Thingiverse

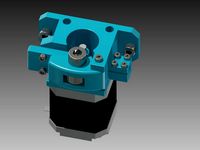

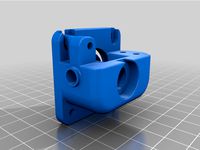

Basic Bowden Extruder V2 by FerociousDesigns

by Thingiverse

Last crawled date: 3 years ago

Please consider leaving a tip or donating via paypal on my website: http://ferociousdesigns.co.uk/ if you like this design! All support is very much appreciated!

Update 10/02/18: Updated both main body and arm to v2. Moved filament hole down 0.5mm to make loading easier as it was hitting the bearing.

This is a further iteration from my 'Simple Bowden Exruder' based on the Anet A8 stock extruder design but optimised for TPU. It requires more parts than the previous iteration, however should perform even better!

Features:

Small Size: Only 2mm deeper than the standard Anet A8 extruder when used as a bowden.

Compatibility: Mounts to any bowden mount that can take a Nema 17 Stepper

Works with flexible filament as well as PLA / ABS etc

Works with various extruder gears from 12 - 14mm diameter

Near 100% supported filament path

PC4M6 In / Out: Prevents grinding on the edge of the arm, and provides more support for the filament to make loading easier.

Printing:

I have tried to orient the parts into the best position for printing, however you are free to print how you want to of course :) I use 10% line supports on everything in Cura as they are very easy to remove. Printed with 25% infill using Anet PLA. During cleanup, bore the filament hole out to 2mm if it is not already.

Required parts:

3x M3x17mm Bolts to mount to bowden mount and stepper

1x M3x12mm Cap head bolt for arm retainer

1x M3x20mm Cap head bolt for spring adjuster

5x M3 Washers (Arm Hinge x3, spring adjuster x2)

4x M3 Nuts (Arm retainer, arm bolt, spring adjuster x2)

4x F623zz bearings (arm hinge x2, spring adjuster x2)

1x 625 bearing (filament idler)

1x Spring 8mm wide x 20mm long

1x MK7 Extruder Gear (Other gears may work but not tested)

Building:

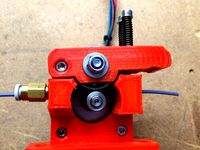

Assemble the arm first and then bolt it to the main body piece. Wind the tensioner out all the way to make it easier to mount.

The arm hinge should go: Washer between bearing on the arm and the front plate, bearing, bearing, washer, m3 nut, washer. Then attach to bowden mount / stepper.

The spring tensioner on the arm should be: M3 bolt with nut tightend all the way up to its head (this should push fit into the 'Extuder button' piece), washer, bearing, bearing, washer, M3 nut, Spring retainer with embedded M3 nut facing the arm.

To set the extruder gear into the right position on the shaft, you can attach the built arm without the front plate.

Update 10/02/18: Updated both main body and arm to v2. Moved filament hole down 0.5mm to make loading easier as it was hitting the bearing.

This is a further iteration from my 'Simple Bowden Exruder' based on the Anet A8 stock extruder design but optimised for TPU. It requires more parts than the previous iteration, however should perform even better!

Features:

Small Size: Only 2mm deeper than the standard Anet A8 extruder when used as a bowden.

Compatibility: Mounts to any bowden mount that can take a Nema 17 Stepper

Works with flexible filament as well as PLA / ABS etc

Works with various extruder gears from 12 - 14mm diameter

Near 100% supported filament path

PC4M6 In / Out: Prevents grinding on the edge of the arm, and provides more support for the filament to make loading easier.

Printing:

I have tried to orient the parts into the best position for printing, however you are free to print how you want to of course :) I use 10% line supports on everything in Cura as they are very easy to remove. Printed with 25% infill using Anet PLA. During cleanup, bore the filament hole out to 2mm if it is not already.

Required parts:

3x M3x17mm Bolts to mount to bowden mount and stepper

1x M3x12mm Cap head bolt for arm retainer

1x M3x20mm Cap head bolt for spring adjuster

5x M3 Washers (Arm Hinge x3, spring adjuster x2)

4x M3 Nuts (Arm retainer, arm bolt, spring adjuster x2)

4x F623zz bearings (arm hinge x2, spring adjuster x2)

1x 625 bearing (filament idler)

1x Spring 8mm wide x 20mm long

1x MK7 Extruder Gear (Other gears may work but not tested)

Building:

Assemble the arm first and then bolt it to the main body piece. Wind the tensioner out all the way to make it easier to mount.

The arm hinge should go: Washer between bearing on the arm and the front plate, bearing, bearing, washer, m3 nut, washer. Then attach to bowden mount / stepper.

The spring tensioner on the arm should be: M3 bolt with nut tightend all the way up to its head (this should push fit into the 'Extuder button' piece), washer, bearing, bearing, washer, M3 nut, Spring retainer with embedded M3 nut facing the arm.

To set the extruder gear into the right position on the shaft, you can attach the built arm without the front plate.

Similar models

grabcad

free

Geared extruder v.3

... some m4 nuts and washers to adjust spring tension

~ 25mm spring

mk8 gear for driving filament

2x 625zz bearings

1x 608zz bearing

thingiverse

free

Bowden Extruder for 2020 Profile - 1.75 MK7 608zz by Enrike_X5

...around 15mm lenth)

1x nema17 stepper

1x ptfe tube

you may need a tap kit (m5 and m8) to correct the threads, and a 2mm drill bit.

thingiverse

free

Alpha Direct Drive Extruder by engineglue

...upply list; this is a minimal design. you can use m4 bolts and nuts to mount it. it mounts to a standard aluminum mounting plate.

thingiverse

free

Rackprint Bowden Extruder by Alex_RP

...x m3 screw ~20mm and nuts

2x m3 screw 15mm

bearing 608zz

mk8 drive gear

2x spring ~20mm with ~3mm inner diameter

thingiverse

free

Filament holder

...n testing stage.

required parts

8mm shaft

2x fl08 bearings

2x m5 bolts

4x m5 washers

2x m5 nuts

1x m3 bolt

1x m3 washer

1x m3 nut

thingiverse

free

Super Simple Bowden Extruder V2 by _AlexY

...aring

nema 17 stepper

4x m3x8mm screws

m3x30mm screw

extruder spring

m3 locknut

2x m5x8mm screws + 2x t-nuts for mounting to 2020

thingiverse

free

Bowden Extruder with captured connector by bradjshannon

...nt path removed for now. not needed except for flexible filaments, anyways

public fusion 360 project link: http://a360.co/2devcfk

thingiverse

free

Schematix: Dual Drive Extruder (Fits E3D v6) by Schematix

....d 4mm o.d

springs (some experimentation may be required) however i use the following:

wire diameter: 0.7mm x 6mm o.d x 18mm long

thingiverse

free

Mini Kossel 1.75mm extruder by wallie

...et head cap screw

2x spring

1x m5 pneumatic straight threaded-to-tube adapter, push in 4 mm 4mm male

tools

m5 manual screw tap

thingiverse

free

Dual stepper MK8 gear direct drive bowden extruder

...

2x m3 washer for holding the bearings in place

2x pneumatic push-in fittings with m5 threads for the bowden tube diameter in use

Ferociousdesigns

thingiverse

free

Bong mouthpiece by FerociousDesigns

...bong mouthpiece by ferociousdesigns

thingiverse

it is what it is, i printed it with tpu. fits on an acrylic water pipe :)

thingiverse

free

KTM Keyring by FerociousDesigns

...tm keyring by ferociousdesigns

thingiverse

it is what it is, i will be printing from tpu personally but use whatever you want :)

thingiverse

free

'Shaguar' Keyring by FerociousDesigns

...;shaguar' keyring by ferociousdesigns

thingiverse

it is what it is, i will be printing from tpu but use whatever you want :)

thingiverse

free

Ford RS Keyring by FerociousDesigns

...ford rs keyring by ferociousdesigns

thingiverse

it is what it is, i will be printing from tpu but use whatever you want :)

thingiverse

free

Tiger Racing Keyring by FerociousDesigns

...tiger racing keyring by ferociousdesigns

thingiverse

it is what it is, i will be printing from tpu but use whatever you want :)

thingiverse

free

BL Touch Mockup by FerociousDesigns

... ferociousdesigns

thingiverse

a model for use in making brackets and holders. obviously is not functional!

added fusion 360 file

thingiverse

free

3 Colour Mixing 'Diamond' Hotend Mockup by FerociousDesigns

...#39; hotend mockup by ferociousdesigns

thingiverse

this is wip!

i still need to confirm the cold ends are at the correct angles.

thingiverse

free

BoltRC Kraken Pod - Remix by FerociousDesigns

...he original design.

someone asked me to modify it to allow a bit less camera angle. all i have done is elongated the camera hole.

thingiverse

free

Lumenier Pagoda 2 - Short Version - Mockup by FerociousDesigns

...ousdesigns

thingiverse

created this to help with designing pods for quadcopters.

fusion 360 file included to use in your models.

thingiverse

free

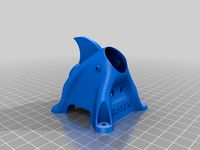

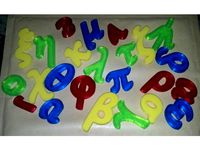

Greek Alphabet - Lowercase by FerociousDesigns

...ts already on thingiverse but none suited what they wanted.

maybe someone else would find them useful, so i have uploaded here :)

Bowden

turbosquid

$199

Vintage Ben Bowden Spacelander bike

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Manooi Artica

...and pendants in various sizes and forms. suspension: galvanized bowden - dia. 1,5 mm. bulb: max 60 w -...

thingiverse

free

Remix Compact Bowden extruder - m6 bowden couplers and bowden tube pass-through

...ouplers and bowden tube pass-through

thingiverse

remix compact bowden extruder - m6 bowden couplers and bowden tube pass-through

thingiverse

free

Bowden Extruder

...bowden extruder

thingiverse

i have created bowden extruder for flsun delta 3d printer.

thingiverse

free

bowden 3mm by spee_D

...bowden 3mm by spee_d

thingiverse

for bowden 3mm

thingiverse

free

Bowden Tube Cutter

...bowden tube cutter

thingiverse

bowden tube cutter

thingiverse

free

Customizable Bowden Clip

...customizable bowden clip

thingiverse

customizable bowden clip

thingiverse

free

Bowden Oiler by fcheshire

...bowden oiler by fcheshire

thingiverse

inline bowden oiler

thingiverse

free

Bowden adapter by helkaroui

...bowden adapter by helkaroui

thingiverse

this is a fixed bowden adapter

thingiverse

free

Adventure3 Bowden Clip

...adventure3 bowden clip

thingiverse

adventure3 bowden clip

V2

3d_export

free

Lamp v2

...lamp v2

3dexport

lamp v2 with solar panel

3d_export

$5

hammerhead v2

...hammerhead v2

3dexport

razer hammerhead v2 headphones, modeled in cinema 4d, render in corona

3d_export

$5

manometer v2

...manometer v2

3dexport

3d_export

$5

potato v2

...potato v2

3dexport

turbosquid

$52

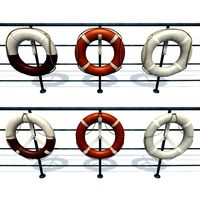

Lifebuoys v2

...squid

royalty free 3d model lifebuoys v2 for download as fbx on turbosquid: 3d models for games, architecture, videos. (1560870)

turbosquid

$2

Mask v2

...turbosquid

royalty free 3d model mask v2 for download as stl on turbosquid: 3d models for games, architecture, videos. (1527741)

turbosquid

free

Flashlight V2

...d

free 3d model flashlight v2 for download as , obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1663559)

turbosquid

$29

Thanos v2

...

royalty free 3d model thanos v2 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1651077)

turbosquid

$29

Titan v2

...d

royalty free 3d model titan v2 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1540228)

turbosquid

$29

Frieza v2

...

royalty free 3d model frieza v2 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1701238)

Extruder

3ddd

$1

Extruded Chair

...extruded chair

3ddd

extruded , tom dixon

inspired by tom dixon extruded chair

turbosquid

$15

Extruded Table

... extruded table for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1634137)

turbosquid

$2

3D Printer Extruder

...d

royalty free 3d model 3d printer extruder for download as on turbosquid: 3d models for games, architecture, videos. (1537359)

turbosquid

$1

Zombie extruded text

...oyalty free 3d model zombie extruded text for download as obj on turbosquid: 3d models for games, architecture, videos. (1322198)

turbosquid

$4

Extruder conical screw

...el extruder conical screw for download as sldpr, ige, and stl on turbosquid: 3d models for games, architecture, videos. (1524433)

turbosquid

$50

3d PRINTER - Extruder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Extruded Table 2

...xtruded table 2 for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1621846)

turbosquid

$10

Maya Extrude Tool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

world earth extrude map

...world earth extrude map

3dexport

3ddd

$1

Simply Elegant Extruded Tree Coffee Table Design

...ble by link studios. the silhouette of a tree is visible at one angle, extruded from the surface to create the support structure.

Basic

3d_export

$5

basic hand

...basic hand

3dexport

basic hand, made in blender

3d_export

$10

Basic coat

...basic coat

3dexport

basic coat<br>arm and waist movement

3ddd

$1

PixMolda Basic Bed

...pixmolda basic bed

3ddd

basic bed , pixellin

pixmolda basic bed by pixellin

3ddd

free

Детский стол Basic

...етский стол basic

3ddd

basic , стол

детский стол для письма basic от производителя moll.

turbosquid

$1

Basic Chair

...urbosquid

royalty free 3d model basic chair for download as on turbosquid: 3d models for games, architecture, videos. (1269713)

turbosquid

$1

Basic Keyboard

...osquid

royalty free 3d model basic keyboard for download as on turbosquid: 3d models for games, architecture, videos. (1298685)

turbosquid

$1

basic table

...urbosquid

royalty free 3d model basic table for download as on turbosquid: 3d models for games, architecture, videos. (1271450)

turbosquid

free

Basic Bandit

...

turbosquid

free 3d model basic bandit for download as blend on turbosquid: 3d models for games, architecture, videos. (1250561)

turbosquid

free

Turret basic

...

turbosquid

free 3d model turret basic for download as blend on turbosquid: 3d models for games, architecture, videos. (1382326)

turbosquid

free

Basic Sword

...urbosquid

royalty free 3d model basic sword for download as on turbosquid: 3d models for games, architecture, videos. (1331031)