Thingiverse

BONDTECH Extruder Filament Guide by EE_Maker

by Thingiverse

Last crawled date: 3 years, 1 month ago

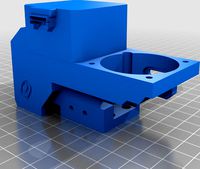

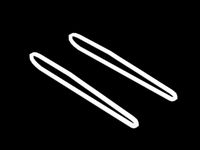

When I updated my BONDTECH BMG extruder to a DIRECT DRIVE setup, I found that I needed to develop a way to deliver the filament into the top of the extruder. I finally decided to use about 1 1/2 feet of thin wall (4MM OD, 3MM ID) poly tube similar to a BOWDEN setup. I mounted the input side of the filament feed-tube to the printer frame just above the spool holder, and then slipped the feed tube into the top of the BMG extruder using it's normal 4mm bowden tube coupler. While this got me started, I soon found two small issues.

Since the ID of the thin-wall tubing is large (3 mm), the 1.75mm diameter filament easily slips through the tubing and on into the DIRECT DRIVE extruder. This is good! However, unlike its thick-wall Bowden tube counterpart, the thin-wall tubing (4mm OD, 3MM ID) is less rigid and therefore more prone to kinks and bends near the top of the BMG input port fitting as the carriage moves about. These kinks can pinch the filament and cause findup which can interfere with proper filament feeding.

Also, every time a filament change is needed, the feed tube must be removed from the BMG extruder entry port fitting. Since these tube fittings are not really designed to handle lots of in-out operations, over time, they can wear out and jam up. This is not usually a problem for BOWDEN setups (as the BOWDEN tube is not removed during a filament change) but becomes is a problem for DIRECT DRIVE setups.

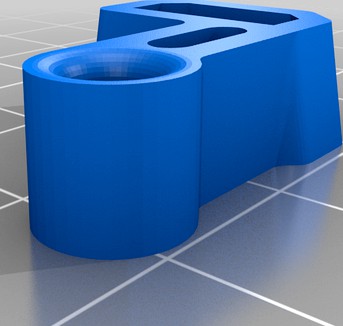

To solve these issues, I designed this Filament-Guide-Support part that slips on (and off) of the BMG filament tension release arm to provide support to the poly filament feed tube. With a simple friction fit over the tension release arm, It holds and positions the guide-tube perfectly above the extruder entry spot. Pot fitting wear is eliminated as the thin wall tubing does not actually have to enter into the extruder tube-fitting at all. Further more, when a filament change is needed, the Guide-Support and poly-guide-tubing "combination" simply slips up and off of the extruder tension arm providing easy access to the filament itself.

This is a simple part to print. If you use a similar setup for your BMG DIRECT DRIVE EXTRUDER, this little guy might just help you out as well! Take care and stay safe!

Since the ID of the thin-wall tubing is large (3 mm), the 1.75mm diameter filament easily slips through the tubing and on into the DIRECT DRIVE extruder. This is good! However, unlike its thick-wall Bowden tube counterpart, the thin-wall tubing (4mm OD, 3MM ID) is less rigid and therefore more prone to kinks and bends near the top of the BMG input port fitting as the carriage moves about. These kinks can pinch the filament and cause findup which can interfere with proper filament feeding.

Also, every time a filament change is needed, the feed tube must be removed from the BMG extruder entry port fitting. Since these tube fittings are not really designed to handle lots of in-out operations, over time, they can wear out and jam up. This is not usually a problem for BOWDEN setups (as the BOWDEN tube is not removed during a filament change) but becomes is a problem for DIRECT DRIVE setups.

To solve these issues, I designed this Filament-Guide-Support part that slips on (and off) of the BMG filament tension release arm to provide support to the poly filament feed tube. With a simple friction fit over the tension release arm, It holds and positions the guide-tube perfectly above the extruder entry spot. Pot fitting wear is eliminated as the thin wall tubing does not actually have to enter into the extruder tube-fitting at all. Further more, when a filament change is needed, the Guide-Support and poly-guide-tubing "combination" simply slips up and off of the extruder tension arm providing easy access to the filament itself.

This is a simple part to print. If you use a similar setup for your BMG DIRECT DRIVE EXTRUDER, this little guy might just help you out as well! Take care and stay safe!

Similar models

thingiverse

free

Idler Arm with Bowden Input by elmerohueso

...removed the wording on top of the arm, and filled in where the the nut is so the u bearing can be screwed directly in to the arm.

thingiverse

free

Creality Ender 3 (Pro) Extruder plate for Bondtech Push-Fit Adapter by Alphaelectric

...ive / push-fit adapter. you can get them anywhere on the net. simply put it in and lock the amount of desired ptfe tube in place.

thingiverse

free

Push-fit adaptor, for Bondtech BMG extruder with 6mm PTFE feed

...an easy push-fit interfaces nicely with polymaker polybox (& similar dry-filament cabinets, via 6mm ptfe 3d-modelled, as a parameteric...

thingiverse

free

Prusa MK3s/+ Bowden Tube Guides by eb3095

...is intended for people who want to end the tube there and feed the filament to a direct drive.

i printed with priline tpu 1.75mm.

grabcad

free

3D Printable Direct Drive Extruder Throat Tube Funnel

...is funnel on my mk8 direct drive extruder, and now filament loading is quite easy with no disassembly required. printed with abs.

thingiverse

free

Tiny Flex Extruder Bowden Variant by tkramm

...r-pulley-drive-gear.html

nema 17 motor

624 bearing

2x m3x12

1x m3x25

1x m4x10

4x m3 hex nut

4x m3x16

1x spring 7mm od 30mm length

thingiverse

free

Ender 5 direct drive extruder cover, cable, and filament guide by MyTechGuyRI

...ice cable management for the hot end wires and i use a bowden tube to run the filament into the extruder. remixed on tinkercad.

thingiverse

free

Ender 6 Filament Guide for Direct Drive by artheoday

...rse

ender 6 filament guide which replaces the extruder motor for direct drive system. this uses bowden tube guide to the hotend.

thingiverse

free

Compact Bowden Extruder, direct drive 1.75mm (Flexible Filament inlay) 4mm Tube, M5 pushfit by sobo84

...ment. works great for me.

maybe you have to cut it a little bit.

idler:

i glued anwasher with epoxid on it. it is just perfect!

thingiverse

free

Bowden tube - MDD Creality Upgraded Extruder Spacer by Batmang

...nto the extruder and not pulling off to the side.

i printed pla with support, 0.2mm layer, 4 wall, 20% infill. it is very strong.

Bondtech

thingiverse

free

x5s bondtech

...x5s bondtech

thingiverse

this allow using a bondtech dual drive on x5s machines

thingiverse

free

Bondtech mount by Nicoande99

...bondtech mount by nicoande99

thingiverse

custom bondtech mount for my velleman k8200 3d printer.

thingiverse

free

Trex2+ Bondtech adpter by fong504

...trex2+ bondtech adpter by fong504

thingiverse

bondtech makerbot 2 clone adapter for the trex2+.

thingiverse

free

Bondtech PTFE tube Holder

...bondtech ptfe tube holder

thingiverse

adjusted a bit to fit my bondtech clone.

thingiverse

free

Bondtech DDX by sebbzor

...of the ddx incase you want to build adapters for it. original stepfile can be found on bondtechs website, all credits go to them.

thingiverse

free

Support BONDTECH Anet_A8 By SergioFPV by SergioFPV

...support bondtech anet_a8 by sergiofpv by sergiofpv

thingiverse

support bondtech anet_a8

thingiverse

free

CR-10S-Bondtech-Mosquito_Mount_Bl_Touch by enoblk

...cr-10s-bondtech-mosquito_mount_bl_touch by enoblk

thingiverse

cr-10s-bondtech-mosquitomount-_bl_touch

thingiverse

free

Bondtech Flying mount by Yakandu

...du

thingiverse

lightweight flying extruder mount for the bondtech bmg with design centred around filament path.

this is a remix.

thingiverse

free

Bondtech Oiler by bamhm182

...t a piece of sponge and put it in the hole. oil it up and you're good to go! been using it for a few months with no problems.

thingiverse

free

RatRig V-Core Pro Bondtech Carriage (Prusa MK3S Bondtech Extruder)

...dtech can be mounted 1:1 :)

i have the mk3s with bondtech and mosquito magnum. i'll try out if my ratrig arrives...

have fun!

Ee

turbosquid

$30

Ladies Fashion ee.3dm

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$90

EE-T1 Osorio P2 Photogrammetry

...uid

royalty free 3d model ee-t2 osorio for download as blend on turbosquid: 3d models for games, architecture, videos. (1696957)

turbosquid

$149

EE-9 Cascavel ver 2

...d model ee-9 cascavel ver 2 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1476505)

turbosquid

$145

EE City Construction Kit. Highrise5

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$145

EE City Construction Kit. Highrise4

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$145

EE City Construction Kit. Highrise2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$145

EE City Construction Kit. Highrise1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Ladies Fashion Band ee.3dm

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Maxim lighting Basix EE 5-Light

...ing

люстра марки maxim lighting, коллекция basix ee 5-light

артикул: 85125icsn

в архиве модель в формате:

-3ds max 2012

-fbx

turbosquid

$10

Star trek symbol CHAH mooz ee

...mbol chah mooz ee for download as max, dwg, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1586918)

Guide

turbosquid

$15

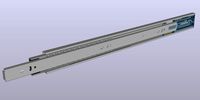

Guide drawer

...squid

royalty free 3d model guide drawer for download as dwg on turbosquid: 3d models for games, architecture, videos. (1261387)

turbosquid

$1

Road Guide

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

archive3d

free

Guide-board 3D Model

...ion sign guide sign

guide-board n170112 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

turbosquid

$2

soap cutter guide

...

royalty free 3d model soap cutter guide for download as stl on turbosquid: 3d models for games, architecture, videos. (1694030)

turbosquid

$15

Blind Guiding tiles

...free 3d model blind guiding tiles for download as 3dm and dae on turbosquid: 3d models for games, architecture, videos. (1156598)

turbosquid

$69

Japanese Tour Guide

...d model japanese tour guide for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1614288)

turbosquid

$10

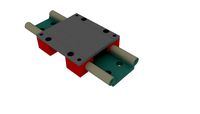

CNC Linear Guide

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Tank Model Guide

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Road Guide 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$9

Guide Books 3

...sformed separately and each have unique texture map on front and back cover. to make your work easier this model comes in thre...

Extruder

3ddd

$1

Extruded Chair

...extruded chair

3ddd

extruded , tom dixon

inspired by tom dixon extruded chair

turbosquid

$15

Extruded Table

... extruded table for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1634137)

turbosquid

$2

3D Printer Extruder

...d

royalty free 3d model 3d printer extruder for download as on turbosquid: 3d models for games, architecture, videos. (1537359)

turbosquid

$1

Zombie extruded text

...oyalty free 3d model zombie extruded text for download as obj on turbosquid: 3d models for games, architecture, videos. (1322198)

turbosquid

$4

Extruder conical screw

...el extruder conical screw for download as sldpr, ige, and stl on turbosquid: 3d models for games, architecture, videos. (1524433)

turbosquid

$50

3d PRINTER - Extruder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Extruded Table 2

...xtruded table 2 for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1621846)

turbosquid

$10

Maya Extrude Tool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

world earth extrude map

...world earth extrude map

3dexport

3ddd

$1

Simply Elegant Extruded Tree Coffee Table Design

...ble by link studios. the silhouette of a tree is visible at one angle, extruded from the surface to create the support structure.

Filament

3ddd

$1

Filament Cage

...filament cage

3ddd

лофт , filament cage

модель бра, делалась по фото!

turbosquid

$3

FILAMENT COUNTER

...d

royalty free 3d model filament counter for download as stl on turbosquid: 3d models for games, architecture, videos. (1563049)

3d_export

$5

Filament lamp 3D Model

...filament lamp 3d model

3dexport

filament lamp 3d model kevin 54161 3dexport

3d_export

$5

Filament bulb candle 3D Model

...filament bulb candle 3d model

3dexport

filament bulb-candle

filament bulb candle 3d model kevin 54163 3dexport

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3ddd

$1

Factory filament metal shade

...factory filament metal shade

3ddd

restoration hardware

restoration hardware. 20th c. factory filament metal shade.

Maker

3d_ocean

$17

Coffee Maker

...coffee maker

3docean

breakfast coffee drip electric maker morning

detailed coffee maker and a plug.

3ddd

$1

coffee maker

...coffee maker

3ddd

кофемашина

coffee maker

3d_export

$10

chapati maker

...chapati maker

3dexport

it is a indian traditional chapati maker

archibase_planet

free

Coffee maker

...aker

archibase planet

percolator coffee-machine coffee maker

coffee maker - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Coffee maker

...aker

archibase planet

percolator coffee-machine coffee maker

coffee maker - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Coffee maker

...aker

archibase planet

percolator coffee-machine coffee maker

coffee maker - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Сoffee maker

...er

archibase planet

coffee maker percolator coffee-machine

сoffee maker n020112 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Coffee maker

...aker

archibase planet

coffee maker percolator coffee-machine

coffee maker - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Juice Maker

...juice maker

3ddd

соковыжималка

fully detailed kenwood juice maker

archibase_planet

free

Coffee maker

...hibase planet

coffee maker percolator coffee-machine

coffee maker n140611 - 3d model (*.gsm+*.3ds) for interior 3d visualization.