Thingiverse

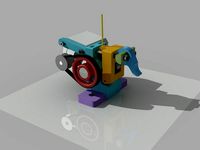

B2D - a few parts modified by dms348

by Thingiverse

Last crawled date: 3 years, 2 months ago

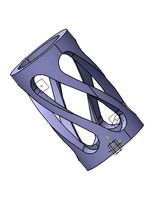

I really love the original design of the B2D feeder. It's compact and excellently designed. There were a few improvements I made on the parts that were derived from my workflow that may be useful to others.

For 1.75mm files:

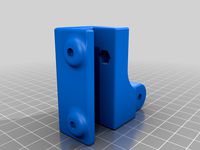

1) Nut and bolt were changed to accommodate a #10 nut with a button head screw

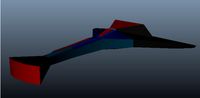

2) Bearing mount and spring housing were modified to have a larger finger pad to more easily squeeze the spring to manually load/unload the length of the bowden tube

3) Two alternative filament "out" parts are uploaded for either a 6mm tube collet/retaining clip, or a 4mm tube push connect fitting that comes with the E3D V6 hot end kit, or also most of the clones available on Amazon (this requires an additional M6 nut)

For 3.00mm files:

4) The in/out and bearing mount files were modified so that the filament run has a smooth curvature with a diameter of ~25cm. I had a lot of trouble using the original files on my Ultimaker Go with the last 25% of a PLA spool because the feeder kept breaking the filament with the straight run

5) The out file is for a 6mm tube collet - the same collet that the OEM Ultimaker 2/2+/Go use on their feeder

Alternative 48Tooth pulley

6) None of the 20Tooth pulleys I bought off Amazon had a 90 degree offset between the two set screws. Instead, most of them were around 98 degrees (out of ~50 pulleys, one or two was 90 degrees, and a few were even 120 degrees offset), so I modified the 48Tooth pulley file for a 98 degree set screw offset.

Alternative "remote" motor location. On my Ultimaker Go, I wanted to move the feeder up towards the top of the printer to help with the filament breaking, but didn't want to re-wire the motor and move it.

7) the "middle" and "top files are modified to allow for a larger belt (in my case, I used a 175 tooth/350mm belt) to run from the 40Tooth part to the 16Tooth pulley on the motor. See a screenshot of the CAD file with the belt run in red for the intended assembly.

8) Included a motor pulley housing

9) Included a spacer/roller part for the belt

Note: these files require additional BOM:

A) 1x longer belt to replace one of the two 130mm belts originally listed

B) 2x 11mm OD 4mm ID roller bearings

C) 1x Large M4 washer

D) 1x 4mm diameter shaft, ~30mm long

For 1.75mm files:

1) Nut and bolt were changed to accommodate a #10 nut with a button head screw

2) Bearing mount and spring housing were modified to have a larger finger pad to more easily squeeze the spring to manually load/unload the length of the bowden tube

3) Two alternative filament "out" parts are uploaded for either a 6mm tube collet/retaining clip, or a 4mm tube push connect fitting that comes with the E3D V6 hot end kit, or also most of the clones available on Amazon (this requires an additional M6 nut)

For 3.00mm files:

4) The in/out and bearing mount files were modified so that the filament run has a smooth curvature with a diameter of ~25cm. I had a lot of trouble using the original files on my Ultimaker Go with the last 25% of a PLA spool because the feeder kept breaking the filament with the straight run

5) The out file is for a 6mm tube collet - the same collet that the OEM Ultimaker 2/2+/Go use on their feeder

Alternative 48Tooth pulley

6) None of the 20Tooth pulleys I bought off Amazon had a 90 degree offset between the two set screws. Instead, most of them were around 98 degrees (out of ~50 pulleys, one or two was 90 degrees, and a few were even 120 degrees offset), so I modified the 48Tooth pulley file for a 98 degree set screw offset.

Alternative "remote" motor location. On my Ultimaker Go, I wanted to move the feeder up towards the top of the printer to help with the filament breaking, but didn't want to re-wire the motor and move it.

7) the "middle" and "top files are modified to allow for a larger belt (in my case, I used a 175 tooth/350mm belt) to run from the 40Tooth part to the 16Tooth pulley on the motor. See a screenshot of the CAD file with the belt run in red for the intended assembly.

8) Included a motor pulley housing

9) Included a spacer/roller part for the belt

Note: these files require additional BOM:

A) 1x longer belt to replace one of the two 130mm belts originally listed

B) 2x 11mm OD 4mm ID roller bearings

C) 1x Large M4 washer

D) 1x 4mm diameter shaft, ~30mm long

Similar models

grabcad

free

Feeder and filament guide for Ultimaker 2

....) of the original feeder but requires additional screws, bearings, bolts, and washers (see cad files for information on sizing).

thingiverse

free

Ultimaker 2 feeder on Ultimaker 1 by vaques

...aker 1 feeder adapter to mount an ultimaker 2 feeder.

i suggest the "alternative um2 feeder - version two" by |robert|.

thingiverse

free

Ultimaker 2 Filament Guide (With bearing) by dirkdirk

...kdirk

thingiverse

an alternative filament guide for the ultimaker 2 with beared wheel.

no more ticking sounds from the feeder...

thingiverse

free

filament guide for bearing - Ultimaker 2 by iNoob

...x-filament.

it works so far! you just need to adjust the robert-feeder a little bit.

printed with 100%infill abs (pla will break)

thingiverse

free

UM reduced extruder for 3.0mm filament by EazyBreezy

... bearing 3x10x4

2x - 625 bearings 5x16x5

5x - m3 nuts

5x - m3x30 screws

1x - m3x12 screw

1x - little spring to the clamp filament

thingiverse

free

Bearing Filament Guide

...3x25mm + nut

1x m4x20mm + nut

1x m5x8mm + t-nut (for mounting to 2020 aluminium profile)

1x 624 bearing (4x13x5mm)

1x 608 bearing

thingiverse

free

Compact Belt Drive Extruder by loco

...) 608 bearing

(1x) 688 bearing

(1x) 8x18mm smooth rod or threaded rod

(2x) m4x50

(2x) m4x20

(1x) m3x30

(3x) m3x10

(4x) m4 hex nut

thingiverse

free

Tiny Flex Extruder Bowden Variant by tkramm

...r-pulley-drive-gear.html

nema 17 motor

624 bearing

2x m3x12

1x m3x25

1x m4x10

4x m3 hex nut

4x m3x16

1x spring 7mm od 30mm length

thingiverse

free

MK8 direct drive extruder 7mm pulley adapter by dasaki

...youtu.be/yt0ruqpbm2u

if you are a curious maker / "tinker" / hacker, have a look at my blog:http://www.therandomlab.com

thingiverse

free

Belt tensioner (for motorized bed K40 by SnakeP)

...ingiverse

parts needed:

3x m4 nuts

2x m4x10 screw

1x m4x14 screw

3x m5x20 screw

3x bearing pulley (https://tinyurl.com/yfcsxp2r)

B2D

thingiverse

free

B2D 2020 mount

... extrusions. i also redesigned the base plate with a larger hole (24mm). the original one did not match nicely my nema 17 motors.

thingiverse

free

B2D Extruder - Dual Flange Bearing Connector

...anges to the b2d.

also, see my other post for the reversed b2d for cultivate3d beast v2 https://www.thingiverse.com/thing:3238664

thingiverse

free

B2D extruder mount for 2020 extrusions by ikarisan

...y 180° and mount the extruder on "the back".

i printed my mount with 30% infill, 4 shells and 4 top and bottom layers.

thingiverse

free

Frame Holder for B2D Extruder AM8 / 2020 or 3030 by peed6687

...ile with m5 screws lying extruderposition

version 6&7 are for 2020 profile for delta printers or lying position on top a 2020

thingiverse

free

B2D Bearing connector dual flange 2.85mm by Rob1992

...ded a small chamfer to the edge of of the hole.

provided are the fusion 360 file i used to make the modifications and a stl file.

thingiverse

free

B2D Extruder - Strong and Silent Bowden Extruder by HeyVye

...stronger base plate.

20/09/2017 - fixed the bowden connector for 2.85 being too tight. adjustable tension for the v3 base plates.

thingiverse

free

YABE Yet Another Belted Extruder

...belted extruder thingiverse its my try to make original b2d more easier to assemble and more stronger. it has:...

3dwarehouse

free

B2D 12

...b2d 12

3dwarehouse

3dwarehouse

free

B2D 24

...b2d 24

3dwarehouse

Few

3d_export

free

ax few polygons

...ax few polygons

3dexport

few polygons ax created by me

turbosquid

free

is a spaceship few resource

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Few Lego gears 3D Model

...few lego gears 3d model

3dexport

lego gears technic

few lego gears 3d model edvarts 58648 3dexport

3d_export

$10

Few kinds of fruits 3D Model

...few kinds of fruits 3d model

3dexport

fruits orange melon lemon mix basket

few kinds of fruits 3d model pumar 50901 3dexport

3d_export

$20

Cancer

...cancer 3dexport river cancer 3d model for 3d printing few ...

3d_export

$5

dagger daga punhal

...dagger daga punhal 3dexport dagger in obj with few polygons and a high precision in...

3d_export

$5

tv table

...tv table 3dexport tv table contains a few books, two speakers. it will beautifuly fill in any...

3d_export

$5

wooden-metal school chair

...chair 3dexport wooden-metal school chair . good quality model, few ...

3d_export

free

3dtext

...from 1-0 upper and lower case letters and a few special...

3d_export

$60

chengdu j-10 c vigorous dragon

...improved version of j-10a, with new electronica and a few external...

Modified

turbosquid

$5

modify car

...bosquid

royalty free 3d model modify car for download as max on turbosquid: 3d models for games, architecture, videos. (1390511)

turbosquid

$35

Soleste modified

...e 3d model soleste modified for download as 3dm, stl, and jpg on turbosquid: 3d models for games, architecture, videos. (1646606)

turbosquid

$35

Screwdriver-Modified

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

APS modified

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Modified skull

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$8

Maruti 800 Modified

...obile engineers. this concept will also helpful to modified car enthusiast. this is made in solidworks & rendered in keyshot.

3d_ocean

$5

Spacecraft with Subdivision Modifier

...raft with subdivision modifier

3docean

fantasy spacecraft vehicle

the model was created in blender using the subdivision modifier

turbosquid

$10

Modified 9mm pistol

...royalty free 3d model modified 9mm pistol for download as fbx on turbosquid: 3d models for games, architecture, videos. (1560956)

3d_export

$10

ak-47 modified

...ak-47 modified

3dexport

turbosquid

$10

modified evo x

...ree 3d model modified evo x for download as obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1461606)

Parts

3d_export

$5

Parts

...parts

3dexport

parts

3d_export

$5

Part

...part

3dexport

part

3d_export

$5

Part

...part

3dexport

machine part

3d_export

$65

Part

...part

3dexport

simple rendering of the scene file

3d_export

$65

Part

...part

3dexport

simple rendering of the scene file

3d_export

$30

fan part

...fan part

3dexport

this is a part of fan of pedastal

3d_export

$10

machine parts

...machine parts

3dexport

3d part modeling work ,contact for 3d work

turbosquid

$59

Mechanical Part

...id

royalty free 3d model mechanical part for download as c4d on turbosquid: 3d models for games, architecture, videos. (1410833)

turbosquid

$17

Road parts

...bosquid

royalty free 3d model road parts for download as 3ds on turbosquid: 3d models for games, architecture, videos. (1192967)

turbosquid

$9

Cutter Parts

...squid

royalty free 3d model cutter parts for download as stl on turbosquid: 3d models for games, architecture, videos. (1220010)