Thingiverse

Anycubic Kossel Plus Heated Bed Leveling Clamps (with STEP files) by MyStoopidStuff

by Thingiverse

Last crawled date: 3 years ago

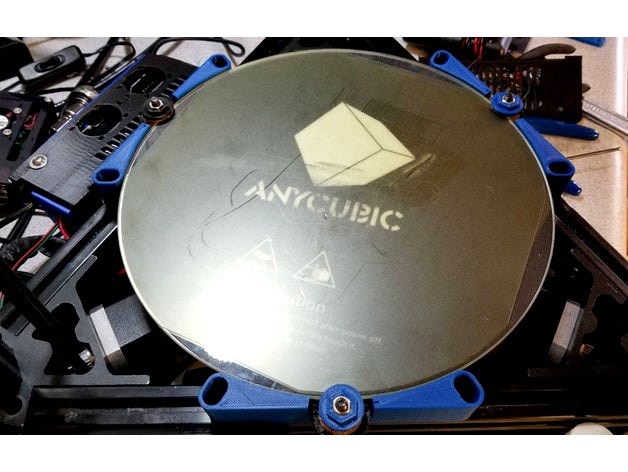

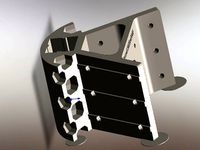

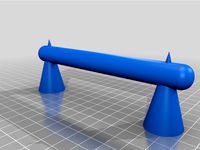

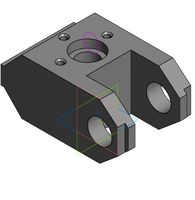

Remixed the Anycubic Kossel Plus Heated Bed Clips by JamesWhite into a leveling clamp setup for the Kossel Plus.

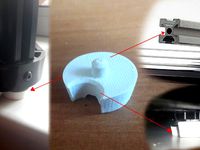

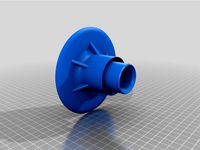

These work like the other types of bed leveling clamps, the lower nut adjusts the level and the top one clamps it all together. The top nut needs to be thin to clear the autlo-leveling sensor that comes with the Plus. The top nuts can be further tightened down with a 13mm or 1/2" nut driver.

I used the following hardware:

3 x M5x30mm bolt (I used pan head, not sure if there is clearance for cap head screws).

6 x M5 nuts (regular, not locknuts)

3 x M5 locknuts

6 x M4x10mm bolts (used to hold the base to the 2020)

6 x M4 T-nuts

6 (or more) washers were used in the base on the M4 screws

I used some 1/16" cork for the pads on the knob parts to insulate between the parts and the bed. Note that cork is not fireproof so use this design at your own risk.

The larger dials have some recessed dots and the bases have a small pip that can be filled with paint if that is desired.

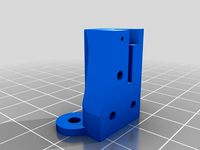

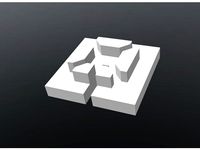

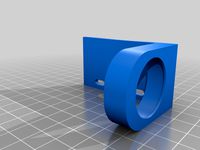

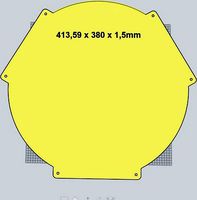

Updated 5/22/2020 - There are 3 versions of the base now:

Bed-Level-Base.stl // this is the original short base, and will not allow clamping of the sides of the bed.

Bed-Level-V6-11mm-base.stl // new version for the heated bed only

Bed-Level-V7C-15mm-base.stl // new version for the bed + 3mm glass plate (Updated 5/22/2020, thanks to feedback from engeltom)

The taller 11mm and 15mm versions were designed to help corral the bed, which the original version does not do. I had used the original version without many problems for months, though it does need to be tightened down to keep the bed from moving around. The 11mm and 15mm versions are not tested for longevity or to know if being in contact with the bed will be a problem. I have however run about 1Kg through with the 15mm version (since I have a glass bed), and they are holding strong.

Originally I printed the parts in PLA (and was using Bed-Level-Base.stl), which worked OK, but as I have been printing more ABS I can see where PLA is not great for that. Since I was printing ABS anyway, I just printed these in ABS and I think they will do much better. I did noticed some warping on the PLA bottom knobs when I swapped everything with ABS so it was probably just in time. I am not sure if just running PLA would be a problem in the long run with these. Since the taller 11mm and 15mm bases are in direct contact with the bed, I printed it in ABS only (not PLA) - I am still testing the taller 15mm part with ABS, but after running several prints with ABS they are holding up fine so far.

Update 10-8-2018, I have been using the blue ABS clamps (15mm) in the pics for the past few months while running dozens of PLA and ABS prints, and they have been holding up well. I have had the bed off a few times, but have not otherwise adjusted them. They have stood up to getting very well stuck items off the PEI without messing with the leveling. So far I am pretty happy with these.

For the safety minded, or people who don't monitor their printers, please take note that Cork is not fireproof. I chose cork because I had it on hand, but other than that I'm not sure what the risk is for using cork with these. It is up to you to weigh and decide upon the risk of using these designs. If you know of a better material to use instead of cork please let me know.

One more thing to note about these, when using the stock Anycubic touch probe for leveling - if the bolt that is used on the left side is too long, it will probably hit the probe. To avoid this I make sure the bed is raised up enough so the screw does not protrude more than a mm or two from the top of the holding clamp. I also make sure the left side mount is pushed back away from the bed which gives a mm or two more clearance for the probe. If this is a problem you will hear the probe touch the screw when it is doing the auto-leveling or the z-height adjustment with the stock firmware. I would consider this a minor issue to be aware of, and is the only problem I have seen so far while using these.

If you use Marlin, I believe you can adjust the "#define DELTA_CALIBRATION_RADIUS" in configuration.h to reduce the circle size that is probed to avoid the screws (that's what I did), however if the scres are too tall they could still hit the head when printing.

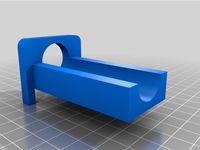

Printing notes:

I would print these with 40% infill or more next time (I used 20% before I realized I forgot to change it). I would also use 3 or more walls at least. I originally printed the short base and rest of the knobs in PLA and used them for months without major problems (aside from having to keep them tight which can require re-leveling). When I re-printed the new 15mm version, I used ABS which is stronger and should not warp as easily. I have printed these with and without supports, both worked fine.

Assembly notes:

Getting the bases to fit with the bed was tight. I had to removed the two washers from the M4 screws used on one of the bases to get it to get a tiny bit of extra clearance for it all to fit. I don't see it being a problem on mine and am not going to re-design it for that.

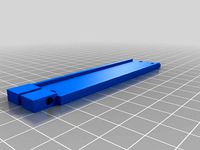

See the pics for more info on how to put them together. The locknut will be a tight fit, but I was able to slowly tighten it down into position without a problem.

Update 10/20/2018 - added STEP files for easy remixing.

Updated 5/22/2020 - Fixed the 15mm base which had an error, thanks to the kind feedback from engeltom.

These work like the other types of bed leveling clamps, the lower nut adjusts the level and the top one clamps it all together. The top nut needs to be thin to clear the autlo-leveling sensor that comes with the Plus. The top nuts can be further tightened down with a 13mm or 1/2" nut driver.

I used the following hardware:

3 x M5x30mm bolt (I used pan head, not sure if there is clearance for cap head screws).

6 x M5 nuts (regular, not locknuts)

3 x M5 locknuts

6 x M4x10mm bolts (used to hold the base to the 2020)

6 x M4 T-nuts

6 (or more) washers were used in the base on the M4 screws

I used some 1/16" cork for the pads on the knob parts to insulate between the parts and the bed. Note that cork is not fireproof so use this design at your own risk.

The larger dials have some recessed dots and the bases have a small pip that can be filled with paint if that is desired.

Updated 5/22/2020 - There are 3 versions of the base now:

Bed-Level-Base.stl // this is the original short base, and will not allow clamping of the sides of the bed.

Bed-Level-V6-11mm-base.stl // new version for the heated bed only

Bed-Level-V7C-15mm-base.stl // new version for the bed + 3mm glass plate (Updated 5/22/2020, thanks to feedback from engeltom)

The taller 11mm and 15mm versions were designed to help corral the bed, which the original version does not do. I had used the original version without many problems for months, though it does need to be tightened down to keep the bed from moving around. The 11mm and 15mm versions are not tested for longevity or to know if being in contact with the bed will be a problem. I have however run about 1Kg through with the 15mm version (since I have a glass bed), and they are holding strong.

Originally I printed the parts in PLA (and was using Bed-Level-Base.stl), which worked OK, but as I have been printing more ABS I can see where PLA is not great for that. Since I was printing ABS anyway, I just printed these in ABS and I think they will do much better. I did noticed some warping on the PLA bottom knobs when I swapped everything with ABS so it was probably just in time. I am not sure if just running PLA would be a problem in the long run with these. Since the taller 11mm and 15mm bases are in direct contact with the bed, I printed it in ABS only (not PLA) - I am still testing the taller 15mm part with ABS, but after running several prints with ABS they are holding up fine so far.

Update 10-8-2018, I have been using the blue ABS clamps (15mm) in the pics for the past few months while running dozens of PLA and ABS prints, and they have been holding up well. I have had the bed off a few times, but have not otherwise adjusted them. They have stood up to getting very well stuck items off the PEI without messing with the leveling. So far I am pretty happy with these.

For the safety minded, or people who don't monitor their printers, please take note that Cork is not fireproof. I chose cork because I had it on hand, but other than that I'm not sure what the risk is for using cork with these. It is up to you to weigh and decide upon the risk of using these designs. If you know of a better material to use instead of cork please let me know.

One more thing to note about these, when using the stock Anycubic touch probe for leveling - if the bolt that is used on the left side is too long, it will probably hit the probe. To avoid this I make sure the bed is raised up enough so the screw does not protrude more than a mm or two from the top of the holding clamp. I also make sure the left side mount is pushed back away from the bed which gives a mm or two more clearance for the probe. If this is a problem you will hear the probe touch the screw when it is doing the auto-leveling or the z-height adjustment with the stock firmware. I would consider this a minor issue to be aware of, and is the only problem I have seen so far while using these.

If you use Marlin, I believe you can adjust the "#define DELTA_CALIBRATION_RADIUS" in configuration.h to reduce the circle size that is probed to avoid the screws (that's what I did), however if the scres are too tall they could still hit the head when printing.

Printing notes:

I would print these with 40% infill or more next time (I used 20% before I realized I forgot to change it). I would also use 3 or more walls at least. I originally printed the short base and rest of the knobs in PLA and used them for months without major problems (aside from having to keep them tight which can require re-leveling). When I re-printed the new 15mm version, I used ABS which is stronger and should not warp as easily. I have printed these with and without supports, both worked fine.

Assembly notes:

Getting the bases to fit with the bed was tight. I had to removed the two washers from the M4 screws used on one of the bases to get it to get a tiny bit of extra clearance for it all to fit. I don't see it being a problem on mine and am not going to re-design it for that.

See the pics for more info on how to put them together. The locknut will be a tight fit, but I was able to slowly tighten it down into position without a problem.

Update 10/20/2018 - added STEP files for easy remixing.

Updated 5/22/2020 - Fixed the 15mm base which had an error, thanks to the kind feedback from engeltom.

Similar models

thingiverse

free

Bed Leveling Thumb Nut - TRONXY P802 by cdsmakestuff

...pla designed around tronxy p802e... will probably fit other similar printers update: 3/9/2017 - i suggest to anyone going...

thingiverse

free

Spider Water/Feed Bowl by ukseal

...hen runs up and out of the tank to make watering easy.

update... im still using the pla version and have had no problems with it.

thingiverse

free

Flashforge Glass Bed Corner Bracket with Factory Nut Relief and Slot for Outer Rubber Band by ABSSS

...e of it moving around during your print. i have also added more factory print bed nut clearance.

used supports and raft in abs.

thingiverse

free

Anet A8 Plus Y-Belt Clamp

...nal belts. so, i will soon post an updated version of the clamp and the cover specific for the glasfiber reinforced gt2 belts....

thingiverse

free

AM8 Ender bed Y carrier by SnoopD0ugFPV

... added some material in some places for strength and removed some in others . make sure to print it strong. i run mine in cf-pla.

thingiverse

free

Dial Indicator Clamp by mariodab

...;t have to remove the dial during printing.

the inside of the clamp had a place for a press fit m3 nut. use any kind of m3 screw.

thingiverse

free

Anycubic Kossel Plus - Bed support + insulation + glass with clamp by MakeTo3D

...ightly smaller than the bed, the v2 model has less margin so it is better for glass flush with the bed.

print the parts in abs !!

thingiverse

free

Sensor holder (for Titan extruder) by tkerpe

...p

i had good results with 0.2mm layer height 20% infill with pla.

created using onscape

fix the clamp with a m3 screw and a nut.

thingiverse

free

Sanding Wedge by Ralf_Hoerhager

...i used an m6 screw and nut to clamp the sandpaper down. the screw and nut are glued in place.

i used pla but abs would be better.

thingiverse

free

Servo Probe Mount by amasraff

... video about how to solve problems on auto bed leveling z axis not going down further than the probe https://youtu.be/subddn-mfrq

Mystoopidstuff

thingiverse

free

Eye Roll Emoticon by MyStoopidStuff

... the person who is just sooo cool they can't be bothered with a discussion of the finer points of 3d fused filament printing.

thingiverse

free

Pegboard webcamera holder 41mm x 7mm by MyStoopidStuff

... of strange for a webcam holder but it works for mine. the inside dimensions are:

41mm x 7mm and it is about 41mm tall (inside).

thingiverse

free

Modular Mounting System - 2020 mount by MyStoopidStuff

...his for m4 and use it with another thing i am working on (a filament runout sensor mount), but thought this could be useful also.

thingiverse

free

spacer for ender 2 ender 3 cr10 - 2.5mm (remix) by MyStoopidStuff

... 2.5mm spacer remixed from the "spacer for ender 2 ender 3 cr10" by raffosan:

https://www.thingiverse.com/thing:2526607

thingiverse

free

Dog paw imprint and heart by MyStoopidStuff

... on them. i've uploaded the step files so these can be re-mixed if you want to add a name or add them to some other project.

thingiverse

free

Pegboard remote control holder 60mm x 30mm (with STEP file) by MyStoopidStuff

...tall (inside)

this was made for a whirlpool ac unit but will probably work with others.

uploaded the step file for easy remixing.

thingiverse

free

LoD (Look of Disapproval) by MyStoopidStuff

...characters" pop from the background color.

update 2/22/2020: see the remix of this thing which is split for easier printing.

thingiverse

free

Shruggie Desk Thing by MyStoopidStuff

... keyed to be printed a bit easier and then glued together. it can be found here:

https://www.thingiverse.com/thing:4130898/files

thingiverse

free

BOITIER TL SMOOTHER HelloBeePrusa SFX (remix) - Heatsink Lid by MyStoopidStuff

...w.amazon.com/easycargo-heatsink-anodized-25x25x10mm-25mmx25mmx10mm/dp/b07b642856

update jan 18, 2019 - step file is now uploaded.

thingiverse

free

Gazebo Cover End Point by MyStoopidStuff

...nd printing the small one first to test and then you can scale up or down from there to get the right fit with your gazebo frame.

Kossel

thingiverse

free

kossel bottom by keisukelin

...kossel bottom by keisukelin

thingiverse

kossel bottom

thingiverse

free

Leg for kossel by exelon

...leg for kossel by exelon

thingiverse

leg for kossel

thingiverse

free

Extruder for kossel by spencer_chen7

...extruder for kossel by spencer_chen7

thingiverse

extruder for kossel

thingiverse

free

Kossel parts by breezer83

...kossel parts by breezer83

thingiverse

kossel parts

thingiverse

free

Anycubic Kossel PID calibration

...ir mount:

kossel raspberry camera ir mount

extruder pid calibration.

simple extruder temperature calibration of your 3d printer.

thingiverse

free

Kossel Medium by flux83

...kossel medium by flux83

thingiverse

vertex for upgraded kossel mini

thingiverse

free

Kossel Mini by salesmendesandre

...kossel mini by salesmendesandre

thingiverse

custom kossel mini

frame 20x20

thingiverse

free

leg for kossel by ionulet

...leg for kossel by ionulet

thingiverse

leg for kossel with channel for end- stop cables

thingiverse

free

Optical Endstops Mounts for Kossel (with Better Kossel carriages) by dellfer

...stops on the anycubic kossel with better kossel carriages by codefreak https://www.thingiverse.com/thing:2501337

more precission

thingiverse

free

kossel??????? by wangrui19890704

...kossel??????? by wangrui19890704

thingiverse

??2020?2060???

Anycubic

thingiverse

free

anycubic filament holder

...anycubic filament holder

thingiverse

anycubic filament holder

thingiverse

free

Cableholder Anycubic Mega

...cableholder anycubic mega

thingiverse

cableholder anycubic mega

thingiverse

free

AnyCubic Toolholder by WildManPrinting

...anycubic toolholder by wildmanprinting

thingiverse

anycubic i3 mega toolholder that clips on the side of the spool a-frame.

thingiverse

free

AnyCubic Funnel by phana007

...anycubic funnel by phana007

thingiverse

funnel for anycubic resin and also a reducer for a normal soda bottle.

thingiverse

free

Anycubic Kossel PID calibration

...ir mount:

kossel raspberry camera ir mount

extruder pid calibration.

simple extruder temperature calibration of your 3d printer.

thingiverse

free

anycubic mega i3

...anycubic mega i3

thingiverse

anycubic i3 mega/mega s led 30mm 10-14v 6500k

thingiverse

free

Handle for anycubic by cruiser7

...handle for anycubic by cruiser7

thingiverse

its easier to handle the cover of the anycubic mono x and wash&care

thingiverse

free

anycubic predator Printbed by Lihyon

...anycubic predator printbed by lihyon

thingiverse

anycubic predator printbed

thingiverse

free

Anycubic Predator Triggers by marcelcountry

...anycubic predator triggers by marcelcountry

thingiverse

anycubic predator triggers

thingiverse

free

support anycubic cable by sarpdental

...support anycubic cable by sarpdental

thingiverse

support anycubic cable

Clamps

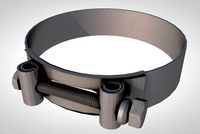

3d_export

$11

clamp

...clamp

3dexport

clamp

3ddd

free

Clamp

... enricо zanolla , капитоне

дизайнерenrico zanollмодель clamp

3ddd

$1

Clamp

...ricо zanolla , капитоне

дизайнеры

enrico zanolla

andrea di filippo

модель clamp

dzstudio

3d_export

free

clamp

...clamp

3dexport

simple clamp model, more free 3d models here:

3d_export

$5

clamping handle

...clamping handle

3dexport

clamping handle

3ddd

$1

Clamp / DZstudio

... dzstudio , капитоне

люстра clamp от dzstudio/enrico zanolla(италия).

3ddd

$1

Светильник Clamp

...светильник clamp

3ddd

clamp

стеганый светильник clamp в двух цветах в черном и белом.

turbosquid

$29

clamp

...ty free 3d model clamp for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1442049)

turbosquid

$29

clamp

...ty free 3d model clamp for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1442041)

3d_export

$5

Clamp-14

...clamp-14

3dexport

3d model of clamp name 14

Heated

3d_export

$5

heat

...heat

3dexport

heat tool

3ddd

$1

electric heating

...electric heating

3ddd

обогреватель

electric heating

3d_export

$6

The heating module

...any questions also you can email to me. designed with solidworks 2017, render with keyshot **************************************

turbosquid

$2

Heating Radiator

...

royalty free 3d model heating radiator for download as blend on turbosquid: 3d models for games, architecture, videos. (1561908)

3d_export

$35

heating instalation with heat pump and solar system

...el , please contact me. before buying a model, you can try to download one of my free models and testing. thank you for watching.

turbosquid

$29

Heating Mantle

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

Heating Radiator

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

AT_airship_control_stand_(heated)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

AT_airship_(heated)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Heating radiator

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Plus

turbosquid

$2

plus-plus puzzle and lego

...d model plus-plus puzzle and lego for download as stl and obj on turbosquid: 3d models for games, architecture, videos. (1662633)

3ddd

$1

Стенка Plus

...стенка plus

3ddd

plus , модная мебель

фабрика "модная мебель", модель plus

3ddd

$1

Спальня METIS plus

... hulsta , metis , спальня

спальня metis plus

design_connected

$11

be plus B+

...be plus b+

designconnected

blå station be plus b+ chairs computer generated 3d model. designed by börge lindau.

design_connected

$11

Bank Plus

...bank plus

designconnected

röthlisberger kollektion bank plus coffee tables computer generated 3d model. designed by atelier oi.

3ddd

$1

elos Plus

... candela

elos plus — мультифункциональный аппарат для проведения лазерного и ipl лечений

3ddd

$1

Calligaris Even Plus

...calligaris even plus

3ddd

calligaris

calligaris_chair_even plus

design_connected

$29

Basket Plus

...nconnected

photo-realistic 3d models of the basket plus bed from bonaldo for 3d architectural and interior design presentations.

3ddd

free

Artpole Faktum Plus

... артполе , панель

artpole faktum plus

размеры:

высота 625мм

ширина 800мм

глубина 17мм

3ddd

$1

Мария / Jazz Plus

...мария / jazz plus

3ddd

мария

кухня фабрики мария модель__jazz plus

Step

3ddd

free

Pro Seda Step by Step

... by step

3ddd

step , proseda , кушетка

pro seda

design_connected

$9

Step

...step

designconnected

porada step coffee tables computer generated 3d model. designed by tarciso colzani.

turbosquid

$49

Steps

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

step

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$11

Step

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$20

Folding steps step stool 3D Model

...tool stepstool steps ladder tool tools garage workshop shed basement

folding steps step stool 3d model pixelblock 43270 3dexport

3d_export

$5

Glass steps

...glass steps

3dexport

well, just glass steps

3ddd

$1

Lago Steps

...lago steps

3ddd

lago

lago steps chair.

3d_export

$10

steps with cocrete

...steps with cocrete

3dexport

design steps for the architecture engineering purpose

archibase_planet

free

Rack step

...rack step

archibase planet

rack step rack gym

rack step - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

Leveling

design_connected

$11

Levels

...levels

designconnected

one nordic levels computer generated 3d model. designed by form us with love.

design_connected

$7

Level

...level

designconnected

zanotta level shelves and storage computer generated 3d model. designed by arik levy.

turbosquid

$29

level

...ty free 3d model level for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1272856)

turbosquid

$1

level

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Mario level

...mario level

3dexport

mario level low quality for fun videos

3ddd

$1

LEVELS OF DISCOVERY

...етская мебель "levels of discovery". rab10003 princess mini rocker

кресло-качалка (мини) "принцесса навсегда"

3d_export

$19

level design

...level design

3dexport

you can use this design (level design) in your own game.

turbosquid

$60

Desert level

...squid

royalty free 3d model desert level for download as fbx on turbosquid: 3d models for games, architecture, videos. (1208131)

turbosquid

$15

Transit Level

...quid

royalty free 3d model transit level for download as max on turbosquid: 3d models for games, architecture, videos. (1158112)

turbosquid

$14

Districts Level

...id

royalty free 3d model districts level for download as max on turbosquid: 3d models for games, architecture, videos. (1408410)

Bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

free

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

free

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

Bed

...bed

3ddd

bed , постельное белье , постель

bed

3d_export

$7

bed adairs bed

...rs bed

3dexport

bed adairs bed in modern style. if you want a smoother surface, please turn on turbosmooth in the modifier list.

Files

archibase_planet

free

File

...file

archibase planet

locker box archive

fp suspension file wh - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

free

File

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$5

Filing cabinet

...locker office paper storage store work

a simple but neatly-made filing cabinet, which ads a touch of relism to any office render.

turbosquid

$8

Filing cabinets

...id

royalty free 3d model filing cabinets for download as fbx on turbosquid: 3d models for games, architecture, videos. (1371140)

turbosquid

$8

File Cabinet

...squid

royalty free 3d model file cabinet for download as fbx on turbosquid: 3d models for games, architecture, videos. (1572208)

turbosquid

$16

Filing Cabinet

...ree 3d model filing cabinet for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1310873)

turbosquid

$2

File Cabinet

... free 3d model file cabinet for download as obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1357577)

turbosquid

$12

Nail File

...e 3d model nail file for download as blend, obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1588508)

turbosquid

$5

File Organiser

...model file organiser for download as blend, obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1636447)

turbosquid

$1

Flat file

...e 3d model flat file for download as 3ds, obj, md3, and blend on turbosquid: 3d models for games, architecture, videos. (1209808)