GrabCAD

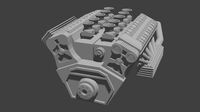

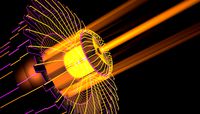

ARCOG Rotary Engine for SIADOR Cycle (RP)

by GrabCAD

Last crawled date: 1 year, 11 months ago

(Rapid Prototyping entry)

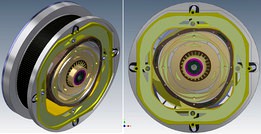

Here is an example of a constant- 3:4 angular-speed-ratio gear train in which the complex involute or epicycloid is reduced into (or replaced with) two simpler interdependent circular arcs, one for the tooth/cog mating surfaces and the other for the compensating arc path of a wobbling gear center/hub. The featured assembly is a proposed in-wheel propulsion system.

ARCOG is a contraction of “ARC COG” (to denote the cog perfectly circular arc feature as opposed to approximate arc of conventional gear), as well as of three-worded, more definitive phrase “ARea-COntact Gerotor”. (“The word ‘gerotor’ was coined by scholar Myron Hill, and is a contraction of the two words GEnerated ROTOR. Simply put, it means that one of the components is formed (generated) by the shape of the other.” Ref: http://www.gerotor.net/about_gerotors.asp ). Also, ARCOG is an acronym of “Alternating-Rotational-Centerpoints Orbital Gyration” and “Axes of Rotation in Cyclic Orbital Gyration” as its rotor specifically rotates alternately in four axes equidistant around the center of gyration. (SIADOR Cycle likewise means Stratified Introduction, Accumulation and Distension Orbital Reverberation Cycle, of which the detail is virtually proprietary.)

There are two pairs of primary gear-train design (with the four-toothed internal gears rotating slower than their three-toothed external mating gears, akin to conventional gearing system) as well as two more-extraordinary pairs of secondary gear-train design (with the three-toothed internal gears rotating 1 1/3 or 4/3 the speed of their smaller, four-toothed external, mating gears): In total, there are eight gears in this assembly with only three relative gear movements as they are grouped into one-, three- and four-geared components. (Take note: One ring body may constitute both internal and external gears in its corresponding inner and outer features.)

This configuration has a function similar to conventional gerotor, yet its primary gear-train design has a nomenclature that closely resembles to that of ordinary gear as its teeth are visually close to that of jagged spur-gear pump than to rounded gerotor pump. Furthermore, what makes this assembly uniquely distinctive is the area-contact sealing provided by the sliding mating surfaces (including those of secondary gear-train design) as opposed to rolling line-contact mating surfaces of conventional gears, such that this makes it ideal for a more successful and profound engine application. Aside from its Guinness World Records bid for a constant-speed-ratio-profile parallel gear train with highest torque capacity, its unique kinematic characteristics also make it possible to device a far more efficient thermodynamic cycle ever.

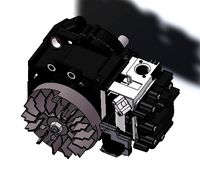

The side benefits of this configuration include a very compact and automatic Infinitely-Variable Transmission with reverse action and without the use of conventional gearing system (or with the use of uniquely-inspired gear-train system that pushes the envelope of what’s deemed possible).

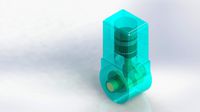

Finally, Prince Piston will kneel down on his journal before a steaming Miss Dainty magically twirling between her opposing hula hoops.

For further info of the rotary engine, visit http://rotaryenginephilippines.blogspot.com/

Here is an example of a constant- 3:4 angular-speed-ratio gear train in which the complex involute or epicycloid is reduced into (or replaced with) two simpler interdependent circular arcs, one for the tooth/cog mating surfaces and the other for the compensating arc path of a wobbling gear center/hub. The featured assembly is a proposed in-wheel propulsion system.

ARCOG is a contraction of “ARC COG” (to denote the cog perfectly circular arc feature as opposed to approximate arc of conventional gear), as well as of three-worded, more definitive phrase “ARea-COntact Gerotor”. (“The word ‘gerotor’ was coined by scholar Myron Hill, and is a contraction of the two words GEnerated ROTOR. Simply put, it means that one of the components is formed (generated) by the shape of the other.” Ref: http://www.gerotor.net/about_gerotors.asp ). Also, ARCOG is an acronym of “Alternating-Rotational-Centerpoints Orbital Gyration” and “Axes of Rotation in Cyclic Orbital Gyration” as its rotor specifically rotates alternately in four axes equidistant around the center of gyration. (SIADOR Cycle likewise means Stratified Introduction, Accumulation and Distension Orbital Reverberation Cycle, of which the detail is virtually proprietary.)

There are two pairs of primary gear-train design (with the four-toothed internal gears rotating slower than their three-toothed external mating gears, akin to conventional gearing system) as well as two more-extraordinary pairs of secondary gear-train design (with the three-toothed internal gears rotating 1 1/3 or 4/3 the speed of their smaller, four-toothed external, mating gears): In total, there are eight gears in this assembly with only three relative gear movements as they are grouped into one-, three- and four-geared components. (Take note: One ring body may constitute both internal and external gears in its corresponding inner and outer features.)

This configuration has a function similar to conventional gerotor, yet its primary gear-train design has a nomenclature that closely resembles to that of ordinary gear as its teeth are visually close to that of jagged spur-gear pump than to rounded gerotor pump. Furthermore, what makes this assembly uniquely distinctive is the area-contact sealing provided by the sliding mating surfaces (including those of secondary gear-train design) as opposed to rolling line-contact mating surfaces of conventional gears, such that this makes it ideal for a more successful and profound engine application. Aside from its Guinness World Records bid for a constant-speed-ratio-profile parallel gear train with highest torque capacity, its unique kinematic characteristics also make it possible to device a far more efficient thermodynamic cycle ever.

The side benefits of this configuration include a very compact and automatic Infinitely-Variable Transmission with reverse action and without the use of conventional gearing system (or with the use of uniquely-inspired gear-train system that pushes the envelope of what’s deemed possible).

Finally, Prince Piston will kneel down on his journal before a steaming Miss Dainty magically twirling between her opposing hula hoops.

For further info of the rotary engine, visit http://rotaryenginephilippines.blogspot.com/

Similar models

grabcad

free

Involute Gear Mechanism

...e profiles of the teeth are involutes of a circle. the involute profile gear tooth produces a constant ratio of rotational speed.

grabcad

free

Epicyclic Gear Train

... gear takes place in analogy to the orbiting of the planets in the solar system. this is how planetary gears acquired their name.

grabcad

free

External and internal rotation gears

...external and internal rotation gears

grabcad

external and internal rotation gears

grabcad

free

Gear Toy

...e at different speed very slowly.

it needs to be improved by adding objects to the internal spur gear.

(maybe hare and tortoise?)

grabcad

free

Fidget Spinner With Planetary Gear

...tp) of the complete assembly.

native files (.prt) and (.asm), together in a (.zip)-folder,

for users of »ptc creo parametric 2.0«

grabcad

free

Gear

...ar train or a transmission. a gear can mesh with a linear toothed part, called a rack, producing translation instead of rotation.

grabcad

free

gear design

... mesh with another toothed part to transmit torque. geared devices can change the speed, torque, and direction of a power source.

grabcad

free

Gerotor

...gerotor

grabcad

i have here a nice, big, internal gear pump, in the form of a gerotor pump.

grabcad

free

Gear

...orque. a gear may also be known informally as a cog. geared devices can change the speed, torque, and direction of a power source

grabcad

free

GEAR

...ues, of two meshing gears differ in proportion to their diameters. the teeth on the two meshing gears all have the same shape.[2]

Rp

turbosquid

$3

Silla con Rp

...squid

royalty free 3d model silla con rp for download as max on turbosquid: 3d models for games, architecture, videos. (1245976)

turbosquid

$8

Panasonic RP-HF410B

...del panasonic rp-hf410b for download as ma, fbx, dae, and obj on turbosquid: 3d models for games, architecture, videos. (1703158)

3d_ocean

$29

Reloop RP-7000 DJ Turntable

...reloop rp-7000 dj turntable

3docean

dj electronic music reloop rp-7000 turntable

reloop rp-7000 dj turntable

turbosquid

$15

Rolland RP 10006

...and rp 10006 for download as max, max, max, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1695252)

3ddd

$1

Reloop RP-7000 DJ Turntable

... rp-7000 , mp3

reloop rp-7000 dj turntable

3ds max 2013 + v-ray

cinema 4d + vray

fbx

obj

3ddd

$1

Technics rp dj 1210

...альные диджейские наушники. technics rp dj-1210.

моделил в свободное время. решил поделиться со всеми :) приятного использования.

turbosquid

$2

RP-46 machine gun

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Panasonic RP-HTX7 Headphones

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

Reloop rp-7000 dj turntable 3D Model

...sic disc white

reloop rp-7000 dj turntable 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl muminjon 105637 3dexport

turbosquid

$2

trash can KCG.240GC(RP 6240GC1PZ)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Rotary

3ddd

$1

Medical Rotary table

...medical rotary table

3ddd

медицинский стол

medical rotary table

turbosquid

$18

Codex Rotary

...squid

royalty free 3d model codex rotary for download as stl on turbosquid: 3d models for games, architecture, videos. (1439894)

turbosquid

$12

Rotary drill

...y free 3d model rotary drill for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1394316)

3d_export

$6

The rotary module 3D Model

...the rotary module 3d model

3dexport

the rotary module

the rotary module 3d model armata2015 98145 3dexport

turbosquid

$40

Rotary Engine

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Rotary Phone

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

ROTARY medal

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$9

Rotary conveyor

...veyor for download as 3ds, max, ige, obj, fbx, stl, and sldas on turbosquid: 3d models for games, architecture, videos. (1300472)

3d_export

$5

Rotary Cylinder 3D Model

...rotary cylinder 3d model

3dexport

rotary cylinder pneumatic pressure torque

rotary cylinder 3d model fau 71217 3dexport

3ddd

$1

Medical Rotary Table M2

...medical rotary table m2

3ddd

медицинский , стол

medical rotary table m2

Cycle

turbosquid

$10

cycle

...e

turbosquid

royalty free 3d model cycle for download as dwg on turbosquid: 3d models for games, architecture, videos. (1480437)

turbosquid

$5

Cycles

...s

turbosquid

royalty free 3d model cycles for download as ma on turbosquid: 3d models for games, architecture, videos. (1660228)

turbosquid

$22

cycle

...quid

royalty free 3d model cycle for download as fbx and obj on turbosquid: 3d models for games, architecture, videos. (1667710)

turbosquid

$1

Cycle

...quid

royalty free 3d model cycle for download as jpg and max on turbosquid: 3d models for games, architecture, videos. (1375216)

turbosquid

$45

cycle

...yalty free 3d model cycle for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1419873)

turbosquid

$25

Cycle

...ty free 3d model cycle for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1432426)

turbosquid

$50

Cycle

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$35

Cycle

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

cycle counter

...cycle counter

3dexport

cycle counter

3d_export

$65

Cycling

...cycling

3dexport

simple rendering of the scene file

Engine

3d_export

$5

engine

...engine

3dexport

engine

3d_export

free

Engine

...engine

3dexport

engine

archibase_planet

free

Engine

...engine

archibase planet

motor engine

engine - 3d model for interior 3d visualization.

archibase_planet

free

Engine

...engine

archibase planet

motor engine mover

engine n170708 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Engine

...engine

archibase planet

engine locomotive train

locomotive - 3d model for interior 3d visualization.

turbosquid

$49

ENGINE

...

turbosquid

royalty free 3d model engine for download as max on turbosquid: 3d models for games, architecture, videos. (1206116)

turbosquid

$1

ENGINE

...osquid

royalty free 3d model ic engine for download as sldas on turbosquid: 3d models for games, architecture, videos. (1382781)

3d_export

$5

engine

...engine

3dexport

3d_export

free

engine

...engine

3dexport

turbosquid

$7

Engine

...d model animated engine mograph element3d for download as c4d on turbosquid: 3d models for games, architecture, videos. (1380716)