Thingiverse

Building Print Bots - Printed Building Concept by MCmaks

by Thingiverse

Last crawled date: 3 years ago

This is just concept modeling, not a "useful" thing.

Printed building concept:

By printing plastic on a large scale, buildings can be constructed with less labor, especially areas that typically require special trades. Specifically, electrical conduits, electrical boxes/gangs, plumbing/piping, and paint-free interior and exterior surfaces could be printed. Other features, including gutters, insulation cavities, stairs/railings, counters, sinks, and door/window (rough) framing could potentially be printed as well. (The labor of painters, plumbers, electricians, etc is significantly reduced). Also, the printed plastic serves as a print-in-place form that can be filled with concrete for strength. Finally, this should enable architectural designs that aren't currently practical/feasible. All the things below are related to this greater printed building concept (concrete bones and plastic skin, veins, nerves, etc).

Printed Building Concept -- Wall Section Models (Not this thing)

https://www.thingiverse.com/thing:2827034

Two STL files (conventional and new style), roughly full scale, not yet printed.

Models the primary features/advantages of the printed building concept.

Plastic as a print-in-place concrete form (concrete skeleton, plastic skin)

Printed (plastic) piping (no in-wall plumping labor)

Printed (plastic) electrical conduit, boxes, and fixtures

Labor-free finished interior and exterior surfaces (no siding, no painting)

Labor-free, printed gutter

Design flexibility

Conventional style (round pipes, schedule xx, compatible with current pipe/conduit/boxes)

New style, print friendly (rectangular pipe/conduit)

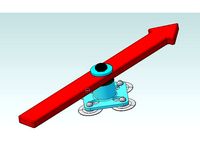

Building Printer Concept Model - Parallel Print Bots (THIS THING)

https://www.thingiverse.com/thing:2852345

A single hot end would most likely be painfully slow, so this approach uses distributed print bots to parallel the printing effort (12 bots animated, 24 hot ends). The bots are essentially scissor lifts with two arms to guide hot ends. (Rough ideas; plastic? maybe PVC. filament or pellets? maybe filament. local accuracy/precision? maybe stereo cameras, machine vision, printed guide marks at lower layers).

Modeled at roughly 1/80 scale. Ver B of STLs have small improvements, but haven't been printed. Part with "top" in the name (upper body) should probably be printed upside down (as oriented in ver B). Also, I only printed one set of arm assy parts and one set of scissor assy parts because they're the same assy twice each. I printed full scale, which then requires M2 x 4mm and M2 x 6mm machine screws. I filed/trimmed as needed and ran a 2mm drill through the thru holes. smaller holes are sized for M2 machine screw to be essentially self-tapping. Probably much easier to build printed 1.5X and assembled with M3 x 6mm and M3 x 9/10mm screws.

https://youtu.be/qp7WvMQVddI

Other Building Printer Concept Models (NOT this thing)

https://www.thingiverse.com/thing:2828296

There's two competing requirements: First, printing plastic in a large volume and second, with enough "resolution" to enable fine features like plumbing and conduit. The things here model two "sketches" -- rough ideas -- for how to accomplish that. Both models use a very large delta (to achieve large volume, easy set-up) combined with a small Cartesian (to achieve fine resolution and high nozzle movement speed). This is very preliminary, just a rough idea, no real details (filament or pellets? probably pellets. Hopper or feed tube? Probably hopper. Material ... maybe PVC? Approach for supports? Lots of options, no clear winner. Time? Probably way too long ,,, maybe better as large nozzle, no details and/or concrete printer).

Printed Building Concept Model (Not this thing)

https://www.thingiverse.com/thing:2828645

Just a house in vertical sections to facilitate a rough simulation.

Thanks to Hans De Ridder and Joerg Schmit for the lowliner model, here: https://grabcad.com/library/mercedes-lowliner-1

Thanks to Saied Kabiri for the concrete mixer model, here: https://grabcad.com/library/concrete-mixer-machine-1

Printed building concept:

By printing plastic on a large scale, buildings can be constructed with less labor, especially areas that typically require special trades. Specifically, electrical conduits, electrical boxes/gangs, plumbing/piping, and paint-free interior and exterior surfaces could be printed. Other features, including gutters, insulation cavities, stairs/railings, counters, sinks, and door/window (rough) framing could potentially be printed as well. (The labor of painters, plumbers, electricians, etc is significantly reduced). Also, the printed plastic serves as a print-in-place form that can be filled with concrete for strength. Finally, this should enable architectural designs that aren't currently practical/feasible. All the things below are related to this greater printed building concept (concrete bones and plastic skin, veins, nerves, etc).

Printed Building Concept -- Wall Section Models (Not this thing)

https://www.thingiverse.com/thing:2827034

Two STL files (conventional and new style), roughly full scale, not yet printed.

Models the primary features/advantages of the printed building concept.

Plastic as a print-in-place concrete form (concrete skeleton, plastic skin)

Printed (plastic) piping (no in-wall plumping labor)

Printed (plastic) electrical conduit, boxes, and fixtures

Labor-free finished interior and exterior surfaces (no siding, no painting)

Labor-free, printed gutter

Design flexibility

Conventional style (round pipes, schedule xx, compatible with current pipe/conduit/boxes)

New style, print friendly (rectangular pipe/conduit)

Building Printer Concept Model - Parallel Print Bots (THIS THING)

https://www.thingiverse.com/thing:2852345

A single hot end would most likely be painfully slow, so this approach uses distributed print bots to parallel the printing effort (12 bots animated, 24 hot ends). The bots are essentially scissor lifts with two arms to guide hot ends. (Rough ideas; plastic? maybe PVC. filament or pellets? maybe filament. local accuracy/precision? maybe stereo cameras, machine vision, printed guide marks at lower layers).

Modeled at roughly 1/80 scale. Ver B of STLs have small improvements, but haven't been printed. Part with "top" in the name (upper body) should probably be printed upside down (as oriented in ver B). Also, I only printed one set of arm assy parts and one set of scissor assy parts because they're the same assy twice each. I printed full scale, which then requires M2 x 4mm and M2 x 6mm machine screws. I filed/trimmed as needed and ran a 2mm drill through the thru holes. smaller holes are sized for M2 machine screw to be essentially self-tapping. Probably much easier to build printed 1.5X and assembled with M3 x 6mm and M3 x 9/10mm screws.

https://youtu.be/qp7WvMQVddI

Other Building Printer Concept Models (NOT this thing)

https://www.thingiverse.com/thing:2828296

There's two competing requirements: First, printing plastic in a large volume and second, with enough "resolution" to enable fine features like plumbing and conduit. The things here model two "sketches" -- rough ideas -- for how to accomplish that. Both models use a very large delta (to achieve large volume, easy set-up) combined with a small Cartesian (to achieve fine resolution and high nozzle movement speed). This is very preliminary, just a rough idea, no real details (filament or pellets? probably pellets. Hopper or feed tube? Probably hopper. Material ... maybe PVC? Approach for supports? Lots of options, no clear winner. Time? Probably way too long ,,, maybe better as large nozzle, no details and/or concrete printer).

Printed Building Concept Model (Not this thing)

https://www.thingiverse.com/thing:2828645

Just a house in vertical sections to facilitate a rough simulation.

Thanks to Hans De Ridder and Joerg Schmit for the lowliner model, here: https://grabcad.com/library/mercedes-lowliner-1

Thanks to Saied Kabiri for the concrete mixer model, here: https://grabcad.com/library/concrete-mixer-machine-1

Similar models

thingiverse

free

Printed Building Concept - Home Model by MCmaks

...100mm. hasn't been printed/tested. maybe useful for dollhouse or similar printed building concept -- wall section models (not this...

thingiverse

free

Building Printer Concept Model by MCmaks

...rcedes-lowliner-1

thanks to saied kabiri for the concrete mixer model, here: https://grabcad.com/library/concrete-mixer-machine-1

thingiverse

free

Printed Building Concept - Wall Section Models by MCmaks

...el (not this thing)

https://www.thingiverse.com/thing:2828645

just a house in vertical sections to facilitate a rough simulation.

thingiverse

free

Conduit Mounting Bracket by triton_9

...ild a crane/claw machine out of nema17s and conduit pipe.

more pieces can be found here:https://www.thingiverse.com/thing:2859618

thingiverse

free

Replacing for "IKEA Samla - Filament enclosure with passages" by EugK

...w.thingiverse.com/thing:1461750

for 32.3mm plastic pipe.

added pipe stand in new design: http://www.thingiverse.com/thing:1799292

thingiverse

free

Conduit Crane Machine NEMA17 Axis Mount by triton_9

...58174

and conduit mounting brackets from this:https://www.thingiverse.com/thing:2862307

will post rest of machine as it is built.

grabcad

free

HOT AIR DRYER "LUXOR HD 600"

...hot air dryer "luxor hd 600"

grabcad

hot air dryer for plastic pellets

thingiverse

free

Cable chain anchor mounts for D-bot by Rexipus

... exact settings will be up to the individual and their printer to decide, but my recommendation is to make them stiff and strong.

thingiverse

free

Dark Nights: Metal - The Murder Machine Emblem by FinePrint3D

...thing:2812599

the dawnbreaker: https://www.thingiverse.com/thing:2805610

the merciless: https://www.thingiverse.com/thing:2813230

thingiverse

free

3/4" EMT Conduit end plug for MPCNC by KB1FCH

...giverse.com/thing:1885144 sized to fit standard us 3/4" emt conduit. made to protect wires running through conduit on mpcnc.

Mcmaks

thingiverse

free

Laptop lady by MCmaks

... pillar supports in slic3r ... be careful with the sun when removing the supports. silhouette filled with white correcting fluid.

thingiverse

free

Remix RepRap Discount case -- For 2020 Mount FLSun i3 by MCmaks

...remix reprap discount case -- for 2020 mount flsun i3 by mcmaks

thingiverse

mounting holes for 2020 plus lcd wire guides.

thingiverse

free

Weighted number blocks -- Slide version by MCmaks

...in/out. nickels (us) can be used to weight blocks proportionally. compatible with scale:https://www.thingiverse.com/thing:2517509

thingiverse

free

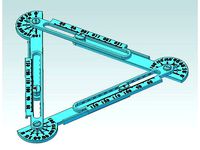

Triangle Properties Learning Aid -- Big version by MCmaks

...mm side lengths.

** i haven't printed this yet -- work in progress.

small version: https://www.thingiverse.com/thing:2519895

thingiverse

free

Closet organizer clips by MCmaks

...ve versions may be easier to print (no support issues), but may need to be painted to have adequate contrast inside dark closets.

thingiverse

free

Whiteboard compass by MCmaks

...arent-hanger-kitchen-bathroom-suction-cup-sucker-20mm/311566424293?sspagename=strk%3amebidx%3ait&_trksid=p2060353.m2749.l2649

thingiverse

free

Whiteboard game spinner by MCmaks

...arent-hanger-kitchen-bathroom-suction-cup-sucker-20mm/311566424293?sspagename=strk%3amebidx%3ait&_trksid=p2060353.m2749.l2649

thingiverse

free

2020 RA Spool Holder with Filtered Filament Guide by MCmaks

...ll piece of foam (10mm x 10mm x 5mm uncompressed) with a hole punched in the middle. filament guide has supports in the stl file.

thingiverse

free

Triangle Properties Learning Aid by MCmaks

...version in the works: https://www.thingiverse.com/thing:2520435

i used no supports or bed adhesion, 0.2mm layer height, i3 clone.

thingiverse

free

Stackable file paper holder organizer - pencil struts by MCmaks

...(1.375" x 1.875"); cut card stock or use small self-stick note. scrap cardboard for the platforms; i used a cereal box.

Bots

turbosquid

$19

Bot

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Bot

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

scanner bot

...scanner bot

3dexport

cool scanner bot who scans for fixing things...

3d_ocean

$9

Apc Bot

...n bot games toys

an all-purpose-constructo-bot. for cartoon purposes. the model is not rigged. please use vray adv for rendering.

3d_export

$75

Bot 3D Model

...bot 3d model

3dexport

robot bot man kiborg character

bot 3d model evgen 19504 3dexport

turbosquid

free

Eye Bot

...eye bot

turbosquid

free 3d model eye bot for download as fbx on turbosquid: 3d models for games, architecture, videos. (1514059)

turbosquid

$29

Gorill-bot

...bosquid

royalty free 3d model gorill-bot for download as fbx on turbosquid: 3d models for games, architecture, videos. (1239456)

turbosquid

$25

Lamp Bot

...bosquid

royalty free 3d model lamp bot for download as blend on turbosquid: 3d models for games, architecture, videos. (1230121)

turbosquid

$10

Spectre Bot

...osquid

royalty free 3d model spectre bot for download as fbx on turbosquid: 3d models for games, architecture, videos. (1616378)

turbosquid

$8

Ultra Bot

...urbosquid

royalty free 3d model ultra bot for download as ma on turbosquid: 3d models for games, architecture, videos. (1330752)

Concept

3d_export

$5

concept house

...concept house

3dexport

concept house blend.

turbosquid

$20

concept

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

concept

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Concept

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Concept

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Bo concept

...bo concept

3ddd

boconcept , декоративный набор

bo concept

3d_ocean

$45

Dreamcar concept

...cept cars from the past.before i became 3d modeler i sketched a lot futuristic cars.when i want it to look more realistic,i st...

3d_ocean

$49

Buggy Concept

... poly massive outdoor robust vehicle

just a model of are own buggy concept vehicle. maybe you can make a beautiful renders of it!

3d_export

free

concept s ii

...concept s ii

3dexport

concept car

3d_export

free

concept s iii

...concept s iii

3dexport

concept car

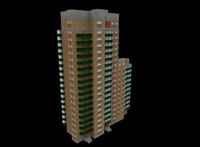

Building

archibase_planet

free

Building

...building high-rise building office building construction

building n050115 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

3d_export

$5

building

...building

3dexport

clasic building

3ddd

$1

building

...building

3ddd

здание

building

archibase_planet

free

Building

...lanet

building office office building construction

building n090914 - 3d model (*.gsm+*.3ds+*.max) for exterior 3d visualization.

archibase_planet

free

Building

...net

building tower construction high-rise building

building n100214 - 3d model (*.gsm+*.3ds+*.max) for exterior 3d visualization.

3d_export

free

Building

...building

3dexport

low poly building;

3d_export

free

Building

...building

3dexport

low poly building;

3d_export

free

Building

...building

3dexport

low poly building;

3d_export

free

Building

...building

3dexport

low poly building;

3d_export

free

Building

...building

3dexport

low poly building;

Printed

design_connected

$27

...print

designconnected

moroso print computer generated 3d model. designed by wanders, marcel.

3ddd

free

Eichholtz Prints

...- eichholtz print central station i

13 - eichholtz print central station ii

14 - eichholtz print marisa

15 - eichholtz print tish

3ddd

$1

Eichholtz Prints

...print abstract - set of 2

10 - eichholtz print orange abstract

11 - eichholtz print buddha right

12 - eichholtz print buddha left

turbosquid

$1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

Eichholtz Prints

...of 4

2 - print dunbar 2 set of 4

3 - print guadeloupe 1 set of 4

4 - print guadeloupe 2 set of 4

5 - print giles

6 - print trett

3ddd

$1

Eichholtz Prints

...nt tutti frutti

3 - eichholtz prints watson - set of 2

4 - eichholtz prints antique nautilus - set of 2

5 - eichholtz print tiara

3d_export

$5

Monster for printing

...monster for printing

3dexport

monster 3d model printing

3ddd

free

printed rug

...printed rug

3ddd

ковер

very creative printed rug

3ddd

free

Eichholtz Prints

...иал: бумага

габариты (вхш): 72 x 62 см

описание: print sweetmeat - постер в деревянной раме.

3 - prints varsity set of 2

арти

3ddd

free

Art Print Posters

...art print posters

3ddd

прованс

art print posters by patrician prints

design_connected

$27

...print

designconnected

moroso print computer generated 3d model. designed by wanders, marcel.

3ddd

free

Eichholtz Prints

...- eichholtz print central station i

13 - eichholtz print central station ii

14 - eichholtz print marisa

15 - eichholtz print tish

3ddd

$1

Eichholtz Prints

...print abstract - set of 2

10 - eichholtz print orange abstract

11 - eichholtz print buddha right

12 - eichholtz print buddha left

turbosquid

$1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

Eichholtz Prints

...of 4

2 - print dunbar 2 set of 4

3 - print guadeloupe 1 set of 4

4 - print guadeloupe 2 set of 4

5 - print giles

6 - print trett

3ddd

$1

Eichholtz Prints

...nt tutti frutti

3 - eichholtz prints watson - set of 2

4 - eichholtz prints antique nautilus - set of 2

5 - eichholtz print tiara

3d_export

$5

Monster for printing

...monster for printing

3dexport

monster 3d model printing

3ddd

free

printed rug

...printed rug

3ddd

ковер

very creative printed rug

3ddd

free

Eichholtz Prints

...иал: бумага

габариты (вхш): 72 x 62 см

описание: print sweetmeat - постер в деревянной раме.

3 - prints varsity set of 2

арти

3ddd

free

Art Print Posters

...art print posters

3ddd

прованс

art print posters by patrician prints