Thingiverse

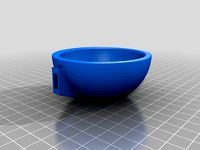

ball valve remix with 1/2 in hose fittings by caj

by Thingiverse

Last crawled date: 3 years, 1 month ago

ball valve remixed normally when i see that a thing does not have a actual picture this means it has not ben printed and there for none of the parts will fit as actual diminutions are not the same as 3d printed parts i run away like the wind because it will take days to remix to make parts fit and work

this thing was as i thought it would be none of the parts fit all parts had to be remixed and reworked for function if the original designer is reading this i upload the concept of the design for demo purposes only

some of the parts was more complex than a 3d printer can print

3d printers can not print rounded o rings they must have sharp edges and the handle had more complexity than a 3d printer could print

so this did take me 2 days to remix but this design makes the work worth while

only parts that need supports and raft is the handle and ball print both of these with a 100% infill "solid"

to put this together the ball and ball butts have to be realy smooth

to make the ball buts smooth i used a round head bolt and took a dremal tool to rough the head up to make it into a round head file for the drill

to make the ball smooth put a nut and bolt through the hole and use the drill and sand paper to smooth and round the surface

then dip all parts in acetone for 2-3 seconds no more than 5 this will make all the parts look like factory parts this is critical for parts that do not leak

use acetone to melt the handle to the ball

the output tubes are made so they will not dry fit so do not worry if they don't this is deliberate use acetone to melt the tube ends to valve parts

also use plumbers grease on the rubber seals and ball and ball buts this will help seal this thing

i have added a rubber washer at the end of this thing it is not there to seal the end it is there to put pressure on the ball and butts to seal those so only tighten the end nut for light pressure one the ball to much and it will break the handle off

i hope the instructions are understandable ??

i will not get upset if you leave me a note saying what the he double tooth picks are you talking about as i have never ben any good at giving instructions ??

i have scowered thingyvers for ball valves i have a idea for a ball valve with way less parts and better seals maby some day i will design and post it but for right now i have made this for my trommel project in progress and all it has to do is work so they are printed and working

this thing was as i thought it would be none of the parts fit all parts had to be remixed and reworked for function if the original designer is reading this i upload the concept of the design for demo purposes only

some of the parts was more complex than a 3d printer can print

3d printers can not print rounded o rings they must have sharp edges and the handle had more complexity than a 3d printer could print

so this did take me 2 days to remix but this design makes the work worth while

only parts that need supports and raft is the handle and ball print both of these with a 100% infill "solid"

to put this together the ball and ball butts have to be realy smooth

to make the ball buts smooth i used a round head bolt and took a dremal tool to rough the head up to make it into a round head file for the drill

to make the ball smooth put a nut and bolt through the hole and use the drill and sand paper to smooth and round the surface

then dip all parts in acetone for 2-3 seconds no more than 5 this will make all the parts look like factory parts this is critical for parts that do not leak

use acetone to melt the handle to the ball

the output tubes are made so they will not dry fit so do not worry if they don't this is deliberate use acetone to melt the tube ends to valve parts

also use plumbers grease on the rubber seals and ball and ball buts this will help seal this thing

i have added a rubber washer at the end of this thing it is not there to seal the end it is there to put pressure on the ball and butts to seal those so only tighten the end nut for light pressure one the ball to much and it will break the handle off

i hope the instructions are understandable ??

i will not get upset if you leave me a note saying what the he double tooth picks are you talking about as i have never ben any good at giving instructions ??

i have scowered thingyvers for ball valves i have a idea for a ball valve with way less parts and better seals maby some day i will design and post it but for right now i have made this for my trommel project in progress and all it has to do is work so they are printed and working

Similar models

thingiverse

free

Check Valve(Remix of UpTime) by AtomiQ

...of 14mm and outer diameter of 19mm. i have stretched this gasket to fit, so you can choose a different one that fits if you want.

thingiverse

free

Mason Jar Dispenser Remix by RollyR

...ioned after a water valve handle and is held on with a stainless steel washer

and 1/4-20 x 1/2" long phillips head cap screw

thingiverse

free

Snowball Fabricator Remix by yatesgd

...original mb part was way too short to even work. i also beefed up the latch at the end of the handle to improve the cup strength.

thingiverse

free

Door Knob to Handle Adaptor

...ead of the ziptie ends up so it wouldn't bother you.

i'll recommend setting more layers of walls than your normal prints.

thingiverse

free

AxeHead-Sealed by rabidninjawombat

...es off the handle, the peas will stay sealed within the axe head.

working on printing on now, will upload pic when its done :d

grabcad

free

Air massage valve for tub/shower hydromassage Revita

...dome.

for the valve printed in abs i first had to remove the plate on the head, necessary for a good adhesion of the first layer

thingiverse

free

dental partial dentures by caj

...as cheep as you might think it is to make your own still way better than $1000 per set as to what you would pay to have them made

thingiverse

free

End Cap for Dyson floor tool by Rouven_26

...inted a replacement part.

the seal is printed in tpu and the main part in petg. however, the seal isn't absolutely necessary.

grabcad

free

Ball Valve DN50 PN40

...mall ball valve with thi most important parts. no seals! i did that to calculate the volume in the valve. so there a no drillings

thingiverse

free

Better handle for Cobra Crossbow by autrion

...e gap 1mm wider and added a ball-snap.

update 09.04.2021: added some more space to the inside of the handle to make it fit better

Caj

3dfindit

free

AFT62-CAJ-NA

...aft62-caj-na

3dfind.it

catalog: yiheda

thingiverse

free

MAN Truck by caj

...man truck by caj

thingiverse

included is the designspark mechanical project file

thingiverse

free

magirus transport truck by caj

...magirus transport truck by caj

thingiverse

magirus-transport-pack-

thingiverse

free

The Simpsons 3d Silhouettes by caj

...the simpsons 3d silhouettes by caj

thingiverse

the simpsons 3d silhouettes

thingiverse

free

Aladdin 3D Silhouettes by caj

...aladdin 3d silhouettes by caj

thingiverse

aladdin 3d silhouettes

thingiverse

free

The Croods 3d Silhouettes by caj

...the croods 3d silhouettes by caj

thingiverse

the croods 3d silhouettes

thingiverse

free

Madagascar 3d Silhouettes by caj

...madagascar 3d silhouettes by caj

thingiverse

madagascar 3d silhouettes

thingiverse

free

puppet Gepetto head and hands by caj

...puppet gepetto head and hands by caj

thingiverse

for making a marionette

thingiverse

free

narrower slide quick release by caj

...narrower slide quick release by caj

thingiverse

remixed for this camera gimble

thingiverse

free

Disney 3d Couples silhouettes by caj

...disney 3d couples silhouettes by caj

thingiverse

disney couples silhouettes

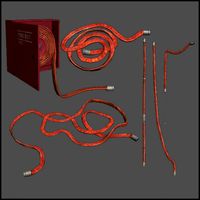

Hose

archibase_planet

free

Hose

...hose

archibase planet

fire-hose fire safety

fire hose cabinet - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$10

hose

...se

turbosquid

royalty free 3d model hose for download as fbx on turbosquid: 3d models for games, architecture, videos. (1479257)

3d_export

$5

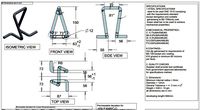

Hose bracket

...hose bracket

3dexport

this file consists of hose bracket 3d model used for tensioning of geo trail mesh along with pdf drawing

archive3d

free

Hose 3D Model

...ire-hose fire safety

fire hose cabinet - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

Hose clamp

...hose clamp

3dexport

turbosquid

$30

Japanese Hose

...free 3d model japanese hose for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1633620)

turbosquid

$39

Spray Hose

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$28

Fire hose

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

vacuum hose

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$6

Fire Hoses

...ow polygonal models, easy to animate. - poly count: 1678 - formats: max /obj /fbx/3ds/dxf - high detail was preserved with 204...

Valve

3d_export

$5

Valve

...valve

3dexport

diverter valve

3d_export

$5

valve

...valve

3dexport

this is a 3d model of a valve available in all formats.

3d_export

free

valve

...valve

3dexport

simple valve 3d model, more free models here:

3d_export

$20

gate valve

...gate valve

3dexport

gate valve

3d_export

$10

stop valve

...stop valve

3dexport

stop valve

3d_export

$5

ball valve

...ball valve

3dexport

ball valve

turbosquid

$14

Valve

...e

turbosquid

royalty free 3d model valve for download as c4d on turbosquid: 3d models for games, architecture, videos. (1217741)

3ddd

$1

valve 02

...valve 02

3ddd

клапан

water valve

3ddd

$1

Valve 01

...valve 01

3ddd

клапан

water valve

turbosquid

$19

Valve

...royalty free 3d model valve for download as ige, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1425806)

Ball

turbosquid

$5

Ball on a Ball

...uid

royalty free 3d model ball on a ball for download as obj on turbosquid: 3d models for games, architecture, videos. (1484719)

archibase_planet

free

Ball

...ball

archibase planet

ball golf ball

ball - 3d model (*.gsm+*.3ds) for 3d visualization.

3d_export

$5

ball

...ball

3dexport

ball

archibase_planet

free

Ball

...ball

archibase planet

ball football soccer ball

ball n100714 - 3d model (*.gsm+*.3ds+*.max) for exterior 3d visualization.

3d_export

$5

ball

...ball

3dexport

soccer ball

archibase_planet

free

Ball

...ball

archibase planet

ball football

ball n100914 - 3d model (*.gsm+*.3ds+*.max) for 3d visualization.

3d_ocean

$5

Snooker Balls

... set balls snooker snooker balls white ball yellow ball

set snooker balls format include : .c4d .3ds .obj build in cinema 4d r13

3d_export

free

ball

...ball

3dexport

this is 3d model ball's

3d_ocean

$2

Soccer Ball

...soccer ball

3docean

ball red and yellow ball red ball soccer ball

a gorgeous red and yellow seamless soccer ball

3d_ocean

$5

Billard Balls

...low poly billiard balls. numbering from 1 to 15 plus the cue ball. each of the balls excluding the cue ball has a 4k texture map.

Remix

turbosquid

$5

MODA Collection Remix Chair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$12

remix yamaha rm1x

...remix yamaha rm1x

3dexport

geometry triangles 15.2k vertices 7.6k pbr no textures 1 materials 1 uv layers yes

3d_ocean

$5

Vray fabric Kvadrat remix green - tileable

...th vray and 3dsmax. high-resolution texture images (2000×2000 px) file included: shader vray 2.40 texture image 3ds max 2011 file

turbosquid

$20

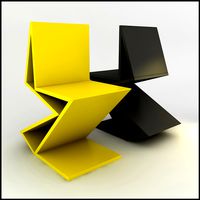

Gerrit Rietveld 1938 Zig Zag Chair Remix

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

multicolored remix parametric table furniture

... fbx, obj, mtl, archive with textures. the model has no glitches. render and materials - vray . without using plugins. good use!

3ddd

$1

Barovier&Toso / Manhattan Remix 7192

... 004293-142405

в коллекции есть люстры 7, 9, 12 рожковые. диаметр соответственный 1000, 1250, 1500 мм.

3ddd

$1

Muuto fiber chair

...grey/grey, dusty green/dusty green, nature/oak, natural white/oak upholstery options remix 183/black, remix 133/grey, remix 643/dusty red leather options black...

3ddd

$1

Barovier&Toso 7190-7195

...7190-7195 3ddd barovier&toso потолочнай люстра фабрики barovier&toso;, коллекция manhattan remix артикул 7190-7195. размеры в inches: 39"...

3d_export

$5

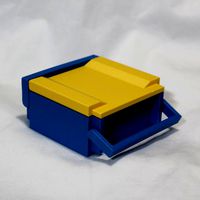

3D Locking Handle Weatherproof Storage Box Container

...handle weatherproof storage box container 3dexport new, improved and remixd! no screws required. print-in-place. weatherproof. parametric. 2 parts. easy...

cg_studio

$49

HTC One Mini 2 Amber Gold3d model

...cell phone mobile cellular super lcd touchscreen touch screen remix amber gold .max .obj .mb .lwo .fbx .c4d .3ds...

Fittings

turbosquid

$21

Fitting

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

fitness

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Fitness

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

fitness

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

fittings

...fittings

3dexport

low poly 3d model for games

3d_export

$5

fittings

...fittings

3dexport

low poly 3d model for game

3d_export

$30

pipe fit

...pipe fit

3dexport

this models basically used for pipe fitting

3d_ocean

$19

Fitting room

...m fitting fitting room furniture interior materials photorealistic restaurant table textured wardrobe

fitting room with textures.

turbosquid

free

Fitness equipment, technogym tools, fitness ball

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

ITRE FIT

...itre fit

3ddd

itre

itre fit, моделировалась по фото. высота 800 мм, диаметр одного - 130 мм.

1

turbosquid

$69

armchairs(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

ring 1+1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

RING 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

house 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Table 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$59

Formula 1(1)

...lty free 3d model formula 1 for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1567088)

design_connected

$11

No 1

...no 1

designconnected

sibast no 1 computer generated 3d model. designed by sibast, helge.

turbosquid

$2

desert house(1)(1)

...3d model desert house(1)(1) for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1055095)

2

design_connected

$11

No 2

...no 2

designconnected

sibast no 2 computer generated 3d model. designed by sibast, helge.

turbosquid

$6

Cliff Rock 2-2

...uid

royalty free 3d model cliff rock 2-2 for download as obj on turbosquid: 3d models for games, architecture, videos. (1619161)

turbosquid

$29

Book variation 2 2

...3d model book variation 2 2 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1366868)

turbosquid

$22

Classic baluster (2) (2)

...assic baluster (2) (2) for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1483789)

turbosquid

$99

Smilodon 2 Pose 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Barrel Barricade 2-2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$6

Wall Trophy (2) (2)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Tire label 2 of 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Кровать, 2 тумбочки, 2 светильника

...кровать, 2 тумбочки, 2 светильника

3ddd

кровать, 2 тумбочки, 2 светильника

нормальное качество

формат 3ds max

без текстур

3ddd

free

Кровать, 2 тумбочки, 2 светильника

...кровать, 2 тумбочки, 2 светильника

3ddd

кровать, 2 тумбочки, 2 светильника

нормальное качество

формат 3ds max

без текстур