GrabCAD

bottle filler for baguettes vending machine

by GrabCAD

Last crawled date: 1 year, 7 months ago

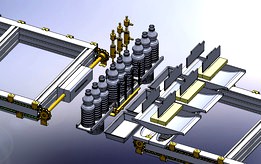

....here we continue with the bottle filler for our machine for dispensing filled baguettes: for reasons of storage space (lack of working memory) in a reduced form and not really everything positioned correctly: so rather unfinished!

we have a bottle filler for filling the drinks bottles with 700 ml drinks - with 3 positions at a distance of 80 mm, with which not only the drinks bottles required here but also other bottles, for example concentrate bottles (concentrated fruit juices) or vinegar bottles, oil bottles - are filled must!

the beverage bottles are made with a bottle former, which forms its own assembly group - also in the food dispenser as required, provided on a small mini conveyor belt that is included in this assembly group here!

that means the bottle filler moves back and forth in the longitudinal direction of the baking section so that the finished bottles can be placed on the mini conveyor belt.

the centerers for the beverage bottles are still missing here, which are supposed to position and hold the new beverage bottles that have been placed on the mini conveyor belt.

the filled beverage bottles - the automatic closing machine, which closes the beverage bottles by means of lid clips, is still missing in the assembly group - are pushed either to the right or left - alternately onto the groups of the bottle turner by means of a motor.

once this has been done, the bottle twister is moved outwards at right angles, i.e. in the shape shown here, because we are producing and finishing the filled baguettes inside the packaging - and rotated 90 degrees in the final position: there the bottles are individually fitted with a vertical conveyor belt into the output chute, which extends over all (!!!) levels of the food distribution machine. that is, the vertical conveyor belt can be clocked and transport the beverage bottles downwards from all baking sections and dispense them!

as far as the theory: the essentials, what I want to have shown - is unfortunately due to limited memory - not completely, not fully shown here - but only important areas of the concept!

for me it's about delimiting the complex structure of the food distribution machines, which are complex here due to the requirements we have created ourselves: so we have planned side slots - and everything is a little cramped.

but since we provide inserts: internal localization of a possible error location and its automated cleaning is easy!

the attached pictures show cutting attempts fo

we have a bottle filler for filling the drinks bottles with 700 ml drinks - with 3 positions at a distance of 80 mm, with which not only the drinks bottles required here but also other bottles, for example concentrate bottles (concentrated fruit juices) or vinegar bottles, oil bottles - are filled must!

the beverage bottles are made with a bottle former, which forms its own assembly group - also in the food dispenser as required, provided on a small mini conveyor belt that is included in this assembly group here!

that means the bottle filler moves back and forth in the longitudinal direction of the baking section so that the finished bottles can be placed on the mini conveyor belt.

the centerers for the beverage bottles are still missing here, which are supposed to position and hold the new beverage bottles that have been placed on the mini conveyor belt.

the filled beverage bottles - the automatic closing machine, which closes the beverage bottles by means of lid clips, is still missing in the assembly group - are pushed either to the right or left - alternately onto the groups of the bottle turner by means of a motor.

once this has been done, the bottle twister is moved outwards at right angles, i.e. in the shape shown here, because we are producing and finishing the filled baguettes inside the packaging - and rotated 90 degrees in the final position: there the bottles are individually fitted with a vertical conveyor belt into the output chute, which extends over all (!!!) levels of the food distribution machine. that is, the vertical conveyor belt can be clocked and transport the beverage bottles downwards from all baking sections and dispense them!

as far as the theory: the essentials, what I want to have shown - is unfortunately due to limited memory - not completely, not fully shown here - but only important areas of the concept!

for me it's about delimiting the complex structure of the food distribution machines, which are complex here due to the requirements we have created ourselves: so we have planned side slots - and everything is a little cramped.

but since we provide inserts: internal localization of a possible error location and its automated cleaning is easy!

the attached pictures show cutting attempts fo

Similar models

grabcad

free

bottle twister

...ed and gratinated rye baguettes - we also need a filling machine at the front and back and a bottle twister each!

step, igs, stl

grabcad

free

mini-conveyor für something sweets

...e outer chocolate rises! that means - we are changing the normal manufacturing procedure - suitable for machines!

step, igs, stl

grabcad

free

magazine for the processing of filled beverage bottles

...l each.

the magazines are intended for vending machines - so are also stored temporarily

assembled into a kind of box.

step, igs

grabcad

free

liquid filling machine

...liquid filling machine

grabcad

fillers (or filling machines) are used for packaging, mainly for food/beverage

grabcad

free

beverage bottle for self-filling

... series of 6 bottles is dispensed in flat magazines - in two filling sequences - ie 12 bottles in a flat magazine area

step, igs

grabcad

free

simple bottle for filling machine

...bcad

... here we have a simple bottle for our bottle and glass filling machine which is currently in work ......

step, igs, stl

grabcad

free

Piston of the filler machine

...

grabcad

this drafting shows the piston of crowner in the filler machine used for capping the bottles after filling with drinks.

grabcad

free

cheese-line for wending machine

... think that i should maybe invite individual lines here in their entirety and not the entire food dispenser.

step, igs, stl, jpg

grabcad

free

separator for tray

...ons.....

especially since a tray separator is not exactly a standard component!

as i said: is only a rough draft

step, igs, stl

grabcad

free

Blow mold for beverage bottle made of preform - soil group

...wered so that the finished molded bottle can be removed.

so also the water heating of the floor part has to be moved.

step, igs

Baguettes

grabcad

free

Baguette

...the shops in europe to grab a couple fresh baguettes will have to work on a baguette storage receptacle....

grabcad

free

baguette

...ho would like to get ready-made items from machines - so they are too lazy to make something themselves! : -) ...

step, igs, stl

grabcad

free

Baguette Ring

...baguette ring

grabcad

design rhino 5.0

and rhinogold 4.0

render v-ray

grabcad

free

Anello Baguette con Ametista

...anello baguette con ametista

grabcad

anello con ametiste

grabcad

free

Tapered Baguette Ring

...uette ring

grabcad

designed with rhinoceros 5.0 and rhinogold 5.5.

render with v-ray.

animation with rhinogod studio animation.

grabcad

free

baguette vending machine

...so detailed.... so here we go - other ready-made baguettes some conceptual details of the form and the like.........

grabcad

free

packaging for fresh filled baguette rolls

...y come from the continuous convection oven, steam oven.

stuffed with sliced ham, slices of sausage, onions, bacon ....

step, igs

grabcad

free

baking dish made of silicone for baguettes

...y/silicone-form-2-1

and other project-parts, which are set at a later date here, as

steam garer, food processor and some more ..

grabcad

free

fresh baguette for vending machine

...matic production is feasible. the pictures show manually generated - a bit primitive - generated, but quite good!

step, igs, stl

Vending

grabcad

free

Vending Trolly

...vending trolly

grabcad

vending trolley for informal vending solutions.

grabcad

free

Vending Stapler

...vending stapler

grabcad

vending stapler

grabcad

free

Vending Machine

...vending machine

grabcad

vending machine

grabcad

free

Vend Cover

...vend cover

grabcad

vend cover

grabcad

free

Vending machine

...vending machine

grabcad

vending machine design

grabcad

free

vending machine

...vending machine

grabcad

necta vending machine

grabcad

free

vending

...vending

grabcad

vid

con

grabcad

free

vending

...vending

grabcad

machine

gene

grabcad

free

Vending Machine

...vending machine

grabcad

rancang bangun vending machine

grabcad

free

Vending machine

...vending machine

grabcad

vending machine version 0.1

Filler

grabcad

free

filler

...filler

grabcad

filler

grabcad

free

Filler

...filler

grabcad

angled filler

grabcad

free

FILLER

...filler

grabcad

filler for water

grabcad

free

Filler

...filler

grabcad

hi

grabcad

free

filler

...filler

grabcad

enjoy

grabcad

free

fuel filler

...fuel filler

grabcad

fuel filler

grabcad

free

pheu filler

...pheu filler

grabcad

pheu filler

grabcad

free

Filler Bin

...filler bin

grabcad

filler bin

grabcad

free

pheu filler

...pheu filler

grabcad

pheu filler

grabcad

free

pheu filler

...pheu filler

grabcad

pheu filler

Bottle

grabcad

free

bottles

...bottles

grabcad

servo bottle, coke bottle

grabcad

free

Reagent bottle - bottle

...reagent bottle - bottle

grabcad

a little reagent bottle. 15ml

grabcad

free

bottle

...bottle

grabcad

nestle(water bottle) and oil bottle

grabcad

free

Bottle

...bottle

grabcad

bottle

it is my second bottle in creo7.0

grabcad

free

Bottle and bottle holder

...design. so i had to make bottle with given specifications. additionally i created two bottle caps with different design concepts.

grabcad

free

Bottle and bottle cap

...bottle and bottle cap

grabcad

these are solidworks surface modeling of bottle, bottlecap and their assembly.

grabcad

free

Bottle

...bottle

grabcad

shampoo / detergent bottle.

a turntable video of the shampoo bottle:

grabcad

free

BOTTLE

...bottle

grabcad

bottle

grabcad

free

Bottle

...bottle

grabcad

bottle

grabcad

free

bottle

...bottle

grabcad

bottle

Machine

grabcad

free

Machine

...machine

grabcad

machine

grabcad

free

machine

...machine

grabcad

machine

grabcad

free

MACHINE

...machine

grabcad

machine

grabcad

free

Machine

...machine

grabcad

machine

grabcad

free

machines

...machines

grabcad

machines

grabcad

free

machine

...machine

grabcad

machine

grabcad

free

Machine

...machine

grabcad

machine

grabcad

free

Machine

...machine

grabcad

machine

grabcad

free

A Machine

...a machine

grabcad

this is a machine

grabcad

free

MACHINE

...machine

grabcad

machine