Thingiverse

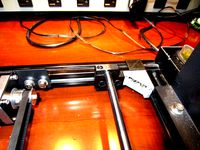

Bearingless Extrusion Carriages by Matthew813

by Thingiverse

Last crawled date: 3 years, 1 month ago

https://cad.onshape.com/documents/836f06f47bc1413878a214c1/w/de43917f29760e7e6655d59b/e/8977885da2700f041dd55800

Go to the link to access ALL the sizes for carriages.

The sizes I have designed for the extrusions so far are:

15x15 Extrusions

20x20 Extrusions

25x25 Extrusions

30x30 Extrusions

20x40 Extrusions

20x60 Extrusions

There are two parts in each studio: the 35mm version and 50mm version. If you need a slimmer bearing for larger print area, you can try the 35mm. The 60mm version is highly recommended as it tends to bind less. The taller the carriages are, the less they’ll bind.

(The Filamolder uses 80mm Carriages.)

If you use these bearings and need to add a hole or mounting point you just bring it into your favorite software and edit it however you want.

(Scaling the bearings in the z doesn’t change the effectiveness of the carriage.)

Aluminum Extrusions are strong, Light, smooth, and widely available both on eBay and amazon. But the biggest issue with aluminum extrusions is if you want to use them as a linear rail then you have to acquire 4 V slot wheels, 8 bearings (2 per wheel) and make/or buy a carriage that is made for the specific rail you are using.

$16.61 PER CARRIAGE (Only for wheels.)

Then you have the trouble of finding/or designing a carriage that works for the specific extrusion you are using and make sure your wheels are accounted for into the design of the carriage. Then you need to buy nuts and bolts and washers and eccentric nuts. In the end, it costs more to make the fully assembled carriages then it actually costs to buy the extrusions.

24.43 PER CARRIAGE (Everything included, like bolts nuts washers carriage plate.)

You can use linear rods or linear sleds, but then it gets even more expensive and there is always the possibility the rod will get bent during shipping. (Sometimes rods can be weaker then the structured aluminum extrusions.)

I was toying around with 3d printed carriages and wheels for my Filamolder 3d printer a while back and was near giving up and going to buy linear rods, but by chance I was scrolling through the thingiverse page and saw some 3d printable IGUS bushings for linear rod. I thought I’d try a version for aluminum extrusions. I never looked back.

https://www.youtube.com/watch?v=-n2uR3FW1mo

Go to the link to access ALL the sizes for carriages.

The sizes I have designed for the extrusions so far are:

15x15 Extrusions

20x20 Extrusions

25x25 Extrusions

30x30 Extrusions

20x40 Extrusions

20x60 Extrusions

There are two parts in each studio: the 35mm version and 50mm version. If you need a slimmer bearing for larger print area, you can try the 35mm. The 60mm version is highly recommended as it tends to bind less. The taller the carriages are, the less they’ll bind.

(The Filamolder uses 80mm Carriages.)

If you use these bearings and need to add a hole or mounting point you just bring it into your favorite software and edit it however you want.

(Scaling the bearings in the z doesn’t change the effectiveness of the carriage.)

Aluminum Extrusions are strong, Light, smooth, and widely available both on eBay and amazon. But the biggest issue with aluminum extrusions is if you want to use them as a linear rail then you have to acquire 4 V slot wheels, 8 bearings (2 per wheel) and make/or buy a carriage that is made for the specific rail you are using.

$16.61 PER CARRIAGE (Only for wheels.)

Then you have the trouble of finding/or designing a carriage that works for the specific extrusion you are using and make sure your wheels are accounted for into the design of the carriage. Then you need to buy nuts and bolts and washers and eccentric nuts. In the end, it costs more to make the fully assembled carriages then it actually costs to buy the extrusions.

24.43 PER CARRIAGE (Everything included, like bolts nuts washers carriage plate.)

You can use linear rods or linear sleds, but then it gets even more expensive and there is always the possibility the rod will get bent during shipping. (Sometimes rods can be weaker then the structured aluminum extrusions.)

I was toying around with 3d printed carriages and wheels for my Filamolder 3d printer a while back and was near giving up and going to buy linear rods, but by chance I was scrolling through the thingiverse page and saw some 3d printable IGUS bushings for linear rod. I thought I’d try a version for aluminum extrusions. I never looked back.

https://www.youtube.com/watch?v=-n2uR3FW1mo

Similar models

thingiverse

free

TEVO Tarantula X carriage (Linear Rail, BL Touch, and Titan Extruder)

...lace the 20x40 aluminum extrusion with a 20x20 aluminum extrusion. otherwise the nozzle will not make contact with the print bed.

grabcad

free

SC35 SCS35UU Linear Rail Bearing

...sc35 scs35uu linear rail bearing

grabcad

35mm bore linear rail block bearing for 35mm round linear rod/shaft

grabcad

free

SC35 SCS35LUU Linear Rail Bearing

...sc35 scs35luu linear rail bearing

grabcad

35mm bore linear rail block bearing for 35mm round linear rod/shaft

thingiverse

free

Kossel Alt Wheel Carriage Conversion by s3rkan

...u can use the effector here:https://www.thingiverse.com/thing:2548508

you should use as an idler gt2 16t idler for the top frame.

thingiverse

free

Magball Carriages for Kossel printer with 2020 extrusions by JohnOCFII

...ension bolt 35mm

35mm m3 bolt

nyloc nut

the openscad file is included along with the stl files in case you wish to make changes.

thingiverse

free

CR10 linear rail bed plate carriage

...you will also need eight aluminum 2020 corner braces, similar to the ones in my...

thingiverse

free

Prusa i3 Y Axis Bearing Rod Support by henryarnold

...mm cap screw and nut for the clamp. you'll also need the captive nut used with the extrusion which came with the printer kit.

thingiverse

free

Y-Axis End Stop holder 8mm bushing by PeteyPub

...motion ball bearing cnc slide bushing

2 - 8mm stainless steel rods

this y-axis switch holder mounts under the aluminum bearing.

thingiverse

free

Linear carriage nema 17 by nikki81

...8mm washers

6x 8mm nuts

1x 608zz bearing

4x lm8uu bearings

1x kw11-3z microswitch

8x 100mm cable ties

4x m3 5mm bolts

4x m3 nuts

thingiverse

free

LM8UU Linear Bearing Puller by TechnoSwiss

...ger bolt if you can't push the new bearing in part way by hand.

printed at 0.21mm layer higher and 40% infill with esun pla.

Matthew813

thingiverse

free

Spinspinspin G1 remix for fast-tl by Matthew813

...spinspinspin g1 remix for fast-tl by matthew813

thingiverse

designed by matthew b. for fast-tl

thingiverse

free

Pictures of wiring setup by Matthew813

...tp://www.thingiverse.com/groups/reprap/topic:6769#comment-914700

just ignore the file, this thing was made fore a comment thread.

thingiverse

free

Fidget Cube Remix by Matthew813

...exible stuff, but i still like everything filleted. don’t judge me.

pictures will come when when my order of flexible stuff does.

thingiverse

free

Synio Spray Cut for MP Select Mini by Matthew813

...matthew813

thingiverse

made for a friend who needed the synio spray pen in smaller pieces so to be printed on an mp select mini

thingiverse

free

Larry's Perch Cleaner by Matthew813

...perch cleaner has gripping spikes that remove waste, treat, and almost anything that sticks onto perches that you want to remove.

thingiverse

free

G3 Bearing-less Fidget Spinner by Matthew813

...easy, cheap fidget spinner that prints in one piece. printed at 20% infill, it has a spin time of 16 seconds without lubrication.

thingiverse

free

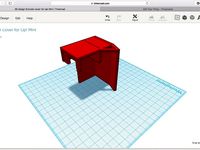

Up! Mini Extruder Cover GEN-2 by Matthew813

...

this is the second version of my up! mini extruder assembly cover, made better, looks better, and most important, works better.

thingiverse

free

A sand flap (printable) by Matthew813

...sign my own and give it a try. it works surprisingly well and will certainly be used in the workings of my filamolder 3d printer.

thingiverse

free

The CUBICAL Spinner by Matthew813

...ts, and a good layer height to print optimally. but once you overcome printing, you will have the coolest fidget-er in the block!

thingiverse

free

Extruder assembly Cover for Up! Mini by Matthew813

...r assembly for the up! mini! just click, print, and snap onto the top of the extruder assembly by the circuit board on your mini.

Bearingless

3d_export

$15

Bell AH-1Z Viper

...the h-1 upgrade program. the ah-1z features a four-blade, bearingless composite main rotor system, uprated transmission, and a new...

thingiverse

free

Baseball bearingless fidget by Speedysloth88

...baseball bearingless fidget by speedysloth88

thingiverse

this is for fidgetters that love baseball.

thingiverse

free

Bearingless Fidget Spinner Remix by LuisDUgena

...erse

warning!!!! this is not working!!!

i wasn't able to print the original bearingless fidget spinner so i've remix it.

thingiverse

free

Spinner Bearingless by PotatoGambit

...nner bearingless by potatogambit

thingiverse

nice little spinner toy. drew up in cad and printed. it doesn't use a bearing.

thingiverse

free

Filaments support without bearing, bearingless (Atom 2.5) by bruesw

...ring, bearingless, improve original atom 2.5 filaments support and smoother curve of filament direction and rolloer when feeding.

thingiverse

free

Filament straightener bearingless by Hitchabout

...dy in play 4mm od ptfe tube throughout instead of bearings.or without a tube.

if it needs to be modifiedhttps://a360.co/2e3jpjy

thingiverse

free

Bearingless Fidget Spinner by CaseyJohnson

...extra mass. printed in protopasta carbon fiber filament, and it turned out very well.

https://www.youtube.com/watch?v=2cwy0jttvms

thingiverse

free

Bearingless Fidget Spinner by morris_lan

... but you might need to push the middle pin down when you remove it from the print bed. in order for it to spin. i hope you enjoy!

thingiverse

free

bearingless fingered y bar for mendel by jamesvilleneuve

...s good to go. i've tested it up to 120mm/s but it is reliable up past 70mm/s for those english like me that is around 160ipm.

thingiverse

free

Bearingless Kossel Carraige by mattshane

...em in vegetable oil for a little bit after printing and they run really smooth.

should have stated originally this is for 1515.

Carriages

archibase_planet

free

Carriage

...arriage

archibase planet

perambulator baby carriage pram

carriage n250908 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

free

carriage

...carriage

3dexport

old fashion carriage model, more files here:

turbosquid

$140

Carriage

...urbosquid

royalty free 3d model carriage for download as max on turbosquid: 3d models for games, architecture, videos. (1482052)

turbosquid

$25

Carriage

...urbosquid

royalty free 3d model carriage for download as max on turbosquid: 3d models for games, architecture, videos. (1285944)

3d_export

free

carriage

...carriage

3dexport

game cart

3d_ocean

$15

Barrel Carriage

...ieval oak old transport wheels wine wood

this model contains a barrel and a carriage. it is a medieval type of wood oak carriage.

turbosquid

$40

Carriage

...ty free 3d model carriage for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1290094)

turbosquid

free

Carriage

...yalty free 3d model carriage for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1239157)

3d_export

$5

Medieval carriage

...medieval carriage

3dexport

medieval carriage in fairy style

turbosquid

$58

Carriage

...d model carriage with scene for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1276262)

Extrusion

turbosquid

free

aluminum extrusion profiles

...free 3d model aluminum extrusion profiles for download as max on turbosquid: 3d models for games, architecture, videos. (1381707)

turbosquid

$5

Cable Cover Extrusion

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

free

30 x 30 extrusion

... x 30 x 40.sldprt<br>30 x 30 x 50.sldprt<br>30 x 30 x 606.sldprt<br>the sketch.sldprt<br>30 x 30 x 40.stl

3d_export

$300

melt-blown fabric extrusion molding machine

...an email to me.<br>designed with solidworks 2017, render with photoview 360<br>**************************************

3d_export

$5

Spaceship - Galaxy Crusher

...with a more ominous twist. it has lots of extrusion and cubes and comes with a whopping 4k texture,...

3d_export

$20

1600 Meltblown cloth production line set drawing CAD

...width of 1600mm. the steel structure frame, feeding host, extrusion screw, heating system, screen changer, metering pump, melting it...

3d_export

$5

one-eyed scary virus

...cinema, the body relief is formed by the standard extrusion noise. the eye texture is...

3d_export

$20

GE TF34 Fan Blade and Nose Cone

...and appropriately sized fillet features are provided.<br>also, a threaded extrusion profile is provided on the fan blade component and...

3d_export

$10

glue injection machine

...injection technology. the ordinary glue injection machine is screw extrusion type, and its instantaneous pressure can reach more than...

3d_export

$1000

bead triangle adhesive laminating machine

...a triangular rubber head with the shape required for extrusion the rear end of the extruder is also provided...