GrabCAD

bike chrome brasse

by GrabCAD

Last crawled date: 2 years ago

Ah steel, the no fuss workhorse of bike frame materials. Steel was the universal choice of racing bike frames until aluminium appeared in the 1970's and 1980's and carbon fibre took over in the 1990's.

There are two distinct types of steel used in the bicycle industry. The first is high tensile, or otherwise known as 'Hi-Ten', this is a cheaper grade steel commonly found in cheaper bikes, especially those from department stores. It offers an incredibility poor strength-weight ratio and so manufacturers will typically use this material in order to hit low price points. By comparison, higher-end steel bikes are likely to use chromoly, or CroMo for short (generally short for chrome molybdenum) steel, which as an alloyed steel offers superior strength properties to Hi-Ten and so can be butted and made thinner/lighter.

Steel is inexpensive, exceptionally durable, highly resistant to fatigue, easily repaired and easy to work with. Unlike carbon fibre and aluminium, damage to a steel frame is typically easily repaired. Somewhat surprisingly despite its strength, steel offers good levels of compliance thanks to its elastic properties. The downside of steel is that it is prone to oxidisation (rust) and carries a weight penalty over other materials.

Touring and adventure bikes are commonly made from steel thanks to the exceptional durability and strength on offer. This enables riders to carry large amounts of luggage without compromising the bikes performance. Steel also features heavily on entry level and recreational bikes where weight isn't such an important factor.

Pros of steel: Cost and ease to manufacture, strength, durability.

Cons of steel: Weight, corrosion resistance.

There are two distinct types of steel used in the bicycle industry. The first is high tensile, or otherwise known as 'Hi-Ten', this is a cheaper grade steel commonly found in cheaper bikes, especially those from department stores. It offers an incredibility poor strength-weight ratio and so manufacturers will typically use this material in order to hit low price points. By comparison, higher-end steel bikes are likely to use chromoly, or CroMo for short (generally short for chrome molybdenum) steel, which as an alloyed steel offers superior strength properties to Hi-Ten and so can be butted and made thinner/lighter.

Steel is inexpensive, exceptionally durable, highly resistant to fatigue, easily repaired and easy to work with. Unlike carbon fibre and aluminium, damage to a steel frame is typically easily repaired. Somewhat surprisingly despite its strength, steel offers good levels of compliance thanks to its elastic properties. The downside of steel is that it is prone to oxidisation (rust) and carries a weight penalty over other materials.

Touring and adventure bikes are commonly made from steel thanks to the exceptional durability and strength on offer. This enables riders to carry large amounts of luggage without compromising the bikes performance. Steel also features heavily on entry level and recreational bikes where weight isn't such an important factor.

Pros of steel: Cost and ease to manufacture, strength, durability.

Cons of steel: Weight, corrosion resistance.

Similar models

grabcad

free

Carbon frame bicycle

...carbon frame bicycle

grabcad

created a carbon fibre frame cycle for a german manufacturer

3dwarehouse

free

bike frame

...bike frame

3dwarehouse

bike frame #bike #carbon #cool #design #fast #fiber #fibre #fork #frame #mold #post #seat #tube #wheel

grabcad

free

Steel Ball

...arious sports, such as in ball bearings for skateboards, as cue balls in billiards, and as projectiles in some types of air guns.

3dwarehouse

free

Cadre en Fibre de carbone/Aluminium

...icker de yamaha. celui-ci est conçu pour un moteur électrique. #air_tricker #bike #bike_frame #cadre #frame #moto #mtb #vtt #vélo

grabcad

free

carbon fibre seatmast

...mast

grabcad

a seatmast matching my

https://grabcad.com/library/custom-carbon-road-bike-frame-1

more to come.. ..stay tuned ;)

3dwarehouse

free

Diagram of the new Hyperion

...rear lettering, reading 'hyperion' is not metal-plated. it is pure carbon fibre because i think it looks cooler that way.

grabcad

free

Warehouse Stairs

...this material is commonly used in a wide range of industrial and construction applications due to its durability and versatility.

grabcad

free

Carbon Fibre Cube Sat

...

grabcad

this is a carbon fibre model for the cube sat with great tensile strength to bear all the loads in an efficient manner.

3dwarehouse

free

carbon fibre frame

...ame, built 1990 by hans-martin riehle, germany. gebr.muster g 9004518.1 #carbon, #bicycle, #bicycle frame, # fahrradrahmen, #velo

grabcad

free

Alloy Wheel

...ion, is an alloy of iron and carbon, the term "alloy wheel" is usually reserved for wheels made from nonferrous alloys.

Chrome

3d_export

$15

Blue Glass Bidet 3D Model

...interior detailed vray mental ray blue glass bidet transparent chrome blue glass bidet 3d model cgaxis 57254...

3d_export

$13

Wall Towel Hanger 3D Model

...bathroom bath water interior detailed vray mental ray white chrome towel hanger hanging hang wall wall towel hanger 3d...

3d_export

$13

Wall Towel Hanger 3D Model

...bathroom bath water interior detailed vray mental ray white chrome towel hanger hanging hang wall wall towel hanger 3d...

3d_export

$19

Tap 3D Model

...tap 3d model 3dexport plambing faucet crane water tap chrome tap 3d model archicube.3d 73176...

3d_export

$15

Wall decorative accessory 3D Model

...wall decorative accessory 3d model 3dexport sculpture abstract artwork chrome wall hanging art beam rail steel decorative accessory contemporary...

3d_export

$25

Keyboard Synthesizer 3D Model

...c4d detailed music instrument sound studio keyboard workstation key chrome metal keyboard synthesizer 3d model cgaxis 70058...

3d_export

$25

Keyboard Workstation 3 3D Model

...c4d detailed music instrument sound studio keyboard workstation key chrome metal keyboard workstation 3 3d model cgaxis 70062...

3d_export

$20

Red Flower in Chrome Pot 3D Model

... plant green 3ds max vray c4d cinema interior foliage white leaf pot vase

red flower in chrome pot 3d model cgaxis 64428 3dexport

3ddd

$1

Next Olsen bed & Gatsby Bedside Table

...olsen , gatsby next olsen bed gatsby bedside table chrome glass table lamp. linens: anthropologie eyelet embroidered sheet set,...

3ddd

$1

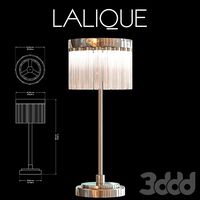

Orgue by Lalique

...diameter: 7.08 in weight: 13.23 pounds materials and finish: chromeplated or gilded, hand polished clear satin crystal or gold...

Bike

3d_export

$10

3D Tire Bike Sport 3D Model

...3d tire bike sport 3d model

3dexport

3d tire bike sport 3d model emiliogallo 93200 3dexport

3d_export

$35

Rigged moto helmet Nc4 3D Model

...racing fia speed sport vehicle automobile casco moto motorbike bike rigged moto helmet nc4 3d model terreo76 30855...

3d_export

$75

Montesa Cota 4RT 260 2014 3D Model

...bike racing sport cross motorcycle scramble scrambler track motocross motorbike spanish montesa cota 4rt 260 2014 3d model gonzo_3d...

3d_export

$6

Tron Light Cycle 3D Model

...tron light cycle 3d model 3dexport tron light cycle bike tron light cycle 3d model laine 81974...

3d_export

$49

Old bicycle 3D Model

...old bicycle 3d model 3dexport old bicycle bike classic classical wheel drive ride vehicle transport pedal saddle...

3d_export

$25

Merida Cyclo Cross Carbon Team 2012 frame set 3D Model

...carbon team 2012 frame set 3d model 3dexport bicycle bike frame merida cyclo cross carbon 2012 fork textured team...

3ddd

$1

Rebook bike Ub5

...rebook bike ub5

3ddd

тренажер

rebook bike ub5

3ddd

$1

Rebook bike indoor

...rebook bike indoor

3ddd

тренажер

rebook bike indoor

3d_ocean

$19

Penny farthing bicycle

...penny farthing bicycle 3docean bicycle bike city classic courier cycle dutch fast frame historical lady...

3d_ocean

$6

Low poly bike

... this low-poly model has details which are polygonal. all major format included .obj .fbx .c4d easy to import to any 3d software.

Brasse

3d_export

$64

Lion Head Door Knocker 3D Model

... brass ornate antique stone sculpture lock cat big statue game ready low

lion head door knocker 3d model soulstice 77966 3dexport

3d_export

$45

Flute 3D Model

...hestra tube brass classic accord detail full realistic photoreal silver gold trumpet model

flute 3d model blacks3d 50445 3dexport

3ddd

$1

Christopher guy 095-60-0253

...mensions

h 76. w 275. d 103 cm

measurements notes

seat width: 230 cm. seat depth: 65 cm. seat height: 45 cm. arm height: 76 cm

3ddd

$1

EICHHOLTZ / Stool Veracruz

... табурет

eichholtz. stool veracruz ( antique brass finish, nickel finish,gunmetal finish)

ø 29 h. 37 cm

3ddd

$1

Double palm trees in a pot

...uble palm trees in a pot

3ddd

пальма , горшок

double palm trees in a pot with brass foot

3ddd

$1

Eichholtz Spance Table Lamp

...3 x e27 (max 40w)

light bulbs:http://www.eichholtz.com/bulb-compact-set-of-6-0128002079114.aspx

материалы: corona 1.0

3ddd

$1

Meurice sconce by Jonathan Adler

...5 watt max g16.5 candelabra bulbs

• can be hung vertically or horizontally. antique brass material settings preview is included.

3ddd

$1

Jonathan Adler Goldfinger armchair

...r

polished brass meets swanky navy velvet in goldfinger collection

w 28" d 32" h 27.5"

renderers - v-ray, corona

3d_ocean

$7

Glass Door Monoblock 005

...cluded material pack — you may mix materials with no restrictions. there is some renders for example — you may download materi...

3d_ocean

$7

Glass Door Monoblock 008

...cluded material pack — you may mix materials with no restrictions. there is some renders for example — you may download materi...