Thingiverse

Anycubic Mega X - Tensioner for x axis by dfsl

by Thingiverse

Last crawled date: 3 years ago

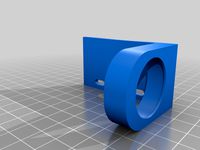

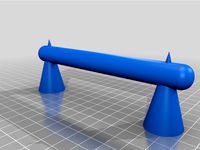

This remix makes the belt tensioner now suitable for the Anycubic Mega X, not only for the i3 Mega (S). Thanks to kulfuerst for his pre-work, he deserves the credits.

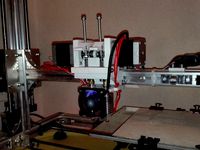

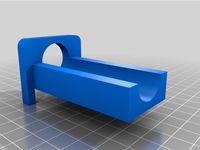

First of all you will need to drill two 8 mm holes into the right sided steel casing next to the extruder. Dismount the extruder (cap with 3 screws, then 2 screws at the steel casing).The part "hole template" can be used for getting the correct positions. A center punch and predrilling makes things easier.

After drilling, the metal frame can be dismantled screw by screw (16 pcs.). Don't forget to dismount the Z-axis endstops (4 screws). Now you can loosen the M4 screw of the belt pulley. Remove screw and sleeve, these won't be needed anymore (keep it nearby as backup). Try to keep the belt on the pulley.

Grab the dismounted extruder and place it on it's origin. Clip the mounting corner (part 2) into the drilled holes, the extruder should now be held. Secure both the mounting corner and extruder with the screws.

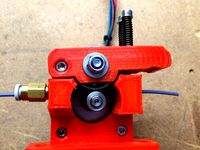

Now the tricky part begins. Prepare part 1 with one M5x40 screw and move it into the steel casing from below. Guide the screw through the upper hole and secure it with a nut. Take the next screw and repeat for the lower hole. After you succeeded, try to get the pulley into part 1. You can use some long tool e. g. screw driver or allen key. Gently press it against the aluminum profile so it fits inside. Now secure it with the M4x12 screw.

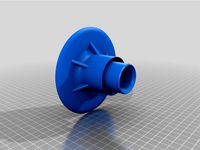

Put the M6 nut into the hand wheel, put both into part 3 and screw in M6 bolt. Pre-thighten the belt with the outer nuts and slide part 3 over the M5 screws. Make sure that both screws are at same length before you finish the assembly with the self securing nuts.

I hope you enjoy my work.

Additional needed parts:

1x drill diameter 8 mm (and some smaller drills for predrilling)

1x Screw ISO 4762 - M4 x 12 (cylinder head)

2x Screw ISO 4017 - M5 x 40 (hexagon head)

2x nut M5

2x nut M5 self securing

1x Screw ISO 4017 - M6 x 20 (hexagon head)

1x nut M6

In further updates I will add screws and nuts to the assembly and pictures.

First of all you will need to drill two 8 mm holes into the right sided steel casing next to the extruder. Dismount the extruder (cap with 3 screws, then 2 screws at the steel casing).The part "hole template" can be used for getting the correct positions. A center punch and predrilling makes things easier.

After drilling, the metal frame can be dismantled screw by screw (16 pcs.). Don't forget to dismount the Z-axis endstops (4 screws). Now you can loosen the M4 screw of the belt pulley. Remove screw and sleeve, these won't be needed anymore (keep it nearby as backup). Try to keep the belt on the pulley.

Grab the dismounted extruder and place it on it's origin. Clip the mounting corner (part 2) into the drilled holes, the extruder should now be held. Secure both the mounting corner and extruder with the screws.

Now the tricky part begins. Prepare part 1 with one M5x40 screw and move it into the steel casing from below. Guide the screw through the upper hole and secure it with a nut. Take the next screw and repeat for the lower hole. After you succeeded, try to get the pulley into part 1. You can use some long tool e. g. screw driver or allen key. Gently press it against the aluminum profile so it fits inside. Now secure it with the M4x12 screw.

Put the M6 nut into the hand wheel, put both into part 3 and screw in M6 bolt. Pre-thighten the belt with the outer nuts and slide part 3 over the M5 screws. Make sure that both screws are at same length before you finish the assembly with the self securing nuts.

I hope you enjoy my work.

Additional needed parts:

1x drill diameter 8 mm (and some smaller drills for predrilling)

1x Screw ISO 4762 - M4 x 12 (cylinder head)

2x Screw ISO 4017 - M5 x 40 (hexagon head)

2x nut M5

2x nut M5 self securing

1x Screw ISO 4017 - M6 x 20 (hexagon head)

1x nut M6

In further updates I will add screws and nuts to the assembly and pictures.

Similar models

thingiverse

free

Dual Extruder by Psycho1981

...ng:

4x allen screw m5

4x square nut m5

4x washer m5

electronic:

-ramps 1.4 board

-atx power supply

-firmware "marlin"

thingiverse

free

Mini Kossel 1.75mm extruder by wallie

...et head cap screw

2x spring

1x m5 pneumatic straight threaded-to-tube adapter, push in 4 mm 4mm male

tools

m5 manual screw tap

thingiverse

free

Height Gauge, Height Marker by Lt_AldoRaine

...with a ø5mm hss-spiral drill (for a tighter fit) and a m6 thread had to be cut manually at the top of the tip. to fix the pencil.

thingiverse

free

NEMA17 Universal Belted 2:1 Reduction Drive by mildw4ve

...rews

2x m3x25 socket hex screws

4x m3x25 or longer socket hex screws for mounting the top plate and anything that might be on it.

thingiverse

free

Artillery Genius - SWX1 filament sensor holder

...5mm

2x flat head screw m3 x 8mm

3x nut m3

2x t-nut m3

1x ptfe tubing

2x pc4 m6

pc4 m6https://www.amazon.de/gp/product/b07n6h43fw

thingiverse

free

Anycubic I3 Mega X V-belt ajusting screw by Filixx

...the screw wont screwable so take a m5 nut and and screw the screw 2 times off and on the thread! or print the screw with 95% size

thingiverse

free

Spoolholder Anycubic i3 Mega by 3D_Wonder

...ga.

inspired by the design of the i3 mega s.

fits for spools up to 90 mm width.

screws:

[2x] m3x12

[1x] m5 x 30 (20 is also okay)

thingiverse

free

i3 Y Axis Belt tensioner by Pmturiel

...axis belt. it fits on prusa i3 steel or similar you need: 2x m5 screw 2x m5 bolt 2x...

grabcad

free

Cam, Ratchet and Pawl

...;

- 1x dome nut din1587 m6;

- 1x sleeve (ericsson) nut m6;

- 1x washer din 125 12;

- 2x washer din 125 6;

- 1x washer din 9021 6.

thingiverse

free

Mini Drill Press for Foredom Flex Shaft H.30 Handpiece by ethanschultzart

...0mm

1x m6 threaded rod 75mm

3x m6 nut

2x m6 washer

2x 10mm tension springs, or rubber bands

1x mdf 1/2" x 4" x 5"

Anycubic

thingiverse

free

anycubic filament holder

...anycubic filament holder

thingiverse

anycubic filament holder

thingiverse

free

Cableholder Anycubic Mega

...cableholder anycubic mega

thingiverse

cableholder anycubic mega

thingiverse

free

AnyCubic Toolholder by WildManPrinting

...anycubic toolholder by wildmanprinting

thingiverse

anycubic i3 mega toolholder that clips on the side of the spool a-frame.

thingiverse

free

AnyCubic Funnel by phana007

...anycubic funnel by phana007

thingiverse

funnel for anycubic resin and also a reducer for a normal soda bottle.

thingiverse

free

Anycubic Kossel PID calibration

...ir mount:

kossel raspberry camera ir mount

extruder pid calibration.

simple extruder temperature calibration of your 3d printer.

thingiverse

free

anycubic mega i3

...anycubic mega i3

thingiverse

anycubic i3 mega/mega s led 30mm 10-14v 6500k

thingiverse

free

Handle for anycubic by cruiser7

...handle for anycubic by cruiser7

thingiverse

its easier to handle the cover of the anycubic mono x and wash&care

thingiverse

free

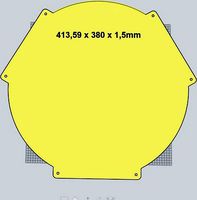

anycubic predator Printbed by Lihyon

...anycubic predator printbed by lihyon

thingiverse

anycubic predator printbed

thingiverse

free

Anycubic Predator Triggers by marcelcountry

...anycubic predator triggers by marcelcountry

thingiverse

anycubic predator triggers

thingiverse

free

support anycubic cable by sarpdental

...support anycubic cable by sarpdental

thingiverse

support anycubic cable

Mega

3ddd

$1

BoConcept / Mega

...boconcept / mega

3ddd

boconcept

boconcept mega

3ddd

free

Angelo - Mega shoin

... mega shoin , shoin

angelo - mega shoin - 3dmax 2008

3ddd

$1

Комод MEGA

...вана по фото с учетом реальных размеров.

стек не сколапсен, есть возможность регулировки уровня сглаживания.

текстуры в архиве.

3ddd

$1

Hulsta / Mega-design

...hulsta / mega-design

3ddd

hulsta

hulsta mega-design

design_connected

$18

Tolomeo Mega

...

photo-realistic 3d models of the tolomeo mega floor lamps from artemide for 3d architectural and interior design presentations.

turbosquid

$119

Mega Soldier

... free 3d model mega soldier for download as obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1148568)

turbosquid

$100

Mega Yacht

... free 3d model mega yacht for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1368903)

3ddd

$1

Massproductions Mega

... massproductions , mega

ширина: 180 см

глубина: 90 см

высота: 79 см

3d_export

$4

mega metro station

...mega metro station

3dexport

mega metro station. ready to game. thanks all downloaders!!

3ddd

$1

BAS Mega

...bas mega

3ddd

bas , ванна

ванна

Tensioner

3d_export

$5

adjustable tension lock

...adjustable tension lock

3dexport

adjustable tension lock

turbosquid

$5

tension ring

...oyalty free 3d model tension ring for download as fbx and stl on turbosquid: 3d models for games, architecture, videos. (1553452)

turbosquid

$3

Tension Chair

...free 3d model tension chair for download as obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1251503)

3d_export

$5

transformador de tension

...transformador de tension

3dexport

transformador de tension entrada 460vac salida 220vac marca audax

turbosquid

$20

Motorbike Chain Tensioner

...y free 3d model motorbike chain tensioner for download as stl on turbosquid: 3d models for games, architecture, videos. (1428322)

turbosquid

$25

TENSION-WOOD-CHAIR

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

tension-bentwood-chair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Tension engagement ring

...n engagement ring for download as obj, fbx, 3dm, dwg, and stl on turbosquid: 3d models for games, architecture, videos. (1491631)

3d_export

$10

Ruby Tension set Ring 3D Model

...ruby tension set ring 3d model

3dexport

tension set ruby ring in 18k

ruby tension set ring 3d model rehansheikh 25254 3dexport

turbosquid

$20

Superficial Tension Exp. Image.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Axis

3ddd

$1

Мария Axis

...

3ddd

кухня , классическая , axis

модель кухни.

3d_export

$22

Axis robot 6-axis robotic arm

...ing parts drawings, standard parts purchased parts list, can be produced directly according to the drawings, welcome to download!

3ddd

free

Versatile Axis

...ddd

nexus , плитка

http://bvtileandstone.com/ceramic-porcelain/versatile-axis/

3d_export

$19

robot 2 axis

...robot 2 axis

3dexport

robot 2 axis

turbosquid

$40

Axis R5F

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$40

Axis S5F

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Axis Athlon

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Linear Axis

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$15

drawing axis

...drawing axis

3dexport

simple rendering of the scene file

3ddd

$1

versatile axis ARC

...versatile axis arc

3ddd

versatile , плитка

versatile axis arc red dot design award