Thingiverse

AO-100 Dual Material Setup by sjkelly

by Thingiverse

Last crawled date: 4 years ago

For the past 3 weeks we have been working on improving and expanding the capabilities of the AO-100 from Aleph Objects.

We noticed a few areas that could be improved. After loosing the Z axis alignment a few times, we started experiencing really bad wobble. Like really really bad. I think this is from flexing the x ends too far, but even after loosening and realigning we still experienced it. We found brass bushings and designed a mount so that the end of the bushing is at the same height as the nozzle. I remembered from a comment on http://www.thingiverse.com/thing:4740 how keeping the bushings at the same level as the nozzle would ensure the nozzle can rotate, but not translate, therefore reducing wobble. We also used nophead's coupler from http://www.thingiverse.com/thing:9622. In hind sight I would have printed the one from the Mendel90.

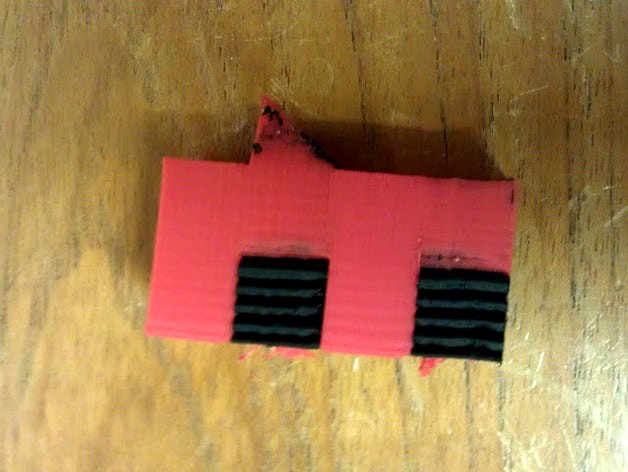

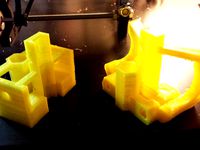

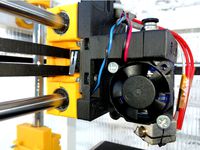

Next task was to add support for dual materials. Our original plan was to use two eMinebea motors (http://store.trinitylabs.com/trinitylabs-micro-extruder-gearhead-motor-and-options/). Since the consensus on their functionality is mixed, we went with a mirrored jonas'-greg's-wade. We designed a simple carriage with two fans and the extruders rotated. Using slic3r 0.8.4 and dob71's Marlin fork (https://github.com/dob71/Marlin) we were able to get dual materials working pretty well. Our original hope was to use PVA and ABS. There is very little data available about printing with PVA, so we were surprised (and a little frustrated :P) to find out PVA and ABS do not stick together. We are currently looking into other options such as PLA/ABS and ABS/PEO. If you have anymore info about sacrificial support for ABS, please let me know!

Edit: I forgot the SCAD's for the x carriage and lower x bushing. will upload tomorrow.

I would like to give a big thanks to Mill-Max Mfg for letting me open source this work. On that note, if you are interested in more info about our setup, please find me on IRC (sjkelly) or email me. Don't contact Mill-Max, they make really nice electronic headers and things(made in the USA!), not RepRaps... :D

We noticed a few areas that could be improved. After loosing the Z axis alignment a few times, we started experiencing really bad wobble. Like really really bad. I think this is from flexing the x ends too far, but even after loosening and realigning we still experienced it. We found brass bushings and designed a mount so that the end of the bushing is at the same height as the nozzle. I remembered from a comment on http://www.thingiverse.com/thing:4740 how keeping the bushings at the same level as the nozzle would ensure the nozzle can rotate, but not translate, therefore reducing wobble. We also used nophead's coupler from http://www.thingiverse.com/thing:9622. In hind sight I would have printed the one from the Mendel90.

Next task was to add support for dual materials. Our original plan was to use two eMinebea motors (http://store.trinitylabs.com/trinitylabs-micro-extruder-gearhead-motor-and-options/). Since the consensus on their functionality is mixed, we went with a mirrored jonas'-greg's-wade. We designed a simple carriage with two fans and the extruders rotated. Using slic3r 0.8.4 and dob71's Marlin fork (https://github.com/dob71/Marlin) we were able to get dual materials working pretty well. Our original hope was to use PVA and ABS. There is very little data available about printing with PVA, so we were surprised (and a little frustrated :P) to find out PVA and ABS do not stick together. We are currently looking into other options such as PLA/ABS and ABS/PEO. If you have anymore info about sacrificial support for ABS, please let me know!

Edit: I forgot the SCAD's for the x carriage and lower x bushing. will upload tomorrow.

I would like to give a big thanks to Mill-Max Mfg for letting me open source this work. On that note, if you are interested in more info about our setup, please find me on IRC (sjkelly) or email me. Don't contact Mill-Max, they make really nice electronic headers and things(made in the USA!), not RepRaps... :D

Similar models

thingiverse

free

Fan mounts for sjkelly's dual carriage by Sound

...formation about my setup (kindly sponsored by lulzbot!) is available at http://devel.lulzbot.com/ao-100/hardware/dual/dual_color/

thingiverse

free

Long Dual Bushing Holder by PETFlasche

...d some problems with wobble and vibration in my x gantry .

so i decide to make a longer bushing holder.

for me it works perfekt !

thingiverse

free

Two x-carriage prusa mendel mod. by Mateusz

... require 2 carriages from part: http://www.thingiverse.com/thing:124255 and software updates done by buildrob to marlin software.

thingiverse

free

X-Carriage for Jim's Flying Motor Mount Dual Extruder by doctek

... for dual nozzle cooling fans. a print cooling solution will be coming soon.

can actual dual-extrusion printing be far behind?

thingiverse

free

Pfierce Dual PNEMAtruder 1.0 by Chooch

...ch as abs for the main structure of the print and pva for water soluble support material.

the offset between nozzles is 35mm.

thingiverse

free

Dual Nozzle Carriage for Flsun Cube by Coscatgon

...n of this.

it should work with the chimera and cyclops dual hotends and clones of them.

please do let me know if you print this!

thingiverse

free

Prusa i3 DiggityDank Carriage Nozzle by LittleMrJ

...zzle works. view it in a slicer & see why.

original design from badass maker dahai8: http://www.thingiverse.com/dahai8/about.

thingiverse

free

ABS printable x-carriage for hypercube evo by svdmk

...beezen's" nut remix https://www.thingiverse.com/thing:2814140 of x-carriage. my carriage is printed with 2 bolted parts.

thingiverse

free

Dual Extrusion with Marlin and Pronterface by doctek

...nd is easier to tweak if needed. i didn't want my extruders to jump while i was priming or calibrating them with pronterface.

thingiverse

free

Pillow Block X-ends and Carriage by LulzBot

...les are wider to accommodate for the wider igus bushings.

these igus bushings can be sourced from our lulzbot.com store and igus.

Sjkelly

thingiverse

free

Heat Friendly Pulley by sjkelly

...t friendly pulley by sjkelly

thingiverse

mashed uphttp://www.thingiverse.com/thing:7218

andhttp://www.thingiverse.com/thing:5213

thingiverse

free

OpenSCAD Idler Pulley by sjkelly

...nd the overhang angle along with the lip height and thickness.

licensed public domain cause reprappers are chill bros and chicks.

thingiverse

free

Bowden Cable Coupling for RepRap by sjkelly

...t for extruders like wades. for my printrbot-variant i am working on http://tesla893.blogspot.com/2011/12/printrbot-part-1.html .

thingiverse

free

Fan mounts for sjkelly's dual carriage by Sound

...formation about my setup (kindly sponsored by lulzbot!) is available at http://devel.lulzbot.com/ao-100/hardware/dual/dual_color/

thingiverse

free

Isaac Y Axis Opto Flag by sjkelly

...isaac. it is much more robust than my previous designs,

this works with the fleming cnc isaac. it can be found at flemingcnc.com.

thingiverse

free

Parametric Clamp by sjkelly

...heir name indicates. the equations are right, just some of the parameters are messed up. it is easy to figure out what does what.

thingiverse

free

Isaac Z Axis Opto Flag by sjkelly

.../thing:124) flag on isaac, along with a printable flag.

i designed the flag in openscad, but i forgot to save the source file :/.

thingiverse

free

Sumo Bot Structure Pieces by sjkelly

...d files for this stuff isn't the greatest. this is the first part of a few uploads i will be making as i assemble this robot.

thingiverse

free

Isaac X Axis Opto Flag by sjkelly

...penscad. the file is not easily parametric (no variables).

i am going to be posting my z and y brackets/flags for isaac as well.

thingiverse

free

Smaller frame vertex concept other side by sjkelly

...g to be part of my "mixtape mendel" which is based of of prusajr's, hacklab.to's and whosaswhatasis's work.

Dual

3ddd

$1

плитка Dual Bianco (Испания)

...й плитки venis dual (испания). технические качества: устойчивость к стирания, отличная геометрия, отсутствие проблем при укладке.

cg_studio

$19

Dual Adjustable Pulley3d model

...y3d model

cgstudio

.3ds .max - dual adjustable pulley 3d model, royalty free license available, instant download after purchase.

3ddd

$1

S370 Dual Mixer With Spout

...: public areas, schools, universities, hospitality, commercial, hospitals and residential

finish options bright chrome – standard

design_connected

$7

GEBERIT Omega 30 Dual Flush Plate

...geberit omega 30 dual flush plate

designconnected

geberit omega 30 dual flush plate computer generated 3d model.

cg_studio

$49

LG L70 Dual White3d model

...

.max .obj .mb .lwo .fbx .c4d .3ds - lg l70 dual white 3d model, royalty free license available, instant download after purchase.

cg_studio

$49

LG L90 Dual Black3d model

...

.max .obj .mb .lwo .fbx .c4d .3ds - lg l90 dual black 3d model, royalty free license available, instant download after purchase.

cg_studio

$49

LG L90 Dual White3d model

...

.max .obj .mb .lwo .fbx .c4d .3ds - lg l90 dual white 3d model, royalty free license available, instant download after purchase.

3d_ocean

$19

Dual Materials - Granite - S01 - Polished Granite

...1 – polished granite description: here i present you with granite – s01 – polished granite surfaces dual materials library for...

3ddd

free

porcelanosa Venis Dual blanco

...d

porcelanosa , плитка

http://porcelanosagrupo.cz/content/pdf_mosaics/dual.pdf

3d_export

$49

LG G Pro Lite Dual 3D Model

...ndroid droid smartphone cell phone mobile cellular tft lcd touchscreen touch

lg g pro lite dual 3d model humster3d 91094 3dexport

Ao

3d_export

$7

lighting ao

...lighting ao

3dexport

3d_export

$5

ao bed

...ao bed

3dexport

design_connected

$11

AO-82 Laura Kirar bench

...r bench

designconnected

mcguire furniture company ao-82 laura kirar bench computer generated 3d model. designed by kirar, laura.

3d_export

$6

table ao

...x trick: no<br>- model parts: 1<br>- render: corona & vray<br>- formats: 3ds max 2015, obj, fbx<br>**

humster3d

$75

3D model of ZIL Bychok 5301 AO Truck 1996

...d model of zil bychok 5301 ao truck 1996 in various file formats. all our 3d models were created maximally close to the original.

3ddd

$1

Beltratto PG 7005 AO/AR/AI

...tto

http://www.beltratto.com/product/ru/2676/pg-7005-ao_ar_ai/

ширина: 70,5 см.

глубина: 50 см.

max2010, max2012, obj

3d_ocean

$3

Pavement 6

...pavement 6 3docean a seamless tileable texture with diffuse, ao bump and normal...

3d_ocean

$3

Pavement 10

...a seamless tileable texture with diffuse, bump, normal and ao ...

3d_ocean

$3

Pavement 9

...pavement 9 3docean a seamless tileable texture with diffuse, ao bump and normal...

3d_ocean

$2

Paper Lampshade

...a seamless tileable texture with diffuse, bump, normal and ao ...

100

3ddd

$1

Life 100-100-48

...life 100-100-48

3ddd

life , журнальный

автор модели: aeroslon

3ddd

$1

100 Dollars

...100 dollars

3ddd

100 dollars текстуры в комплекте :-)

3ddd

free

Alexandria 100

...alexandria 100

3ddd

alexandria

мебель для ванной alexandria 100

3d_export

$100

phenom 100

...phenom 100

3dexport

дуже якісна модель приватного літака феном 100

design_connected

$4

100% Design

...100% design

designconnected

ligne roset 100% design writing desks computer generated 3d model. designed by jeffrey bernett.

3d_export

$5

hyundai h 100

...hyundai h 100

3dexport

hyundai h 100

3ddd

free

Fendi Canova 100

...fendi canova 100

3ddd

тумба , fendi

fendi canova 100

3ddd

$1

Банкетка Монтсеррат 100

..., капитоне , монтсеррат

банкетка монтсеррат 100

3ddd

$1

Brilux Aves 100

...brilux aves 100

3ddd

бра. brilux aves 100. польша. материалы настроены.

3ddd

$1

акватон / премьер 100

...акватон / премьер 100

3ddd

акватон

раковина акватон премьер 100, сделано по размерам

Setup

3d_ocean

$5

Light Setup

...

3docean

light setup lightbox lights render setup

that’s light setup. easy for use. just delete spheres and position your object!

3d_ocean

$5

HDRI Studio Lighting Setup

...ate the hdri into many lighting combinations. increase/decrease intensity. this is the complete lighting setup for vray using ...

3d_ocean

$5

MentalRay Studio Lighting Setup

...ene which you can change. the colors of the lights are ofcourse tweak-able. this is a basic light setup for you to use for pro...

3d_ocean

$9

Fireworks - Render Setup

...can be used for any kinds of short movies, or other works. includes a well documentation which includes the steps to change th...

3d_ocean

$15

Render Setups Chair Wall

...render setups chair wall

3docean

chair max render setups vray wall white

render setups chair wall

3d_ocean

$5

Vray scene setup

...studio scene 2. vray setup 3. 2 vray cameras, one of them with dof 4. vray lights 5. vitra panton chair model 6. photoshop fil...

3d_ocean

$15

Vray Furniture Scene Setup

...vray furniture scene setup

3docean

chair create easy furniture light scene setup shadow vray

vray furniture scene setup

3d_ocean

$5

Studio light Setup VRAY

... in 3ds max 2010 for vray 1.5. light,material,camera and render setup are included. you can use it in higher version of 3dsmax...

3d_ocean

$8

Galaxy Render Setup

... maya maya 2015 render universe

created in maya using particle expressions, this galaxy can be rendered easily with simple steps.

3d_ocean

$7

Leather Render Setup

...r16. features: – included hdri. – easily selected focus point. – multipass layering + main object luma. – auto preview with pr...

Material

3d_ocean

$5

Concrete material

...concrete material

3docean

concrete cover material realistic textures

realistic concrete material

3d_ocean

$3

Wood Material

...wood material

3docean

wood material include normal map

3d_ocean

$3

Terrain material

...terrain material

3docean

terrain material include normal map

3d_ocean

$3

Grass Material

...grass material

3docean

grass material

include normal map

3d_ocean

$7

R16 Material Kit(50+ Materials!)

...ls -fabrics -automotive materials -architectural materials -a complimentary studio -abstract materials -rocks all for the pric...

3d_ocean

$5

Frozen Materials

...erials the project includes the frozen materials and frosted effect. for the material included diffuse and map normal. thank you!

3d_ocean

$50

Motion Graphics Material Pack (100 Materials)

...terials ready to use in your next motion graphics masterpiece. in the package you will find a c4d file with all the materials,...

design_connected

$16

Material Pendant

...material pendant

designconnected

new works material pendant computer generated 3d model. designed by noergaard & kechayas.

3d_export

$10

material handler

...material handler

3dexport

3d_ocean

$5

Realistic Wood Material

...wood material wooden

realistic wood material is included pine render material. it has bump and reflect so that it can use simply.