Thingiverse

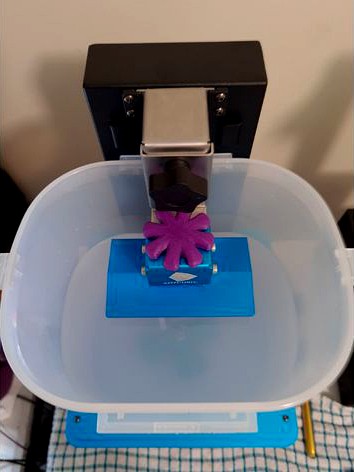

ANYCUBIC Photon Zero to Wash and Cure Station Adapter by akjmphoto

by Thingiverse

Last crawled date: 4 years, 11 months ago

ANYCUBIC Wash and Cure Station Adapter for mounting the buildplate

from the ANYCUBIC PHOTON ZERO for Washing models/plate

Engineered By: Anthony Musgrove

Tested By: Anthony Musgrove

Contact: anthony@hunter3dprinting.com.au

CAD: Creo Parametric 3.0

Creation Date: 28/12/2020

Additional Hardware Needed:

1x M6x16mm BOLT (Bunnings, a few dollars)

1x M6 NUT (Comes with pack of bolts from Bunnings)

(Bunnings Link: https://www.bunnings.com.au/pinnacle-m6-x-16mm-stainless-steel-hex-bolt-and-nut-10-pack_p2320001)

1x M6 FLAT WASHER (12mm OD)

(Bunnings Link: https://www.bunnings.com.au/pinnacle-m6-stainless-steel-flat-washer-12-pack_p0130533)

Print Settings (all_bracket_parts.stl):

* Layer Height: 0.2

* Wall Count: 3

* Infill: 15%, Lines

* Material Tested: PLA+ (Purple, 3DFillies)

* Printed Temp: 210 degrees C

* Support Material: Enable supports build-plate only - support may be used for washer recess (against buildplate) and possibly a little bit on the rounded edges.

* Print Time: 34 minutes (approx) on CTC Replicator Dual

Print Settings (bolt_wheel.stl):

* Layer Height: 0.2

* Wall Count: 3

* Infill: 30%, Gyroid

* Material Tested: PLA+ (Purple, 3DFillies)

* Printed Temp: 210 degrees C

* Support Material: Enable supports, build plate only, it will be used for the NUT recess.

* Print Time: 34 minutes (approx) on CTC Replicator Dual

Files:

all_bracket_parts.stl ALL bracket parts, oriented in their designated print orientation - don't change orientation!

bolt_wheel.stl The wheel/knob to tighten and loosen the bolt. Oriented in print position - print as it is, with supports.

Assembly:

* Print all_bracket_parts.stl (all three parts, top, bottom and middle)

* Print bolt_wheel.stl with the separate print settings above.

* Ensure no elephant foot on any of the holes - clean up with a deburring tool to ensure correct fitment.

* Superglue inside the NUT hole, spray the NUT with Accelerator, and install NUT in place, let

it fuse well.

* Superglue the washer recess on the MIDDLE part, then spray the WASHER with Accelerator, and install

WASHER in place, let it fuse well.

* Prepare the top piece for installation - the centre slot piece should have superglue placed on

top of it, and then the middle piece slides down onto it, with the washer side UP - the WASHER side MUST

go TOWARDS the NUT on the BOTTOM piece.

* Slide the middle piece down the spine, letting the spine go through the spine hole, all the way down

until the middle piece is firm up against the alignment slider

* Once fused, place enough super glue over the washer, and the plastic piece, ready for the surface with the NUT to

also slide down the spine - press this firmly together and spray with accelerator.

* Superglue inside the bolt-wheel (knob) bolt fitment area. Spray the top of the bolt with accelerator and install

the head of the bolt into the bolt-wheel (knob) bolt fitment area. let it fuse well.

from the ANYCUBIC PHOTON ZERO for Washing models/plate

Engineered By: Anthony Musgrove

Tested By: Anthony Musgrove

Contact: anthony@hunter3dprinting.com.au

CAD: Creo Parametric 3.0

Creation Date: 28/12/2020

Additional Hardware Needed:

1x M6x16mm BOLT (Bunnings, a few dollars)

1x M6 NUT (Comes with pack of bolts from Bunnings)

(Bunnings Link: https://www.bunnings.com.au/pinnacle-m6-x-16mm-stainless-steel-hex-bolt-and-nut-10-pack_p2320001)

1x M6 FLAT WASHER (12mm OD)

(Bunnings Link: https://www.bunnings.com.au/pinnacle-m6-stainless-steel-flat-washer-12-pack_p0130533)

Print Settings (all_bracket_parts.stl):

* Layer Height: 0.2

* Wall Count: 3

* Infill: 15%, Lines

* Material Tested: PLA+ (Purple, 3DFillies)

* Printed Temp: 210 degrees C

* Support Material: Enable supports build-plate only - support may be used for washer recess (against buildplate) and possibly a little bit on the rounded edges.

* Print Time: 34 minutes (approx) on CTC Replicator Dual

Print Settings (bolt_wheel.stl):

* Layer Height: 0.2

* Wall Count: 3

* Infill: 30%, Gyroid

* Material Tested: PLA+ (Purple, 3DFillies)

* Printed Temp: 210 degrees C

* Support Material: Enable supports, build plate only, it will be used for the NUT recess.

* Print Time: 34 minutes (approx) on CTC Replicator Dual

Files:

all_bracket_parts.stl ALL bracket parts, oriented in their designated print orientation - don't change orientation!

bolt_wheel.stl The wheel/knob to tighten and loosen the bolt. Oriented in print position - print as it is, with supports.

Assembly:

* Print all_bracket_parts.stl (all three parts, top, bottom and middle)

* Print bolt_wheel.stl with the separate print settings above.

* Ensure no elephant foot on any of the holes - clean up with a deburring tool to ensure correct fitment.

* Superglue inside the NUT hole, spray the NUT with Accelerator, and install NUT in place, let

it fuse well.

* Superglue the washer recess on the MIDDLE part, then spray the WASHER with Accelerator, and install

WASHER in place, let it fuse well.

* Prepare the top piece for installation - the centre slot piece should have superglue placed on

top of it, and then the middle piece slides down onto it, with the washer side UP - the WASHER side MUST

go TOWARDS the NUT on the BOTTOM piece.

* Slide the middle piece down the spine, letting the spine go through the spine hole, all the way down

until the middle piece is firm up against the alignment slider

* Once fused, place enough super glue over the washer, and the plastic piece, ready for the surface with the NUT to

also slide down the spine - press this firmly together and spray with accelerator.

* Superglue inside the bolt-wheel (knob) bolt fitment area. Spray the top of the bolt with accelerator and install

the head of the bolt into the bolt-wheel (knob) bolt fitment area. let it fuse well.