Thingiverse

Auto-Level Mounts for Ender 3, CR-10, Tevo, etc. by Modmike

by Thingiverse

Last crawled date: 3 years ago

New!

1) Added BL Touch mount V2.0

2) Added M8 inductive sensor mount - Big thanks to GroovyDrifter for inspiration!

2) Revised SN04 mount to use easier to find M3 20mm bolts

3) Added detailed instructions.

Notes

I have not personally tested the M8 and BL Touch mounts, let me know how they work for you please.

Sensor Mounts

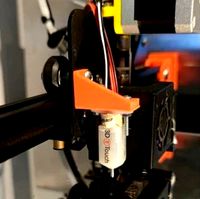

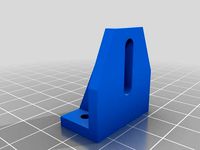

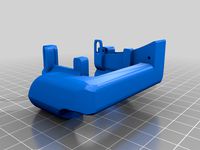

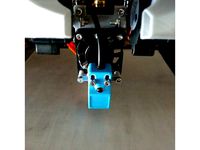

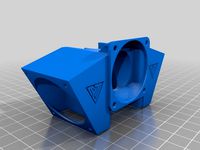

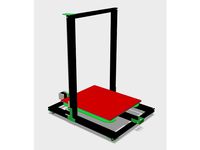

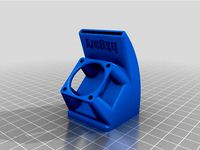

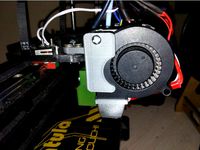

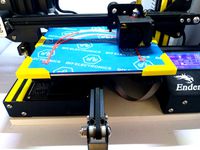

These mounts allow you to add commonly available auto-level sensors to Creality printers such as the CR10, CR10 variants, Ender 2, Ender 3, and Tevo printers that use the stock stock Creality hot end / carriage combinations.

The mounts feature solid mounting points and a wire management clamp along the top to neatly secure and route sensor wires.

All designs are based on the Creality Ender 3 hot end & carriage configuration.

Sensor Selection

I like the SN04 sensors because they are light, robust, and inexpensive. I would avoid the heavier M8 style sensors because their heavier weight could negatively impact print quality, especially at higher speeds.

If you have a glass plate you should get a BL Touch. If you have a thin glass plate on an aluminum bed, an SN04 with an 8mm detection range would probably work.

Required mounting hardware:

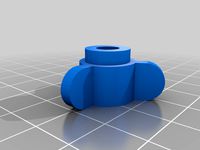

SN04: 2X M3 20mm cap or pan head bolt, 2X M3 washers, & 2X M3 Nylock nuts, regular M3s will do in a pinch but will loosen with vibration

BL Touch: 2X M3 10mm cap or pan head bolt. 2X M3 Nylock nuts, 2X M3 washers to shim if necessary, regular M3 nuts will do in a pinch but will loosen with vibration

M8: 1X M3 10mm or 12mm cap or pan head bolt & 1X M3 Nylock nut, regular M3s will do in a pinch but will loosen with vibration.

Sensor performance

While some sensors can work on 5 volts, their minimum input voltage is usually 6V. Using only 5 volts degrades accuracy and shortens detection range, which is a problem if you are using a glass plate.

I highly recommend you power your sensor with 12V or 24V by directly connecting it to your controllers power input terminals. The Ender 3 has a 24V power supply, I am not sure about other Creality printers but they are typically 12V, which also works well.

Firmware

You will need to install a new version of Marlin to enable auto-level capability to your printer. It can be a chore becasue Creality did not install a boot loader. Persevere becasue there are many advantages such as:

1) Adding auto level cpability

2) Adding critical thermal runaway protection to prevent fires

3) Adding useful LCD menus such as bed corner leveling

4) Geting the latest open source version of Marlin and all it's

additional features

5) Most importantly, getting full control of your printer!

I recommend you install Marlin 2.0.x bug fix. Marlin version 1.19 will be the last version for the 1 series. You can download it by going to the following URL and clicking on the "Clone or Download" button, in the upper right hand corner of the page. Select "Download Zip" to download.

https://github.com/MarlinFirmware/Marlin/tree/bugfix-2.0.x

Version 2.0.x requires Platform IO, it does not compile with Arduino IDE. I know this is a real drag but as I said, 1.19 is the end of that branch. If you are ok with 1.19 and familiar with Arduino IDE, then by all means stick with that.

If you want to stay current, you will need to install Platform IO and Atom. Now c'mon, are you a maker or what?!

https://www.letscontrolit.com/wiki/index.php/Tutorial_Install_Platformio

It works great on Mac also! By the way, try to stay away from custom vendor versions provided. They may take up valuable memory you can't spare have trail behind the official version.

Here are a few great video tutorials. I prefer the USBAsp method but most people seem to prefer the Arduino method.

How to flash firmware with USBAsp:

https://www.youtube.com/watch?v=AQX_AEdXqt4

How to flash firmware with an Arduino board:

https://www.youtube.com/watch?v=QWwtbmg_AxQ

How to configure Marlin to fit in limited memory:

https://www.youtube.com/watch?v=2TrGeL8ZdGU&t=18s

Installation

If you are powering the sensor with anything more than 5V (and you really should be), you will need to reduce the sensors signal wire output voltage.

WARNING!

If you do not put a voltage divider or Schottky diode on the sensor's output wire, you WILL BLOW YOUR BOARD!

I initially tried a Voltage divider but they can be tricky to setup becasue most modern sensors already include a 10K pulldown resistor in their circuit. Worse still, they can heat up quite a bit, especially at 24V.

To simplify installation and better protect your controller board, I recommend using a commonly available 1N4148 30V (or more) Schottkey barrier diode. It will stop any current from flowing to your boards signal pin and destroying it. An added benefit is that most diodes fail in the open position, further protecting your board.

I ended up using a Bat85,113 becasue it's what I had on hand.

Wiring

What follows is for the SN04 and M8, the BL-Touch works using the servo pin. Please refer to it's instructions for wiring.

First, make sure you have the right wiring colors for your particular sensor. My color codes may not be the same as yours, although most of them seem similar.

Refer to the included schematic and make sure you have it handy to refer back to easily.

Strip the wires and connect as follows:

Vcc (typically brown) goes to the positive terminal of your power source, such as power supply.

Ground (typically blue, yes I know pretty weird and counter intuitive) goes to the ground (-) of your power source.

Signal (typically black, seriously? What the heck were they thinking?) goes to the diode side with the black stripe. The other end of the diode goes to the signal pin of your controllers Z end stop connector.

I highly recommend you solder the diode to the signal wire and crimp a dupont connector on the other end of the diode for security's sake. If the wire comes loose ,you could have a nice bed crash, don't ask me how I know!

Checking your work

Before connecting the signal wire to your controller, power up and check the amperage at the end of the diode going to the signal pin, it should be 0. If not, you wired it backwards or the diode is shorted.

Now set your multimeter to DC Volts and check the voltage at the signal pin. You might be surprised to see 24V or 12V (voltage will be equal to the power source you used to drive the sensor) coming out of the diode.

This is normal and expected. The diode stops current (amps) not voltage from flowing to the sensor pin, thereby perfectly protetcing your board.

The best way to figure out which of the 2 or 3 pins on your Z endstop is the signal pin, find the schematics. 3 pin connectors typically have the signal pin in the middle, as per typical Ramps boards.

If you can't find the conector, use a multi tester to test each pin. If you get 5V on a 2 pin connector then the other pin is signal. DO NOT connect to 5V.

Sensor offsets

You will need to set the probe's physical distance from the nozzle in Marlin so that it knows where the probe is. Set the X & Y offsets according to your probe.

Sensor #define SENSOR_LEFT #define SENSOR_Front

SN04 -40.6 -7.5

BL Touch -40.2 -11.5

M8 -40.2 -3.5

I would also enable safe homing at the centre of the bed to prevent head crashes.In Marlin:

define Z_SAFE_HOMING

The final and MOST CRITICAL step is to determine the Z offset. For some reason this step seems to confuse people the most. There are a multitude of ways to do this and some tutorials are overly complicated, or even incorrect. You do not need to heat the bed for the offset calculation.

The Z offset is the physical distance between the nozzle and the probes detection point. This is usally a negative number. I recommend you do not store this in firmware becasue it can change after a nozzle change, head crash, etc.

From the terminal of your choice, pronterface, S3D or whatever, connect to your board and send the following G-Codes to your printer:

1) M851 Z0 - Makes sure offset is clear

2) G28 - Home

3) G1 Z0 - to make sure head is at true 0

4) M211 S0 - Disable software endstops

5) From the LCD, go to prepare, move Z axis, .1mm

6) Use a piece of paper to adjust height by lowering head

(turn knob left)

7) When the proper height is achieved, read the number on the

display, we will use -.8 for this example. If your value is

higher than 1.2, lower your sensor a little and restart.

8) M851 Z-.8

9) M500 to save

10) M501 to load

11) M2111 S1 - Restore software endstops

12) Exit out of LCD menu back to first screen

Lets double check our work:

13) G28 - Home printer

14) G1 Z0

15) Now test your paper again.

You are done!

1) Added BL Touch mount V2.0

2) Added M8 inductive sensor mount - Big thanks to GroovyDrifter for inspiration!

2) Revised SN04 mount to use easier to find M3 20mm bolts

3) Added detailed instructions.

Notes

I have not personally tested the M8 and BL Touch mounts, let me know how they work for you please.

Sensor Mounts

These mounts allow you to add commonly available auto-level sensors to Creality printers such as the CR10, CR10 variants, Ender 2, Ender 3, and Tevo printers that use the stock stock Creality hot end / carriage combinations.

The mounts feature solid mounting points and a wire management clamp along the top to neatly secure and route sensor wires.

All designs are based on the Creality Ender 3 hot end & carriage configuration.

Sensor Selection

I like the SN04 sensors because they are light, robust, and inexpensive. I would avoid the heavier M8 style sensors because their heavier weight could negatively impact print quality, especially at higher speeds.

If you have a glass plate you should get a BL Touch. If you have a thin glass plate on an aluminum bed, an SN04 with an 8mm detection range would probably work.

Required mounting hardware:

SN04: 2X M3 20mm cap or pan head bolt, 2X M3 washers, & 2X M3 Nylock nuts, regular M3s will do in a pinch but will loosen with vibration

BL Touch: 2X M3 10mm cap or pan head bolt. 2X M3 Nylock nuts, 2X M3 washers to shim if necessary, regular M3 nuts will do in a pinch but will loosen with vibration

M8: 1X M3 10mm or 12mm cap or pan head bolt & 1X M3 Nylock nut, regular M3s will do in a pinch but will loosen with vibration.

Sensor performance

While some sensors can work on 5 volts, their minimum input voltage is usually 6V. Using only 5 volts degrades accuracy and shortens detection range, which is a problem if you are using a glass plate.

I highly recommend you power your sensor with 12V or 24V by directly connecting it to your controllers power input terminals. The Ender 3 has a 24V power supply, I am not sure about other Creality printers but they are typically 12V, which also works well.

Firmware

You will need to install a new version of Marlin to enable auto-level capability to your printer. It can be a chore becasue Creality did not install a boot loader. Persevere becasue there are many advantages such as:

1) Adding auto level cpability

2) Adding critical thermal runaway protection to prevent fires

3) Adding useful LCD menus such as bed corner leveling

4) Geting the latest open source version of Marlin and all it's

additional features

5) Most importantly, getting full control of your printer!

I recommend you install Marlin 2.0.x bug fix. Marlin version 1.19 will be the last version for the 1 series. You can download it by going to the following URL and clicking on the "Clone or Download" button, in the upper right hand corner of the page. Select "Download Zip" to download.

https://github.com/MarlinFirmware/Marlin/tree/bugfix-2.0.x

Version 2.0.x requires Platform IO, it does not compile with Arduino IDE. I know this is a real drag but as I said, 1.19 is the end of that branch. If you are ok with 1.19 and familiar with Arduino IDE, then by all means stick with that.

If you want to stay current, you will need to install Platform IO and Atom. Now c'mon, are you a maker or what?!

https://www.letscontrolit.com/wiki/index.php/Tutorial_Install_Platformio

It works great on Mac also! By the way, try to stay away from custom vendor versions provided. They may take up valuable memory you can't spare have trail behind the official version.

Here are a few great video tutorials. I prefer the USBAsp method but most people seem to prefer the Arduino method.

How to flash firmware with USBAsp:

https://www.youtube.com/watch?v=AQX_AEdXqt4

How to flash firmware with an Arduino board:

https://www.youtube.com/watch?v=QWwtbmg_AxQ

How to configure Marlin to fit in limited memory:

https://www.youtube.com/watch?v=2TrGeL8ZdGU&t=18s

Installation

If you are powering the sensor with anything more than 5V (and you really should be), you will need to reduce the sensors signal wire output voltage.

WARNING!

If you do not put a voltage divider or Schottky diode on the sensor's output wire, you WILL BLOW YOUR BOARD!

I initially tried a Voltage divider but they can be tricky to setup becasue most modern sensors already include a 10K pulldown resistor in their circuit. Worse still, they can heat up quite a bit, especially at 24V.

To simplify installation and better protect your controller board, I recommend using a commonly available 1N4148 30V (or more) Schottkey barrier diode. It will stop any current from flowing to your boards signal pin and destroying it. An added benefit is that most diodes fail in the open position, further protecting your board.

I ended up using a Bat85,113 becasue it's what I had on hand.

Wiring

What follows is for the SN04 and M8, the BL-Touch works using the servo pin. Please refer to it's instructions for wiring.

First, make sure you have the right wiring colors for your particular sensor. My color codes may not be the same as yours, although most of them seem similar.

Refer to the included schematic and make sure you have it handy to refer back to easily.

Strip the wires and connect as follows:

Vcc (typically brown) goes to the positive terminal of your power source, such as power supply.

Ground (typically blue, yes I know pretty weird and counter intuitive) goes to the ground (-) of your power source.

Signal (typically black, seriously? What the heck were they thinking?) goes to the diode side with the black stripe. The other end of the diode goes to the signal pin of your controllers Z end stop connector.

I highly recommend you solder the diode to the signal wire and crimp a dupont connector on the other end of the diode for security's sake. If the wire comes loose ,you could have a nice bed crash, don't ask me how I know!

Checking your work

Before connecting the signal wire to your controller, power up and check the amperage at the end of the diode going to the signal pin, it should be 0. If not, you wired it backwards or the diode is shorted.

Now set your multimeter to DC Volts and check the voltage at the signal pin. You might be surprised to see 24V or 12V (voltage will be equal to the power source you used to drive the sensor) coming out of the diode.

This is normal and expected. The diode stops current (amps) not voltage from flowing to the sensor pin, thereby perfectly protetcing your board.

The best way to figure out which of the 2 or 3 pins on your Z endstop is the signal pin, find the schematics. 3 pin connectors typically have the signal pin in the middle, as per typical Ramps boards.

If you can't find the conector, use a multi tester to test each pin. If you get 5V on a 2 pin connector then the other pin is signal. DO NOT connect to 5V.

Sensor offsets

You will need to set the probe's physical distance from the nozzle in Marlin so that it knows where the probe is. Set the X & Y offsets according to your probe.

Sensor #define SENSOR_LEFT #define SENSOR_Front

SN04 -40.6 -7.5

BL Touch -40.2 -11.5

M8 -40.2 -3.5

I would also enable safe homing at the centre of the bed to prevent head crashes.In Marlin:

define Z_SAFE_HOMING

The final and MOST CRITICAL step is to determine the Z offset. For some reason this step seems to confuse people the most. There are a multitude of ways to do this and some tutorials are overly complicated, or even incorrect. You do not need to heat the bed for the offset calculation.

The Z offset is the physical distance between the nozzle and the probes detection point. This is usally a negative number. I recommend you do not store this in firmware becasue it can change after a nozzle change, head crash, etc.

From the terminal of your choice, pronterface, S3D or whatever, connect to your board and send the following G-Codes to your printer:

1) M851 Z0 - Makes sure offset is clear

2) G28 - Home

3) G1 Z0 - to make sure head is at true 0

4) M211 S0 - Disable software endstops

5) From the LCD, go to prepare, move Z axis, .1mm

6) Use a piece of paper to adjust height by lowering head

(turn knob left)

7) When the proper height is achieved, read the number on the

display, we will use -.8 for this example. If your value is

higher than 1.2, lower your sensor a little and restart.

8) M851 Z-.8

9) M500 to save

10) M501 to load

11) M2111 S1 - Restore software endstops

12) Exit out of LCD menu back to first screen

Lets double check our work:

13) G28 - Home printer

14) G1 Z0

15) Now test your paper again.

You are done!

Similar models

thingiverse

free

BL-Touch sensor mount for Ender 3 and CR10 by Tommyskyywalker

... the ender3 (and therefore also the cr-10 and other creality printers that use the same hot end design).

just print and have fun!

thingiverse

free

BL-Touch sensor mount for Ender 3 and CR10 ##UPDATED-VERSION## by Tommyskyywalker

...the ender3 (and therefore also the cr-10 and other creality printers that use the same hot end design).

just print and have fun!

thingiverse

free

Replicator 2X Fan duct BL Touch Mount by jin0711

...licator 2x cooling fan duct by worksbysolo bl touch mount remix

the xy offset value from tool0 to bl touch is ( 14.50, -49.32 ).

thingiverse

free

Simple Brackets for BL Touch Sensor (Wade) by tomskidoodle

...gs / wade extruder, but can be used anywhere. the rear mount bracket is slightly offset to allow for hot end cables at the rear.

thingiverse

free

Wanhao Duplicator 6 PLUS BLTouch Sensormount by zauberflo

...9 and 29.

on j10, ctl is pin 10, botton is pin 11. on j11, ac-det is on pin a9. tx and rx goes to txd2(pin 16) and rxd2 (pin 17).

thingiverse

free

Creality Ender 3 Pro Hero Me

...er-series-p00287p1.html )

mounting offsets for bltouch sensor: x = -38.15, y = -7.2

many thanks to the authors of original parts.

thingiverse

free

M8 inductive sensor hot-swap for Adjustable BL-Touch mount

...e (or any m8 size sensor) in place of bltouch mount.

other files can be downloaded from https://www.thingiverse.com/thing:3148733

thingiverse

free

E3D Hemera for Creality with TriangleLab Filament Sensor

...quot;#define nozzle_to_probe_offset { -43, -1, 0 }"

you will need 2 m3 x 30 screws and m3 nuts to mount the filament sensor.

thingiverse

free

SN08-N/SN04-N Sensor Mount (on 40mm Fan) Flsun Prusa I3 2017 by lembasbrot

...ider adjusting your offset values and auto bed leveling limits accordingly to avoid any collisions.

y-offset: -55mm

x-offset: 0mm

grabcad

free

Creality Ender 3 Pro BL Touch Mount

...built into the design. this is gen 1, i am working on other designs to enhance cooling with stock ender parts and mount your blt.

Modmike

thingiverse

free

AUSDOM AW335 Shroud Pi Cam Mount by Nmiller77505

...shroud pi cam mount by nmiller77505 thingiverse remixed from modmike#39;s ender 3 pi cam model. retrofitted to mount an...

thingiverse

free

Camera holder for Waveshare 10299 RPi Camera (F) by Dream_Design_Print

...printing. this holder is made for the holder from modmike ...

thingiverse

free

Creality Ender 3 Pi Cam Mount by Modmike

...ase note that i've specifically allowed this derivative and exempted it from the restrictions of my creative commons license.

thingiverse

free

Ender 3 X Axis GoPro Mount by SynJa

...by synja thingiverse this is a simple remix of modmike#39;s pi mount to accept gopro style prong mounts, i.e....

thingiverse

free

CR10V2 X-axis mount for picam v2 by schmooot

...me do it for some reason. so sorry modmike. https://www.thingiverse.com/modmikedesigns the arm has a flat spot right near the...

thingiverse

free

Creality Ender 3 Pi Cam Mount (with Neopixel Stick bracket) by 877

...bracket) by 877 thingiverse description this is remix of modmike great design found here: https://www.thingiverse.com/thing:2886101 i added support for...

thingiverse

free

Creality Ender 3 Pi Cam Extender Arm by SFLeBrun

...with the creality ender 3 pi cam mount by modmike which works good on my ender 3 pro with...

thingiverse

free

Pi Camera Arm With Cable Chain Clip

...was used from this file-https://www.thingiverse.com/thing:3781016 or you can use modmike camera case found here - https://www.thingiverse.com/thing:2886101 my file is...

thingiverse

free

Creality Ender / CR-6 SE Octopi Touchscreen Case & Mount by MaximumDude

...the pi camera body and mounting arm from michael (modmike triffon's creality ender 3 pi cam mount which fit...

Tevo

thingiverse

free

TEVO Logo by limwenyao

...verse

tevo logo - for customizing your builds to look cooler with the tevo logo! pdf version is editable with adobe illustrator.

thingiverse

free

Tevo Tornado e3d Tevo Flash Style fan Mount by DemolitionX

...an mount by demolitionx

thingiverse

just messing around and made a tevo flash style fan mount for the e3d v6 on the tevo tornado

thingiverse

free

BODEN TUBE CLAMP FOR TEVO TARANTULA PRO AND TEVO TORNADO

... and tevo tornado

thingiverse

bodwen tube clamp. printable adjustable tension clamp for tevo tarantula pro and tornado extruder.

thingiverse

free

TEVO Tornado Model by JMDesigns

...tevo tornado model by jmdesigns

thingiverse

tevo tornado model

thingiverse

free

Tevo Tarantula FanDuct by hkgary_g

...tevo tarantula fanduct by hkgary_g

thingiverse

fanduct for tevo tarantula

thingiverse

free

FAN TEVO TARANTULA by llprokall

...fan tevo tarantula by llprokall

thingiverse

fan tevo tarantula

thingiverse

free

Tevo Tarantula filament by Xbertus

...tevo tarantula filament by xbertus

thingiverse

suport for filamente tevo tarantula

thingiverse

free

TEVO Top Brackets by _Godoy_

...tevo top brackets by _godoy_

thingiverse

top brackets for tevo tarantula

thingiverse

free

Tevo Tarantula Spool Holder

...tevo tarantula spool holder

thingiverse

strong spool holder for tevo tarantula

thingiverse

free

tevo tarantula spacer by poundskinnyboy

...tevo tarantula spacer by poundskinnyboy

thingiverse

it's a tevo tarantula spacer

Cr

turbosquid

$15

Creazioni CR-673 CR-4461

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Ravak CR 055.00

...ravak cr 055.00

3ddd

ravak , смеситель

ravak cr 055.00

turbosquid

$100

CR-002

...

turbosquid

royalty free 3d model cr-002 for download as stl on turbosquid: 3d models for games, architecture, videos. (1686037)

3ddd

$1

Ravak CR 012.00

...ravak cr 012.00

3ddd

ravak , смеситель

смеситель ravak cr 012.00

3ddd

free

Консоль CR Currin

...ь , cr currin

консоль cr currin

ширина - 1675 мм

глубина - 510 мм

общая высота - 810 мм

3ddd

$1

CR 39444

...0

диаметр: 100

тип патрона: gu5,3 gu10

количество ламп: 1

мощность: 35w

цвет: золото хрусталь

материал: металл хрусталь exclusive

3d_ocean

$89

Honda CR-Z

...www.youtube.com/watch?v=rrbb4d4lypk ` he honda cr-z‘s exterior styling is formed around a “one-motion wedge” concept with a lo...

3ddd

$1

Creazoni / STEFY CR-8901

...creazoni / stefy cr-8901

3ddd

creazoni

creazioni stefy cr-8901

turbosquid

$60

Chain-CR-001

...squid

royalty free 3d model chain-cr-001 for download as stl on turbosquid: 3d models for games, architecture, videos. (1680536)

turbosquid

$99

Honda CR-Z

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Ender

3ddd

$1

Enders / Elegance

...enders / elegance

3ddd

обогреватель

уличный газовый обогреватель enders elegance

высота: 2200 мм

3d_export

free

ender 3 frame cavity covers

... of the creality ender 3 - makes it look a bit more attractive it just slides into the open channels of the aluminium framework

turbosquid

$1

pen support for ender 3

...y free 3d model pen support for ender 3 for download as blend on turbosquid: 3d models for games, architecture, videos. (1611282)

3d_ocean

$9

Ender Dragon Minecraft

...ojang obj poly videogames

ender dragon minecraft created with cinema 4d r15 formats included: max 2013 – fbx 2012 – c4d r15 – obj

3d_export

free

Creality ender enclosure webcam mount

...e creality enclosure. sure is better than a tripod. change it up if it helps. i printed pla with 50% infill on my dd ender 3 pro.

3d_export

free

ender 3 enclosure corners

...er corners and 4 upper corners, using 25mmx25mm angled aluminium pieces that gets covered on inside of the frame with plexiglass

3d_export

free

ender 3 3d print bed clips

...ed + normal aluminium bed frame of the creality ender 3 = 6mm (b) these clips are designed for glass plate + aluminium bed = 4mm

3d_export

$5

GRUMPY CAT

...grumpy cat 3dexport grumpy cat to print in ender ...

3d_export

$5

Logs fire

...with one multi material for corona and vray r ender. albedo, normal, uvmap, roughness format jpg 4096x4096 models:...

3d_export

$42

excavator

...is the original size. 0.12 mm printing surface creality ender5 ...

Auto

3d_export

$5

auto

...auto

3dexport

auto

3ddd

$1

auto

...auto

3ddd

max7

turbosquid

$69

AUTO

...to

turbosquid

royalty free 3d model auto for download as obj on turbosquid: 3d models for games, architecture, videos. (1453538)

3d_export

$10

Auto

...auto

3dexport

3d_export

free

auto

...auto

3dexport

3ddd

$1

Auto posters

...auto posters

3ddd

машина

auto posters

turbosquid

$50

auto

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$28

Auto

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

auto

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

auto

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Level

design_connected

$11

Levels

...levels

designconnected

one nordic levels computer generated 3d model. designed by form us with love.

design_connected

$7

Level

...level

designconnected

zanotta level shelves and storage computer generated 3d model. designed by arik levy.

turbosquid

$29

level

...ty free 3d model level for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1272856)

turbosquid

$1

level

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Mario level

...mario level

3dexport

mario level low quality for fun videos

3ddd

$1

LEVELS OF DISCOVERY

...етская мебель "levels of discovery". rab10003 princess mini rocker

кресло-качалка (мини) "принцесса навсегда"

3d_export

$19

level design

...level design

3dexport

you can use this design (level design) in your own game.

turbosquid

$60

Desert level

...squid

royalty free 3d model desert level for download as fbx on turbosquid: 3d models for games, architecture, videos. (1208131)

turbosquid

$15

Transit Level

...quid

royalty free 3d model transit level for download as max on turbosquid: 3d models for games, architecture, videos. (1158112)

turbosquid

$14

Districts Level

...id

royalty free 3d model districts level for download as max on turbosquid: 3d models for games, architecture, videos. (1408410)

Etc

3ddd

free

Oranges, mandarins etc.

...син , мандарин , фрукты

oranges, mandarins etc.

3ddd

$1

Bowls, dishes etc.

...bowls, dishes etc.

3ddd

посуда , сервиз

bowls, dishes etc. for contemporary kitchens

turbosquid

$30

theater for( cinema, collage, etc.)

...model theater for( cinema, collage, etc.) for download as fbx on turbosquid: 3d models for games, architecture, videos. (1258736)

3d_export

$40

stage light ETC 3D Model

...am shaper lighting concert music electric studio set movie lens lamp zoom reflector

stage light etc 3d model braz 7043 3dexport

3d_ocean

$8

Realistic TV/Blu-ray/DVD etc. remote

...3docean

blu-ray dvd realistic remote technology television tv

this is a model of a television, dvd, blu-ray, etc. remote control.

3d_ocean

$12

Desk accessories (pen, eraser, etc.)

...ats included: .c4d, .obj – the model contains 58530 polygons – not rigged, scene setup / lighting from the preview, are included.

3d_export

$5

kitchen assets - pots pans etc

...fferent material as they have a separate material id for the ability to personalise or have alternate lid types e.g. foggy glass.

3d_export

$15

bentley continental 2015 with all surroundings complete with lightmaterials etc

...als etc

3dexport

in the car model, each part as a separate object, which allows you to make animation or destruction in the game

3d_export

$12

set of 73 parts bolts nuts washers nails etc

...red with eevee. the wood texture is not included. all the other materials are procedural pbr configured in the native blend file.

3ddd

free

Suitcase

...suitcase 3ddd suitcase plastic suitcase for tools etc ...

10

turbosquid

$25

10

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

a-10

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

EX 10

...ex 10

3ddd

samsung , фотоаппарат

ex 10

3ddd

$1

Bed 10

...bed 10

3ddd

постельное белье

bed 10

evermotion

$25

Scene 10 Archinteriors vol. 10

...dering design interior

take a look at textured and shadered visualization scene ready to be rendered.. evermotion 3d models shop.

3ddd

$1

Curtains 10

...curtains 10

3ddd

curtains 10

3ds max 2011,fbx + textures

polys: 100355

3ddd

free

PLANTS 10

...plants 10

3ddd

цветок , горшок

plants 10,, with 3 different color planter boxes

turbosquid

$24

Chandelier MD 89310-10+10 Osgona

... chandelier md 89310-10+10 osgona for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1218762)

design_connected

$29

Nuvola 10

...nuvola 10

designconnected

gervasoni nuvola 10 computer generated 3d model. designed by navone, paola.

design_connected

$22

Kilt 10

...kilt 10

designconnected

zanotta kilt 10 computer generated 3d model. designed by progetti, emaf.

Mounts

3d_export

free

mounting bracket

...the part of a hinge, handle or latch that mounts the hardware to a cabinet. mounting plates make it...

turbosquid

$2

MOUNTING

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mounts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mount Fuji

...fuji

turbosquid

free 3d model mount fuji for download as obj on turbosquid: 3d models for games, architecture, videos. (1579977)

3d_export

$5

Headphone mount LR

...headphone mount lr

3dexport

headphone mount l+r

turbosquid

$39

Mount rainier

...quid

royalty free 3d model mount rainier for download as fbx on turbosquid: 3d models for games, architecture, videos. (1492586)

turbosquid

$5

pipe mounting

...quid

royalty free 3d model pipe mounting for download as obj on turbosquid: 3d models for games, architecture, videos. (1293744)

turbosquid

$3

Mounting Tires

...uid

royalty free 3d model mounting tires for download as fbx on turbosquid: 3d models for games, architecture, videos. (1708511)

3d_export

$5

Magnetic GoPro Mount

...pro mount

3dexport

cool magnetic mount for gopro. allows you to mount the camera on flat metal surfaces and get exclusive shots.

turbosquid

$5

Stone Mount

...ty free 3d model stone mount for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1370306)

3

turbosquid

$10

Mountain Bike 3 -3 of 3

...model mountain bike 3 (#3 of 3) for download as fbx and blend on turbosquid: 3d models for games, architecture, videos. (1438752)

turbosquid

$6

Rock 3-3

...urbosquid

royalty free 3d model rock 3-3 for download as obj on turbosquid: 3d models for games, architecture, videos. (1628065)

turbosquid

$29

Books 150 pieces 3-3-3

...books 150 pieces 3-3-3 for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1384033)

turbosquid

$3

Genesis 3 Clothing 3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

hinge 3

...hinge 3

3dexport

hinge 3

3ddd

$1

Розетка 3

...розетка 3

3ddd

розетка

розетка 3

turbosquid

$50

is-3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Mountain Bike 3 -2 of 3

...model mountain bike 3 (#2 of 3) for download as fbx and blend on turbosquid: 3d models for games, architecture, videos. (1438750)

turbosquid

$10

Mountain Bike 1 -3 of 3

...model mountain bike 1 (#3 of 3) for download as fbx and blend on turbosquid: 3d models for games, architecture, videos. (1438743)

3d_export

$5

3 CATS

...3 cats

3dexport

3 cats pen holder