor shaft fits, just put the parts together in the most obvious way. If you do something wrong there, i cant help you, too.

Then you should seal everything up water tight.

You can either do this the proper way and use silicone, which is made for this purpose and definitely water proof.

Or you can do it like me and use a hotglue. With a hotglue i dont mean a drop or a little or some hotglue, i mean something like a lot or much or a whole stick of hotglue. Your hotglue gun shouldnt make pfft it should make BLAAAAAARGHHHH while applying the glue. If you arent sure whether you used not enough or to less hotglue, you should add more.

These images tell you more about a hotglue:

(Yes, the tube adapter broke of in the second image. Be careful when removing the tube)

The tube adapters are designed for aquarium tubes with 12 mm inner diameter and 16 mm outer diameter. If the tubes dont fit, heat them up in a bowl of boiling water to make them soft and then push them over the adapters.

How to design a centrifugal pump

I used Fusion 360. You can access the design here: https://a360.co/3ixGKq7

About my used tolerances:

Everything that should fit tight together has a gap of 0.15 mm like the cap and the case.

The spinny thingy and the not so spinny thingy have a gap of radially 0.5 mm and axially 0.8 mm.

This part is really important to me as it was hard to find any solid information on the internet.

The things i found and used while designing are the following:

Centrifugal pump impeller vane profile

This article describes a conventional impeller blade design method in the Section 5.3 CONSTRUCTION OF VANE PROFILE. Thats the method i used and its called circular arc method.

A Review of Different Blade Design Methods for Radial Flow Centrifugal Pump

Here, further blade design methods are discussed which also may be helpful.

The Theory and Design of a Centrifugal Pump

Thats a bachelor thesis from 1911 which handles all the theory, but misses any practical advice on "how to do this" or "how to do that" but its quite interesting to read. Simply the fact that it was written on a typewriter made me curious.

Pump Handbook by Igor J. Karassik

This document probably contains every piece of information for every pump type on nearly 1800 pages (Why is this allowed to be called a handbook? I am happy that its digital because i could never even lift it). Its really interesting and has a lot of useful, detailed information. If you dont find your seeked knowledge there, it doesnt exist yet.

DESIGN AND ANALYSIS OF CENTRIFUGAL PUMP IMPELLER USING ANSYS FLUENT

Ajith MS made a good job simulating and comparing the different impeller blade design methods here. Its a nice addition if the 1800 pages werent enough for you.

Investigation of a centrifugal pump impeller vane profile using CFD

Another paper which researches the fluid dynamics of different impellers with simulation.

After reading a lot about pumps, this is how my sketch looks in Fusion 360:

I also included the impeller profile as a .svg and a .dxf file if you want to have a closer look.

Different pump sizes

If you need a different height, diameter, motor shaft, tube size or something else feel free to ask and i will upload your requested size. Thats not hard for me, so dont hesitate.

Similar models

grabcad

free

Twist vane Impeller

...twist vane impeller

grabcad

impeller which is used in centrifugal pump

grabcad

free

centrifugal pump impeller and shaft

...centrifugal pump impeller and shaft

grabcad

a small practice mode of centrifugal pump impeller and its shaft

grabcad

free

Impeller Blades

...esigned using- catia v5 * work file uploaded in .catpart

surface modelling made in - solidworks 2018

material assigned- aluminium

grabcad

free

Enclosed Impeller

...the two shrouds. closed-impellers are installed on radial flow centrifugal pumps and can be either single inlet, or double inlet.

grabcad

free

Centrifugal Impeller

...centrifugal impeller

grabcad

a centrifugal compressor impeller

number of vanes: 8 blades and splitters

grabcad

free

Centrifugal impeller

...centrifugal impeller

grabcad

it is an impeller of centrifugal pump i have designed. it is just a model.

grabcad

free

Water Pump

...t, direct it into the impeller and then slow and control the fluid before discharge.

centrifugal pump specification: 125-100-250

grabcad

free

Reverse Vane Impeller

...the fluid being pumped by accelerating it from the center of the impeller to the outside of the impeller.

impeller overhung pump

grabcad

free

centrifugal pump

...tating impeller along its axis and is cast out by centrifugal force along its circumference through the impeller's vane tips.

thingiverse

free

Mini Impeller type Water pump by electricdiylab

...a mini 12v dc motor

i have also attached a cad drawing if you required to do some modification you can do.

www.electricdiylab.com

Ulf

3ddd

$1

mirror Epoca by Ulf Moritz

... ulf moritz

5 зеркал разных размеров с различными вариантами компоновки.

∅ 80 мм

∅ 120 мм

∅ 240 мм

∅ 400 мм

∅ 700 мм

3ddd

free

Обои Marburg ulf moritz pearl

...f moritz pearl

3ddd

marburg

обои marburg ulf moritz pearl арт

76822, вложены diffuse, reflect и

bump карты, разрешение 750*2500

3ddd

$1

Kahrs Ulf

...loads/images/7/7d/7d6/7d6fe34e6b7e0a4c3c9df721ce01bcd787b22a8b.jpg

отдельная благодарность kalando81 за модель кресла.

3ddd

$1

Обои

...кому-нибудь пригодится. ссылка на всю коллекцию: wall-covering.ru/germany/marburg/pearl/pearl.htm коллекция "pearl". "ulf moritz™". marburg wallcoverings (германия)...

unity_asset_store

$5

Viking Ulf

...ur workflow with the viking ulf asset from maksim bugrimov. find this & other humanoids options on the unity asset store.

3d_sky

free

mirror Epoca by Ulf Moritz

...y

mirror epoca ulf moritz

5 mirrors of different sizes with different layout options. ∅ ∅ 80 mm 120 mm 240 mm ∅ ∅ ∅ 400 mm 700 mm

3d_sky

free

Wallpaper Marburg ulf moritz pearl

...er marburg ulf moritz pearl

3dsky

wallpaper marburg ulf moritz pearl art 76822, nested, reflect and diffuse bump map, 750 * 2500

3dfindit

free

4047-L-ONFF-1-ULF-1.6GPF

...4047-l-onff-1-ulf-1.6gpf

3dfind.it

catalog: whitehall

3d_sky

$8

Kahrs Ulf

...e.ru/uploads/images/7/7d/7d6/7d6fe34e6b7e0a4c3c9df721ce01bcd787b22a8b.jpg special thanks kalando81 model for the chair.

thingiverse

free

Cory Doctorow's decimated head for 3D printing - 16000 triangles by Ulf

...000 triangles by ulf

thingiverse

cory doctorow's 3d scanned head reduced to only 16,000 triangles with netfabb professional.

Vom

thingiverse

free

Meine Art vom Frosch by DirksBastelbude

...meine art vom frosch by dirksbastelbude

thingiverse

thingiverse

free

FIAT Luxus Wagon - vom munde abgespart by Syzguru11

...fiat luxus wagon - vom munde abgespart by syzguru11

thingiverse

fiat luxus wagon - vom munde abgespart

thingiverse

free

3D scan of Jüngling vom Magdalensberg by oliverlaric

...

3d scan of jüngling vom magdalensberg.

for more information visit http://threedscans.com/kunsthistorisches-museum-wien/jungling/

thingiverse

free

Halterung für Gummischutzbacken vom Proxxon Schraubstock by oobdoo

...roxxon schraubstock by oobdoo

thingiverse

ne kleine halterung wo ich die schutzbacken vom proxxon schraubstock aufbewahren kann.

thingiverse

free

FIAT Luxus Wagon mit schasdoernchen - vom munde abgespart by Syzguru11

...agon mit schasdoernchen - vom munde abgespart by syzguru11

thingiverse

fiat luxus wagon mit schasdoernchen - vom munde abgespart

thingiverse

free

FIAT Luxus Wagon vom munde abgespart / mother / phoenix by Syzguru11

... wagon vom munde abgespart / mother / phoenix by syzguru11

thingiverse

fiat luxus wagon vom munde abgespart / mother / phoenix

thingiverse

free

DJI Logo by Mike-vom-Mars

...corate your box, bag or controller. comes in two versions - solid and outlined.

use double sided tape, for example, to attach it.

thingiverse

free

Backen vom Greifer zum greifen von LED´s by JohnQgeL

...backen vom greifer zum greifen von led´s by johnqgel

thingiverse

for our project

thingiverse

free

Winged Heart Keychain by Mike-vom-Mars

... keychain

prints without supports, adding a brim may help for better heatbed adhesion since the parts are relatively small sized.

thingiverse

free

The Speedy Sperm by Mike-vom-Mars

...s with a black marker after printing. can be printed in various sizes.

no supports needed

no infill required, prints good without

Centrifugal

turbosquid

$209

Carpet centrifuge

...royalty free 3d model carpet centrifuge for download as sldas on turbosquid: 3d models for games, architecture, videos. (1445260)

turbosquid

$32

Centrifugal Pump

... free 3d model centrifugal pump for download as sldas and ige on turbosquid: 3d models for games, architecture, videos. (1643069)

3d_export

$12

Centrifugal Pump 3D Model

...centrifugal pump 3d model

3dexport

centrifugal pump

centrifugal pump 3d model fau 71172 3dexport

3d_export

$7

zy series centrifugal blower

...zy series centrifugal blower

3dexport

zy series centrifugal blower

3d_export

$20

Centrifugal pump 3D Model

... 3d model

3dexport

pump centrifugal turbomachinery turbo water machines industry

centrifugal pump 3d model qepasol 93421 3dexport

archive3d

free

Centrifuge 3D Model

...d

centrifuge spin dryer

dlc-213 n281107 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$8

Centrifuge Laboratory 3D Model

...oratory centrifuge

centrifuge laboratory 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl 3d1startup 105313 3dexport

3d_export

$7

centrifugal compressor

...ded, and also, step file and .stl files are also given so that anyone can operate this 3d model in any other designing softwares.

turbosquid

$120

Centrifugal Space Station

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$8

centrifugal fan 4-72-12 b4-72-12 no6 d c centrifugal fan

...centrifugal fan 4-72-12 b4-72-12 no6 d c centrifugal fan

3dexport

[centrifugal fan] 4-72-12, b4-72-12, no6 d, c centrifugal fan

Mond

3ddd

$1

Maisons du monde

... фоторамка , часы

декортивный набор maisons du monde

3ddd

free

Maisons Du Monde

... свеча , фоторамка , часы

maisons du monde

3ddd

$1

Maisons du monde PIRATE

...f surfer plaques. maisons du monde

-ковер manufacture rug. maisons du monde

-постельное белье maisons du monde

присутствует fbx

3ddd

$1

Maisons du Monde Velvet

...maisons du monde velvet

3ddd

maisons du monde

maisons du monde velvet child's armchair

polys: 41509

3ddd

$1

Maisons Du Monde

... свеча , тумба , часы

maisons du monde

3d_export

$5

maisons-du-monde-diamant

...maisons-du-monde-diamant

3dexport

maisons-du-monde-diamant

3ddd

$1

Maisons du monde ROBOT

...-постер ensemble de 2 toiles robot. maisons du monde

-подушки set of 4 robot child’s cushions. maisons du monde

присутствует fbx

3ddd

free

Maisons du monde CAMPUS

... monde

-постер andrews usa flag wall art. maisons du monde

-книги

-светофор

-карандаши

-рисунки

-меловая доска

присутствует fbx

3ddd

$1

Sideboard Archibald Maison Du Monde

...e

3ddd

сервант , maison du monde

сервант archibald от maison du monde

размеры 215х177х48

3d_export

$5

lampe photographe maisons du monde

...lampe photographe maisons du monde

3dexport

lampe photographe maisons du monde

Pump

3d_export

$5

pump

...pump

3dexport

pump

archibase_planet

free

Pump

...pump

archibase planet

petrol pump petrol station gas station

pump - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_ocean

$8

Pumps

...ps

3docean

girls heels high kicks pumps shoes stilettos womens

womens high heels, pumps or stilettos. polygon model – no textures

3ddd

free

Pump

...ump

3ddd

pump , versus

производитель: versus

модель: pumphttp://www.versus.as/

turbosquid

$3

Pumps

...s

turbosquid

royalty free 3d model pumps for download as skp on turbosquid: 3d models for games, architecture, videos. (1275250)

3d_export

$5

pump

...pump

3dexport

turbosquid

$39

Realistic Water pump SYLLENT PUMP

...realistic water pump syllent pump for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1312864)

turbosquid

$150

Pumpe

...yalty free 3d model pumpe for download as ige, blend, and stl on turbosquid: 3d models for games, architecture, videos. (1284318)

3d_export

$10

gear pump

...gear pump

3dexport

it is a gear pump in iges format

turbosquid

$19

Old Water Pumps Gas Pumps

...pumps gas pumps for download as 3ds, obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1207997)