Thingiverse

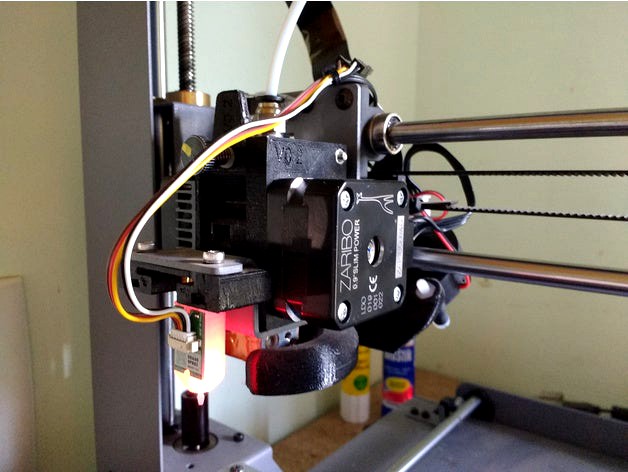

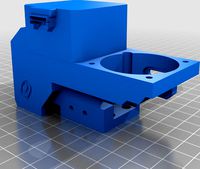

Bondtech BMG for the Cocoon Create Touch by dkselw

by Thingiverse

Last crawled date: 4 years, 1 month ago

Geared Bondtech extruder for the Cocoon Create Touch/ Wanhao I3 Plus.

This extruder uses the existing heatbreak, in my case the Micro Swiss all metal heatbreak. I wanted to try the geared Bondtech drive, but did not want to have to purchase another heatbreak, as I had already installed the Micro Swiss all metal heatbreak.

I used this https://www.thingiverse.com/thing:2669164 for the model of the existing printer.

The Bondtech dimensions and clearances were measured using models from here https://github.com/BondtechAB/Bondtech_Prusa_i3/tree/master/CAD-Files

Hardware

I used the gears and bearings from inside a Bondtech BMG extruder.

Zaribo Pancake Extruder Motor https://zaribo.com/electronics/126-zaribo-pancake-motor-by-ldo.html . I believe this is the same as the LDO-42STH25-1404MAC . The Stepperonline 17HS10-0704S should also work and is recommended for other geared extruders, such as the "Bunny and Bear Geared MK3 Extruder".

3mm thick aluminium spacer for the heatsink. Trace around the side of the heatbreak cooling block for dimensions.

PC4-M10 Straight Pneumatic Fitting (supposed to have a M10 thread, but mine ended up being 1/8 NPT).

4mm OD Capricorn Bowden PTFE Tubing for between the heatbreak and just below the drive gears.

4mm OD PTFE for the reverse bowden tubing.

1 x PEM IUBB-M3-1 heat-set insert. I used the Lulzbot Heat-Set Insert Tapered, M3-0.5mm Internal Thread, 3.8mm L. A longer heat-set insert would be better.

The filament path in the model is 1.75mm diameter. This will need to be drilled out to 2mm after printing.

I ended up having to use a reamer to get the bearings to fit nicely as my printer was printing the holes too small.

Use a 4mm drill to clean out the holes for the PTFE tubing.

Use a 4.2mm drill to clean the hole before inserting the heat-set insert.

Depending on how well your existing printer is calibrated, you may need to drill out other holes to size as required.

I did not have screws long enough to go all the way through the fan, extruder and spacer to the motor, so I used the existing screws to attach the heatsink to the spacer, extruder and the motor. The fan was then attached to the heatsink with short 3mm screws.

If you use the hinge pivot shaft from the Bondtech extruder, you will need to shorten it so that it does not protude past the outside face of the case. I used a piece of 3mm shaft from an old CDROM drive.

The white Bondtech gear protrudes out the back of the extruder. Check the clearance between the gear and the x-axis bearing screws. You may need to slide the heatbreak towards the front along the sheet metal bracket and/or shorten the x-axis screw. Mine had just over 1mm clearance without moving anything.

If you use the specified pancake stepper, you will loose about 5mm of the X travel. If you use the existing stepper, a bit more.

I printed the parts using the amf files, not the stl files.

Slicer settings:

0.2mm layer height

20% Gyroid infill

10 layers top and bottom

5 perimeters

This extruder uses the existing heatbreak, in my case the Micro Swiss all metal heatbreak. I wanted to try the geared Bondtech drive, but did not want to have to purchase another heatbreak, as I had already installed the Micro Swiss all metal heatbreak.

I used this https://www.thingiverse.com/thing:2669164 for the model of the existing printer.

The Bondtech dimensions and clearances were measured using models from here https://github.com/BondtechAB/Bondtech_Prusa_i3/tree/master/CAD-Files

Hardware

I used the gears and bearings from inside a Bondtech BMG extruder.

Zaribo Pancake Extruder Motor https://zaribo.com/electronics/126-zaribo-pancake-motor-by-ldo.html . I believe this is the same as the LDO-42STH25-1404MAC . The Stepperonline 17HS10-0704S should also work and is recommended for other geared extruders, such as the "Bunny and Bear Geared MK3 Extruder".

3mm thick aluminium spacer for the heatsink. Trace around the side of the heatbreak cooling block for dimensions.

PC4-M10 Straight Pneumatic Fitting (supposed to have a M10 thread, but mine ended up being 1/8 NPT).

4mm OD Capricorn Bowden PTFE Tubing for between the heatbreak and just below the drive gears.

4mm OD PTFE for the reverse bowden tubing.

1 x PEM IUBB-M3-1 heat-set insert. I used the Lulzbot Heat-Set Insert Tapered, M3-0.5mm Internal Thread, 3.8mm L. A longer heat-set insert would be better.

The filament path in the model is 1.75mm diameter. This will need to be drilled out to 2mm after printing.

I ended up having to use a reamer to get the bearings to fit nicely as my printer was printing the holes too small.

Use a 4mm drill to clean out the holes for the PTFE tubing.

Use a 4.2mm drill to clean the hole before inserting the heat-set insert.

Depending on how well your existing printer is calibrated, you may need to drill out other holes to size as required.

I did not have screws long enough to go all the way through the fan, extruder and spacer to the motor, so I used the existing screws to attach the heatsink to the spacer, extruder and the motor. The fan was then attached to the heatsink with short 3mm screws.

If you use the hinge pivot shaft from the Bondtech extruder, you will need to shorten it so that it does not protude past the outside face of the case. I used a piece of 3mm shaft from an old CDROM drive.

The white Bondtech gear protrudes out the back of the extruder. Check the clearance between the gear and the x-axis bearing screws. You may need to slide the heatbreak towards the front along the sheet metal bracket and/or shorten the x-axis screw. Mine had just over 1mm clearance without moving anything.

If you use the specified pancake stepper, you will loose about 5mm of the X travel. If you use the existing stepper, a bit more.

I printed the parts using the amf files, not the stl files.

Slicer settings:

0.2mm layer height

20% Gyroid infill

10 layers top and bottom

5 perimeters

Similar models

thingiverse

free

Sapphire Plus direct extruder mount and other mods by pit21

...e ptfe coupling holder is modified of pc4-m10 ptfe coupler 2020 mount by modestandroid https://www.thingiverse.com/thing:3703529

thingiverse

free

1Pc. Flexion Extruder Adapter for the Robo R1 and the Robo R1+ by oldfarmhand

...g socket head screws

2 3mm 05 20mm long flat socket head screws

if you use the adapter with fan bracket you will need a 40 mm fan

thingiverse

free

Extruder Motor Spacer for 3DFused Direct Drive mount by Critterninja

...ere, just a 3mm thick spacer, set to the same shape of the standard 42x42mm motor and a hole in the middle to fit over the shaft.

thingiverse

free

reverse bowden for Prusa MK3, Bear Upgrade and Zaribo on IKEA Lack enclosure by uepsie

...n be found here:https://github.com/gregsaun/bear_extruder_and_x_axis/tree/master/optional_parts/reverse_bowden

happy printing :-)

thingiverse

free

One Piece Simple Direct Drive Extruder by Tobeca

...geared extruder) and a 608zz bearing (+ screw and nut).

no springs, you have to adjust the pressure at the mounting of the motor.

thingiverse

free

think&have torque extruder by thinkandhave

... a flat screwdriver and a quick clamp. the gear has to run smooth and the filament has to pass through the center of the hobbing.

thingiverse

free

Tevo Black Widow extruder spacer by tuxcat

...d line up with the holes in the extruder. moving the extruder here gives the added benefit of another 18mm~ of printable height!

thingiverse

free

BMG Direct Drive Adapter for Ender 3 V2 with Hero Me Gen5 by scaryPug

... endstop.

you also might need to cut the original hero me cable management tube to install this.

.step file added for easy tweak.

grabcad

free

Motor Spacer for SCUTTLE 12v DC motor

...

if you add this spacer, you must verify your m3x10mm screws are still long enough to engage the motor threads at least by 3mm.

thingiverse

free

Dual Drive Gear Ninjaflex extruder hole drilling template by OrdSolutions

...a/etc...)

http://www.ordsolutions.com/ninjaflex-extruder/https://www.facebook.com/ordsolutionsinchttps://twitter.com/ordsolutions

Bondtech

thingiverse

free

x5s bondtech

...x5s bondtech

thingiverse

this allow using a bondtech dual drive on x5s machines

thingiverse

free

Bondtech mount by Nicoande99

...bondtech mount by nicoande99

thingiverse

custom bondtech mount for my velleman k8200 3d printer.

thingiverse

free

Trex2+ Bondtech adpter by fong504

...trex2+ bondtech adpter by fong504

thingiverse

bondtech makerbot 2 clone adapter for the trex2+.

thingiverse

free

Bondtech PTFE tube Holder

...bondtech ptfe tube holder

thingiverse

adjusted a bit to fit my bondtech clone.

thingiverse

free

Bondtech DDX by sebbzor

...of the ddx incase you want to build adapters for it. original stepfile can be found on bondtechs website, all credits go to them.

thingiverse

free

Support BONDTECH Anet_A8 By SergioFPV by SergioFPV

...support bondtech anet_a8 by sergiofpv by sergiofpv

thingiverse

support bondtech anet_a8

thingiverse

free

CR-10S-Bondtech-Mosquito_Mount_Bl_Touch by enoblk

...cr-10s-bondtech-mosquito_mount_bl_touch by enoblk

thingiverse

cr-10s-bondtech-mosquitomount-_bl_touch

thingiverse

free

Bondtech Flying mount by Yakandu

...du

thingiverse

lightweight flying extruder mount for the bondtech bmg with design centred around filament path.

this is a remix.

thingiverse

free

Bondtech Oiler by bamhm182

...t a piece of sponge and put it in the hole. oil it up and you're good to go! been using it for a few months with no problems.

thingiverse

free

RatRig V-Core Pro Bondtech Carriage (Prusa MK3S Bondtech Extruder)

...dtech can be mounted 1:1 :)

i have the mk3s with bondtech and mosquito magnum. i'll try out if my ratrig arrives...

have fun!

Cocoon

turbosquid

$29

cocoon

...y free 3d model cocoon for download as c4d, obj, fbx, and 3ds on turbosquid: 3d models for games, architecture, videos. (1559035)

3ddd

$1

Cocoon

...cocoon

3ddd

roche bobois

1600x1600

3ddd

$1

Heal Cocoon Chair

...heal cocoon chair

3ddd

heal , cocoon

heal cocoon chair

3d_export

$6

COCOON - PURIST BATH

...cocoon - purist bath

3dexport

inspired by cocoon -

3d_export

$6

COCOON - ZEN BATH

...- zen bath

3dexport

bathtub from cocoon ( bycocoon ) with cocoon jp collection faucets. manufacturer : preview renders - corona

archive3d

free

Cocoon 3D Model

...hive3d

cocoon seat canopy

cocoon canopy - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

MacMaster Cocoon Pendant Light

...macmaster cocoon pendant light

3ddd

macmaster , cocoon

подвесная люстра от серии cocoon

turbosquid

$14

Cocoon armchair

...ee 3d model cocoon armchair for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1396538)

3ddd

$1

Eglo / Cocoon Pinneti 91903

...03

3ddd

eglo

eglo cocoon pinneti 91903http://www.eglo.com/international/produkte/interior-lighting/cocoon/pinneti/91903

3ddd

$1

Cocoon Couture

...cocoon couture

3ddd

вешалка

https://www.cocooncouture.com/room_accessories.php

Bmg

turbosquid

$3

.50 BMG

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

.50 BMG

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

50 BMG Cartridge

...e 3d model 50 bmg cartridge for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1303035)

turbosquid

$30

Sniper 50 bmg

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Cal 50 BMG

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

cg_studio

$25

.50 BMG Cartridge3d model

...odel

cgstudio

.3ds .max .obj .wrl - .50 bmg cartridge 3d model, royalty free license available, instant download after purchase.

3d_export

$5

50 caliber BMG round 3D Model

...d 3d model

3dexport

50cal caliber 50 round bullet bmg cartridge browning rifle

50 caliber bmg round 3d model csw92 27660 3dexport

3d_export

$22

.50 BMG Cartridge 3D Model

...ectile rifle round pistol cartridge m2 hb 127x99mm nato browning barrett m82a1

.50 bmg cartridge 3d model plutonius 8091 3dexport

turbosquid

free

LAR Grizzly .50 BMG Sniper

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$8

cartrige m50 bmg

...aterials are logically named<br>the main format is in 3ds max 2009.<br>satisfcation garranteed..<br>thank you !

Touch

3ddd

$1

Touch

...touch

3ddd

touch , альфа банк

электронный терминал для очереди

3ddd

$1

GSG / Touch

... ванна

http://www.ceramicagsg.com/sanitaryware-touch/bathtub-touch-free-standing.html

turbosquid

$10

Oculus Touch

...squid

royalty free 3d model oculus touch for download as skp on turbosquid: 3d models for games, architecture, videos. (1462433)

turbosquid

$64

iPod Touch

...ty free 3d model ipod touch for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1299603)

3ddd

$1

iPod Touch 5

...ipod touch 5

3ddd

apple , плеер

модель ipod touch 5

3ddd

$1

Asnaghi "Touch"

...asnaghi "touch"

3ddd

asnaghi , touch

фабрика: asnaghi

модель: touch

3ddd

free

Japanese stone touch

...japanese stone touch

3ddd

фонарь

japanese stone garden touch

японский садовый фонарь

икеокоми-гата

3d_ocean

$15

IPOD TOUCH 5

...apple blender ipad iphone ipod mp3 nano player touch

3d model of ipod touch 5 in 3 colours. available in .3ds, .blend, .obj, .x3d

3d_ocean

$12

iPod touch 5G

...pod jobs nano steve touch

ipod touch 3d model. formats, fbx, obj, max(2010) textures and materials with multiple colors included.

3ddd

$1

HTC Touch HD

...http://www.gsmarena.com/htc_touch_hd-2525.php фото:http://i.smartphone.ua/img/phones/htc-touch-hd/foto_001.jpg

Create

turbosquid

free

creates

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

creat

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Диван Create Classics

...диван create classics

3ddd

диван create classics

3d_export

$5

Blank for creating a robot

...blank for creating a robot

3dexport

a blank for creating a female robot, or an anthropomorphic creature.

turbosquid

$38

Create a snow scene

...royalty free 3d model create a snow scene for download as fbx on turbosquid: 3d models for games, architecture, videos. (1493726)

turbosquid

$30

Create a tropical scene

...lty free 3d model create a tropical scene for download as fbx on turbosquid: 3d models for games, architecture, videos. (1493052)

turbosquid

$10

Ammo Create Set

...lty free 3d model ammo create set for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1349983)

turbosquid

$4

Hand Painted Create

...free 3d model hand painted create for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1304173)

turbosquid

$15

Sculptural Twists And Turns Create

... model sculptural twists and turns create for download as max on turbosquid: 3d models for games, architecture, videos. (1449864)

turbosquid

$30

Wacom Bamboo Create Tablet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.