Thingiverse

Bicycle spoke nipple insertion tool by cmh

by Thingiverse

Last crawled date: 2 years, 11 months ago

I enjoy building bike wheels, and I enjoy nice tools. I also enjoy 3D printing and making nice tools with the 3D printer. This is one of those cases. In the photo on the top is a $20 spoke nipple insertion tool, (I'm not affiliated with BHS but am a very happy customer) it's a really nice piece of steel with a taper on the pointy end that creates a friction fit when inserted in the top of a spoke nipple, which allows you to pass the spoke nipple through the rim and thread it onto the spoke. I've used other spokes in the past, but you have to take time to thread the spoke nipple onto the spare spoke, and then thread it off, and that takes time. Using the tapered end and the friction fit is much, much faster.

I had an idea of how I could create my own version - yes, even though I already bought the fancy one - that anyone could 3D print. I searched until I found a screwdriver handle that I liked - see the sources for a fantastic little screwdriver handle, then cleaned it up, gutted it, cut off the threads and scaled it down. I put a hole in the end, and sized this to around 2mm. Into this hole, I inserted a piece of wire clothes hanger, which measures 2.3mm and is therefore large enough to get the friction fit once the end is tapered.

To make your own, find a wire clothes hanger - or any wire that's around 2.3mm in diameter. Cut it to length, and then file or grind a taper on the end. This may take some doing, and I suggest having a spare spoke nipple on hand to test the friction fit. Once you've done that, put the wire in a vice with the taper pointing down, and lightly hammer the wire into the handle. Voila! Bicycle spoke nipple inserter.

To make getting at the spoke nipples from the top as easy as possible, be sure to check out my spoke nipple shuffler - it quickly organizes spoke nipples so they're heads up, making it really quick and easy to grab one as needed.

Happy wheelbuilding!

Update: I built a wheel using this instead of my purchased tool for the same purpose, and have to say that it worked quite well. The only issue I have is the taper on the end of the wire is a bit too gradual - it holds the nipple quite well but the tip continues and it winds up hitting the spoke. This isn't a huge problem, and could be addressed by shortening the pointed end of the tip.

I had an idea of how I could create my own version - yes, even though I already bought the fancy one - that anyone could 3D print. I searched until I found a screwdriver handle that I liked - see the sources for a fantastic little screwdriver handle, then cleaned it up, gutted it, cut off the threads and scaled it down. I put a hole in the end, and sized this to around 2mm. Into this hole, I inserted a piece of wire clothes hanger, which measures 2.3mm and is therefore large enough to get the friction fit once the end is tapered.

To make your own, find a wire clothes hanger - or any wire that's around 2.3mm in diameter. Cut it to length, and then file or grind a taper on the end. This may take some doing, and I suggest having a spare spoke nipple on hand to test the friction fit. Once you've done that, put the wire in a vice with the taper pointing down, and lightly hammer the wire into the handle. Voila! Bicycle spoke nipple inserter.

To make getting at the spoke nipples from the top as easy as possible, be sure to check out my spoke nipple shuffler - it quickly organizes spoke nipples so they're heads up, making it really quick and easy to grab one as needed.

Happy wheelbuilding!

Update: I built a wheel using this instead of my purchased tool for the same purpose, and have to say that it worked quite well. The only issue I have is the taper on the end of the wire is a bit too gradual - it holds the nipple quite well but the tip continues and it winds up hitting the spoke. This isn't a huge problem, and could be addressed by shortening the pointed end of the tip.

Similar models

thingiverse

free

Bicycle wheel building tool - spoke nipple shuffler v2 by Lexapskov

...d to shake the nipples , and they'll fall into the slots with the heads pointing up. you can then use a tapered metal point .

thingiverse

free

Bicycle spoke nipple shuffler - wheel building tool by cmh

...ld hold oil and you could dunk the spoke nipple after you grab it from the shuffler. the base isn't necessary for normal use.

grabcad

free

Double-Ended Detachable Screwdriver

... around. the unique shape also gives an ergonomic feel when using this tool.

-- the bit is just an example of a real life bit --

thingiverse

free

simple spoke tool. by eddiema

...n quite a bit to suit other nipple sizes.

my tool did one wheel and still looks usable but don't expect it to last forever.

thingiverse

free

Nipple Wrench by calviniba

...ng tool. however, it did survive building two wheels and probably could have done a third before i would have to replace the tip.

thingiverse

free

Tap and Die for 3D printed threads by DaveGadgeteer

...t may show artifacts especially at fitting ends.

i printed these with 5% infill, and i don't think they'd be water tight.

thingiverse

free

Simple 4mm Screwdriver w/ Swivel top (handle)

...e longer to fit 90mm bit extentions, and changed the hole size on the end of the handle to properly fit the bit extention listed.

thingiverse

free

2-part, reinforced Makedo Screwdriver

... mm.

tinkered in tinkercad, parts split and shaft extended then duplicated as a hole to create the insertion point in the handle.

grabcad

free

Bicycle spoke cutting and threading machine

...hreading machine

grabcad

this machine fits spokes in the right length and rolls thread with 2 rolling ties in 2 steps. have fun!

thingiverse

free

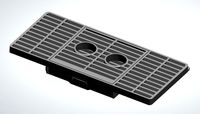

Rubbermaid Wire Shelf Hanger Stop

... existing shelving.

note: these fit wires of 8mm diameter. if needed you can easily modify this design for different size wires.

Cmh

thingiverse

free

Remix of Vice jaws for bicycle maintenance by cmh by dillanasche

... of vice jaws for bicycle maintenance by cmh

i used tinkercad to make bigger holes for larger magnets that are 19.1mm in diameter

thingiverse

free

Railing post for doll house by cmh

... printing replacements. this was about 8 minutes of work with sketchup before a meeting at work, it's a pretty simple design.

thingiverse

free

JVC Parasol LCD by MACO-CMH

.../ 620 / 660.

ver vídeo de instalación y como queda en https://cmhtec.blogspot.com/2020/11/accesorios-hechos-con-impresion-3d.html

thingiverse

free

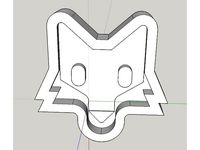

Fox emoji by cmh

... to add to something.

i've included the original sketchup file in case you wanted to change the extrusion depths or whatever.

thingiverse

free

X-Acto knife holder for pegboard by cmh

...nd make the holes deeper. sized for the #2 knife or the fantastic inexacto hobby knife by smorloc of which i've printed many.

thingiverse

free

JVC Parasol LCD GY-HC500 / 550 by MACO-CMH

...

thingiverse

ver vídeo de como queda y se instala en https://cmhtec.blogspot.com/2020/11/accesorios-hechos-con-impresion-3d.html

thingiverse

free

Sappho Buddha by cmh

...r nose was a little rough, but when i printed the entire thing at full scale, the results were just fine with no supports at all.

thingiverse

free

Key cover for Schlage keys by cmh

...using it somewhere else and the h didn't make any sense. i still have that one posted but also have one without any markings.

renderosity

$12

Carnival for CMH

...----------------------------<br />

the character, clothing, lights & poses are not included in this pack!</p>

thingiverse

free

Simple CO2 holder for octagonal inflator by cmh

...int (maybe) and it works like a champ. the inflator i have is tapered, so i just press it down into the octagon and it stays put.

Spoke

design_connected

$13

Spokes

...spokes

designconnected

foscarini spokes computer generated 3d model.

3ddd

$1

Foscarini Spokes

...ель: spokes

размер:↑ 71 cm, ↔ 32.5 см.

описание: подвесной светильник, сталь, алюминий, белый, желтое золото.

сайт: foscarini.com

3ddd

$1

Foscarini Spokes

...ь: spokes 2

размер:↑ 52.5 cm, ↔ 52 см.

описание: подвесной светильник, сталь, алюминий, белый, желтое золото.

сайт: foscarini.com

3d_export

$10

spoke wheel 1910

...spoke wheel 1910

3dexport

3d model of a metal spoke wheel of the beginning of the 20th century.

turbosquid

free

Rim 7 spoke

...osquid

royalty free 3d model rim 7 spoke for download as max on turbosquid: 3d models for games, architecture, videos. (1706021)

design_connected

$13

Harlow Spoke Chandelier L

...harlow spoke chandelier l

designconnected

gabriel scott harlow spoke chandelier l computer generated 3d model.

design_connected

$13

Harlow Spoke Chandelier S

...harlow spoke chandelier s

designconnected

gabriel scott harlow spoke chandelier s computer generated 3d model.

turbosquid

free

8 Spoke Rims

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

15 spoke rim 3D Model

...15 spoke rim 3d model

3dexport

spoke 15 rim esser black chrome tire wheel carpart

15 spoke rim 3d model esser 621 3dexport

cg_studio

$2

Classic Spoked Wheel3d model

...ed wheel3d model

cgstudio

.max - classic spoked wheel 3d model, royalty free license available, instant download after purchase.

Nipple

3d_export

$5

angle grease nipple

...angle grease nipple

3dexport

angle grease nipple

3d_export

$5

side grease nipple

...side grease nipple

3dexport

side grease nipple

3d_export

$10

Nipples 3D Model

...s infants young children feed formula breast silicone latex pacifier soother rubber child

nipples 3d model firdz3d 81977 3dexport

3d_export

$8

nipple cream tube 01

...& .obj. please rate, when you buy. thanks! :) also, please check out my other useful portfolio items that you may be missing!

3d_export

$8

Baby Bottle Nipple 02

...gt;please rate, when you buy. thanks! :)<br>also, please check out my other useful portfolio items that you may be missing!

3d_export

$9

Baby Bottle Nipple 01

...gt;please rate, when you buy. thanks! :)<br>also, please check out my other useful portfolio items that you may be missing!

3d_export

$8

Pacifier 3D Model

...3dexport pacifier dummy binky soother rubber plastic silicone nipple nipple infant baby babies suck teat teething kid child milk...

3d_export

$5

lp400 rim

...lp400 rim 3dexport rim with nuts and nipple for everyone<br>you can use it for your own projects,...

3d_export

$5

Pacifier 3D Model

...pacifier 3d model 3dexport pacifier baby dummy rubber nipple teat kid tetine child milk realistic decoration 3d model...

3d_export

$15

Gongs 3D Model

...model 3dexport gong gongs chinese chau tam-tam tamtam suspended nipple bowl music percussion gamelan indonesian orchestra opera canang instrument...

Bicycle

3d_export

$15

bicycle

...bicycle

3dexport

simple bicycle

3ddd

$1

bicycle

...bicycle

3ddd

велосипед

bicycle

archibase_planet

free

Bicycle

...ibase planet

bicycle bike cycle two-wheeled bicycle

bicycle n080115 - 3d model (*.gsm+*.3ds+*.max) for exterior 3d visualization.

archibase_planet

free

Bicycle

...bicycle

archibase planet

bicycle cycle bike

bicycle n120411 - 3d model (*.3ds) for 3d visualization.

3d_export

$10

Bicycle

...bicycle

3dexport

bicycle toy or technique for children.

3d_export

$5

bicycle

...bicycle

3dexport

this is 3d model toy bicycle,

archibase_planet

free

Bicycle

...bicycle

archibase planet

bicycle cycle bike

bicycle n270309 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Bicycle

...bicycle

archibase planet

bicycle cycle bike

bicycle n090211 - 3d model (*.3ds) for exterior 3d visualization.

archibase_planet

free

Bicycle

...bicycle

archibase planet

bicycle cycle bike

bicycle n011211 - 3d model (*.3ds) for exterior 3d visualization.

archibase_planet

free

Bicycle

...bicycle

archibase planet

bicycle cycle bike

bicycle n120608 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Insertion

turbosquid

$10

insert a bracelet

... 3d model the link element insert for download as max and max on turbosquid: 3d models for games, architecture, videos. (1609593)

turbosquid

$56

Threaded Inserts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

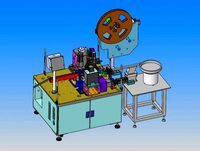

$14

drawing of needle inserting machine

...lectronic manufacturers use pin machines to help customers to insert needles, so as to obtain processing costs and obtain wealth.

3d_export

$5

Siemsn EQ 6 Inlet insert

...placed there without any problems. the insert is then straight for normal cups and a square insert can be removed for large cups.

turbosquid

$5

metal insert for earring rings

...for earring rings for download as 3dm, 3dm, obj, pdf, and stl on turbosquid: 3d models for games, architecture, videos. (1569103)

turbosquid

$1

Base insert - Stone&Wood 50mm

...e 3d model base insert - stone&wood 50mm for download as on turbosquid: 3d models for games, architecture, videos. (1325614)

turbosquid

$1

Base insert - Stone&Rails 30mm

...odel base insert - stone&rails 30mm for download as blend on turbosquid: 3d models for games, architecture, videos. (1325627)

turbosquid

$1

Base insert - Stone&Rails 40mm

...odel base insert - stone&rails 40mm for download as blend on turbosquid: 3d models for games, architecture, videos. (1325624)

turbosquid

$1

Base insert - Stone&Wood 40mm

...model base insert - stone&wood 40mm for download as blend on turbosquid: 3d models for games, architecture, videos. (1325617)

turbosquid

$14

Black moka pot with metal inserts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Tool

archibase_planet

free

Tools

...tools

archibase planet

tools instruments implements

tools n070114 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

3d_ocean

$12

Tools

...tools

3docean

hammer metal old screw tools wrench

maya

turbosquid

$6

Tool Cart / Tool Box

...

royalty free 3d model tool cart / tool box for download as on turbosquid: 3d models for games, architecture, videos. (1241859)

3d_ocean

$15

crimp tool

... tool copper cutter crimp crimp tool electrical electrical tools press tools pressing tool tools wire cutter

created in maya 2013

3d_ocean

$5

Tools

...tools

3docean

3d models paint tools work

3d,models,works,paint,art,create,working,

3d_export

free

tools

...tools

3dexport

coldsteel

turbosquid

$15

Tools

...turbosquid

royalty free 3d model tools for download as blend on turbosquid: 3d models for games, architecture, videos. (1331352)

3ddd

$1

bar tool

...bar tool

3ddd

барный

bar tool

turbosquid

$10

tools

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Tools

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.