3dExport

belt grinder-belt sander

by 3dExport

Last crawled date: 1 year, 10 months ago

grinder (english belt grinder / belt sander) is the household name of a small desktop belt-grinding machine that works with a tape no more than 2000mm long. grinders have now gained the greatest popularity among knife makers, but this machine tool can be useful in the factory shop for the prompt performance of small locksmith or carpentry work, and in any home or garage workshop. grinder is essentially an advanced "younger brother" of a sharpener (a sharpener, or a sharpening machine, is also often called an emery, although this is incorrect). younger ones – because they are modern, and advanced ones - because, thanks to a huge selection of sanding belts, they can perform more types of work. at the same time, some work is more convenient to perform on a sharpener – mainly sharpening tools for metalworking: cutters, cutters, drills. once again, we make a reservation that here we are not discussing serious machines with grinding wheels used for centerless or deep grinding. also, we are not talking about many craftsmen do all the small grinding work on a grinding machine the old-fashioned way, but when a grinder appears in the workshop, 10-15 percent of the tasks remain for the sharpener, everything else is more convenient, faster and safer to do with a sanding belt. the work on the grinder is carried out by endless sanding belts. this type of consumables is very convenient to use – the replacement of tapes is carried out almost instantly and without the use of additional tools. the range of sanding belts allows you to perform a huge range of work - contouring, stripping, stripping, grinding, polishing, sharpening, applying directional risks, cleaning from rust and old coatings. on the sharpener, they mainly make "lenticular" concave descents on a knife, although if you put a cup or a disc, you can make straight ones. the grinder allows you to make straight descents and is convenient in cutting the edge for welding. at the same time, if necessary, a large diameter contact wheel can be installed on the grinder, when working on a sanding belt, the temperature is better removed from the workpiece than when working on a grinding wheel. for any work related to grinding, a lower temperature in the working area is very important – the life of the sanding belt is extended, there is less chance of overheating the workpiece. an important point is the safety of work. of course, when working on any machine, it is necessary to use personal protective equipment - glasses and a respirator, optionally also earplugs or headphones. but it is obvious that the damage caused by the rupture of the tape cannot be compared with the possible damage caused by a flying grinding wheel when working on a sharpener.

Similar models

grabcad

free

Machine Grinder Lathe Chisel

...e rotates and thend rubs against the workpiece so that cutting or grinding occurs. thanks already readig the taks. copyright 2022

3dwarehouse

free

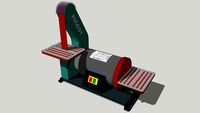

Ponceuse à bande stationnaire combinée (belt grinder)

...l #meuler #meuleuse #métal #outils #poncer #ponceuse #sander #sanding #stationary #stationnaire #tape #tools #travail #wood #work

grabcad

free

Grinder

...e grinder to cut tile, mortar and pavers; make quick work of rust and loose paint removal; sharpen blades and cut or grind steel.

cg_trader

$5

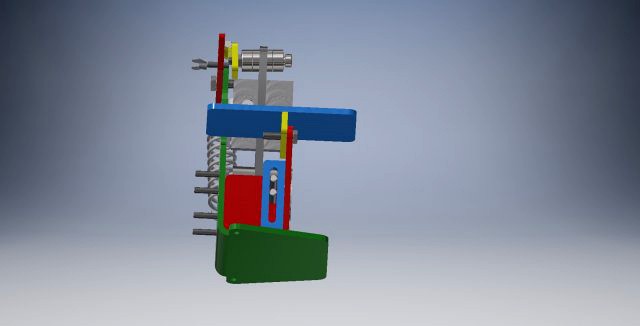

Accessories set for mini belt grinder | 3D

...like mini electric belt sander adjustable speed grinder diy polishing grinding machine cutter edges sharpener 15/25mm belt sander

thingiverse

free

Angle Grinder (belt sander attachment) by Marco222

...er (belt sander attachment) by marco222

thingiverse

angle grinder belt sander attachment

(videos of the working tool at the end)

thingiverse

free

Adapter for chinese Belt sander to Bosch angle grinder by stephan99

..._warehouse=uk&rmmds=search

by cutting the clamping part as shown in the picture and mounting this adapter it works perfectly.

grabcad

free

DIY Belt sander / Belt grinder

...diy belt sander / belt grinder

grabcad

designed to support 72"x 2" sanding belt.

grabcad

free

72x2in Belt Grinder With Multiple Rests/Tools

...iple rests/tools, including square, angled, radius, small and large contact wheels and drill bit sharpener.

designed in freecad.

grabcad

free

belt grinder

...belt sander for small workshops. 50mm belt file, support base and angled head and body joint for horizontal and vertical position

3d_export

$25

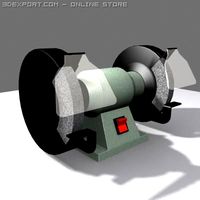

Bench Grinder 3D Model

... model

3dexport

tools power bench grinder grinding wheel industrial sharpening

bench grinder 3d model midnight oil 28071 3dexport

Sander

3ddd

free

Sander Mulder Josephine

...sander mulder josephine

3ddd

sander mulder

http://www.sandermulder.com/josephine.html

3ddd

free

Sander Mulder Pandora

...sander mulder pandora

3ddd

sander mulder

http://www.sandermulder.com/pandora.html

3ddd

free

Sander Mulder - Sputnik

...нальный столик от sander mulder

модель - sputnik

ссылка на сайт производителя:http://www.sandermulder.com/sputnik.html

turbosquid

$17

Sander Wall Mirror

... free 3d model sander wall mirror for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1202867)

3ddd

free

Sander Wall Mirror

...l mirror

3ddd

канат , веревка , морской

зеркало

3ddd

$1

Riley Sanders — Dowel Lamp

...riley sanders — dowel lamp

3ddd

дизайнерский светильник от riley sanders.

используется как на столе так и на полу.

turbosquid

$25

Sander Grinder

...quid

royalty free 3d model for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1388762)

3d_export

$9

sander

...e rendered with vray<br>- no compositing used, product is ready to render as previews, lights and cameras included in file.

3ddd

$1

Картины абстракция Malcolm Sanders Eclipse

...картины абстракция malcolm sanders eclipse

3ddd

картина

malcolm sanders eclipse

size: 32in x 28in | 81cm x 71cm

vray

corona

3d_export

$10

sander

...table for automatic grinding of shaft parts, including automatic feeding mechanism of shaft parts. welcome to download and learn!

Grinder

3d_export

$7

belt grinder

...belt grinder

3dexport

belt grinder

archibase_planet

free

Coffee grinder

... planet

coffee-grinder coffee grinder kitchen ware

coffee grinder n030510 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$1

Grinder

...turbosquid

royalty free 3d model grinder for download as c4d on turbosquid: 3d models for games, architecture, videos. (1408552)

turbosquid

$10

Grinder

...

royalty free 3d model grinder for download as , fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1568436)

turbosquid

$25

Grinder

...yalty free 3d model grinder for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1508433)

turbosquid

$5

Grinder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$4

Grinder

... 3d model grinder for download as c4d, obj, fbx, dae, and 3ds on turbosquid: 3d models for games, architecture, videos. (1603976)

3d_ocean

$14

Meat grinders

...eat grinders

3docean

kitchen meat grinders tools

this is little meat grinders with an old design, 1960-1980, made in 3ds max 2008

archibase_planet

free

Coffee grinder

...ase planet

coffee-grinder kitchen equipment

coffee grinder gipfel n270810 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archive3d

free

Grinder 3D Model

...

coffee-grinder grinder

grinder n120108 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Belt

3d_export

$6

belt

...d then comes off and fastens at the front of the seat. version: 2015 units: millimetres x-form: yes polys: 120 950 verts: 163 944

3d_export

$7

belt grinder

...belt grinder

3dexport

belt grinder

3d_export

$5

Belt conveyor

...belt conveyor

3dexport

belt conveyor

3ddd

$1

column belt

...column belt

3ddd

колонна

column belt

turbosquid

$5

Belt

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$5

Leather Belt

...ather belt is created in 3dsmax 2011 and rendered with vray 1.5 and it has all the texture included with the multiple obj format.

3d_ocean

$5

Belt Ring

...belt ring

3docean

belt jewelry ring

belt ring 3d model. total weight 3.5 gram & 1.1 stone size. 3dm and obj file format.

design_connected

$11

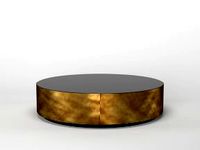

Belt Oval

...belt oval

designconnected

meridiani belt oval computer generated 3d model. designed by parisio, andrea.

design_connected

$11

Belt Round

...belt round

designconnected

meridiani belt round computer generated 3d model. designed by parisio, andrea.

design_connected

$11

Belt Square

...belt square

designconnected

meridiani belt square computer generated 3d model. designed by parisio, andrea.