Thingiverse

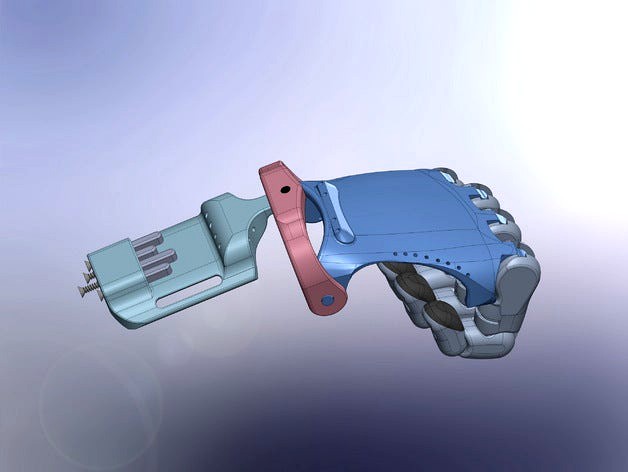

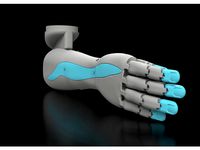

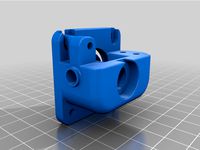

Cathy's Lucky Fin - Prosthetic Hand - Bowden / Push-Pull Variant by Rhadamanthys76

by Thingiverse

Last crawled date: 3 years ago

Outline

This prosthetic hand model has no elastics for finger return or hardware (tendon anchors and screws for tensioning excluded)

It uses the palm from the Flexy Hand 2 with different fingers and the remaining parts I already designed in the Flexy Hand Reloaded remix

Video of the printed hand (https://youtu.be/FpLIcS0G04E)

This is a specific variant (Left Hand thumbless) since its a model I've been working on for my daughter

Specifics of this design

The hand works on the Bowden Cable principle, where the cables that pull the fingers closed also push the fingers back open

Fingers have single channel for the cable

Fingers offset with respect to one another (not all parallel)

No hardware required for the fingers, pins are incorporated in the phalanges and they click into place

The Gimbal mechnism allows an additional degree of movement - Radial & Ulnar deviation

The design is made for using crimps for terminations (I'm using #1 single barrel fishing crimps)

The fingertips are in 2 parts:

One to be printed in regular PLA

The second flexible portion provides grip without sacrificing the shape of the finger

Tendons

This hand is designed to use push pull actuation so strings that work with the other e-Nable prosthetic designs won’t work here

I've found Nickel Titanium cables to be the best for this purpose. They’re incredibly flexible, kink resistant and work very well as bowden cables

A company called Aquateko makes fishing leader cables with this material at reasonable prices and they come in a range of sizes http://www.aquateko.com/category_s/21.htm

I used the 25lb single strand cable for the hand I made (scaled to 65%)

Grip

The fingertips could be printed directly, however I only have access to Filaflex and its not tacky enough to provide grip. I've made the cuts straight to allow for printing in case there are any other filaments that could be used

The other option is to use the provided mould. The mould is made to use "pourable" material. I have experimented with Smooth-on's Mold Star 15 and had excellent results, the tips come out really soft and tacky (Shore Hardness of 15A versus Filaflex @ 85A)

Silicone works brilliantly for this application and its extremely durable, the only down side I found to this particular brand was that the color cant be changed, its a greenish cyan color - If anyone knows of better pourable silicone for this, I'll be happy to hear suggestions

The proximal joints have a slot running across for an additional point on the finger for grip. The idea is to insert O-ring cord stock here. A piece of rubber band should work too

Assembly

The phalanges have slots to slide the pins - align, push and they click into place - keep in mind that there needs to be slight flex for this to work - I tried printing the fingers with 30% infill and they wouldnt flex enough to slide the joints in. 5% infill works great

Similarly, the Gimbal is spread slightly and slid onto the palm till the pins on the palm pop into place

The Gauntlet is inserted into the gimbal and the printed pin goes in from the bottom

Each tendon has a crimp at one end that sits in the groove in the fingertip - glue or melted PLA keeps it in place well

The tendon lines are routed through the fingers, palm, and terminate in another crimp that resides in the tensioner - same as fingertip, glue or melted pla to keep the crimp in place

Its easier to begin terminating the cable at the tensioner and routing the cable from the back of the hand to the tip

I still need to finish building the hand and get my daughter to start using the hand. There will be other changes coming once I get to see how it works out for her

Update 15-Nov-2016, List of changes

Palm: If you notice in the video, lateral movement (radial & ulnar deviation) produces a slight bending of the fingers

This movement has to do with the position of the tendon where it passes the pivot point above the wrist

The range of motion of the finger has to do with the distance of the tendon from the same pivot point

New Alternate Palm has the tendon channels reversed (index and middle tendons pass to the left of the pivot point and vice versa for ring and little) Also the index tendon channel passes furthest from the pivot point - With this, Radial deviation will cause the index finger to bend and allow a pinch grip

Modified Gauntlet to eliminate need for housing (tubing for tendon support), tendons have more support printed

Modified the proximal joints o-ring groove to a dovetail shape for easier installation

Uploaded all the CAD files for the parts (SW 2014)

This prosthetic hand model has no elastics for finger return or hardware (tendon anchors and screws for tensioning excluded)

It uses the palm from the Flexy Hand 2 with different fingers and the remaining parts I already designed in the Flexy Hand Reloaded remix

Video of the printed hand (https://youtu.be/FpLIcS0G04E)

This is a specific variant (Left Hand thumbless) since its a model I've been working on for my daughter

Specifics of this design

The hand works on the Bowden Cable principle, where the cables that pull the fingers closed also push the fingers back open

Fingers have single channel for the cable

Fingers offset with respect to one another (not all parallel)

No hardware required for the fingers, pins are incorporated in the phalanges and they click into place

The Gimbal mechnism allows an additional degree of movement - Radial & Ulnar deviation

The design is made for using crimps for terminations (I'm using #1 single barrel fishing crimps)

The fingertips are in 2 parts:

One to be printed in regular PLA

The second flexible portion provides grip without sacrificing the shape of the finger

Tendons

This hand is designed to use push pull actuation so strings that work with the other e-Nable prosthetic designs won’t work here

I've found Nickel Titanium cables to be the best for this purpose. They’re incredibly flexible, kink resistant and work very well as bowden cables

A company called Aquateko makes fishing leader cables with this material at reasonable prices and they come in a range of sizes http://www.aquateko.com/category_s/21.htm

I used the 25lb single strand cable for the hand I made (scaled to 65%)

Grip

The fingertips could be printed directly, however I only have access to Filaflex and its not tacky enough to provide grip. I've made the cuts straight to allow for printing in case there are any other filaments that could be used

The other option is to use the provided mould. The mould is made to use "pourable" material. I have experimented with Smooth-on's Mold Star 15 and had excellent results, the tips come out really soft and tacky (Shore Hardness of 15A versus Filaflex @ 85A)

Silicone works brilliantly for this application and its extremely durable, the only down side I found to this particular brand was that the color cant be changed, its a greenish cyan color - If anyone knows of better pourable silicone for this, I'll be happy to hear suggestions

The proximal joints have a slot running across for an additional point on the finger for grip. The idea is to insert O-ring cord stock here. A piece of rubber band should work too

Assembly

The phalanges have slots to slide the pins - align, push and they click into place - keep in mind that there needs to be slight flex for this to work - I tried printing the fingers with 30% infill and they wouldnt flex enough to slide the joints in. 5% infill works great

Similarly, the Gimbal is spread slightly and slid onto the palm till the pins on the palm pop into place

The Gauntlet is inserted into the gimbal and the printed pin goes in from the bottom

Each tendon has a crimp at one end that sits in the groove in the fingertip - glue or melted PLA keeps it in place well

The tendon lines are routed through the fingers, palm, and terminate in another crimp that resides in the tensioner - same as fingertip, glue or melted pla to keep the crimp in place

Its easier to begin terminating the cable at the tensioner and routing the cable from the back of the hand to the tip

I still need to finish building the hand and get my daughter to start using the hand. There will be other changes coming once I get to see how it works out for her

Update 15-Nov-2016, List of changes

Palm: If you notice in the video, lateral movement (radial & ulnar deviation) produces a slight bending of the fingers

This movement has to do with the position of the tendon where it passes the pivot point above the wrist

The range of motion of the finger has to do with the distance of the tendon from the same pivot point

New Alternate Palm has the tendon channels reversed (index and middle tendons pass to the left of the pivot point and vice versa for ring and little) Also the index tendon channel passes furthest from the pivot point - With this, Radial deviation will cause the index finger to bend and allow a pinch grip

Modified Gauntlet to eliminate need for housing (tubing for tendon support), tendons have more support printed

Modified the proximal joints o-ring groove to a dovetail shape for easier installation

Uploaded all the CAD files for the parts (SW 2014)

Similar models

thingiverse

free

Flexy Hand Reloaded by Rhadamanthys76

...;ve included the solidworks files used as well as the original flexy hand sw models (only the left hand thumbless variant though)

thingiverse

free

Cathy's Lucky Fin V3 by Rhadamanthys76

... using this option), fingertips mould, gauntlet and tensioner

i used pla+, printed with 0.15 resolution, 25% infill and 2 shells

thingiverse

free

Falcon Hand V1 by Btown

...arrett estep. it was designed and developed in cooperation with seattle pacific university.

www.spu.edu

www.enablingthefuture.org

grabcad

free

HOLD THE CAN

...pen and close ,and individually with a push pin, layer gaps 0.2mm and 0.08mm.

a simple servo can do the job of straps and cable

thingiverse

free

Balancer for Adaptive Grip Prosthetic by Gyrobot

...eo, to visualise the mechanism working : http://youtu.be/ch6iualgqxo

http://www.gyrobot.co.ukhttp://www.facebook.com/gyrobotuk

thingiverse

free

V.2 Flex Fingers, Swivel Thumb Prosthetic Hand by 1d1

...ximation of an actual hand. the mesh palm is scaled the same percentage as the palm or can be printed larger for a bigger pocket.

grabcad

free

Mold for Prosthetic Hand | TRINOTA

... required to produce fingers and a thumb for a prosthetic hand - palm is 3d printed. all molds are 3d printed.

www.trinota.com

grabcad

free

3-D Printed Terminal Prosthetic

...bags with little effort and serves as the opposing digit to the thumb for grasping items that require a "pinch" motion.

thingiverse

free

Aline's Index by millgem

...h the small holes in the finger parts, but a doubled monofilament line will, which is then used to draw the braided line through.

grabcad

free

Raptor Prosthetic Hand

...ic as the interface to the actuation cable. this will maintain grip strength by prevent crushing or jamming of the entire system.

Rhadamanthys76

thingiverse

free

The Lucky Paw Prosthetic Hand by Rhadamanthys76

...7715636887179986

for more information and amazing stories:http://enablingthefuture.orghttps://www.facebook.com/enableorganization

thingiverse

free

Flexy Hand Reloaded by Rhadamanthys76

...;ve included the solidworks files used as well as the original flexy hand sw models (only the left hand thumbless variant though)

thingiverse

free

Cathy's Lucky Fin V3 by Rhadamanthys76

... using this option), fingertips mould, gauntlet and tensioner

i used pla+, printed with 0.15 resolution, 25% infill and 2 shells

thingiverse

free

ArmPO v3 by poparaguay

...modificados a partir de la prótesis de mano de rhadamanthys76 esta versión cuenta con dos canales, uno para los...

thingiverse

free

Po Elbow (Beta) by poparaguay

...by editing gyrobot's flexyhand and cathy's lucky fin by rhadamanthys76 (see armpo v3)https://www.thingiverse.com/thing:2803120 fusion 360 public link: https://a360.co/2gkau47 for...

Cathy

turbosquid

$79

Cathy

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$50

Character Cathy

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

AIRNOVA Cathy CHAIR

...air

3ddd

airnova , cathy

длинна 431

глубина 475

высота 1090

полигонов 18199

вершин 18666

3ddd

$1

rugiano Rea, rugiano ZOE, rugiano Cathy

...rugiano rea, rugiano zoe, rugiano cathy

3ddd

rugiano

стул и 2 стола rugiano rea, rugiano zoe, rugiano cathy

3d_export

$149

North American P 51D Mustang Cathy Beloved 3D Model

...ce single-seat army military aviation bomber escort

north american p 51d mustang cathy beloved 3d model panaristi 96415 3dexport

cg_studio

$129

North American P-51D Mustang - Cathy Beloved3d model

...wo .fbx - north american p-51d mustang - cathy beloved 3d model, royalty free license available, instant download after purchase.

3d_export

$6

rugiano-rea-rugiano-zoe-rugiano-cathy

...#39;t forget to rate it please - enjoy hope you like it! the archive contains 3ds max fbx files if you have a question contact me

thingiverse

free

Cathy by cerberus333

...cathy by cerberus333

thingiverse

cat woman?

werecat?

thingiverse

free

Cathy's Shell by 3dlabmemphis

...cathy's shell by 3dlabmemphis

thingiverse

first 3d scan for cathy! shell from desk.

thingiverse

free

Cathy Wong by tszwing

...cathy wong by tszwing

thingiverse

this is you!

Prosthetic

turbosquid

$49

Prosthetic Arm

...uid

royalty free 3d model prosthetic arm for download as max on turbosquid: 3d models for games, architecture, videos. (1556291)

turbosquid

$20

Prosthetic for small dogs 3D print model v2

...osthesis for small dogs 3d print model v2 for download as stl on turbosquid: 3d models for games, architecture, videos. (1290474)

3d_export

$10

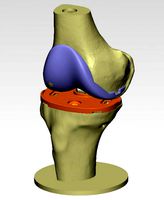

knee joint prosthesis with guides sample of individual prosthetics

...mm, 20 grams tibial component: ti6al4v material, 76×77×70 mm, 90 grams femoral component: cocrmo material, 70×52×62 mm, 290 grams

3d_export

$5

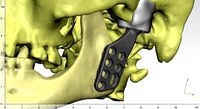

individual tmj prosthesis real operation

...left tmj. it consists of the following parts:: * prosthetic condylar process (ti6al4v); * joint cavity prosthesis (high molecular...

3d_export

$44

Hip Replacement

...damaged bone and cartilage is removed and replaced with prosthetic components. the damaged femoral head is removed and replaced...

3d_export

$10

itap implant osteointegration operation

...the implant. tested on more than 15 operations. itap prosthetic is an installation of "intraosseous transcutaneous amputation prosthesis". in...

thingiverse

free

Prosthetic arm

...prosthetic arm

thingiverse

prosthetics arm

3d printable

thingiverse

free

Prosthetic Arm

...prosthetic arm

thingiverse

a prosthetic arm purely for asthetic purposes. it was made for a client's wedding.

thingiverse

free

Dog Prosthetic by 3DESIGNER27

...animal allies. cheap alternative for dog prosthetic limb. scale in your slicer to fit the dog you are looking to apply prosthetic

thingiverse

free

XOR Prosthetic Hand by chandlersupple

...xor prosthetic hand by chandlersupple

thingiverse

prosthetic hand - two part

Lucky

3d_export

$12

Lucky

...texture - 3000x3000 png. lucky_teeth_texture - 3000x3000 png. lucky_eyes_texture - 3000x3000 png. collar_texture - 3000x3000 png.

3ddd

$1

Lucky Charm

...lucky charm

3ddd

sicis

lucky charm by sicis.

turbosquid

$15

Lucky Bamboo

...squid

royalty free 3d model lucky bamboo for download as max on turbosquid: 3d models for games, architecture, videos. (1234742)

3ddd

$1

Tonon Lucky 906.01_901.21

...

3ddd

tonon , lucky

tonon

lucky 906

906.01 and 906.21

size:

w 530mm

d 550mm

h 870 mm

vizpark

$26

Lucky Chestnut

...

lucky chestnut is a set of 5 realistic 3d models of the pachira aquatica plant, ready to render for pbr and various 3d formats.

turbosquid

$15

Lucky 38

...d

royalty free 3d model lucky 38 for download as obj and c4d on turbosquid: 3d models for games, architecture, videos. (1470229)

3ddd

$1

Кожаный Диван LUCKY

...кожаный диван lucky

3ddd

lucky

http://www.gruppoeuromobil.com/desiree/divani/divani/lucky.htm#

turbosquid

$25

Lucky-by-Tonon

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Lucky.3ds

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$6

Lucky Chair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Bowden

turbosquid

$199

Vintage Ben Bowden Spacelander bike

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Manooi Artica

...and pendants in various sizes and forms. suspension: galvanized bowden - dia. 1,5 mm. bulb: max 60 w -...

thingiverse

free

Remix Compact Bowden extruder - m6 bowden couplers and bowden tube pass-through

...ouplers and bowden tube pass-through

thingiverse

remix compact bowden extruder - m6 bowden couplers and bowden tube pass-through

thingiverse

free

Bowden Extruder

...bowden extruder

thingiverse

i have created bowden extruder for flsun delta 3d printer.

thingiverse

free

bowden 3mm by spee_D

...bowden 3mm by spee_d

thingiverse

for bowden 3mm

thingiverse

free

Bowden Tube Cutter

...bowden tube cutter

thingiverse

bowden tube cutter

thingiverse

free

Customizable Bowden Clip

...customizable bowden clip

thingiverse

customizable bowden clip

thingiverse

free

Bowden Oiler by fcheshire

...bowden oiler by fcheshire

thingiverse

inline bowden oiler

thingiverse

free

Bowden adapter by helkaroui

...bowden adapter by helkaroui

thingiverse

this is a fixed bowden adapter

thingiverse

free

Adventure3 Bowden Clip

...adventure3 bowden clip

thingiverse

adventure3 bowden clip

Fin

archibase_planet

free

Fins

...fins

archibase planet

flippers fins

fins - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

free

Fin

...fin

3ddd

adventure time , fin

настало время приключений!)

turbosquid

$1

Fins

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

archive3d

free

Fins 3D Model

...s 3d model

archive3d

flippers fins

fins - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$3

Fin Sword

...rbosquid

royalty free 3d model fin sword for download as obj on turbosquid: 3d models for games, architecture, videos. (1370918)

turbosquid

$5

SailFish fin

...alty free 3d model sailfish fin for download as stl and sldpr on turbosquid: 3d models for games, architecture, videos. (1166142)

turbosquid

$39

Stealth fins

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Finned lamp

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Fin Dining Chair

...e 3d model fin dining chair for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1329735)

turbosquid

free

yellow fin tuna

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Variant

turbosquid

$6

M10 Variant

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$27

Delta Variant 01

...delta variant 01

designconnected

zanotta delta variant 01 computer generated 3d model. designed by progetti, emaf.

design_connected

$20

Delta Variant 02

...delta variant 02

designconnected

zanotta delta variant 02 computer generated 3d model. designed by progetti, emaf.

3d_export

$5

Shade - Variant A

...shade - variant a

3dexport

shade model that can be used in hospitals and clinics.

turbosquid

$3

Crowbar Grip Variant

...oyalty free 3d model crowbar grip variant for download as fbx on turbosquid: 3d models for games, architecture, videos. (1315114)

turbosquid

$7

AK47 variant - Hpoly

... model ak47 variant - hpoly for download as obj, dae, and fbx on turbosquid: 3d models for games, architecture, videos. (1545025)

3d_export

$5

Virus - Variant A

...rus - variant a

3dexport

virus model that can be used in a variety of situations, medical animations, posters, movies and so on!

turbosquid

$50

M1A2 Abrams Variant

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Shelf, Shelves Variants

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Minoan Column (variant A)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Pull

3ddd

$1

Muuto Pull Lamp

...muuto pull lamp

3ddd

muuto , pull lamp

model of pull lamp, designed by muuto

3d_ocean

$24

Pull-down Machine

...n equipement gym gymnastic indoor machine pull pull-down silver sport workout

3d model of black and silver pull-down gym machine.

turbosquid

$19

Pull high

...rbosquid

royalty free 3d model pull high for download as ige on turbosquid: 3d models for games, architecture, videos. (1338664)

turbosquid

$9

Pull Rod

...urbosquid

royalty free 3d model pull rod for download as c4d on turbosquid: 3d models for games, architecture, videos. (1343200)

3ddd

$1

Pull and Bear Sneakers

...pull and bear sneakers

3ddd

обувь , кроссовки

pull and bear sneakers

turbosquid

$38

Pull Station

... free 3d model pull station for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1290796)

turbosquid

$20

Pouf with pulls

...ee 3d model pouf with pulls for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1186069)

turbosquid

$24

Pull Toy

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Pull Saw

... 3d model pull saw for download as ma, max, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1178540)

turbosquid

$1

Pull Switch

...model pull switch for download as max, 3ds, fbx, obj, and dxf on turbosquid: 3d models for games, architecture, videos. (1649377)

Push

3ddd

$1

Pushe

...pushe

3ddd

pushe

pushe

3ddd

$1

Pushe

...pushe

3ddd

pushe

диван pushe

3ddd

$1

PUSHE

...pushe

3ddd

pushe , угловой

размер 320x260 см

3ddd

$1

Pushe / Hilton

...pushe / hilton

3ddd

om , pushe

pushe / hilton

3ddd

$1

Pushe / Enio

...pushe / enio

3ddd

om , pushe

pushe / enio

3ddd

$1

Pushe / Volana

...pushe / volana

3ddd

om , pushe

pushe / volana

3ddd

$1

Pushe / Адорес

...pushe / адорес

3ddd

om , pushe

pushe / адорес

3ddd

$1

Pushe / Kosta

.../ kosta

3ddd

om , pushe , угловой

pushe / kosta

3ddd

$1

Pushe / Narciss

...rciss

3ddd

om , pushe , угловой

pushe / narciss

3ddd

$1

Pushe / Grande

...grande

3ddd

om , pushe , угловой

pushe / grande

Hand

3d_export

$8

hand

...hand

3dexport

fantasy hand

3d_export

$5

hand

...hand

3dexport

male hand

3d_export

$5

hand

...hand

3dexport

realistic male hand

3d_export

$5

hand

...hand

3dexport

hand with nails and structure

archibase_planet

free

Hand

...hand

archibase planet

hand

hand n190111 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Hand

...hand

3ddd

hand

модель руки будды

3d_export

$5

hand

...hand

3dexport

it is my wrist of hand and this is on 3d sculpt

3d_export

$5

hand

...hand

3dexport

realistic male hand obj file

3d_export

$7

hand-006 rigged hand

...hand-006 rigged hand

3dexport

rigged right hand 3d model additional textures for pbr rendering included

3d_ocean

$6

Hand

...

this 3d models of the hands, made in 3ds max, has textures(.jpg), materials(.mat), rigged, the models in .max, fbx, obj format.